Preparation method of expansible graphite modified high-flame-retardant rigid polyurethane foam

A technology of rigid polyurethane foam and expanded graphite, which is applied in the field of cold insulation materials for pipes and storage tanks. It can solve the problems of affecting the mechanical properties and foaming process of rigid polyurethane foam, the difficulty of improving the flame retardancy of rigid polyurethane foam, and increasing costs. Achieve the effects of not easy to precipitate, low toxicity, and improve oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

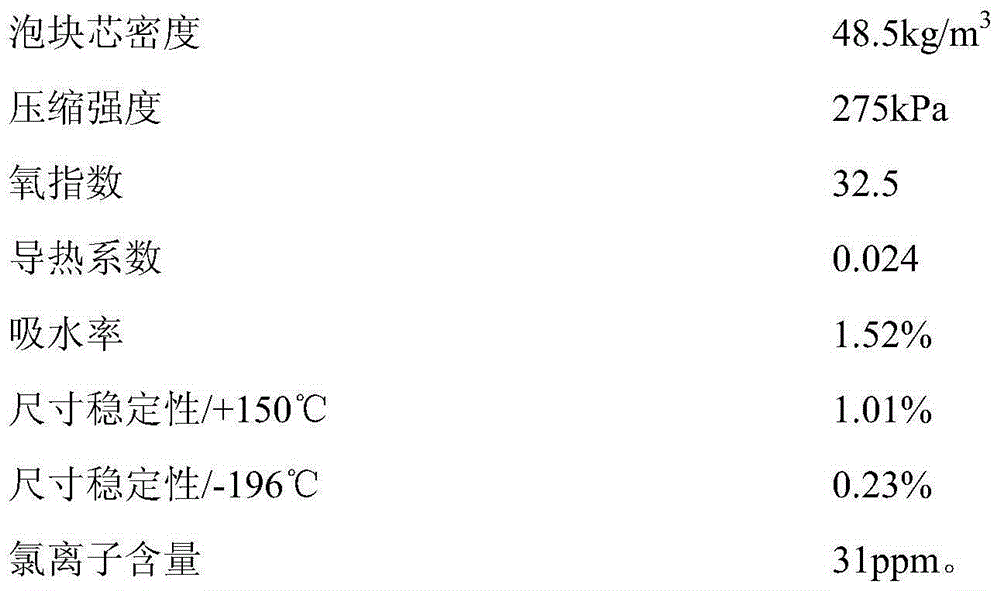

Embodiment 1

[0030] A preparation method of expandable graphite modified high flame-retardant polyurethane rigid foam, comprising the following steps:

[0031] (1), preparation white material: Weigh respectively 60g polyester polyol PS-3152 (Nanjing Jinling Stepan Chemical Co., Ltd., the same below), 10g polyether polyol 635C (Jurong Ningwu Chemical Co., Ltd., below) The same), 10g polyether polyol 380 (Jurong Ningwu Chemical Co., Ltd., the same below), 20g structural flame-retardant polyether polyol F-7190 (Shanghai Bluestar Chemical New Material Co., Ltd., the same below), 2.0 g foam stabilizer B8525 (Gossmit company, the same below), 1.0g foam stabilizer L6863 (Momentive, the same below), 10g triethyl phosphate TEP, 0.1g starting catalyst PC-5 (Air Chemical Co., Ltd. , the same below), 0.1g starting catalyst PC-8 (Air Chemical Co., Ltd., the same below), 1.0g triethylenediamine catalyst DabcoJXP-508 (Air Chemical Co., Ltd., the same below), 1.0g DabcoK-15 catalyst ( Bluestar Chemical N...

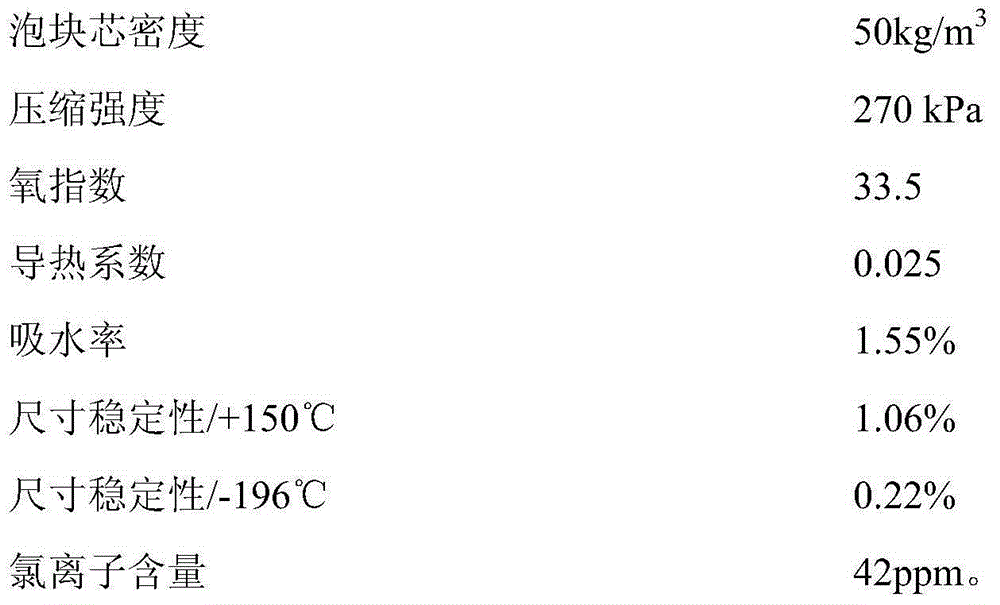

Embodiment 2

[0036] A preparation method of expandable graphite modified high flame-retardant polyurethane rigid foam, comprising the following steps:

[0037](1), preparation of white material: Weigh 40g polyester polyol PS-3152, 10g polyester polyol PS-2412 (Nanjing Jinling Stepan Chemical Co., Ltd., the same below), 10g polyether polyol 635C, 10g Polyether polyol N450 (Jurong Ningwu Chemical Co., Ltd., the same below), 10g polyether polyol 380, 30g structural flame retardant polyether polyol F-7190, 10g structural flame retardant polyether polyol Y- 501F (Shandong Yinuowei Polyurethane Co., Ltd., the same below), 2.0g foam stabilizer SD624 (Suzhou Side New Material Technology Co., Ltd., the same below), 1.0g foam stabilizer B8525, 10g triethyl phosphate TEP, 10g tris(2-chloropropyl) phosphate TCPP, 0.1g starting catalyst PC-5, 0.1g starting catalyst PC-8, 1.0g triethylenediamine catalyst DabcoJXP-508, 1.0g DabcoK-15 catalyst, 1.0 gDabcoTMR-2 catalyst and 1.0g distilled water, stir even...

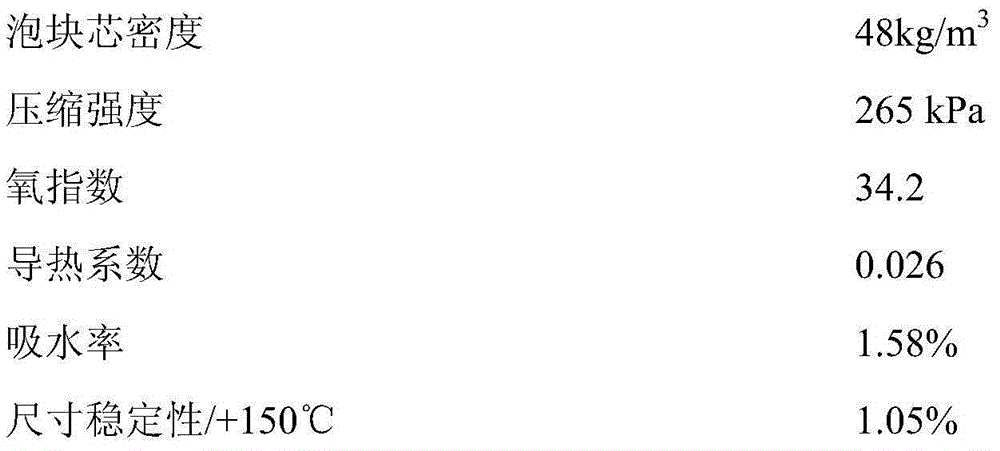

Embodiment 3

[0042] A preparation method of expandable graphite modified high flame-retardant polyurethane rigid foam, comprising the following steps:

[0043] (1), prepare white material: take by weighing 45g polyester polyol PS-2352 (Nanjing Jinling Stepan Chemical Co., Ltd., the same below), 5g polyether polyol 635C, 5g polyether polyol N210 (Jurong City Ningwu Chemical Co., Ltd., the same below), 20g polyether polyol NJ-410HN (Jurong Ningwu Chemical Co., Ltd., the same below), 20g structural flame-retardant polyether polyol F-7190, 5g structural flame-retardant Polyether polyol Y-502F (Shandong Yinuowei Polyurethane Co., Ltd., the same below), 2.0g foam stabilizer SD622 (Suzhou Side New Material Technology Co., Ltd., the same below), 1.0g foam stabilizer B8525, 8g three Ethyl phosphate TEP, 8g trichloroethyl phosphate TCEP, 0.1g starting catalyst PC-5, 0.1g starting catalyst PC-8, 0.9g triethylenediamine catalyst A-33 (Blue Star Chemical New Material Industry Co., Ltd. Co., Ltd., the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com