Light-emitting diode packaging structure and manufacture method thereof

A technology of light-emitting diodes and packaging structures, which is applied to light sources, lighting devices, point light sources, etc., can solve the problem of uneven distribution of fluorescent materials and achieve the effect of optimal light uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

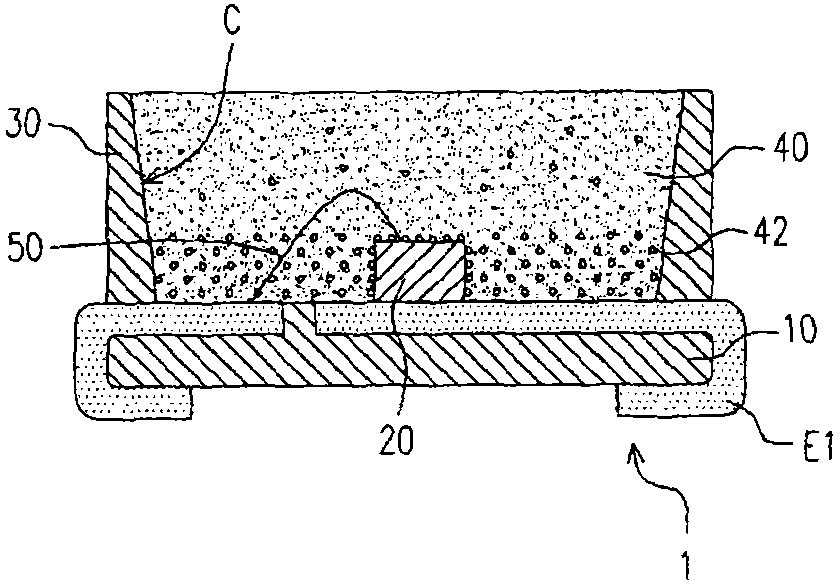

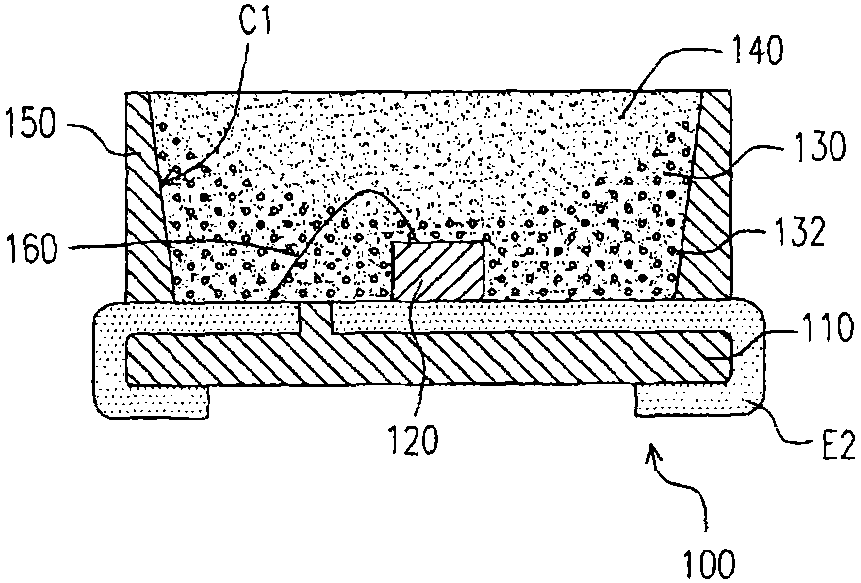

[0047] figure 2 It is a schematic cross-sectional view of a light emitting diode packaging structure according to an embodiment of the present invention. Please refer to figure 2 , in this embodiment, the LED packaging structure 100 includes a carrier 110 , a LED chip 120 , a first encapsulant 130 , a second encapsulant 140 and a housing 150 . In particular, the LED packaging structure 100 of this embodiment is a surface mount (SMD) LED packaging structure 100 .

[0048] In detail, the casing 150 is disposed on the carrier 110 and covers part of the carrier 110 , wherein the casing 150 and the carrier 110 form a cavity C1 . The light emitting diode chip 120 is disposed on the carrier 110 and accommodated in the cavity C1 to emit a light, wherein the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com