Patents

Literature

66results about How to "Guaranteed Suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicine granule, preparation method thereof, and preparation containing same

InactiveCN101548953AHigh drug contentRounded surfaceOrganic active ingredientsPill deliveryChemistryBiomedical engineering

The invention discloses a medicine granule containing the following components by mass percent: 75 to 95 of medicine, 2 to 22 of thinner for pelletization, 0.06t to 0.5 of glidant, and 1.5 to 3.5 of adhesive. The invention also discloses a preparation method thereof and a preparation containing same. The medicine granule has high medicine content, round surface, higher rigidity and smaller grain diameter, can be directly used for tabletting, has less weight increment if being coated and can achieve a better taste masking effect. The method for preparing the medicine granule can simultaneously realize pelletization and coating technologies in a tangent spraying fluidized bed, has simple production steps and high efficiency, and can be applied to mass production.

Owner:SHANGHAI INST OF PHARMA IND +1

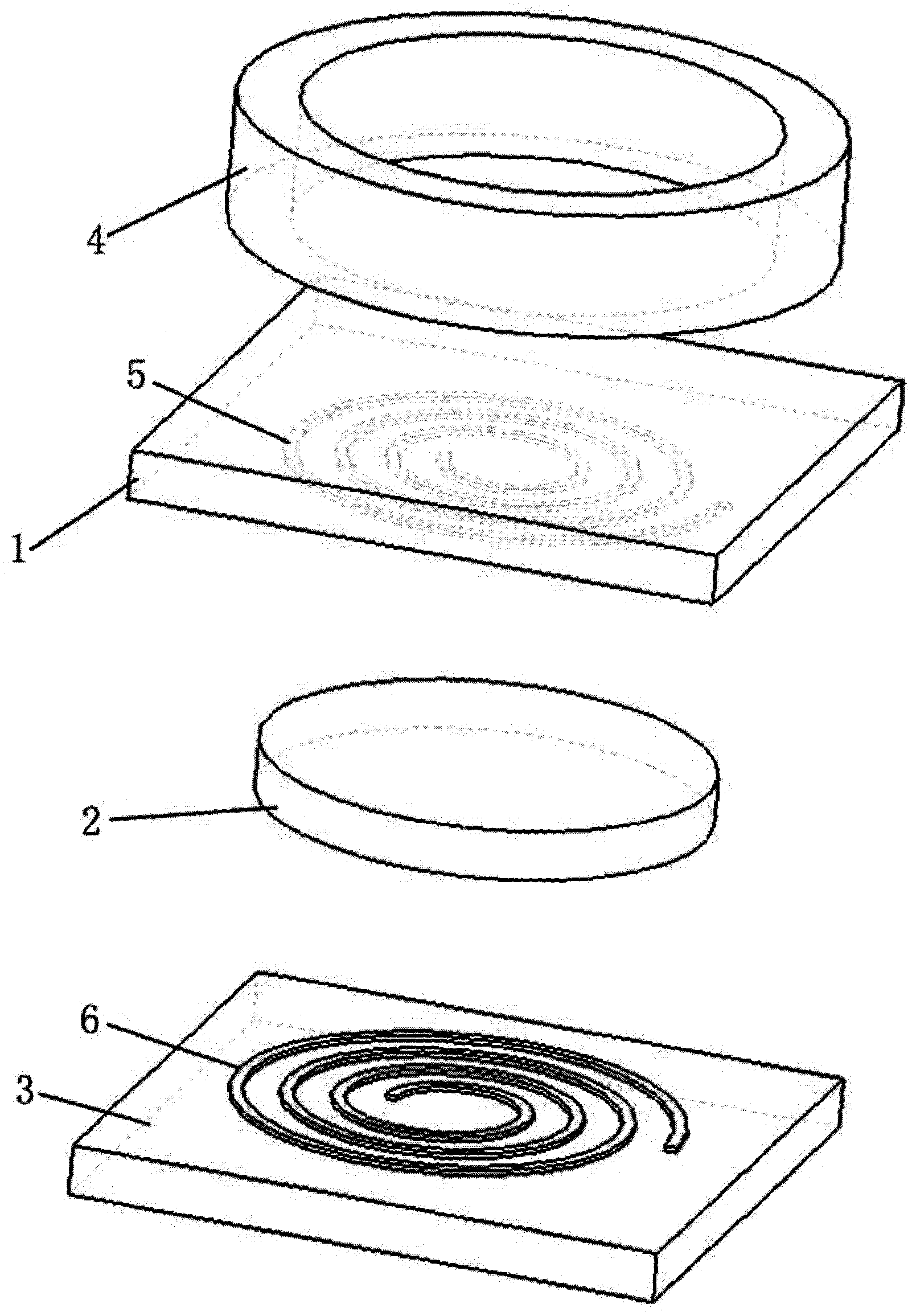

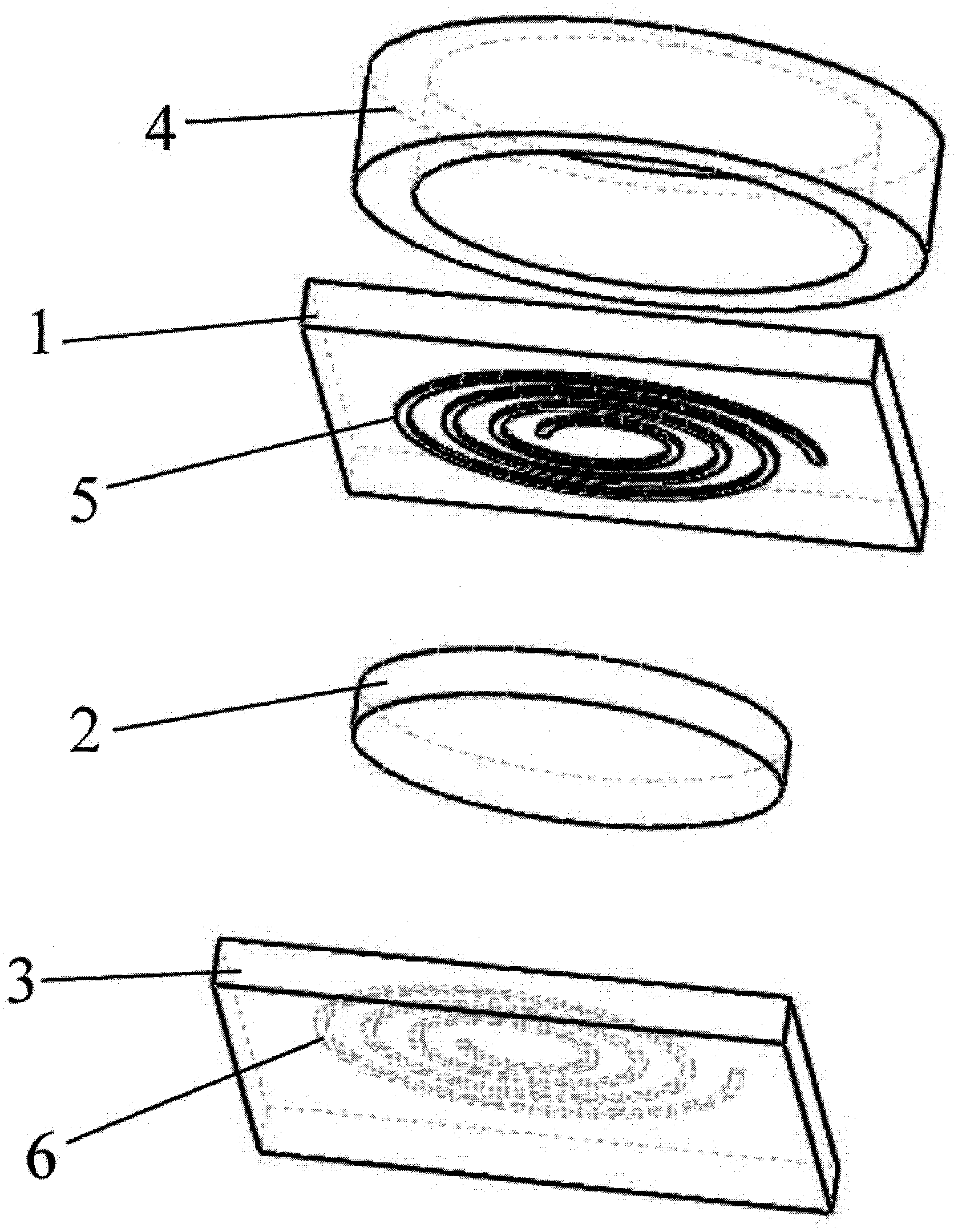

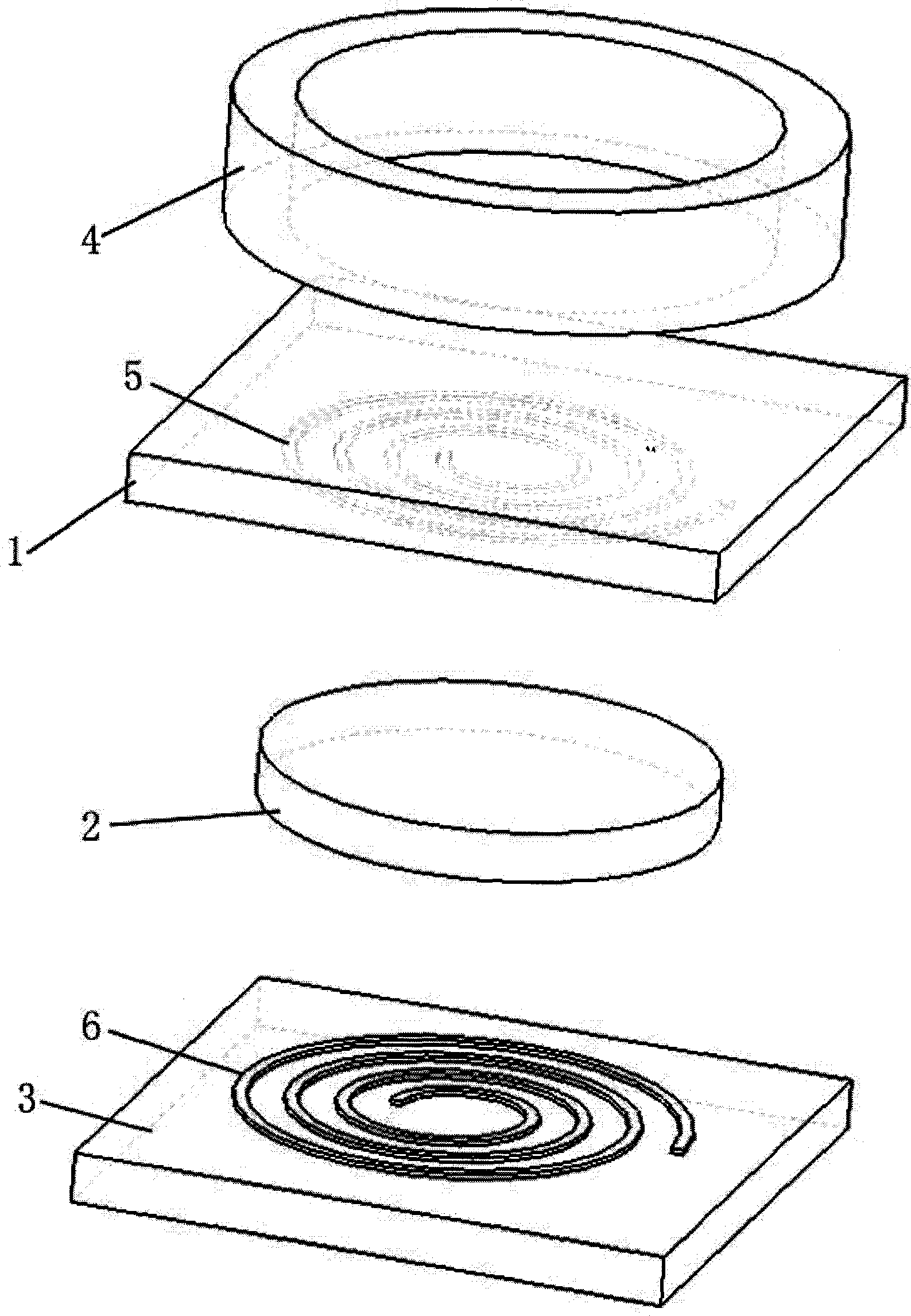

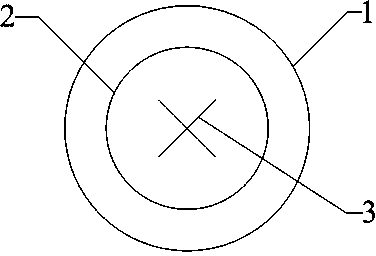

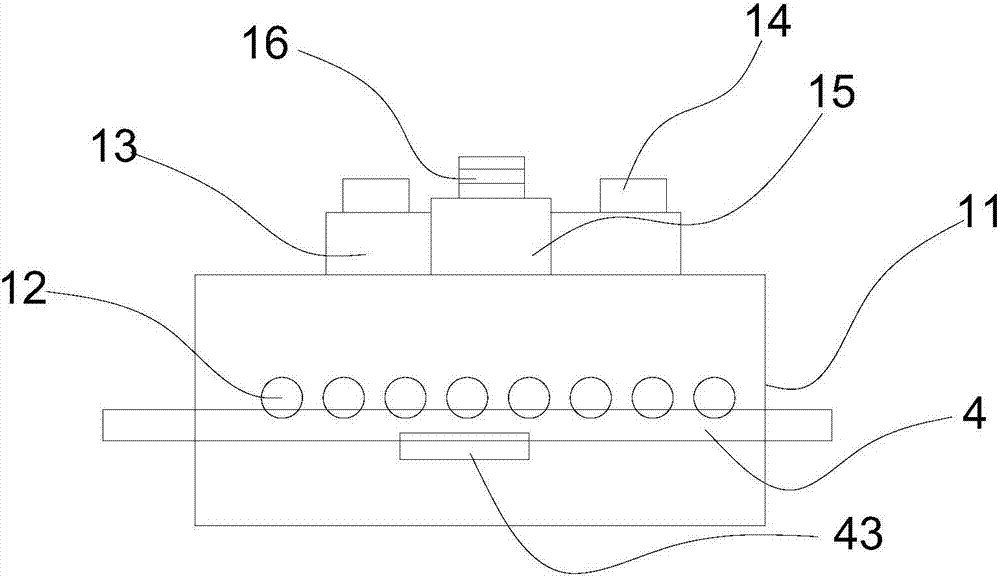

Micro-electro-mechanical system (MEMS)-based vibration energy acquisition device

InactiveCN102694452ARealize acquisitionAchieve levitationBatteries circuit arrangementsElectric powerGraphiteAmbient vibration

The invention discloses a micro-electro-mechanical system (MEMS)-based vibration energy acquisition device. The MEMS-based vibration energy acquisition device comprises an upper pyrolytic graphite thin plate, a suspended permanent magnet, a lower pyrolytic graphite thin plate and a lifting permanent magnet, wherein the upper pyrolytic graphite thin plate, the suspended permanent magnet and the lower pyrolytic graphite thin plate are arranged from top to bottom in sequence; an upper induction coil is arranged on the lower side surface of the upper pyrolytic graphite thin plate; and a lower induction coil is arranged on the upper side surface of the lower pyrolytic graphite thin plate. According to the MEMS-based vibration energy acquisition device provided by the invention, a permanent magnet serves as a suspension body; anti-magnetic material structures are respectively arranged above and below the permanent magnet; an induction coil is arranged on each anti-magnetic material; in order to realize the suspension of the permanent magnet well, the lifting permanent magnet is also arranged on the upper anti-magnetic material structure; in a static state, the permanent magnet is suspended between the two anti-magnetic material structures; and under the action of ambient vibration, the permanent magnet moves up and down without friction, so that induced electromotive force is generated in the upper and lower induction coils and is stored by a power storage loop.

Owner:ZHENGZHOU UNIV

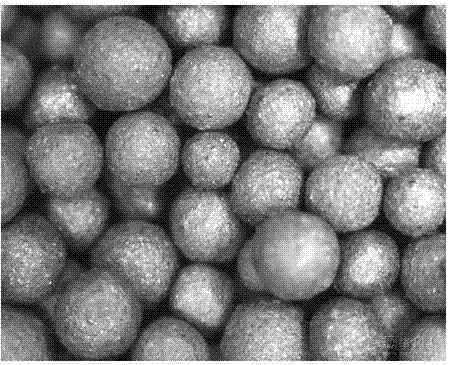

Ultralow-density high-strength vitrified china ball proppant and preparation method thereof

InactiveCN106883838AGood drainage and permeabilityReduce pollutionFluid removalDrilling compositionSlurryMaterials science

The invention provides an ultralow-density high-strength vitrified china ball proppant. The ultralow-density high-strength vitrified china ball proppant comprises the following ingredients in percentage by mass: 20-70% of SiO2, 1-50% of Al2O3, 10-30% of B2O3, 0-15% of CaO, 0-15% of MgO, 0-5% of Na2O, 0-5% of Fe2O3, 0-5% of BaO, 0-5% of BeO, 0-5% of Bi2O3, 0-5% of La2O3, 0-5% of PbO, 0-5% of TiO2, 0-5% of ZnO and 0-5% of ZrO2. The invention also provides a preparation method of the ultralow-density high-strength vitrified china ball proppant, the preparation method comprises the step of preparation of a precursor, and the preparation of the precursor comprises the sub-steps of adding raw materials into a solvent to obtain a mixed slurry, and then performing grinding and drying to obtain a precursor powder. The prepared proppant is ultralow in density and high in strength.

Owner:山东雅丽支撑新材料科技有限公司 +1

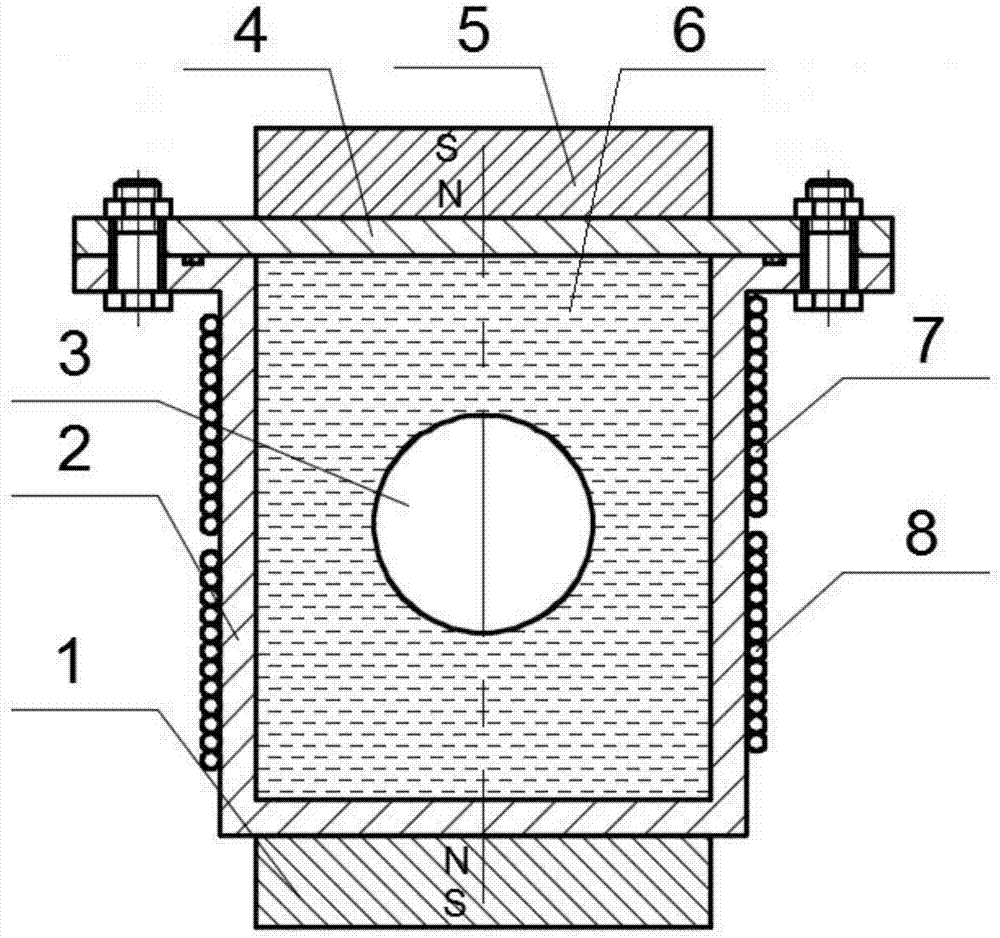

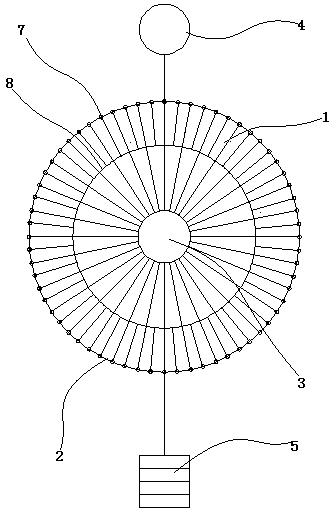

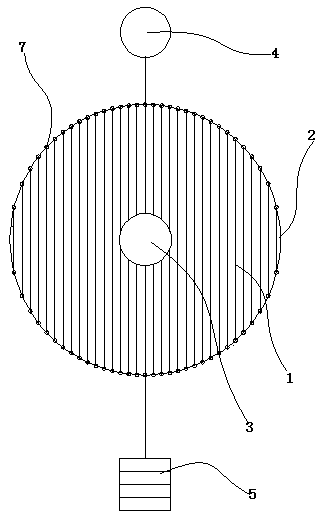

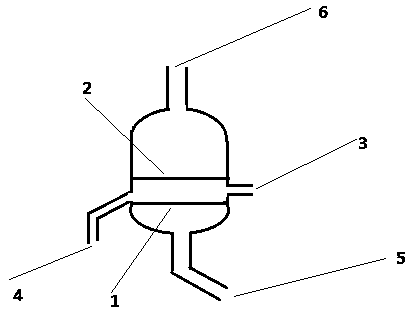

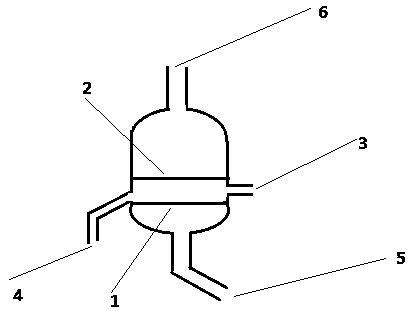

Magnetic fluid acceleration sensor based on first-order buoyancy principle

InactiveCN104849495ASolve mobility problemsSolve the problem that injection is difficult or even impossible to fillAcceleration measurementMagnetic liquidsAcceleration Unit

A magnetic fluid acceleration sensor based on a first-order buoyancy principle belongs to the field of mechanical engineering measurement. The problem that the existing magnetic fluid acceleration sensor cannot be applied in engineering practice due to a variety of structure problems is solved successfully. The device comprises a first permanent magnet (1), a shell (2), a mass block (3), an end cover (4), a second permanent magnet (5), magnetic liquid (6), an upper coil (7), and a lower coil (8). When acceleration is produced outside, the nonmagnetic mass block moves in a cavity, the volume distribution of the magnetic liquid (6) in the shell (2) changes, a signal is output, and first-order buoyancy formed by the first permanent magnet (1) and the second permanent magnet (5) inside the magnetic liquid (6) causes frequency difference between the mass block (3) and the shell (2). Thus, the sensitivity of the sensor is improved.

Owner:BEIJING JIAOTONG UNIV

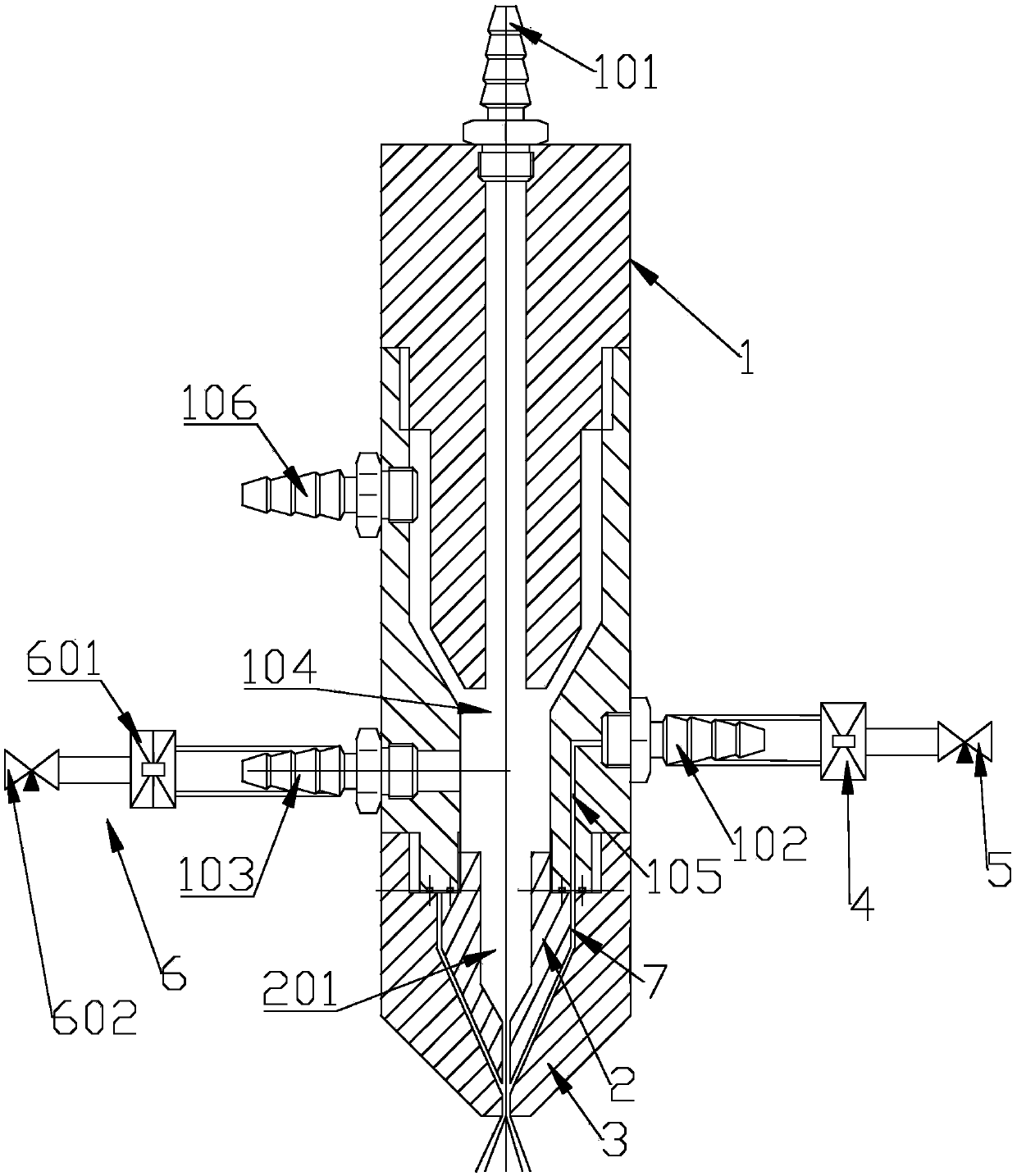

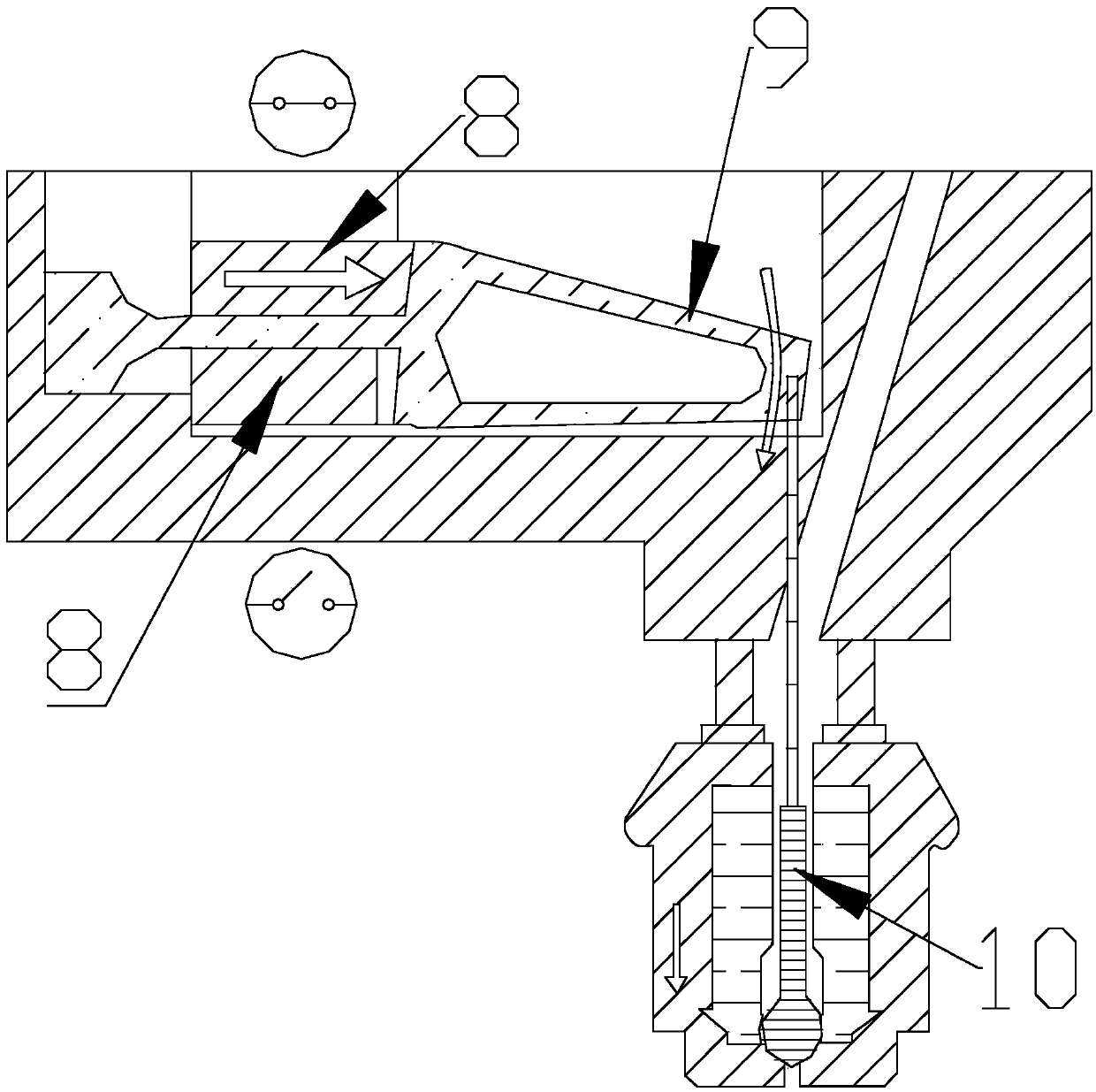

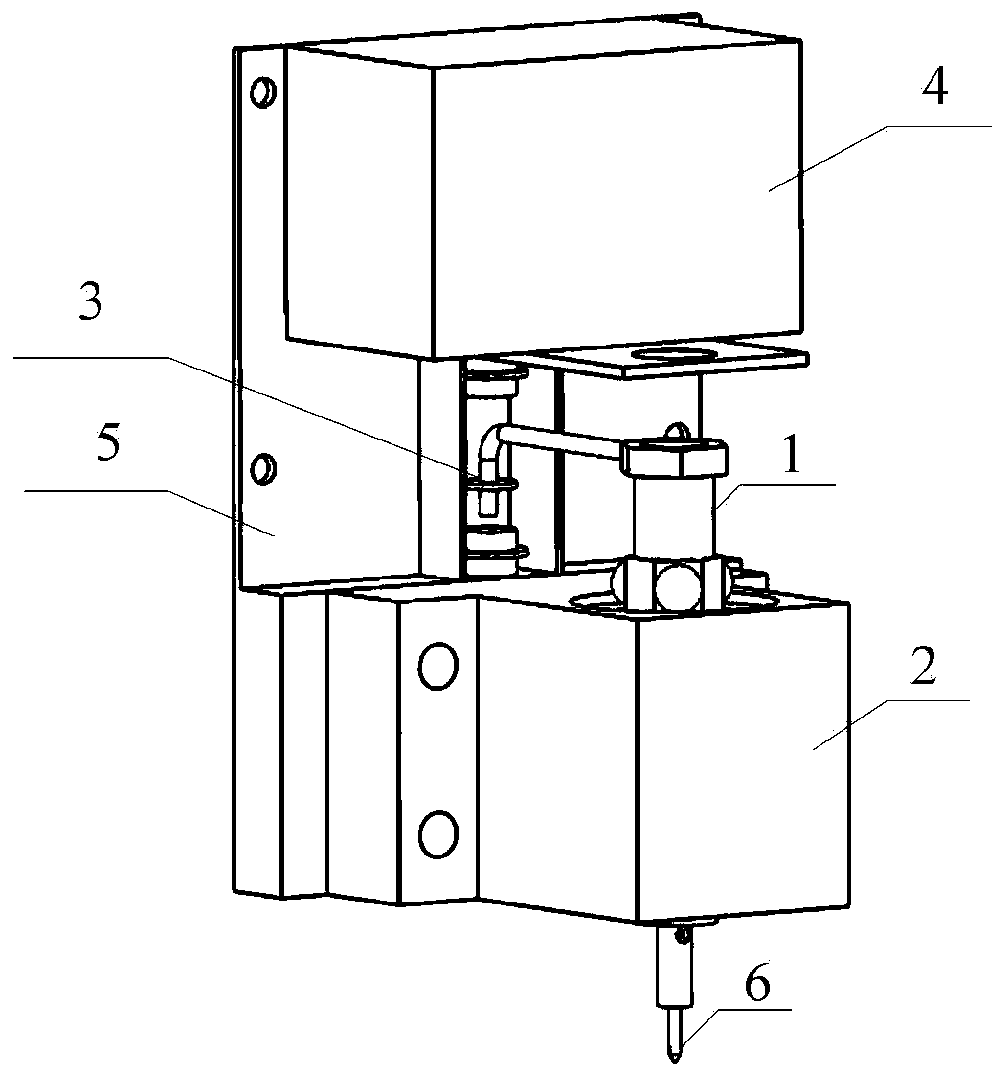

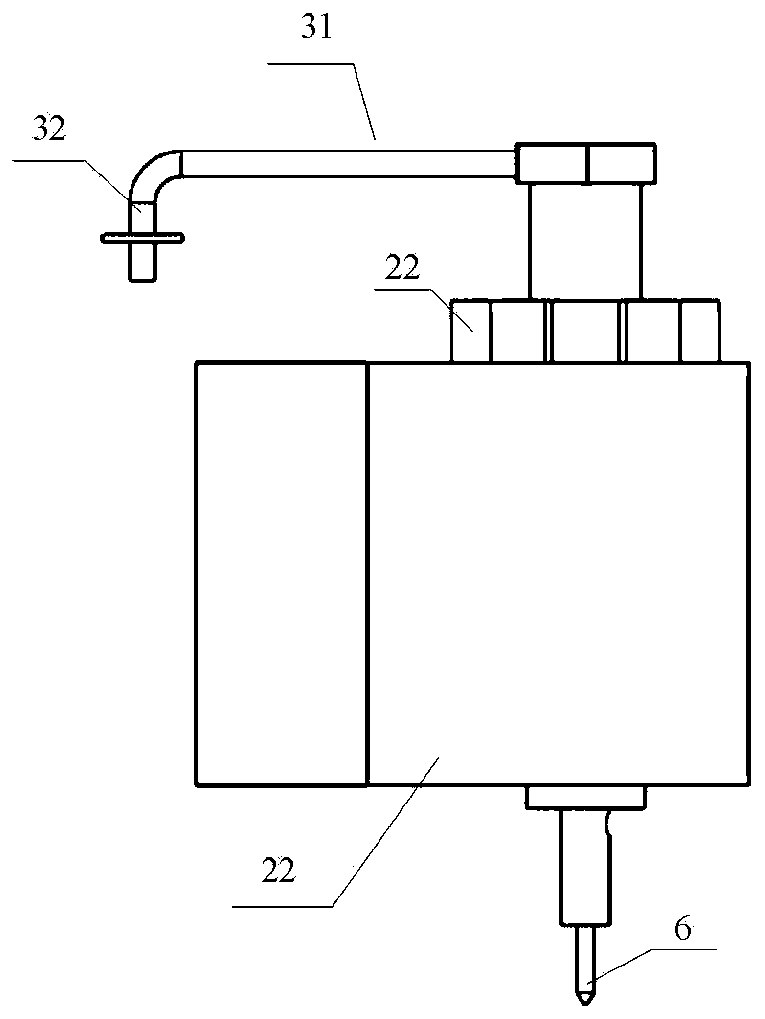

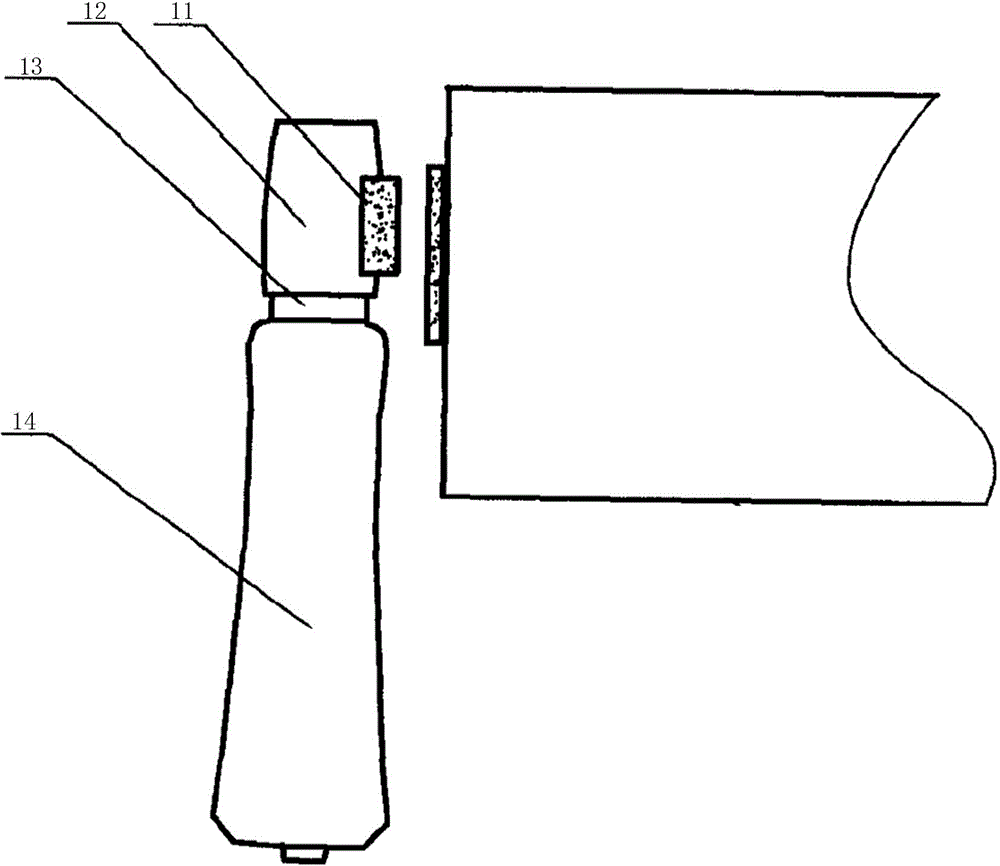

Novel liquid spot-spray torch and spot-spray method thereof

ActiveCN105499003AHigh control precisionFast dynamic responseLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a novel liquid spot-spray torch and a spot-spray method thereof, comprising a torch body, an air guide cone and a nozzle. The torch body is provided with a liquid inlet, an air inlet and a negative pressure port, the torch body is internally provided with a first liquid storage cavity and a first air cavity, the liquid inlet is communicated with the first liquid storage cavity, one end of the air inlet is communicated with the first air cavity, the other end of the air inlet is connected with a piezoceramic direct-drive valve which is connected with a first pressure adjusting valve, the negative pressure port is close to a liquid incoming end of the torch body, one end of the negative pressure port is communicated with the first liquid storage cavity, the other end of the negative pressure port is connected with a negative pressure generator, the air guide cone is connected with a liquid outgoing end of the torch body, the air guide cone is internally provided with a second liquid storage cavity which is communicated with the first liquid storage cavity, the nozzle sleeves the liquid outgoing end of the torch body, and the inner wall of the nozzle and the outer wall of the air guide cone form a second air cavity which is communicated with the first air cavity. The novel liquid spot-spray torch and the spot-spray method thereof have the advantages that the spraying requirements for high frequency and high precision can be met, high-speed spot spraying can be implemented, and production efficiency can be improved.

Owner:广州高印力信息技术有限公司

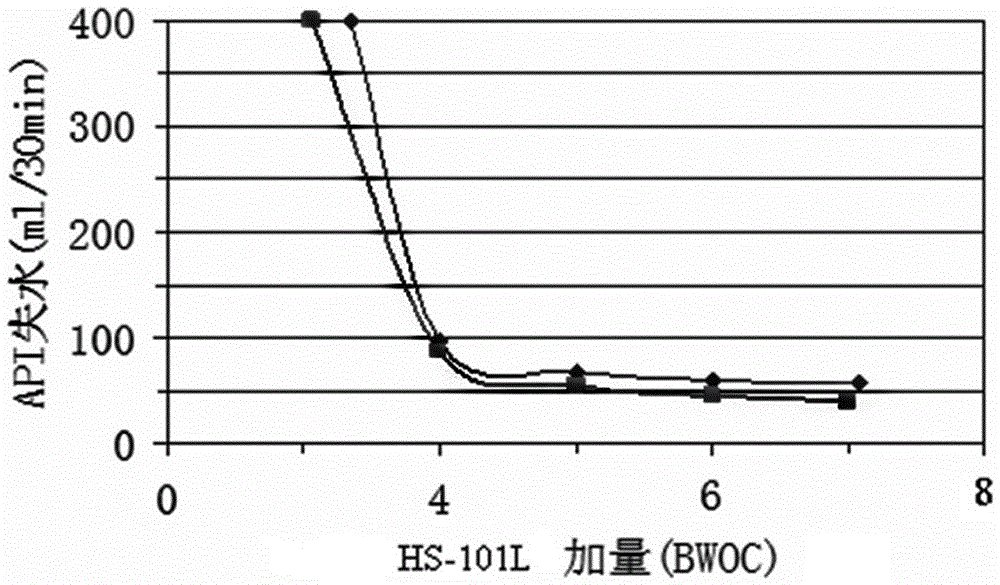

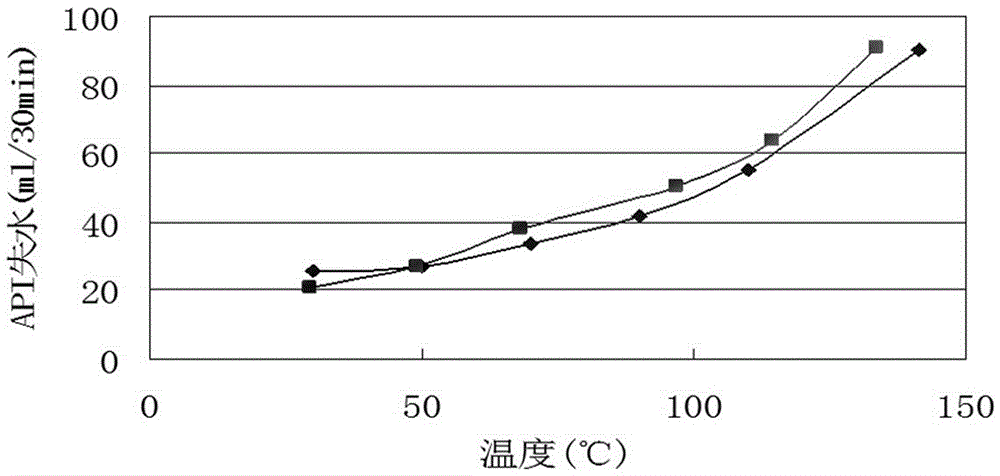

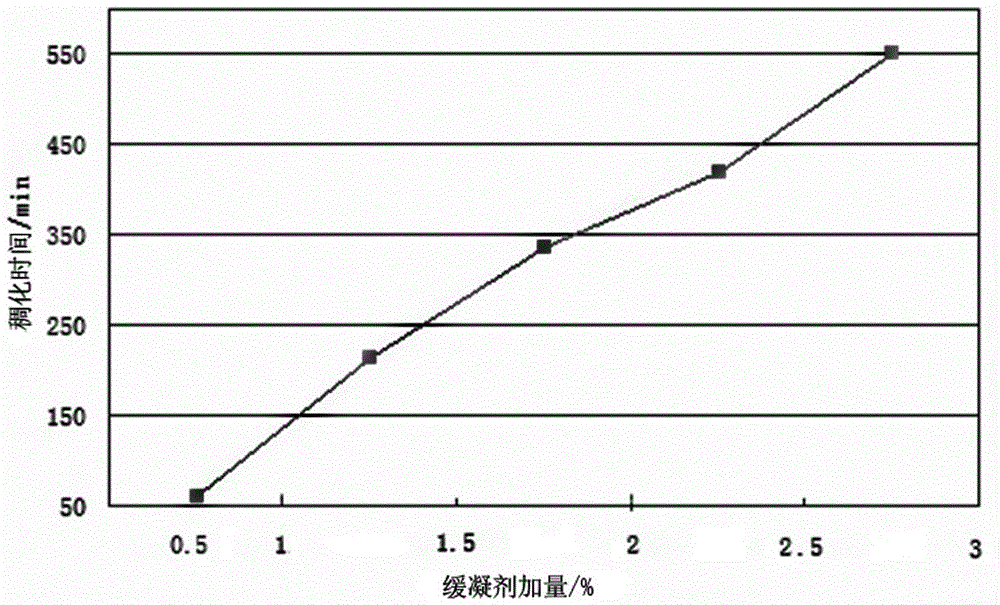

High-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in oil field

ActiveCN105694832AExcellent dehydration performanceGood adaptabilityDrilling compositionSolid phasesSilica fume

The invention relates to high-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in an oil field. The cement grout is prepared from components of raw materials in parts by weight as follows: 600 parts of G-grade oil well cement, 30-36 parts of an HS101L fluid loss agent, 8-20 parts of an HS201L retarder, 1.8 parts of an HS-301S dispersant, 150 parts of quartz sand, 30 parts of silica fume, 1.8 parts of an HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of bis(2-ethylhexyl) sulfosuccinate sodium salt, wherein the grain size of the quartz sand is 80-120 meshes, the grain size of the silica fume is 300-400 meshes, and the content of silicon dioxide is 90% or higher. Liquid-phase raw materials are added to a grout mixing container and mixed uniformly; solid-phase substances are added to a solid-phase container and stirred uniformly, the solid-phase mixture is added to the grout mixing container, finally, a defoaming agent is added, and the mixture is stirred uniformly. The cement grout can be used under the condition of 50-180 DEG C, has prominent large-temperature-difference-resistant performance and can effectively avoid a super-retarding phenomenon caused by large temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

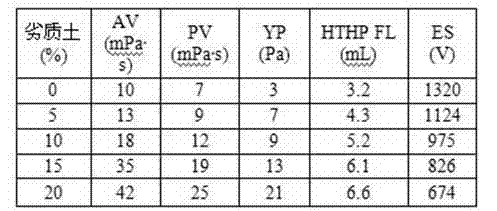

Oil-based drilling fluid

InactiveCN103923623AAvoid condensationGuaranteed SuspensionDrilling compositionOleic Acid TriglycerideCalcium hydroxide

The invention discloses oil-based drilling fluid and belongs to the technical field of chemistry of the oil-gas field. The oil-based drilling fluid comprises the following components in percentage by weight: 1%-3% of wetting agent, 50-80% of base oil, 5%-10% of CaCl2 salt water, 2%-5% of emulsifying agent, 3%-6% of fluid loss agent, 0.5%-3% of calcium hydroxide, 0.3%-2% of gelling agent, 0.5%-3% of viscosity increasing agent and the balance of weighting material, wherein the wetting agent comprises the following components in percentage by weight: 60% of vegetable pin tar and 40% of vegetable oleic acid. The oil-based drilling fluid has the advantages that the components of the wetting agent are low in cost and are not limited by the source; the condensation of the weighing material can be effectively avoided, the suspending stability of the weighing material in the drilling fluid system is improved and the requirement of the drilling construction of the non-conventional oil-gas reservoir for the high-density oil-based drilling fluid is met.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

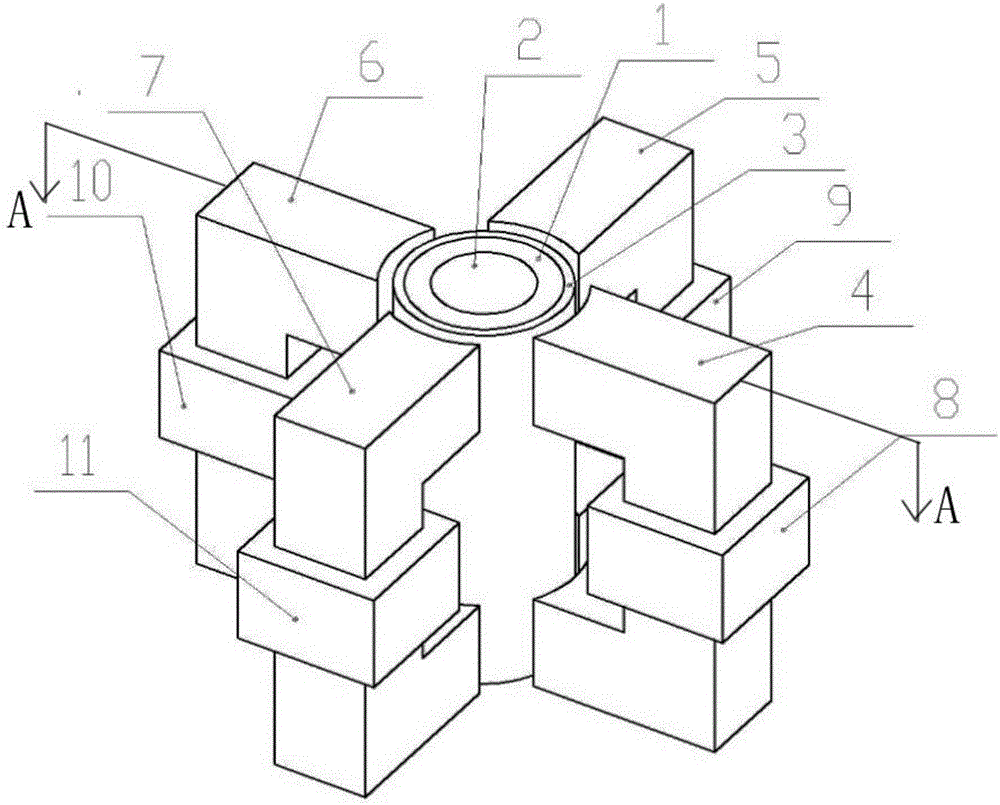

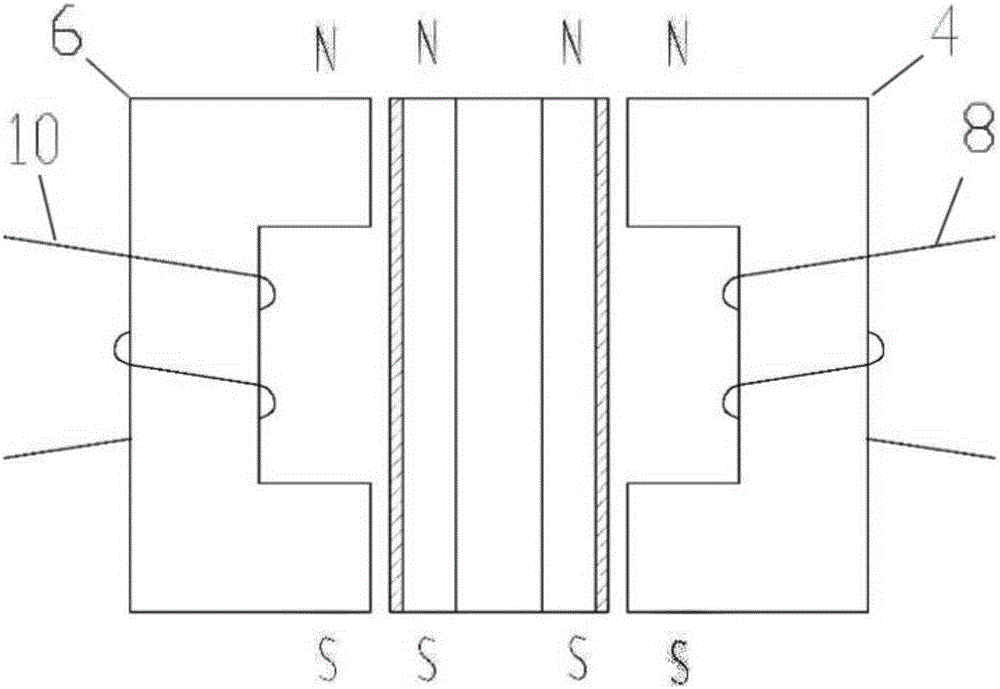

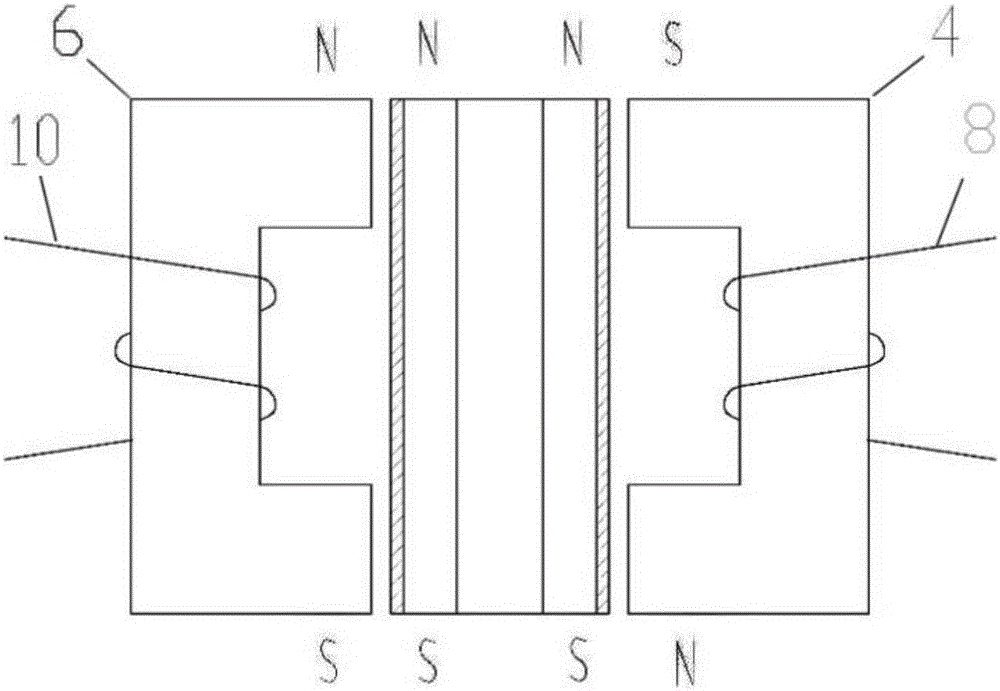

Mixed radial magnetic bearing of permanent magnetic rotor

InactiveCN106015333AGuaranteed SuspensionImprove stabilityShaftsMagnetic bearingsPermanent magnet rotorMagnetic bearing

The invention relates to a mixed radial magnetic bearing of a permanent magnetic rotor. A rotor is changed to a rotor comprising a permanent magnet, magnetic suspension radial bearing stator cores are electromagnets, and electromagnetic coils are arranged on the electromagnets; a group of radial bearings comprise more than four radial bearing stators in an even number and are uniformly distributed along the circumferential direction; a direct current in a special direction is electrified to the coil of each radial bearing; axial magnetization is adopted for the permanent magnet, the magnetic suspension radial bearing cores form a plurality of electromagnets which are distributed along the circumferential direction with the electromagnetic coils thereon respectively, and the electromagnets generate electromagnetic forces by connecting a power supply to attract or repel the rotor, so that the rotor is in a balanced state. The magnetic pole directions of the electromagnets are determined by the current directions of the electromagnetic coils arranged thereon respectively. Compared with a conventional bearing, the size of a single electromagnetic core can be reduced, so that the size of the whole magnetic suspension bearing is reduced, and the bearing has better system stability.

Owner:TIANJIN EMAGING TECH

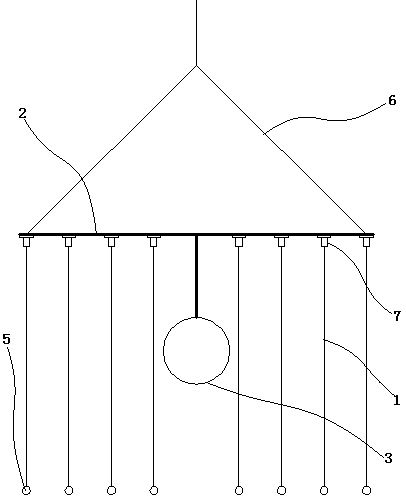

Installation and construction method of vertical pipe in pipe well

InactiveCN107956923AGuaranteed SuspensionImprove straightnessPipe laying and repairLoad-engaging elementsButt jointArchitectural engineering

The invention discloses an installation and construction method of a vertical pipe in a pipe well. The installation and construction method is used for vertically installing the vertical pipe which isformed by connecting a plurality of pipe sections in a butt joint manner in the pipe well. The vertical pipe comprises the N pipe sections, and from the top to the bottom of the vertical pipe, the Npipe sections include the pipe section 1, the pipe section 2, the pipe section 3 ... and the pipe section N. The installation and construction method comprises the sequential following steps that S1,a hoist is installed; S2, the pipe sections are hoisted, wherein the pipe section 1 and the pipe section 2 are hoisted, a pipe opening in the upper end of the pipe section 2 is welded to a pipe opening in the lower end of the pipe section 1 in a butt joint manner, a main lifting hoist is used for increasing the height of the connected vertical pipe sections, an auxiliary lifting hoist is used forsequentially hoisting the pipe section 3 ... and the pipe section N, and the pipe section 3 ... and the pipe section N are sequentially connected to the connected vertical pipe sections; and S3, the vertical pipe is fixed in the pipe well. According to the installation and construction method, the transportation frequency of the pipe sections is small, the pipe sections are easy to center and connect in a butt joint manner, welding regions are fixed, the welding quality is convenient to control, and the welding efficiency is convenient to improve.

Owner:CHINA MCC5 GROUP CORP

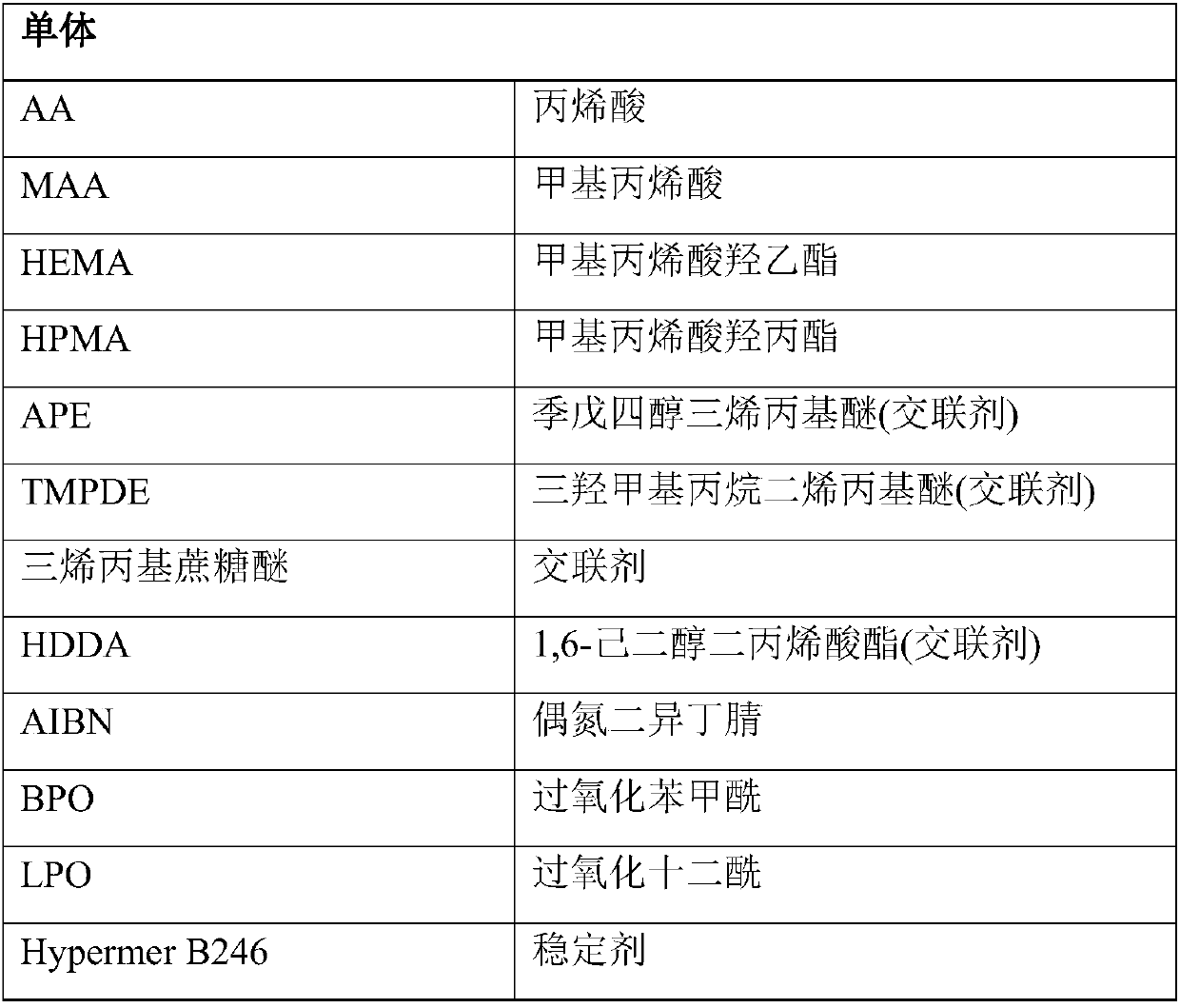

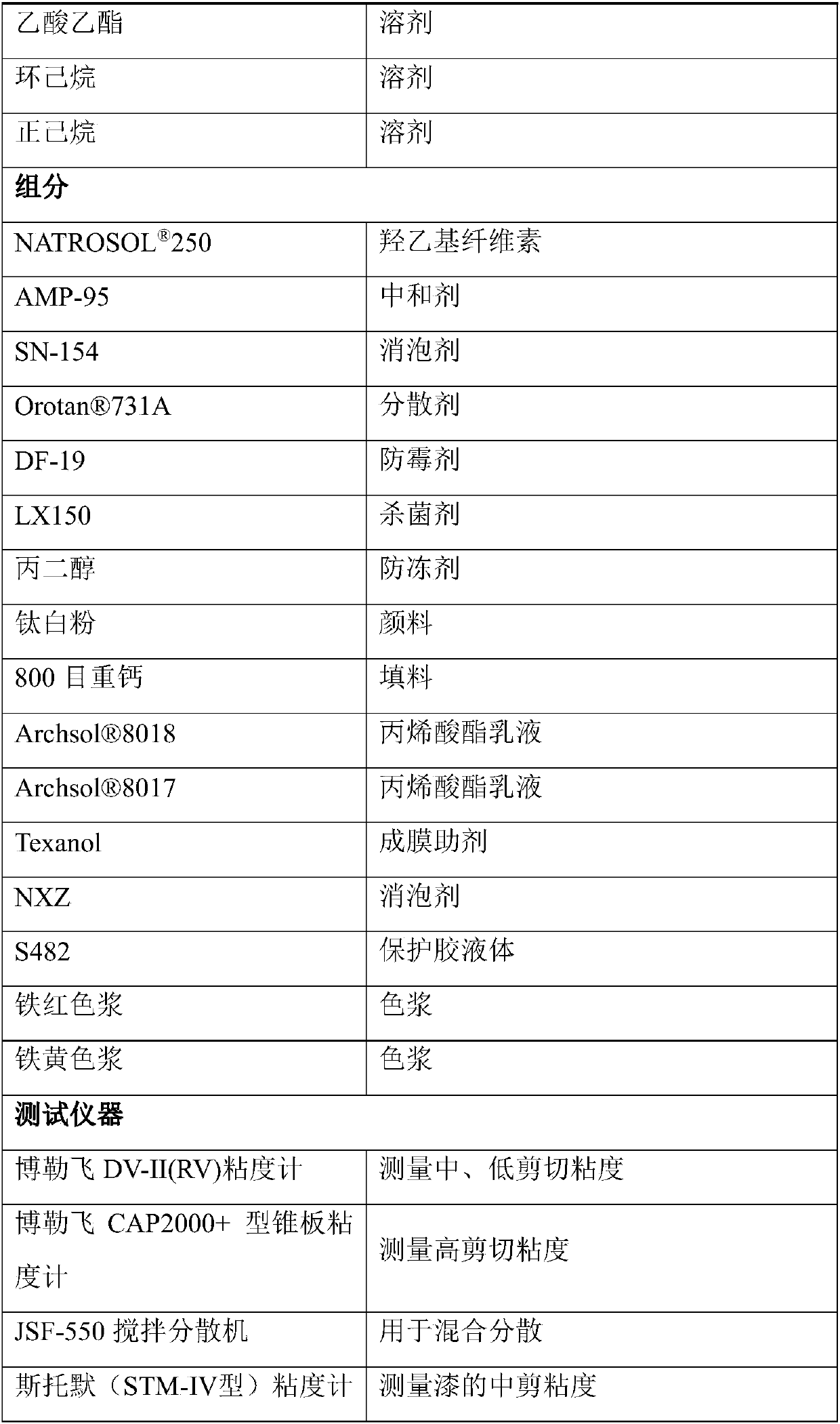

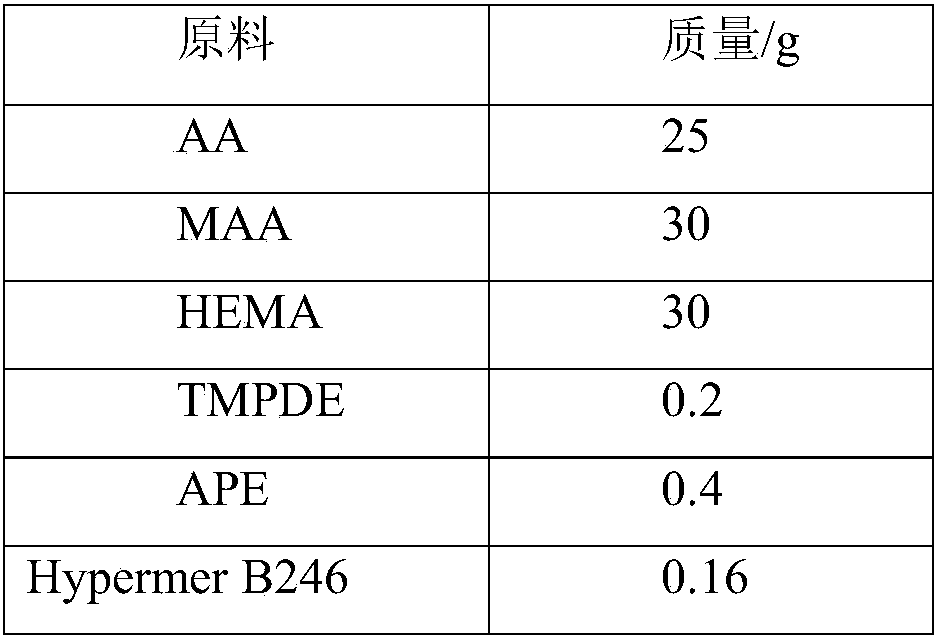

Highly-crosslinked acrylate copolymer as well as preparation method and application thereof as thickening agent

PendingCN109957062AIncrease viscosityHigh molecular weightMulticolor effect coatingsMonomer compositionCarboxylic acid

The invention relates to a highly-crosslinked acrylate copolymer as well as a preparation method and application thereof as a thickening agent. The copolymer is prepared by precipitation polymerization triggered by free radicals of a monomer composition containing the following monomers in a solvent: a) 10-80wt% of first monomer component selected from one or more of olefin monounsaturated monomers containing at least one carboxyl group; b) 89.9-15wt% of second olefin monounsaturated monomer component selected from one or more of C1-C4 hydroxyl alkyl esters of a straight chain or a branched chain of (methyl)acrylic acid; and c)0.01-5wt% of crosslinked component selected from polyalkenyl polyether with at least two polymerizable olefin unsaturated double bonds. The highly-crosslinked acrylate copolymer disclosed by the invention shows excellent performances such as high thickening efficiency as well as good system compatibility and storage stability in a multi-color coating.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

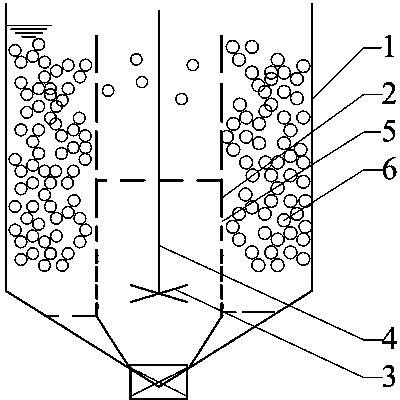

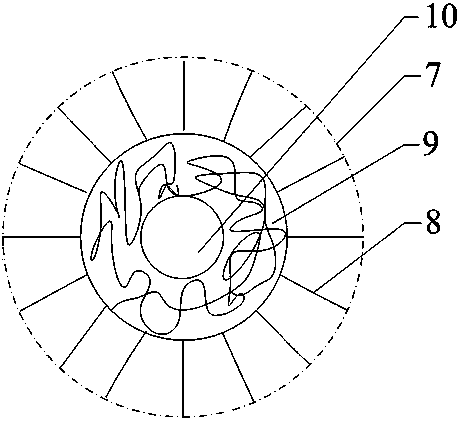

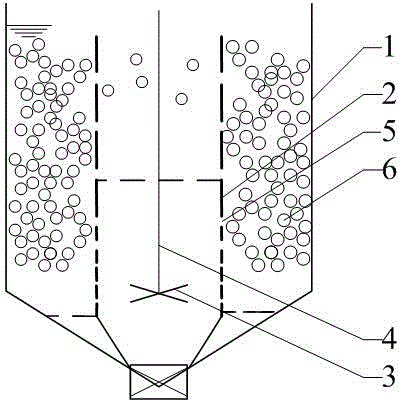

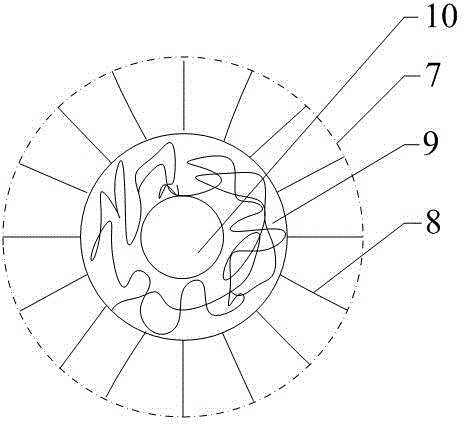

Reactor for realizing suspension of biofilm carriers under low aeration quantity

ActiveCN103508555AAvoid accumulationAvoid violent collisionsTreatment using aerobic processesSustainable biological treatmentMaterial consumptionEngineering

The invention relates to a reactor for realizing suspension of biofilm carriers under low aeration quantity. The reactor comprises a vertical cylindrical shell, wherein a vertical hollow cylinder is coaxially arranged in the shell, and a stirring paddle is mounted in the hollow cylinder; a plurality of through holes are formed on the wall of the hollow cylinder; the bottom end of the hollow cylinder is fixedly connected with the bottom end of the shell; and the biofilm carriers are filled in a circular space between the hollow cylinder and the shell. According to the unique structure design of the reactor and the control to the rotating speed of the stirring paddle, the biofilm carriers in the reactor can be ensured always in the suspension state under the low aeration quantity, and excellent fluidization character is maintained, so that the partial nitrification advantages are stably kept, the advantages are created for simultaneous nitrification and denitrification, and the aeration energy consumption and the carbon source material consumption in the denitrification phase are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

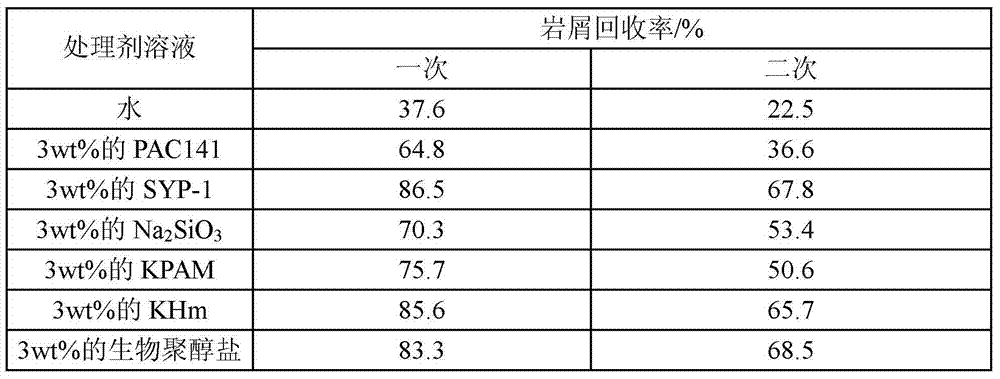

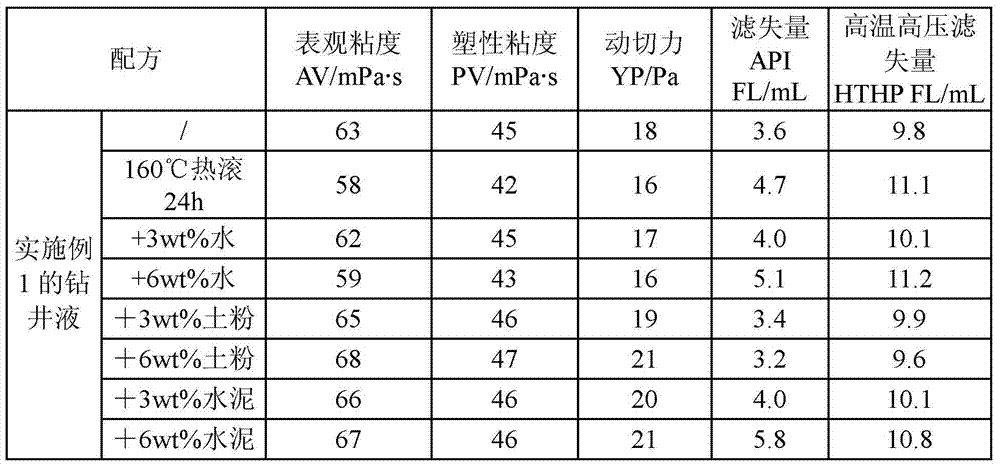

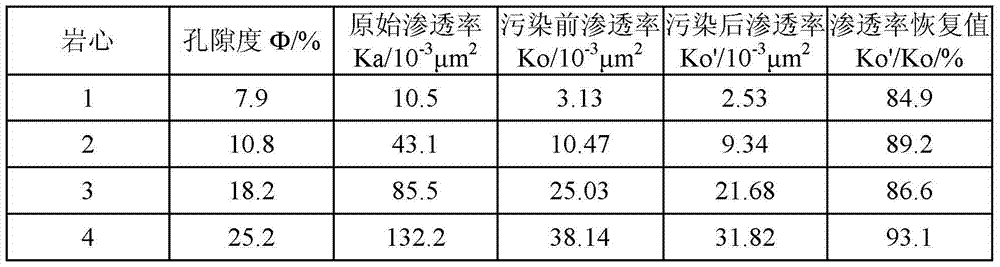

A Drilling Fluid Suitable for Tight Sandstone Reservoirs

ActiveCN105295872BImprove the lubrication effectAvoid harmDrilling compositionLiquid densitySodium Bentonite

Owner:PETROCHINA CO LTD

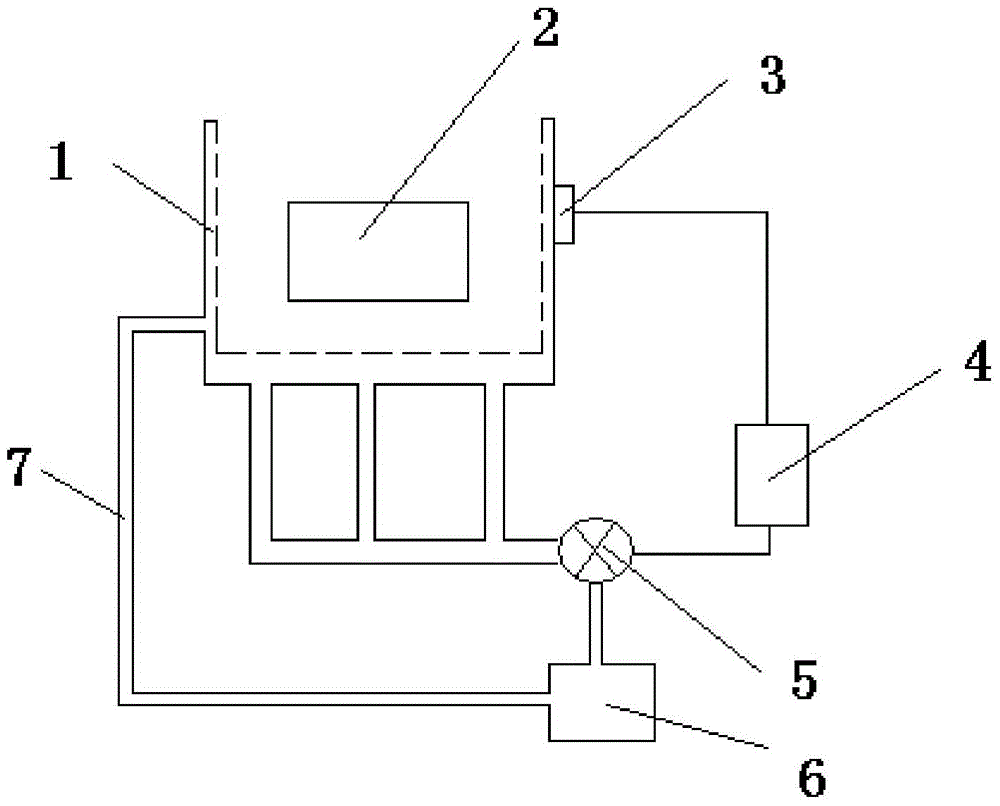

Magnesium-lithium alloy surface treatment device

ActiveCN104862685AEfficiency for uniform surface preparationImprove Surface Treatment EfficiencyMetallic material coating processesLithiumSalt spray test

The invention discloses a magnesium-lithium alloy surface treatment device, and aims to enable a magnesium-lithium alloy to be uniform in a conversion film layer in the chemical conversion process and to generate no corrosion spots in inspection by a salt spray test. The magnesium-lithium alloy surface treatment device is characterized by comprising a treatment tank for placing treatment liquid, wherein multiple liquid spray holes are formed in the bottom of the treatment tank; the liquid spray holes are connected with a variable frequency pump through a liquid channel formed in the bottom of the treatment tank; the variable frequency pump is connected to a treatment liquid source; a control end of the variable frequency pump is connected to a controller; a position sensor is arranged on the side wall of the treatment tank, and is connected to the controller; when a magnesium-lithium alloy workpiece is treated, the treatment liquid is sprayed through the liquid spray holes to suspend the magnesium-lithium alloy workpiece in the treatment liquid; the position sensor detects position change information of the magnesium-lithium alloy workpiece to return to the controller; and the controller adjusts the liquid outlet pressure of the variable frequency pump according to the position change information so as to stably suspend the magnesium-lithium alloy workpiece in the treatment liquid.

Owner:西安四方超轻材料有限公司

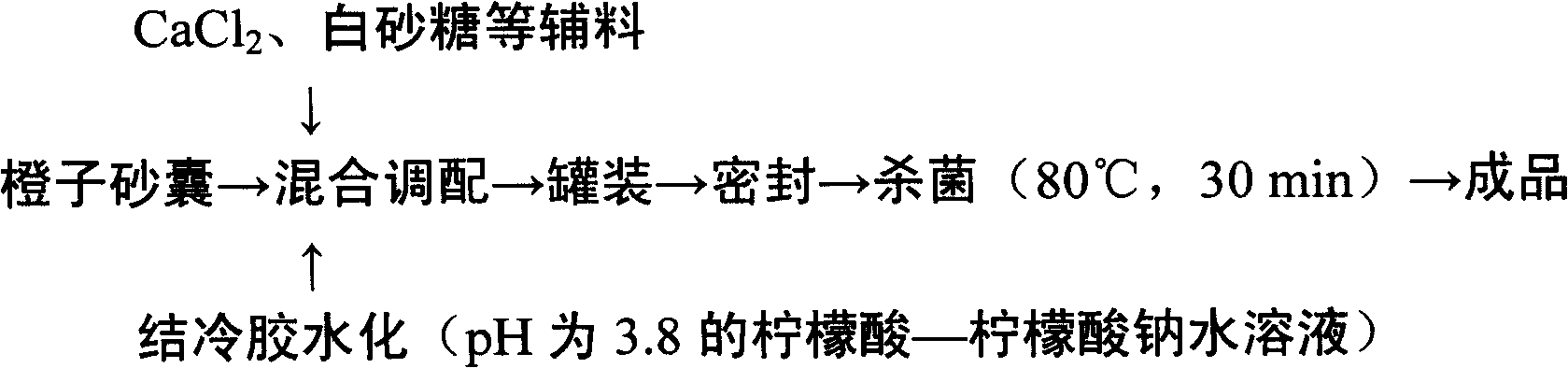

Formulating method for orange gizzard suspending beverage

The invention relates a method for preparing orange gizzard suspended beverage and pertains to the technical field of non-alcoholic beverage. The orange gizzard suspended beverage of the invention is prepared from such components as orange gizzard, a suspending agent, a color fixative and calcium chloride; the particles of the orange gizzard suspended beverage are uniformly suspended, with apparent appearance, dainty and pleasant taste but no turbidness, ,and has a long shelf life.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

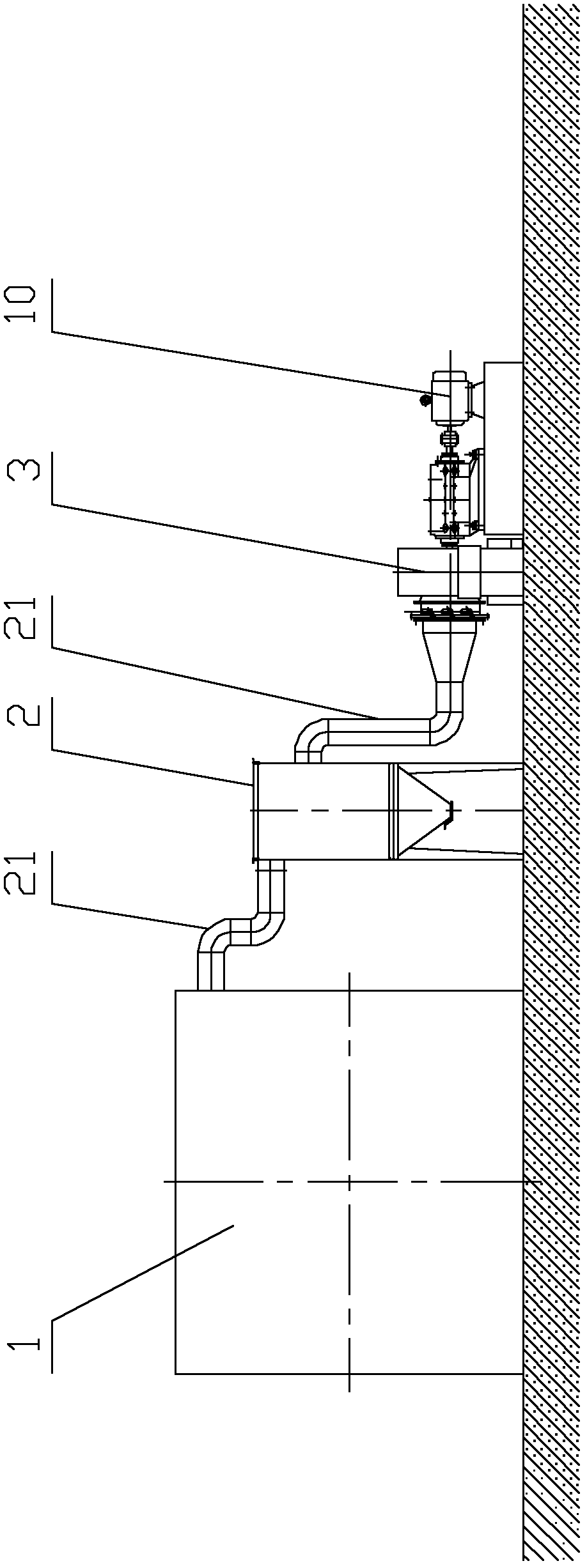

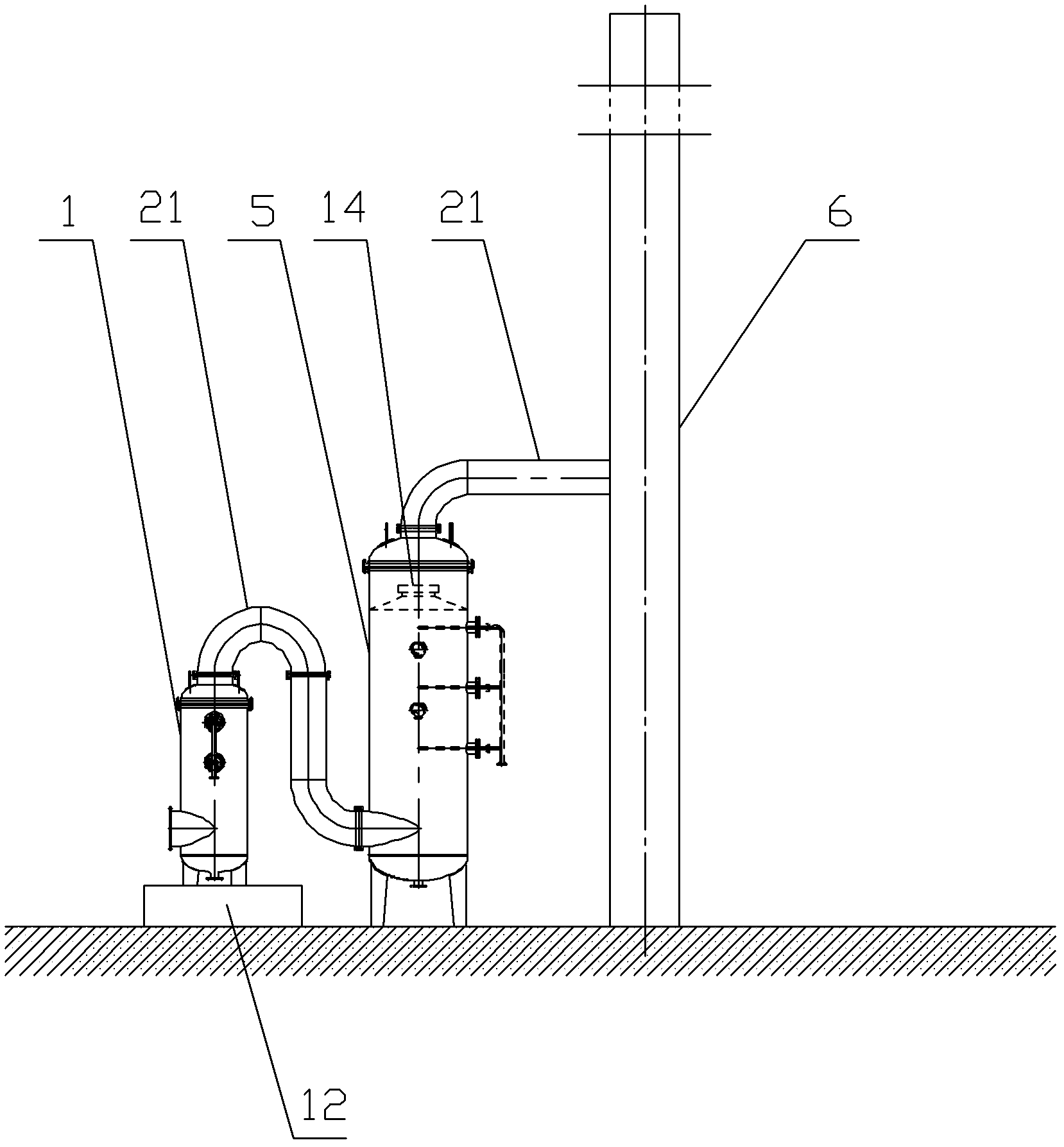

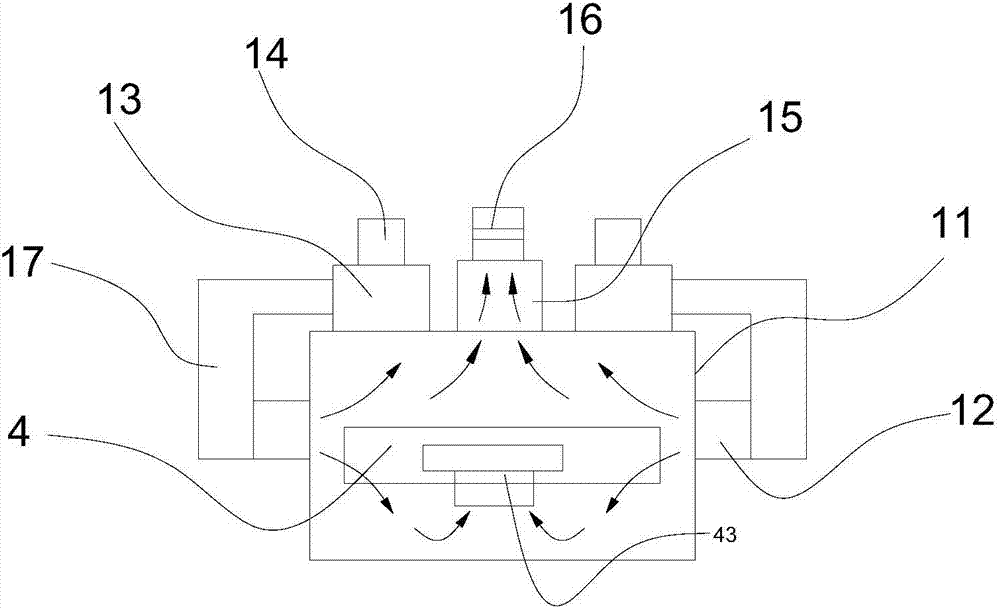

Condensing dioxygen method desulfuration denitration integration device and process thereof

InactiveCN102580489AImprove energy efficiencyRun smoothlyCombination devicesRecycling by productWater tanks

The invention discloses a condensing dioxygen method desulfuration denitration integration device and a process thereof. The integration device comprises a boiler room smoke vent, a first level dry type dust removing device, an induced draft fan, a second level wet type dust removing device, a comprehensive desulfuration denitration tower and a chimney which are sequentially connected through flues. An ozone filling device is disposed on the flue on which the first level dry type dust removing device is connected with the induced draft fan. A liquid inlet of the second level wet type dust removing device and a liquid inlet of the comprehensive desulfuration denitration tower are both connected with a circulating water tank. A liquid outlet of the second level wet type dust removing device is connected with a precipitation water tank. A liquid outlet of the comprehensive desulfuration denitration tower and a liquid outlet of the precipitation water tank are both connected with the circulating water tank. A liquid outlet of the circulating water tank is connected with a crystallization tower, and a liquid outlet of the crystallization tower is connected with the circulating water tank. By means of a set of device, the process adopts the dry and wet method for desulfurating, denitrating and dedusting smoke of coal-fired boilers, and has the advantages of being high in energy efficiency, stable in operation, little in investment, low in operation cost, strong in applicability and free of secondary pollution, treating wastes with processes of wastes, recycling by-products and the like.

Owner:无锡市灵龙机械设备有限公司

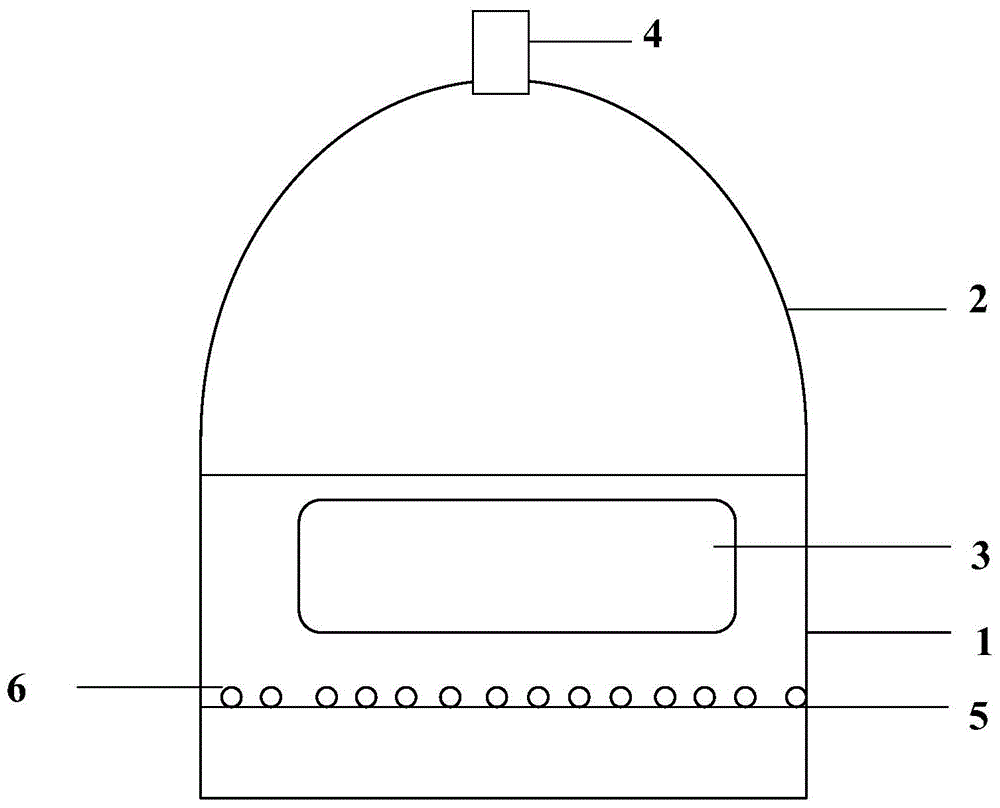

Sintering furnace with silicon wafer capable of being dried in suspended manner

ActiveCN107966015AEasy to take awayImprove drying efficiencyDrying gas arrangementsFurnace typesSiliconAir heating

The invention discloses a sintering furnace, capable of facilitating flowing of drying gas flow in a drying furnace area, with a silicon wafer capable of being dried in a suspended manner. The sintering furnace with the silicon wafer capable of being dried in the suspended manner comprises the drying furnace area, a sintering furnace area, a cooling furnace area and a conveying device, and a gas spraying device is arranged below the portion, located in the drying furnace area, of the conveying device; the drying furnace area comprises a furnace body; a gas extracting device is arranged on thetop of a drying furnace cavity; gas inflow pipes are arranged on the side wall of the furnace body, and the gas inflow pipes are uniformly distributed on the side face of the furnace body in the length direction; the gas inflow pipes are located above the upper surface of the conveying device at the gas inflow port position in the drying furnace cavity, and the other portion is located below the upper surface of the conveying device; and an air heating air blowing device is arranged on the top of the furnace body, and an air outlet of the air heating air blowing device is communicated with thegas inflow pipes. By adopting the sintering furnace with the silicon wafer capable of being dried in the suspended manner, the drying gas flow can be optimized, and the drying efficiency is improved.

Owner:LESHAN TOPRAYCELL

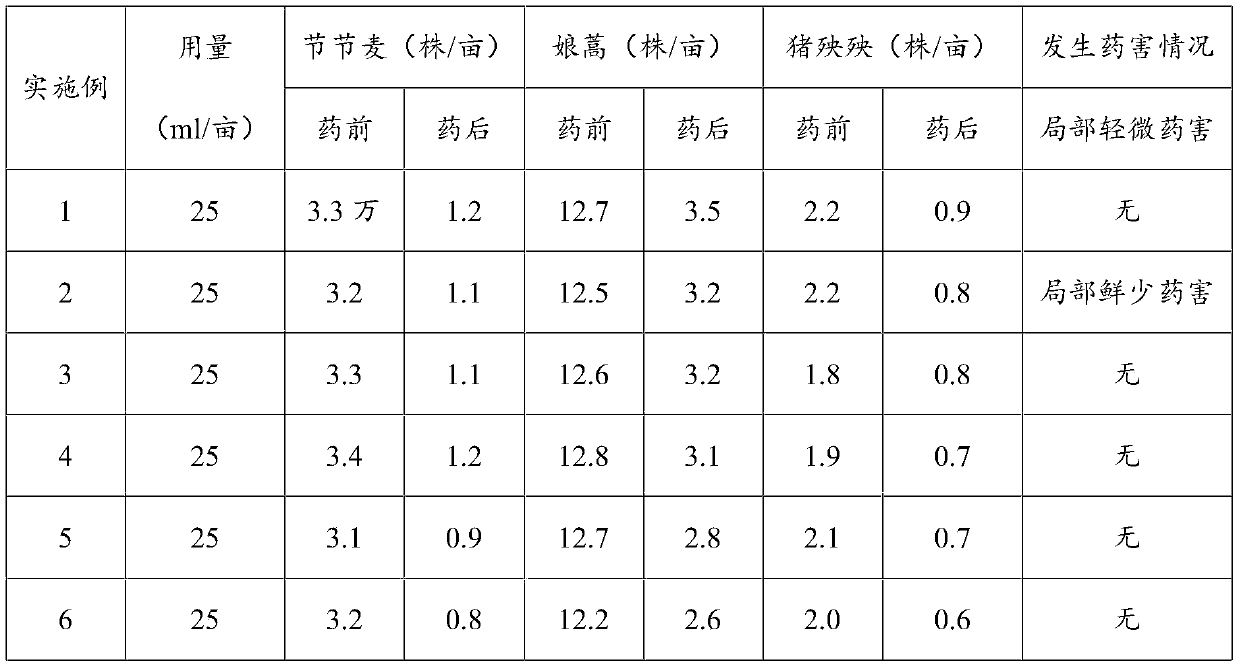

Mesosulfuron-methyl composition containing safener and preparation method thereof

InactiveCN111165489AImprove the effect of prevention and controlGood storage stabilityBiocideAnimal repellantsPhytotoxicityActive ingredient

The invention discloses a mesosulfuron-methyl composition containing a safener and a preparation method thereof. The mesosulfuron-methyl composition is prepared from an active ingredient I, an activeingredient II, an auxiliary agent and the safener, wherein the active component I is mesosulfuron-methyl, the active component II is selected from one or a combination of two of pyroxsulam, diflufenican and florasulam, the adjuvant comprises an auxiliary agent and a filler, and the safener is selected from one or a combination of two of mefenpyr-diethyl, isoxadifen-ethyl and cyclopropanesulfamide.Due to the addition of the safener, weeds in a wheat field can be effectively prevented and killed, the herbicide resistance of crops to herbicides can be remarkably improved, phytotoxicity of mesosulfuron-methyl to wheat is reduced, and the yield is increased. In addition, the active ingredient II can significantly improve the pesticide effect, improve the weed control effect of the herbicide and reduce the dosage of the herbicide.

Owner:镇江建苏农药化工有限公司

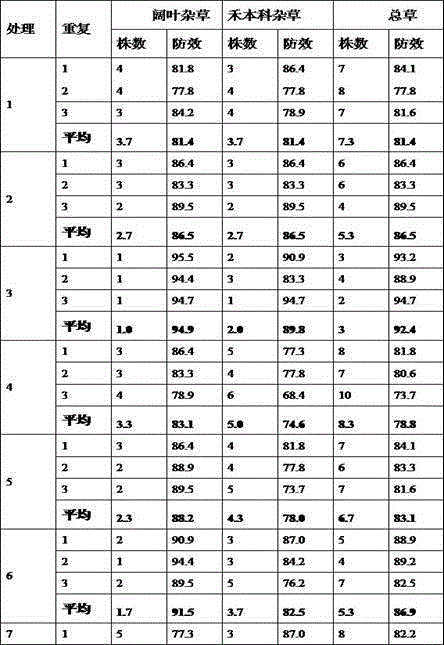

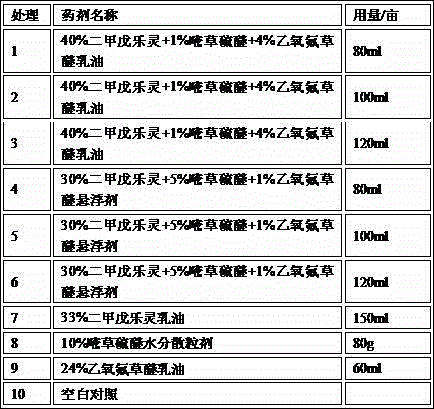

Herbicide formed by mixing pendimethalin with pyrithiobac-sodium and oxyfluorfen

InactiveCN104798785AGood storage stabilityImprove crushing efficiencyBiocideAnimal repellantsFilling materialsSolvent

The invention discloses a herbicide formed by mixing pendimethalin with pyrithiobac-sodium and oxyfluorfen. The herbicide comprises pendimethalin, pyrithiobac-sodium, oxyfluorfen and one or more additives, and further comprises one or more of filling materials or solvents, wherein the mass percentage of pendimethalin is 10% to 40%; themass percentage of pyrithiobac-sodiumsubtypeis 1% to 25%;the mass percentage of oxyfluorfen is 1% to 30%; the total mass of pendimethalin, pyrithiobac-sodium and oxyfluorfen is 12% to 80% of that of the herbicide. As the ingredients are matched reasonably in type and content, the herbicide can be used for effectively preventing and killing weeds in cotton fields. The three main ingredients having complementary advantages are mixed to give full play to the advantages; various weeds can be prevented and killed through once application of the herbicide, that is, both time and labor are saved. The herbicide provided by the invention is an efficient, broad-spectrum and safe weed composition, and can be used for well preventing and killing the weeds in the cotton fields.

Owner:山东华阳农药化工集团有限公司

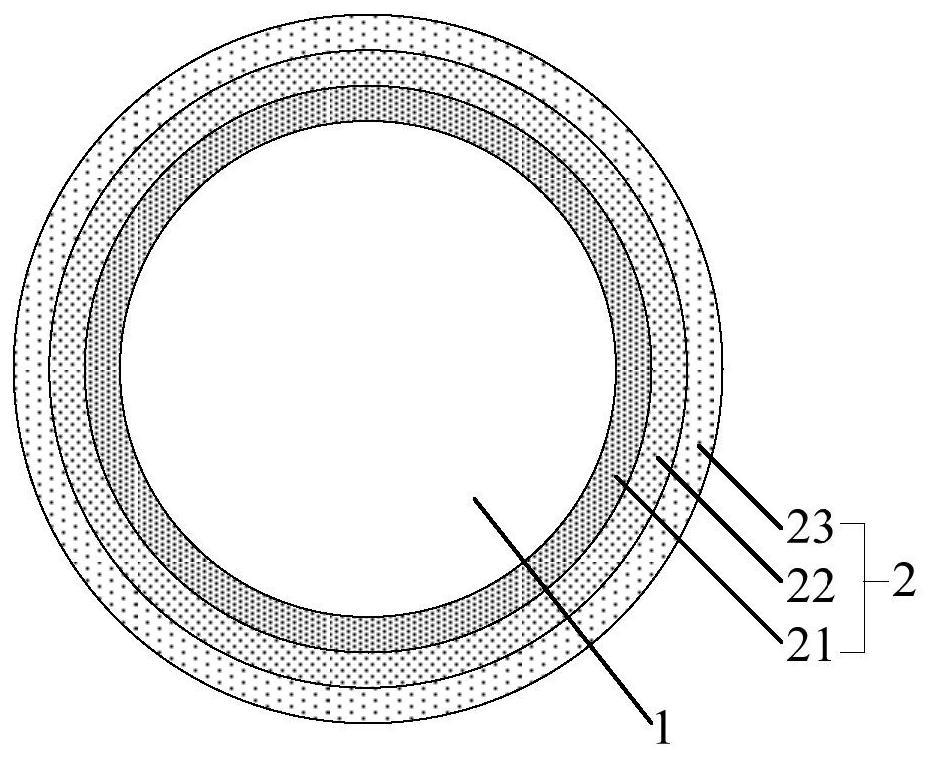

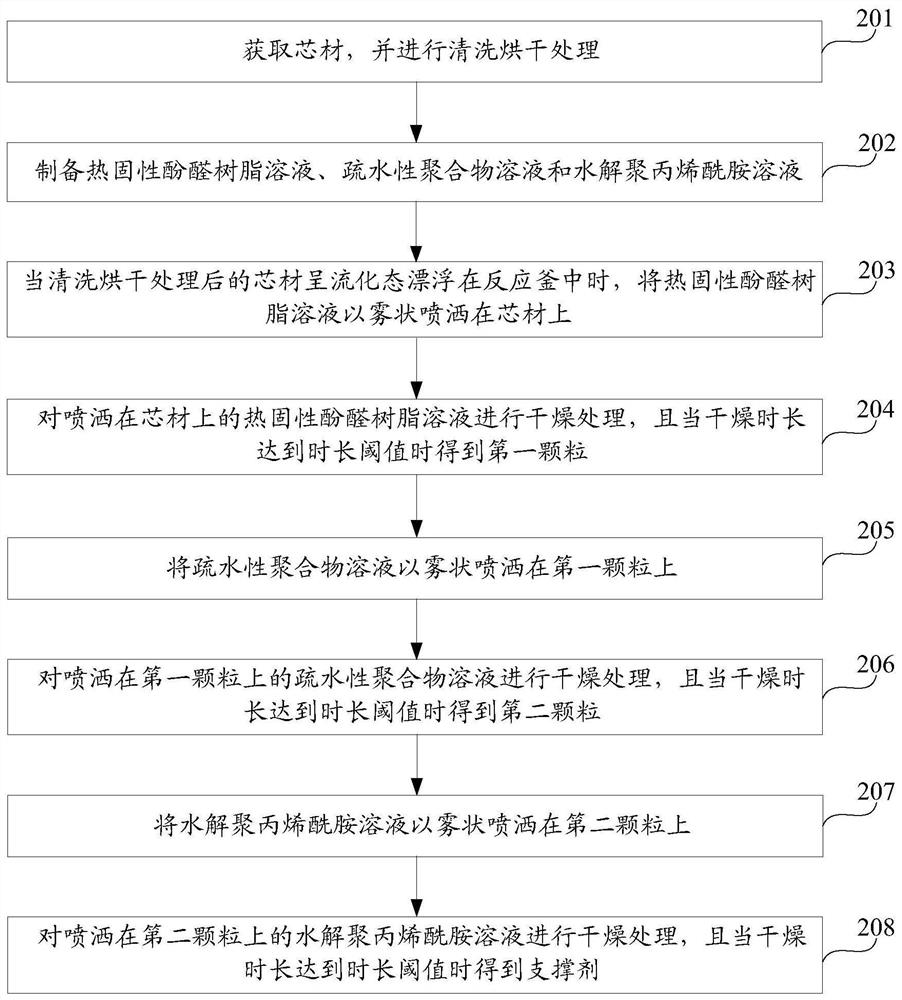

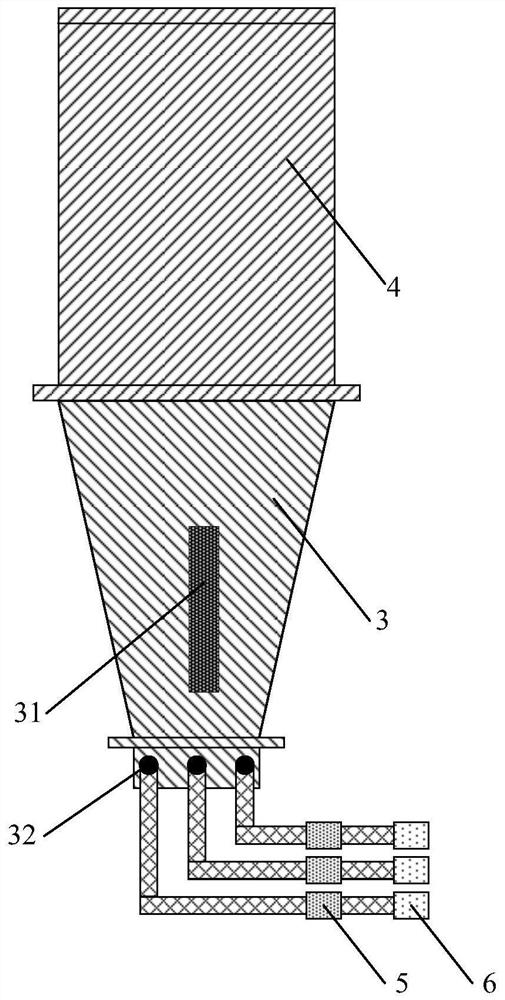

Proppant and preparation method thereof

PendingCN111607383AGuaranteed compressive strengthGuaranteed anti-scour propertiesFluid removalDrilling compositionPolyacrylamideEngineering

The invention discloses a proppant and a preparation method thereof, and belongs to the technical field of hydraulic fracturing. The proppant comprises a core material and a capsule material; the capsule material comprises a first wrapping layer, a second wrapping layer and a third wrapping layer which sequentially wrap the core material; thermosetting phenolic resin, used as the first wrapping layer, a hydrophobic polymer used as the second wrapping layer, hydrolyzed polyacrylamide used as the third wrapping layer sequentially coat the core material, so that the proppant can be obtained. As the core material is ceramsite or quartz sand with the particle size of 70-140 meshes, the compressive strength of the proppant is ensured while the volume of the proppant is ensured. Due to the adhesion of the thermosetting phenolic resin, the connection stability between the second wrapping layer and the third wrapping layer which sequentially wrap the core material and the core material is ensured. Due to the anti-scouring characteristic of the hydrophobic polymer and the suspension characteristic of the hydrolyzed polyacrylamide, it is guaranteed that the proppant can suspend in a fracturing fluid, and cracks can be supported for a long time.

Owner:PETROCHINA CO LTD

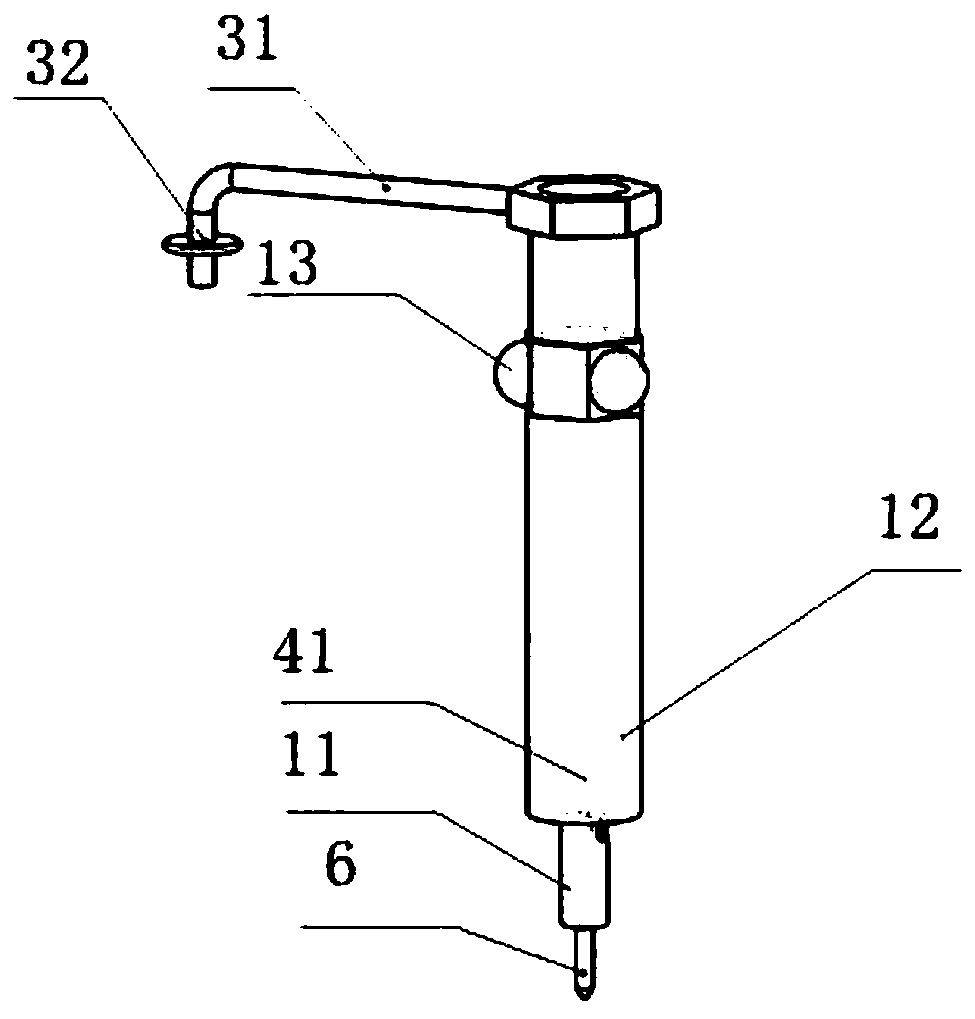

Surface microstructure measurement sensor

PendingCN111351451AReduce frictionHigh precisionUsing optical meansMechanical pressure/force controlPhysicsMicrostructure

The invention discloses a surface microstructure measurement sensor. The sensor is used for measuring the morphology of the surface of a to-be-measured workpiece, and comprises: a contact pin used formeasuring the microstructure; a contact pin shaft, wherein one end of the contact pin shaft is connected with the contact pin, and the contact pin shaft is used for moving up and down along with thecontact pin when the contact pin measures the microstructure; a magnetic constant force module connected with the other end of the contact pin shaft and used for adjusting the measuring force betweenthe contact pin and the to-be-measured workpiece; a contact pin shaft air floating module surrounding the periphery of the contact pin shaft and used for suspending the contact pin shaft; and a displacement measurement module arranged over the contact pin shaft and used for measuring the displacement of the contact pin shaft in the vertical direction. An air gap is formed in the outer surface of the contact pin shaft through the contact pin shaft air floating module, so it is ensured that the contact pin shaft is suspended and has minimum friction, and the contact pin measurement precision isimproved. The measuring force between the contact pin and the to-be-measured workpiece can be adjusted through the magnetic constant force module, so that the contact pin transmits the surface topography of the workpiece to the sensor more truly.

Owner:NAT INST OF METROLOGY CHINA

Marine fish real-time image monitoring and controlling statistics system

The invention discloses a marine fish real-time image monitoring and controlling statistics system, which comprises an underwater image device, and a light supplement fiber network arranged on the underwater image device. The light supplement fiber network includes a plurality of light equalizing optical fibers. The light equalizing optical fibers are connected together by an electrical net. The light equalizing optical fibers are connected onto a light source of the electrical net on one end thereof. Light escape lines are arranged on the surface of the light equalizing optical fibers. The light equalizing fibers of a planar structure is used for the light supplement, the space of light supplement coverage radiation is large, compared with the ordinary light in the prior art, the system has a large irradiation area and no characteristic of high light spots, the light is distributed uniformly throughout the entire light supplement fiber network, the dispersion of light is relatively uniform, the impact on fish is particularly small, the behavior of fish in the image will not be affected, and in particular, the abnormal behavior of fish will not occur, basically.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

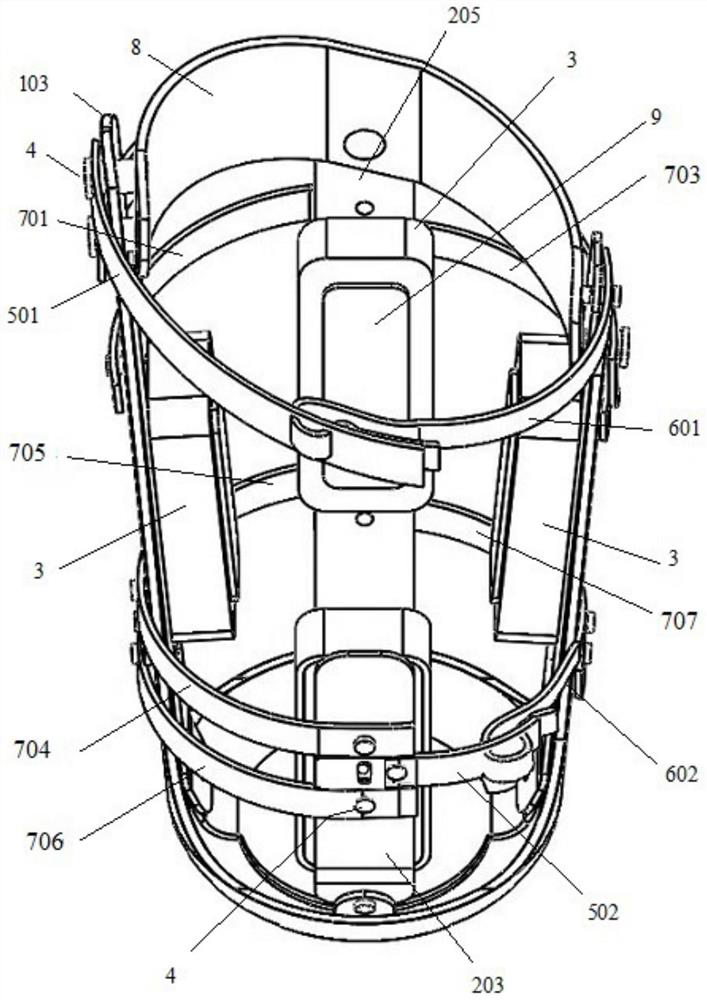

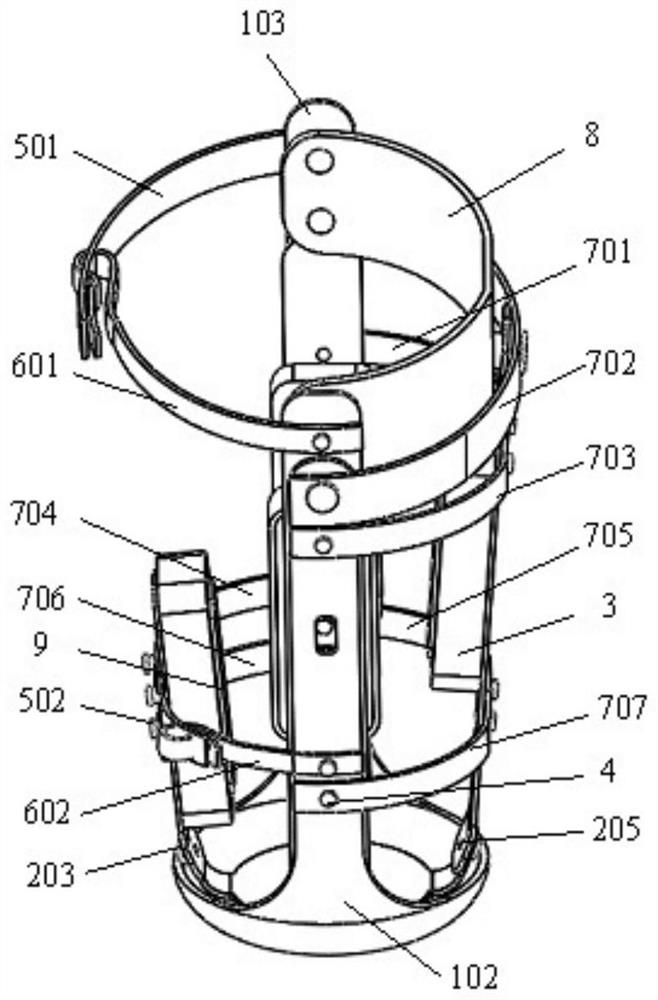

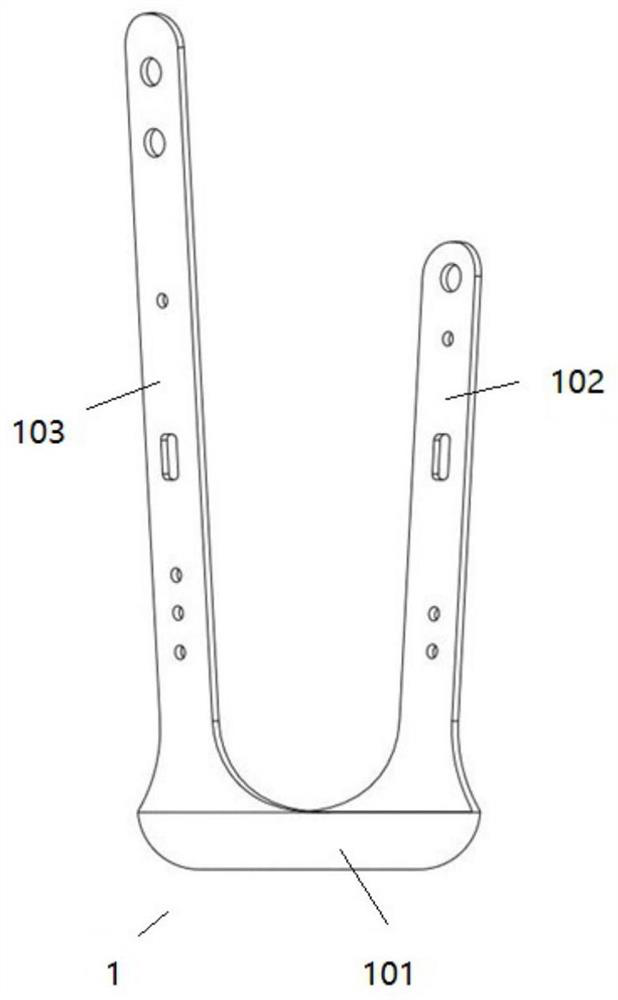

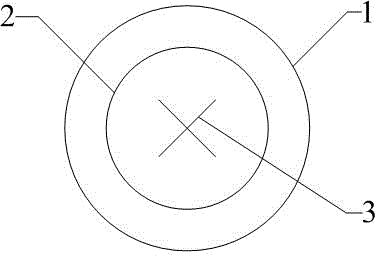

Fully open constant force receiving cavity

The invention relates to a fully open constant force receiving cavity. The fully open constant force receiving cavity comprises an outer frame (1), an inner frame (2) arranged inside the outer frame (1), a plurality of transverse connection fixing assemblies connected with the outer frame (1) and the inner frame (2), and a plurality of constant force mechanisms (3) arranged on the inner frame (2),wherein the outer frame (1), the inner frame (2) and the transverse connection fixing assemblies enclose a cavity, the outer frame (1) comprises an outer frame base (101), and a plurality of outer frame support bars longitudinally arranged on the outer frame base (101), the inner frame (2) comprises an inner frame base (201), and a plurality of inner frame support bars longitudinally arranged onthe inner frame base (201), the inner frame base (201) and the outer frame base (101) are in corresponding positions, and the outer frame support bars and the inner frame support bars are in corresponding positions. Compared with the prior art, the fully open constant force receiving cavity ensures the accuracy of force and motion transmission during use, improves the comfort, and has the controllable function.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

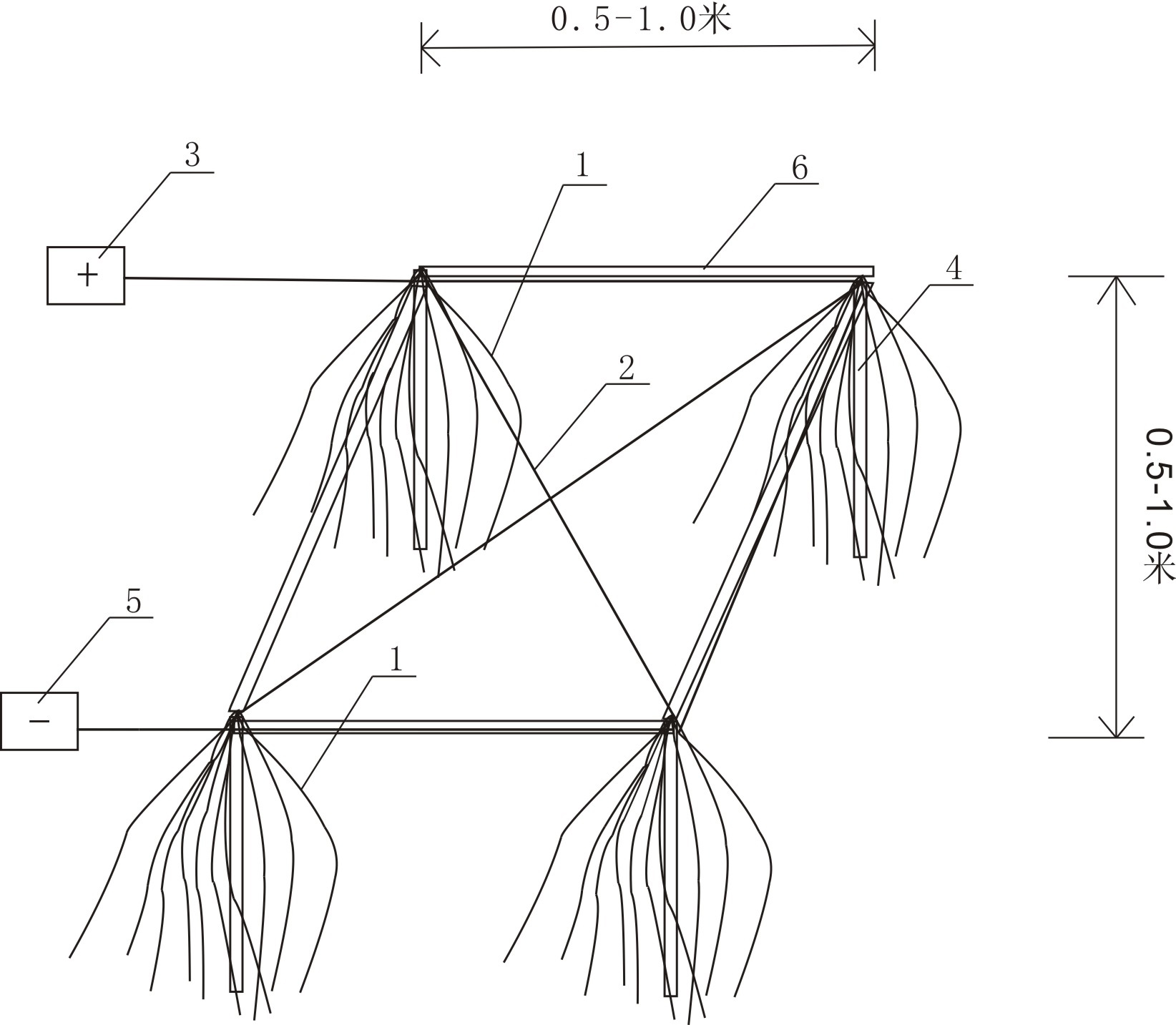

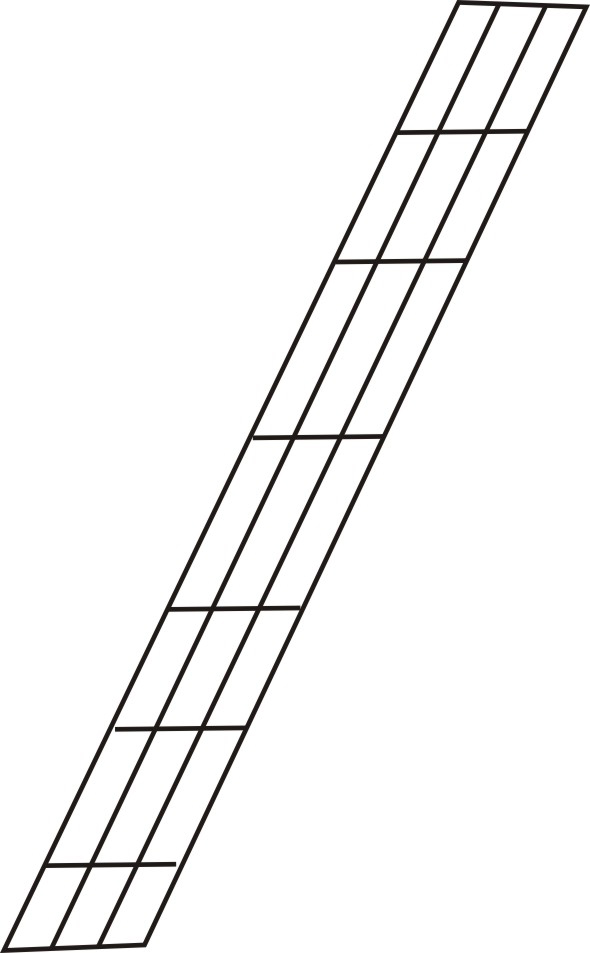

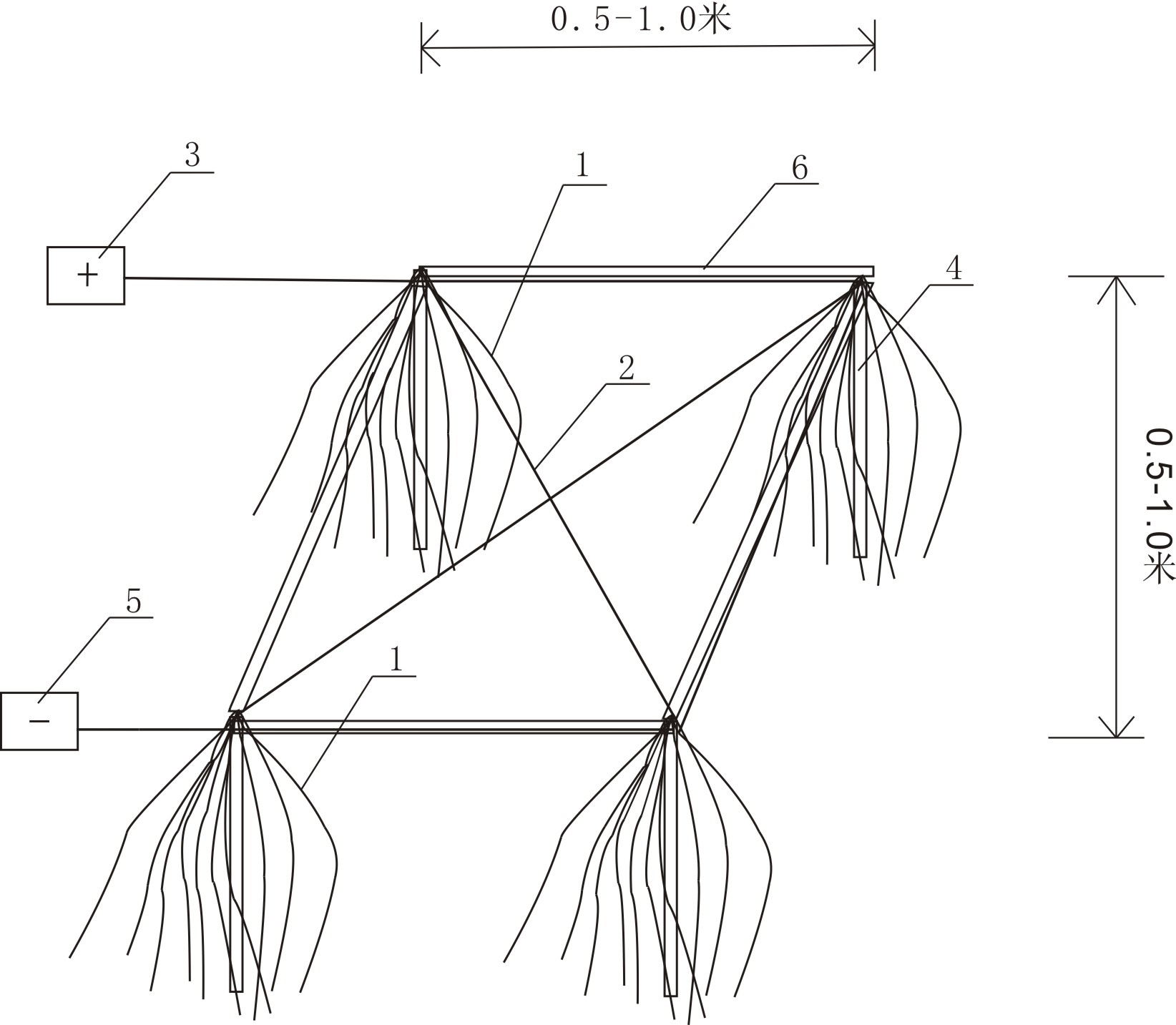

Viscous fish egg killing device

InactiveCN102630619ASimple structureEasy to operateClimate change adaptationPisciculture and aquariaNegative thinkingZoology

The invention relates to a viscous fish egg killing device. Every two conductive egg collectors are distributed at a certain interval, one of every two conductive egg collectors is connected with the positive pole of a power supply, the other one of every two conductive egg collectors is connected with the negative pole of the power supply, and each conductive egg collector is connected with the power supply in series or parallel by virtue of a wire. The viscous fish egg killing device provided by the invention adopts multiple conductive egg collectors, every two conductive egg collectors arerespectively connected with the positive pole and negative pole of the power supply, the characteristic that the egg collector can attract fish to lay eggs is utilized, after the conductive egg collectors are electrified, an electric field is formed between the two conductive egg collectors, fertilized eggs in the egg collector can be killed, a method for eliminating the fish which invades is provided in the aspect of eliminating the fertilized eggs of the fish in negative thinking, and the viscous fish egg killing device disclosed by the invention is simple in structure, easy in operation and high in efficiency.

Owner:CHINA THREE GORGES UNIV

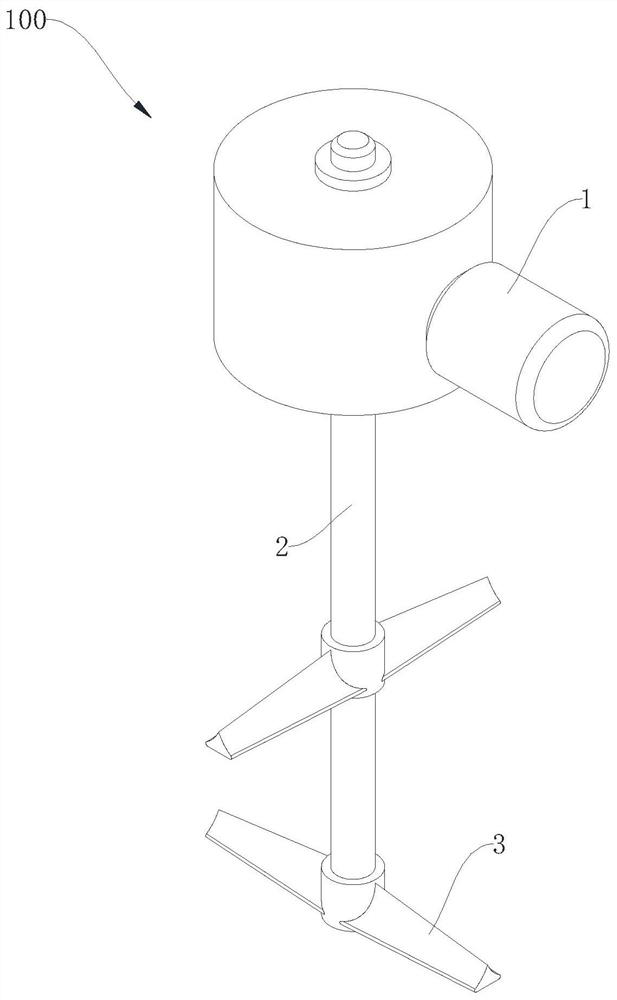

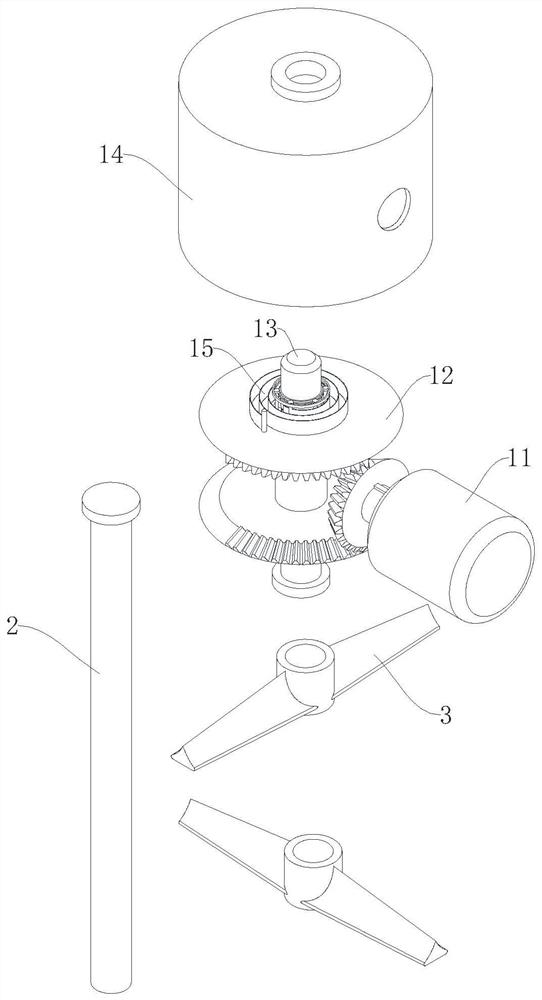

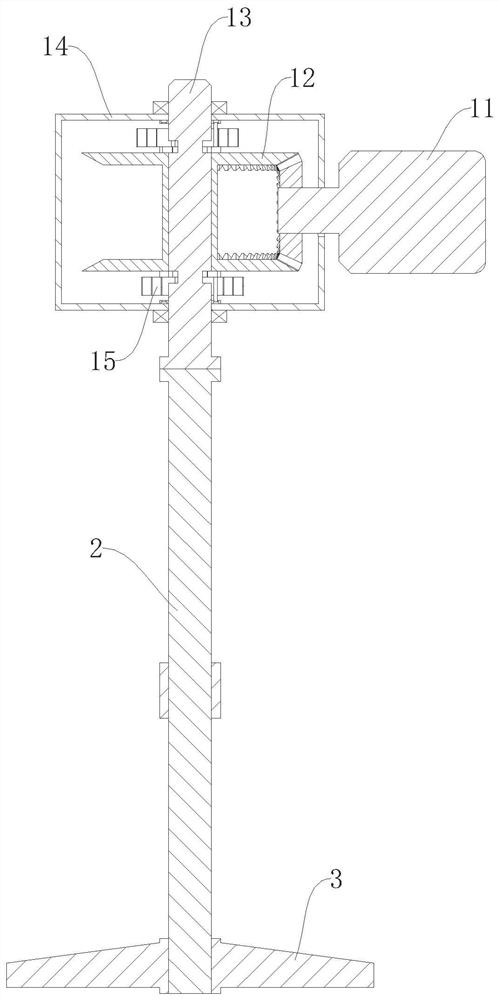

Stirring device for sewage treatment and flocculation equipment with same

ActiveCN113617243AGuaranteed StrengthGuaranteed mixing effectRotary stirring mixersMixer accessoriesPhysicsImpeller

The invention discloses a stirring device for sewage treatment which comprises a driving part, a stirring shaft and an impeller, the impeller is concentrically and fixedly arranged on the stirring shaft, and the driving part is suitable for driving the stirring shaft to rotate in a reciprocating mode; the driving component comprises a rotary power source, a driving mechanism, a driving shaft, a shell and an energy storage mechanism, the one-way rotation of the rotary power source is suitable for driving the driving shaft to rotate forwards or backwards through the driving mechanism, and the driving shaft is concentrically and fixedly connected with the stirring shaft; the shell is fixedly arranged, energy storage mechanisms are arranged between the shell and the driving shaft, the number of the energy storage mechanisms is two, the energy storage mechanisms are suitable for storing energy through forward rotation and reverse rotation of the driving shaft respectively, and the energy storage mechanisms are suitable for releasing energy during forward rotation and reverse rotation conversion or reverse rotation and forward rotation conversion of the driving shaft. The stirring device has the advantages of full stirring, good mixing effect, good flocculation effect, reliable structure, stable operation and low cost.

Owner:浙江长城搅拌设备股份有限公司

Target physiotherapy cup

InactiveCN105311685AGuaranteed SuspensionEasy to replaceMedical devicesSuction devicesEngineeringPiston

The invention discloses a target physiotherapy cup. The target physiotherapy cup is composed of structures including a lower cup body (1), an upper cup body (2), a target information bag (3) and an air pin piston (4). A traditional cup with the external treatment function is changed into the novel cup with the internal treatment function and the external treatment function.

Owner:北京中卫神农慢性病医学研究院有限公司

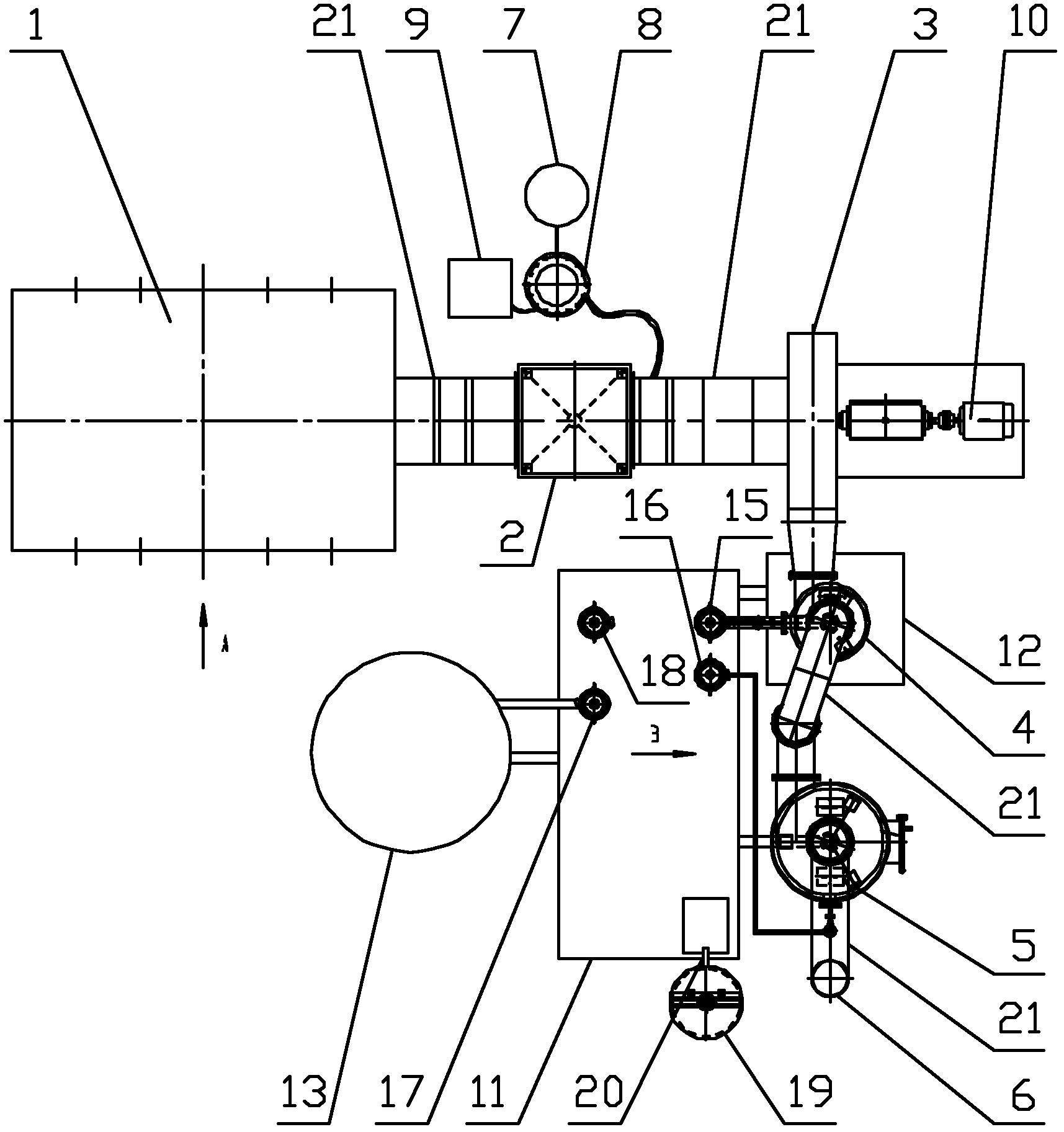

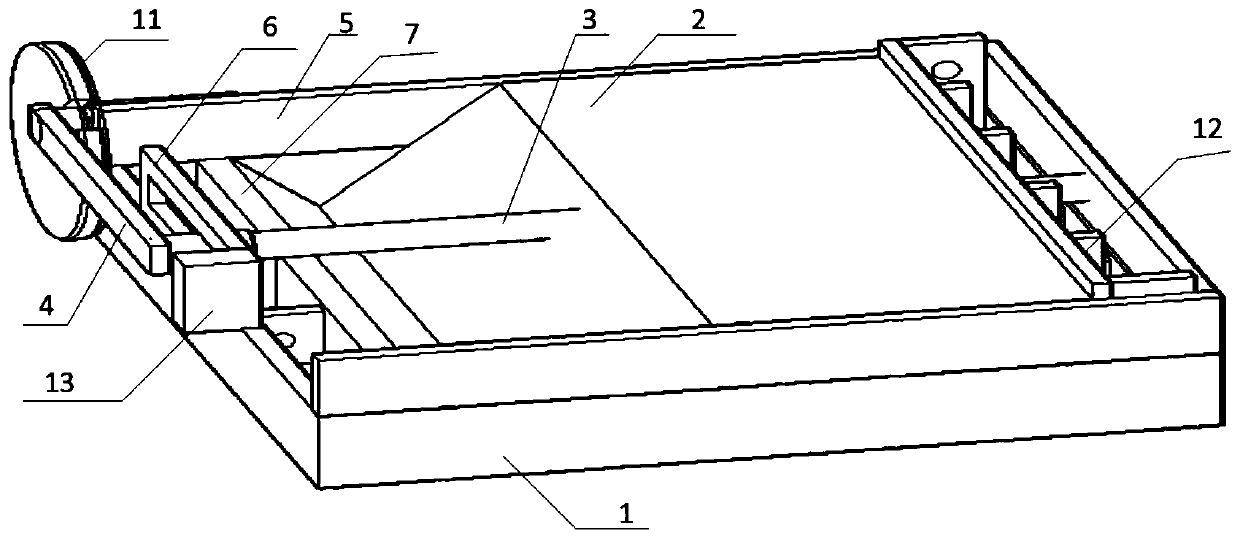

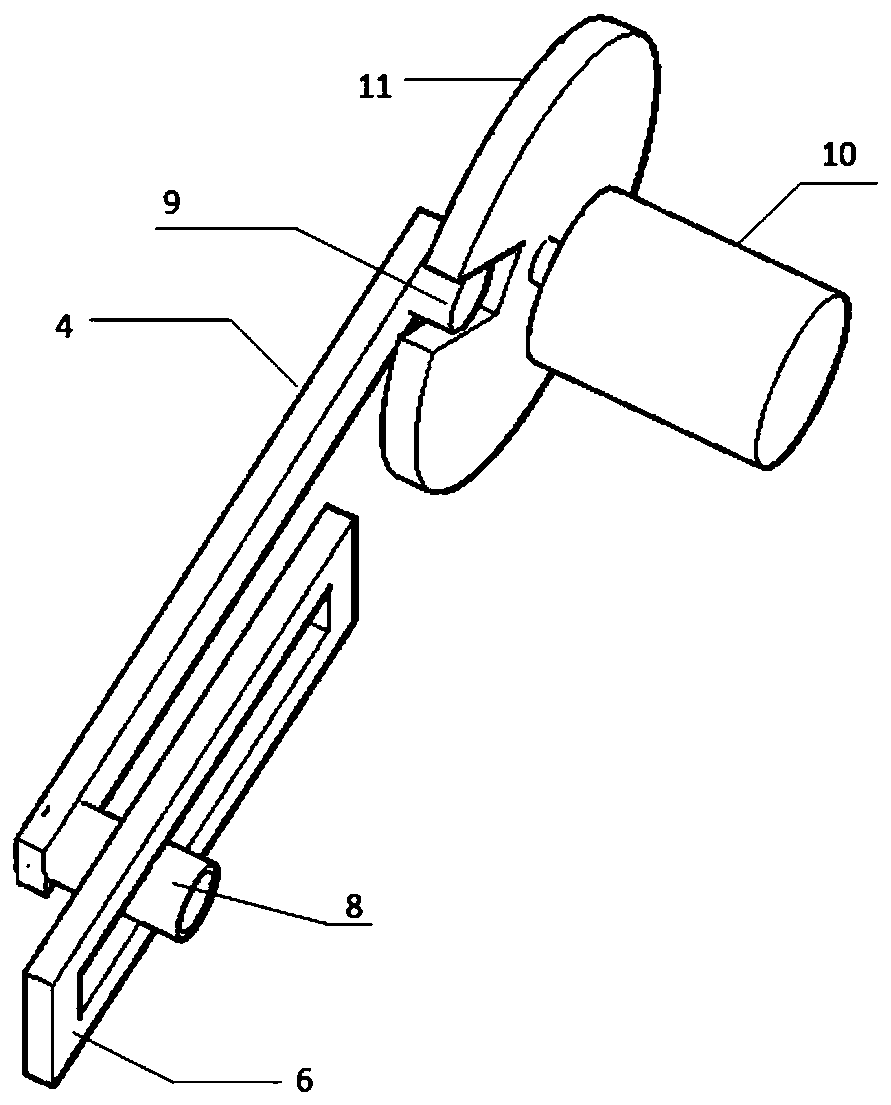

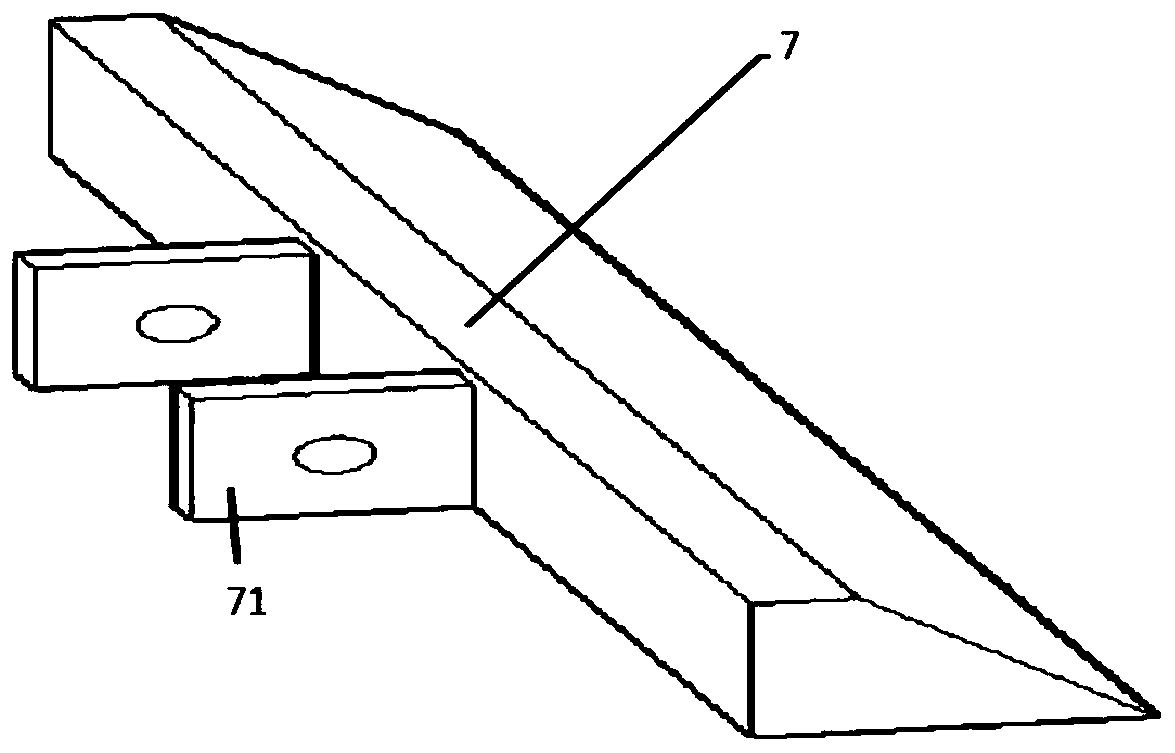

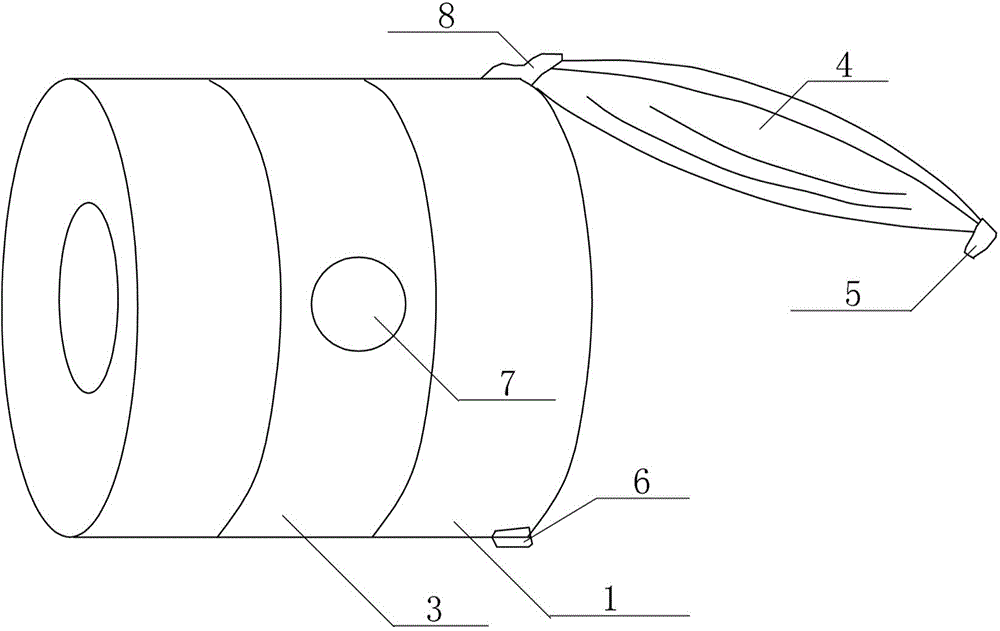

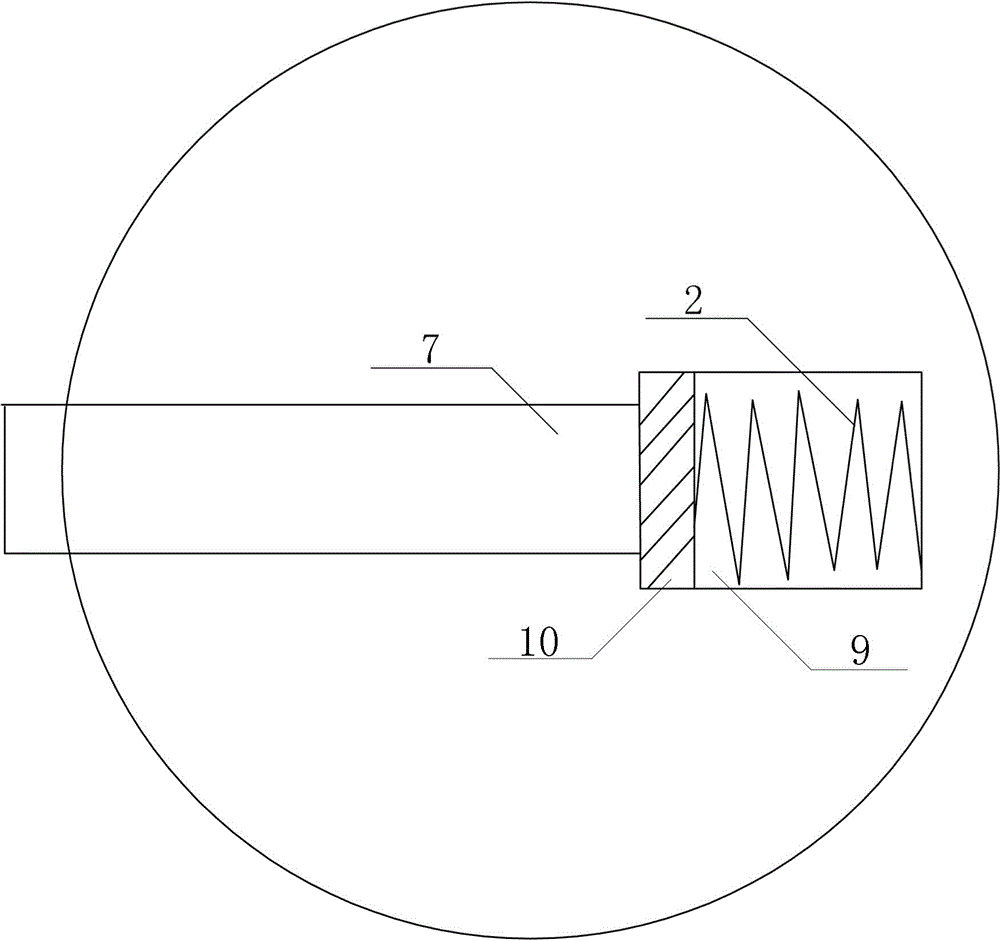

Experimental device for simulating interaction between submarine suspended pipeline and shoulder-spanning soil body

PendingCN110657936AImprove applicabilityEasy to adjustVibration testingExperimental DevicesGeotechnical engineering

The invention discloses an experimental device for simulating interaction between a submarine suspended pipeline and a shoulder-spanning soil body. The experimental device comprises a main soil box, an experimental pipeline, a shoulder-spanning soil body supporting block and a driving device; a displacement sensor is arranged on the box, the shoulder-spanning soil body supporting block is locatedat the bottom of the main soil box, the experimental pipeline is located over the shoulder-crossing soil body supporting block, one end of the experimental pipeline is connected with the driving device, and the other end of the experimental pipeline is fixed to the main soil box; and a graduated scale is arranged in the inner side of the main soil box along the experimental pipeline direction. Thedevice has the advantages that the lateral reciprocating motion process of the experimental suspended pipeline on the shoulder-spanning soil body is simulated, the experimental soil body is preventedfrom sliding down through the shoulder-spanning soil body supporting block, suspension is guaranteed, one end of an experimental pipeline model is fixed, the other end of the experimental pipeline model is connected with a transmission connecting rod, and the motion state of a real seabed suspended pipeline on the shoulder-spanning soil body is simulated.

Owner:OCEAN UNIV OF CHINA

Medicine granule, preparation method thereof, and preparation containing same

InactiveCN101548953BHigh drug contentRounded surfaceOrganic active ingredientsPill deliveryAdhesiveFluidized bed

The invention discloses a medicine granule containing the following components by mass percent: 75 to 95 of medicine, 2 to 22 of thinner for pelletization, 0.06t to 0.5 of glidant, and 1.5 to 3.5 of adhesive. The invention also discloses a preparation method thereof and a preparation containing same. The medicine granule has high medicine content, round surface, higher rigidity and smaller grain diameter, can be directly used for tabletting, has less weight increment if being coated and can achieve a better taste masking effect. The method for preparing the medicine granule can simultaneouslyrealize pelletization and coating technologies in a tangent spraying fluidized bed, has simple production steps and high efficiency, and can be applied to mass production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

Umbrella handle convenient for placing umbrella

The invention discloses an umbrella handle convenient for placing an umbrella. A magnet is arranged at the middle part of the umbrella handle, wherein a suction cup is arranged at one end of the umbrella handle; the magnet is a strip-shaped magnet; a limiting slot is formed in the umbrella handle; two bottom ends of the limiting slot are in contact with one end of a spring and one end of the magnet respectively; a limiting sheet is arranged at one end, located in the limiting slot, of the magnet; the limiting sheet is clamped at the front end of the limiting slot; the other end of the magnet penetrates out of a hole in the wall of the umbrella handle; the limiting slot and the magnet are located at a central axis in the umbrella handle; a ring-shaped shielding cover is arranged on the umbrella handle and is arranged in a ring-shaped groove in the periphery of the umbrella handle; a through hole is formed in the shielding cover, and surrounds and covers the magnet and the peripheral area of the magnet. Through adoption of the structure, the magnet is easily released when the umbrella is required to be suspended; the magnet is well hidden and protected when the umbrella is not required to be suspended.

Owner:童振庆

A gas-liquid separation device

InactiveCN106644665BIncrease contact areaImprove separation efficiencyPreparing sample for investigationSpectrographProduct gas

Owner:TIANJIN NORMAL UNIVERSITY

Reactor for realizing suspension of biofilm carriers under low aeration quantity

ActiveCN103508555BAvoid accumulationAvoid violent collisionsTreatment using aerobic processesSustainable biological treatmentMaterial consumptionEngineering

The invention relates to a reactor for realizing suspension of biofilm carriers under low aeration quantity. The reactor comprises a vertical cylindrical shell, wherein a vertical hollow cylinder is coaxially arranged in the shell, and a stirring paddle is mounted in the hollow cylinder; a plurality of through holes are formed on the wall of the hollow cylinder; the bottom end of the hollow cylinder is fixedly connected with the bottom end of the shell; and the biofilm carriers are filled in a circular space between the hollow cylinder and the shell. According to the unique structure design of the reactor and the control to the rotating speed of the stirring paddle, the biofilm carriers in the reactor can be ensured always in the suspension state under the low aeration quantity, and excellent fluidization character is maintained, so that the partial nitrification advantages are stably kept, the advantages are created for simultaneous nitrification and denitrification, and the aeration energy consumption and the carbon source material consumption in the denitrification phase are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com