Condensing dioxygen method desulfuration denitration integration device and process thereof

A desulfurization and denitrification, condensation-type technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of increased investment and operation costs, complex flue gas purification equipment, high construction and operation costs, etc., to achieve stable operation, Oxidation reaction promotion, strong applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

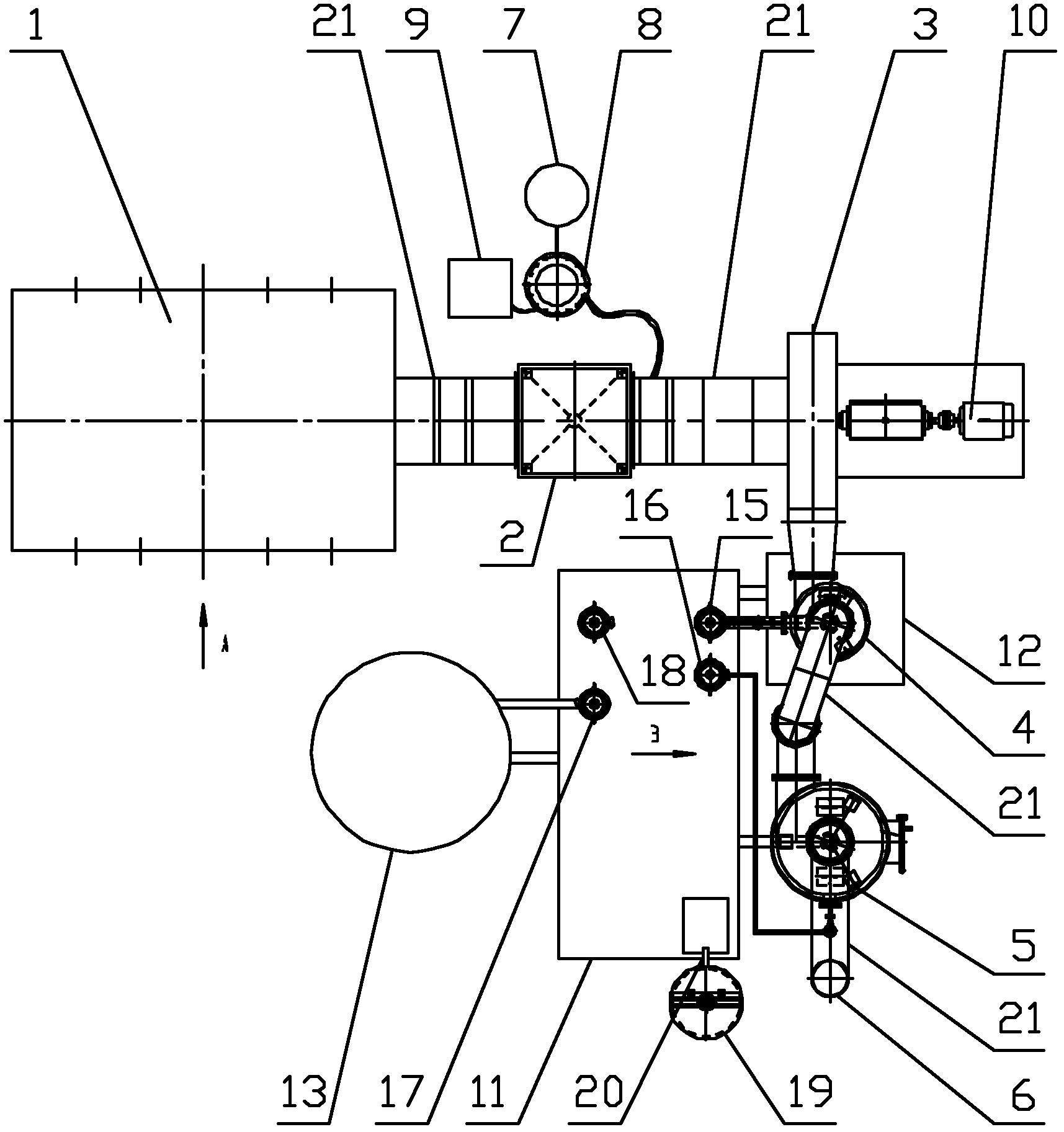

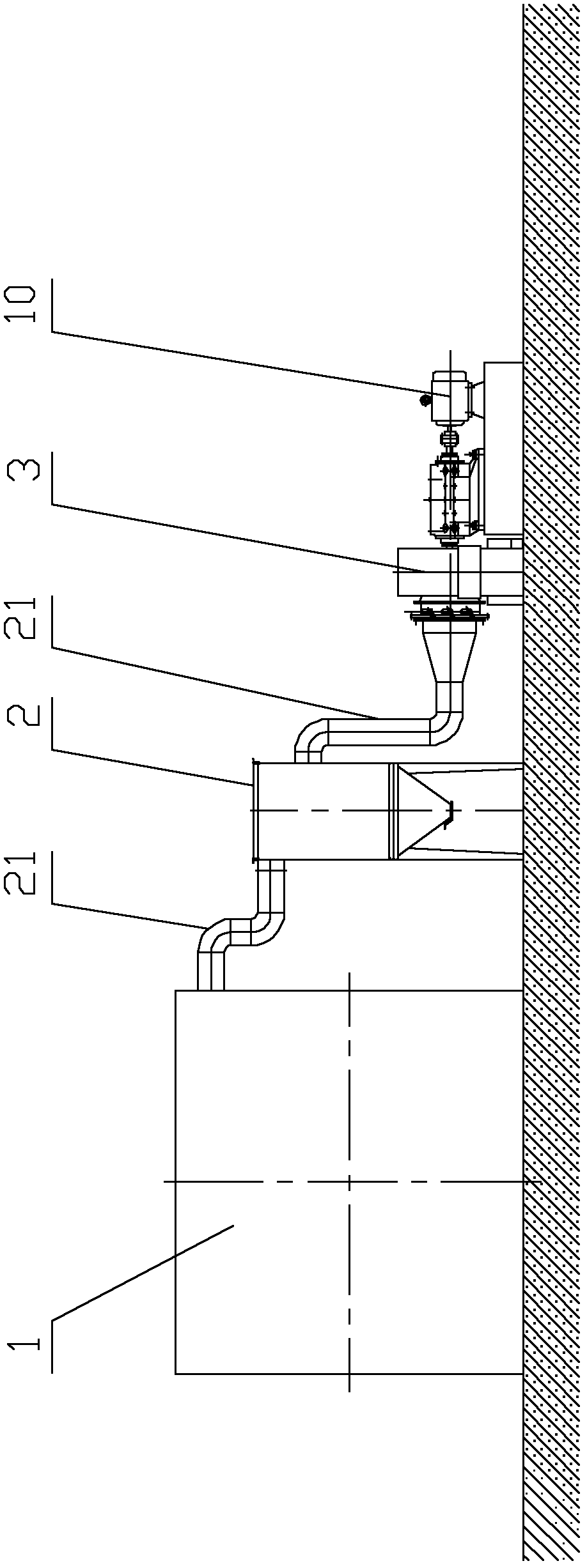

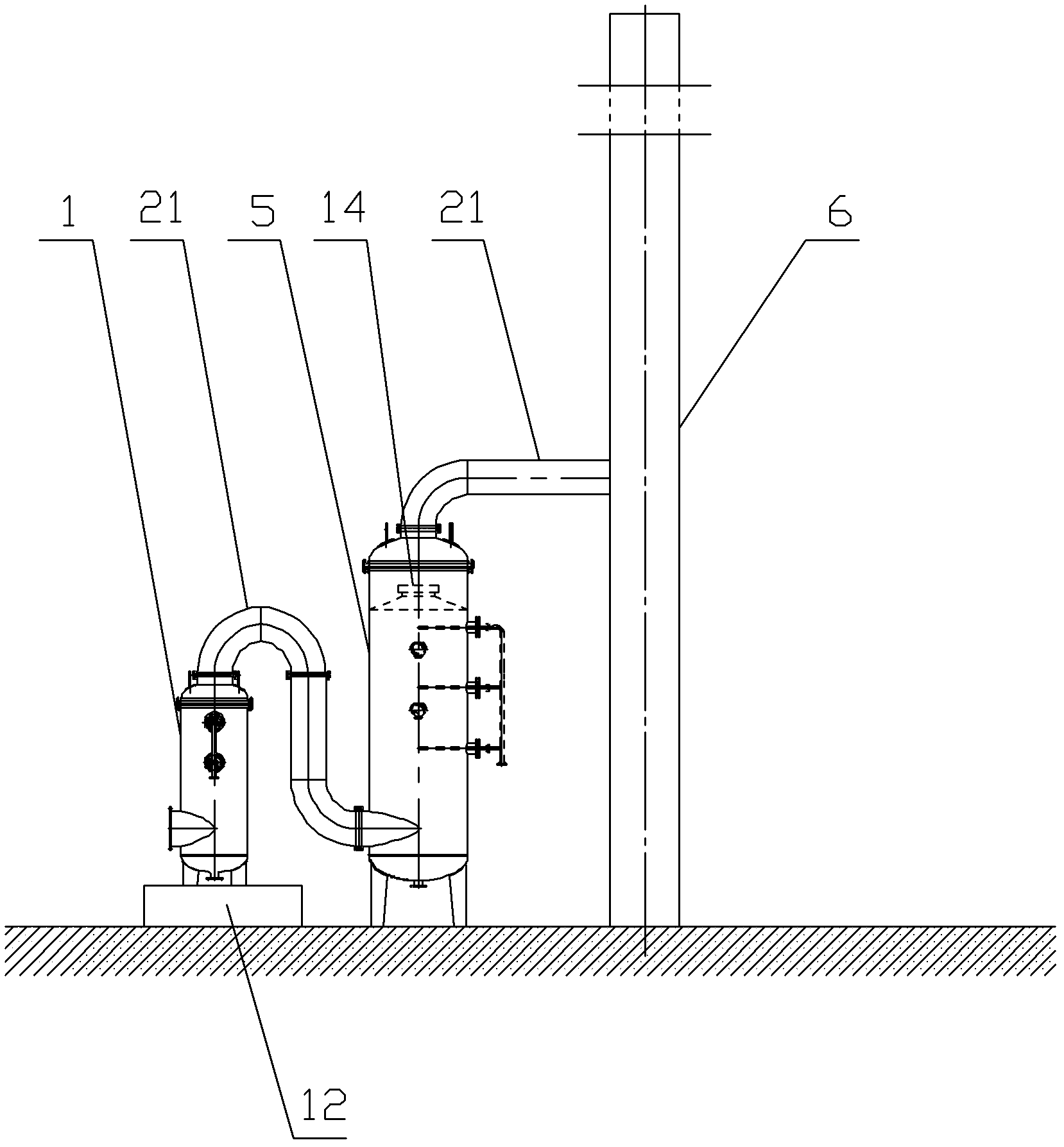

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0051] like Figure 1~3 As shown, the condensing double oxygen method desulfurization and denitrification integrated device includes a boiler room 1 smoke outlet connected in sequence through a flue 21, a first-stage dry dust removal equipment, an induced draft fan 3, a second-stage wet dust removal equipment, Integrated desulfurization and denitrification tower 5 and chimney 6. Among them: the first-stage dry dust removal equipment is a multi-tube dust collector, and more preferably a ceramic multi-tube cyclone dust collector 2; the second-stage wet dust removal equipment is a dust removal / condensation tower 4.

[0052] Further, an ozone injection device is provided on the flue 21 connecting the ceramic multi-tube cyclone dust collector 2 and the induced draft fan 3 . Among them: the ozone fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com