Oil-based drilling fluid

An oil-based drilling fluid and base oil technology, applied in the field of oil and gas field chemistry, can solve the problems of too thick drilling fluid, poor tripping, limited sources, etc., and achieve excellent rheological properties, convenient drilling construction, and wide source of components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

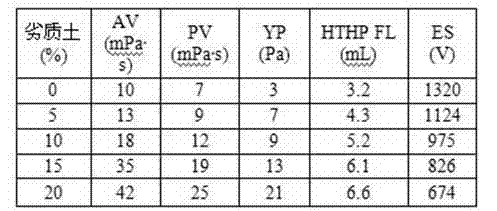

Examples

Embodiment 1

[0034] Oil-based drilling fluid, by weight percentage, consists of the following components: 3# white oil 60%, wetting agent 1%, CaCl 2 Salt water 6%, calcium petroleum sulfonate 3%, oxidized pitch 3%, calcium hydroxide 0.5%, myristic acid 1%, stearic acid 2%, barite 23.5%.

Embodiment 2

[0036] Oil-based drilling fluid, by weight percentage, consists of the following components: 3# white oil 50%, wetting agent 2%, CaCl 2 5% brine, 4% barium petroleum sulfonate, 5% pitch oxide, 1% calcium hydroxide, 1% aluminum isooctanoate, 3% stearic acid, 29% barite.

Embodiment 3

[0038] Oil-based drilling fluid, by weight percentage, consists of the following components: 0# diesel oil 70%, wetting agent 3%, CaCl 2 Salt water 8%, calcium dodecylbenzenesulfonate 2%, humic acid amide 4%, calcium hydroxide 1%, myristic acid 0.3%, aluminum stearate 0.5%, barite 11.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com