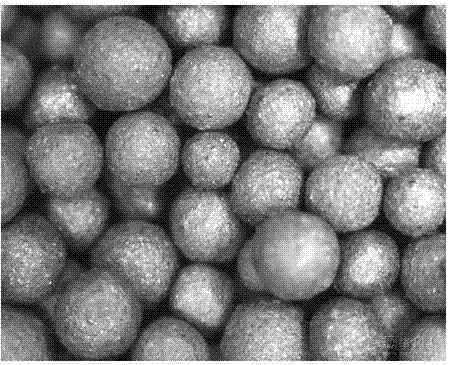

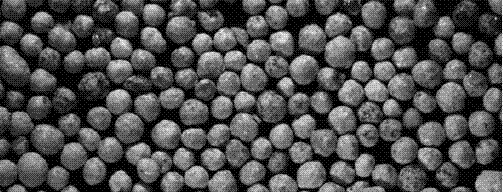

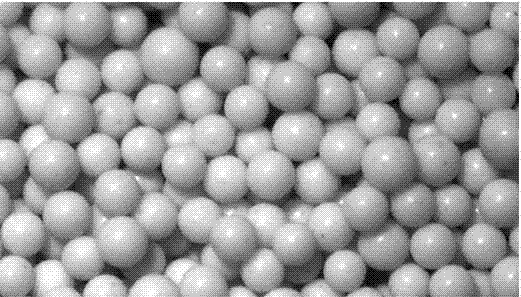

Ultralow-density high-strength vitrified china ball proppant and preparation method thereof

An ultra-low density, vitrified ceramic ball technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc. Reduce and other problems to achieve the effect of reducing density, reducing product density and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Embodiment 1 A kind of preparation method of ultra-low-density high-strength vitrified ceramic ball proppant

[0143] Accurately weigh 2.1Kg of fumed silica, 8Kg of kaolin, 4Kg of boric acid, 2Kg of aluminum sulfate, 2Kg of magnesium nitrate, 1.3Kg of sodium carbonate, and 10g of polyethylene oxide with an electronic scale.

[0144] Dissolve boric acid, aluminum sulfate, magnesium nitrate, and sodium carbonate in 60Kg of water with stirring, then add kaolin and fumed silica to the above solution and stir evenly, and finally add 10g of polyethylene oxide

[0145] Transfer the above slurry into a homogenization equipment for homogeneous dispersion, use a laser particle size analyzer to detect the particle size in the slurry to D50=5μm, then spray dry the slurry to obtain the precursor powder of the product.

[0146] Transfer the above precursor powder into a granulator, spray into the reserved slurry with 0.8 times the amount of dry powder for granulation, and obtain pref...

Embodiment 2

[0151] Example 2 A preparation method of ultra-low density and high strength vitrified ceramic ball proppant

[0152] Accurately take by weighing 4.8Kg of superfine quartz sand micropowder, 5.8Kg of kaolin, 5.7Kg of borax, 2Kg of aluminum nitrate, 2.6Kg of magnesium nitrate, 0.5Kg of sodium hydroxide, 10g of polyethylene oxide with the scale of electronic platform.

[0153] Dissolve borax, aluminum nitrate, magnesium nitrate, and sodium hydroxide in 60Kg of water with stirring, then add kaolin and ultrafine quartz sand micropowder into the above solution and stir evenly, and finally add 10g of polyethylene oxide.

[0154] Transfer the above slurry into a homogenization equipment for homogeneous dispersion, and use a laser particle size analyzer to detect the particle size in the slurry to D50=5μm, then spray dry the slurry to obtain the precursor powder of the product.

[0155] Transfer the above precursor powder into a granulator, spray into the reserved slurry with 0.8 times...

Embodiment 3

[0160] Example 3 A preparation method of ultra-low density and high strength vitrified ceramic ball proppant

[0161] Accurately weigh 25Kg of silica sol solution (silica sol content is 15%), 9Kg of aluminum silicate, 5Kg of borax, 1.6Kg of calcium carbonate, 0.4Kg of magnesium carbonate, 1Kg of aluminum nitrate, and 10g of polyethylene oxide with an electronic scale.

[0162] Dissolve borax, aluminum nitrate, and silica sol solution in 55Kg of water with stirring, then add aluminum silicate, calcium carbonate, and magnesium carbonate to the above solution and stir evenly, and finally add 10g of polyethylene oxide.

[0163] Transfer the above slurry into a homogenization equipment for homogeneous dispersion, and use a laser particle size analyzer to detect the particle size in the slurry to D50=5μm, then spray dry the slurry to obtain the precursor powder of the product.

[0164] Transfer the above precursor powder into a granulator, spray into the reserved slurry with 0.8 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com