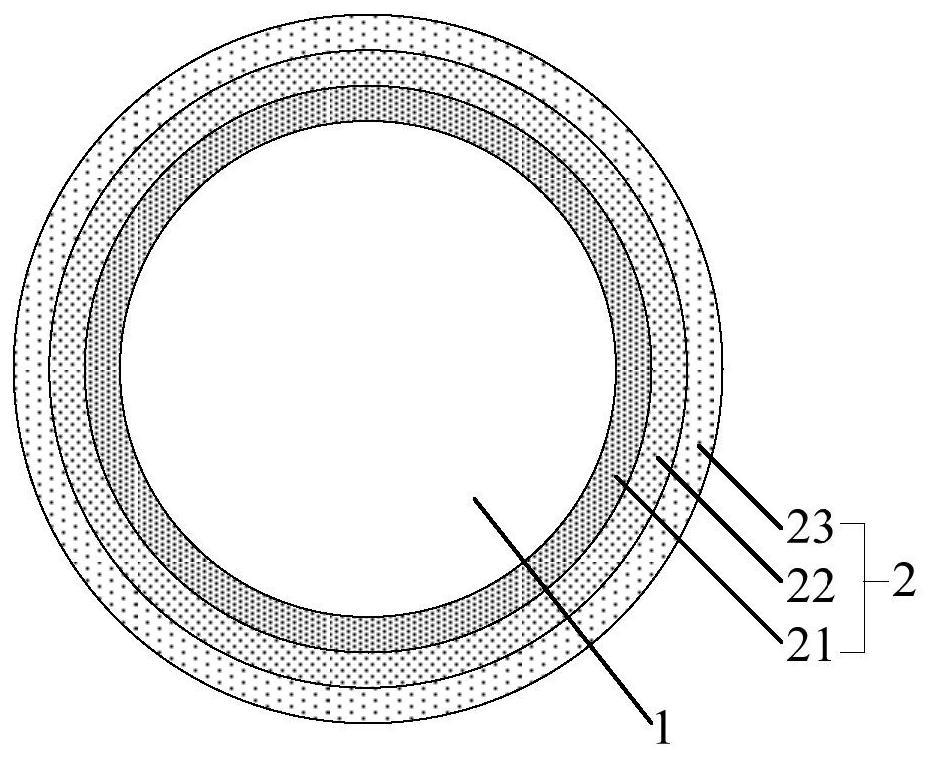

Proppant and preparation method thereof

A technology of proppant and core material, which is applied in the field of hydraulic fracturing, can solve the problem of single function of proppant and achieve the effect of ensuring compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

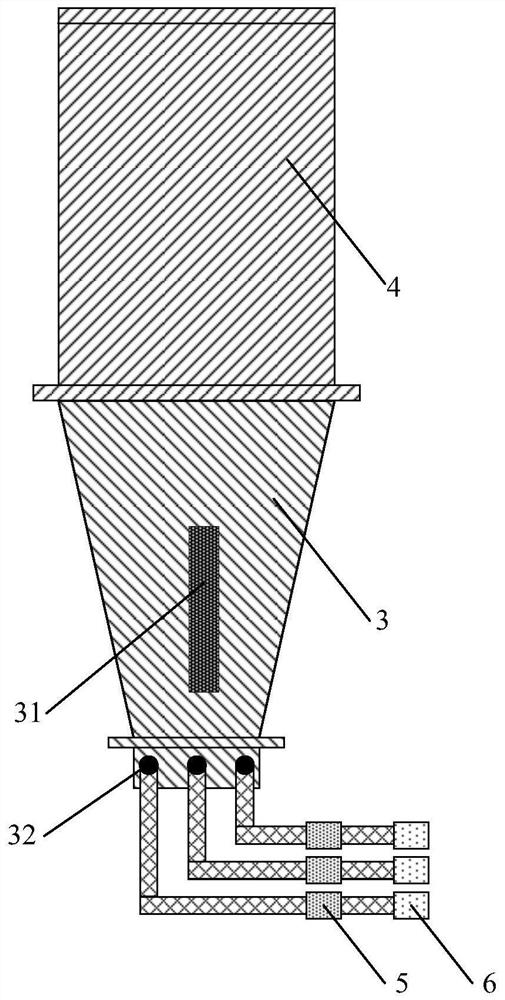

Method used

Image

Examples

preparation example Construction

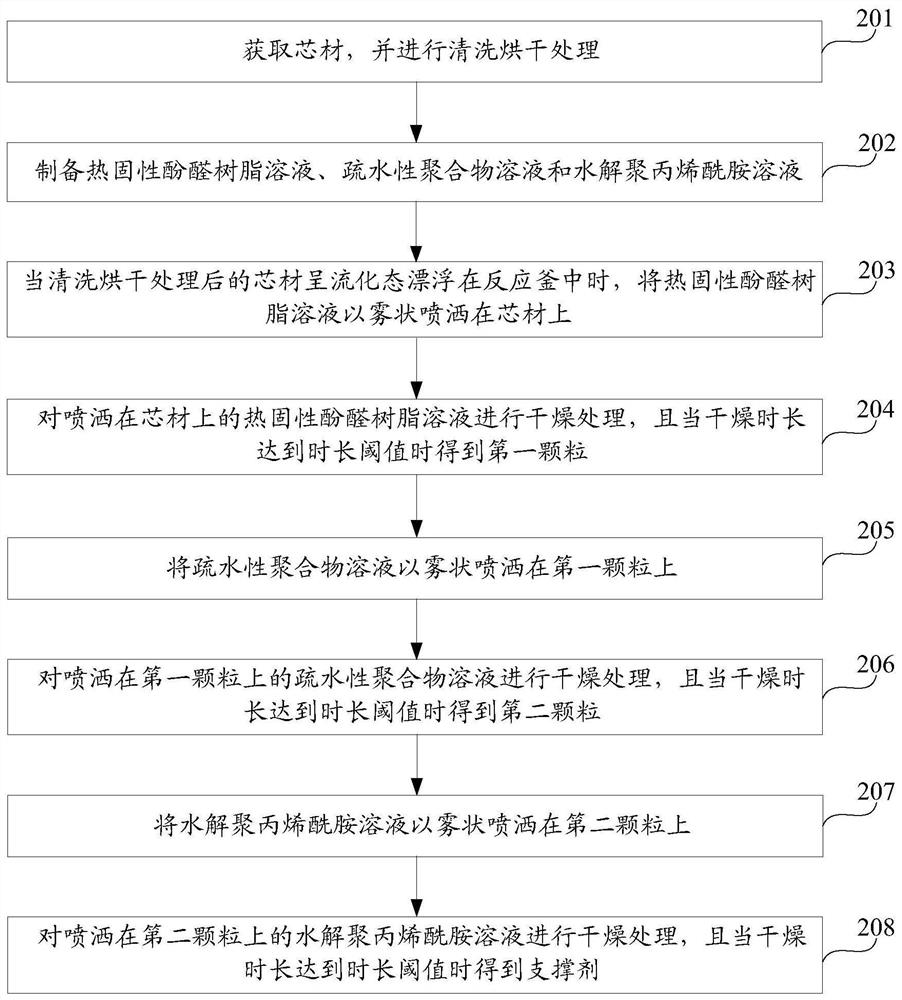

[0041] figure 2 It is a schematic flow chart of a preparation method of a proppant provided in an embodiment of the present application. as attached figure 2 As shown, the preparation method includes the following steps.

[0042] Step 201: Obtain the core material, and perform cleaning and drying treatment.

[0043] In order to avoid the large volume of the proppant obtained after preparation, when obtaining the core material, the core material with a particle size within the range of 70-140 mesh can be selected. The obtained core material is cleaned to remove the adsorbate on the surface of the core material, and then the cleaned core material is dried to remove residual water droplets on the surface of the core material. Among them, the core material can be ceramsite or quartz sand, so as to ensure the compressive strength of the core material, and the core material can be dried at a temperature of 90-100 degrees Celsius, for example, at a high temperature of 95 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com