Air conditioner heat exchanger flat pipe and heat exchanger applying flat pipe

A heat exchanger and flat tube technology, applied in the field of automotive air conditioning, can solve the problems of limited product weight and heat transfer performance, high heat exchanger brazing process requirements, and limited number of heat transfer medium channels, etc., to achieve overall performance Effects of lifting, compact structure, and overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

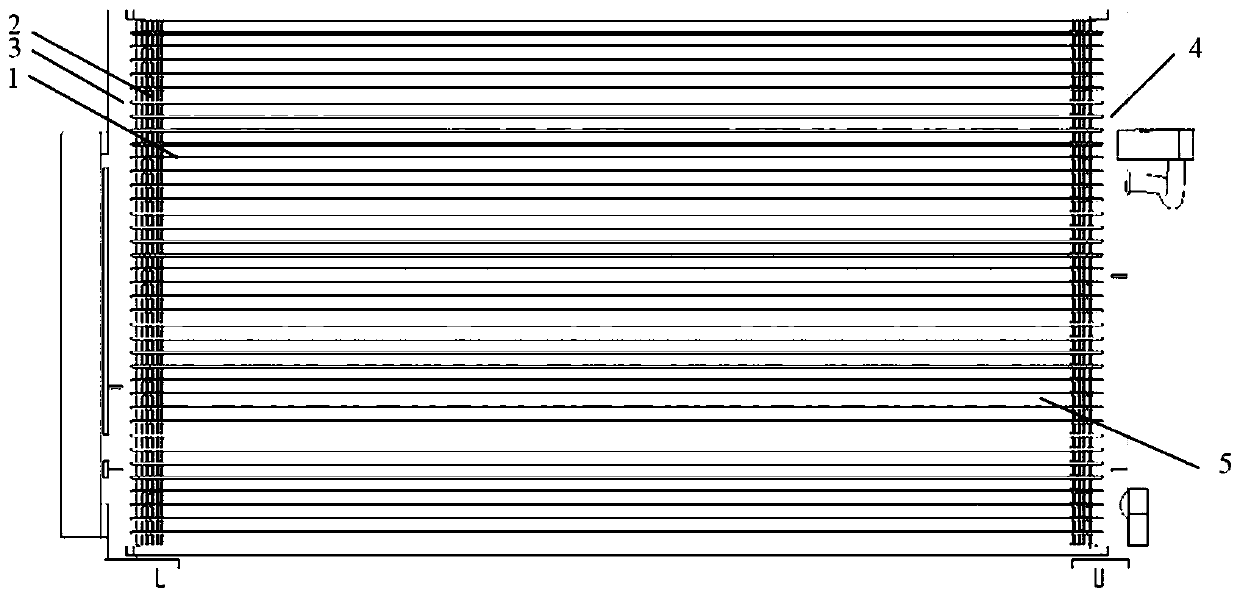

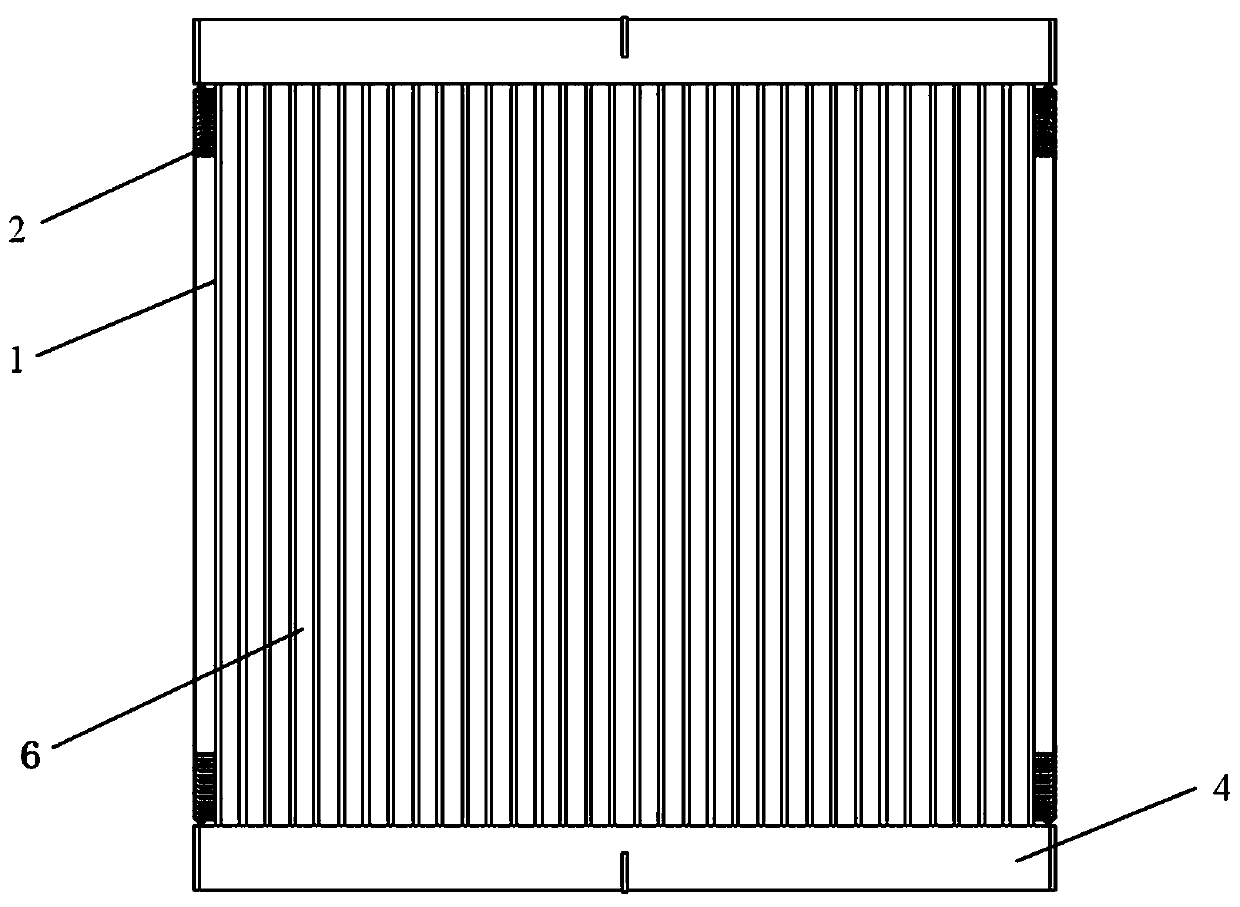

[0042] The specific implementation of the flat tube of the air conditioner heat exchanger and the heat exchanger using the flat tube of the present invention will be described in detail below in conjunction with the accompanying drawings.

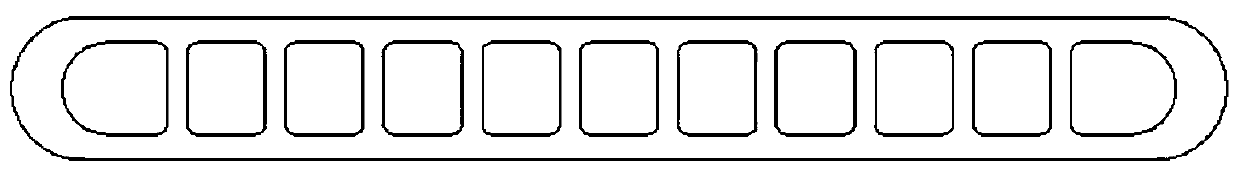

[0043] See attached Figure 5-8 , the two sub-parts of the flat tube 1 are the flat tube body 11 and the inner fins 12 respectively. The flat tube body 11 is folded from an aluminum plate, and its material is a double-sided composite material with solder; the inner fin 12 is stamped or rolled by aluminum foil, and its material is a non-composite material without solder; the inner fin 12 The material wall thickness FT is smaller than the material wall thickness TT of the flat tube body 11 .

[0044] The flat tube body 11 forms the outer wall of the flat tube by folding the plate. In the middle area of one of the long sides of the flat tube, there is a plate lap end 13. The plate lap end 13 has a certain length and protrudes toward the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com