Method for treating foundation throughthrough sintered water-permeable pile

A foundation treatment and permeable pile technology, which is applied to sheet pile walls, foundation structure engineering, ceramic products, etc., can solve problems such as poor water permeability, low strength, and easy corrosion of permeable concrete piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For a road project near the sea, land reclamation is required, and the subgrade will be built after the bearing capacity of the foundation meets the requirements. The land reclamation project was built by dredging reclamation on the original basis of the coast. The geological conditions from top to bottom are plain fill, dredger fill, sand with silt, gravel silt and strong weathered muddy sand. The thick silt layer leads to a wide range of soft foundation treatment and great difficulty, making it difficult to control the overall investment. Therefore, in order to reduce the post-construction settlement and ensure the stability of the building, sintered permeable piles can be used to treat the marine soft soil foundation.

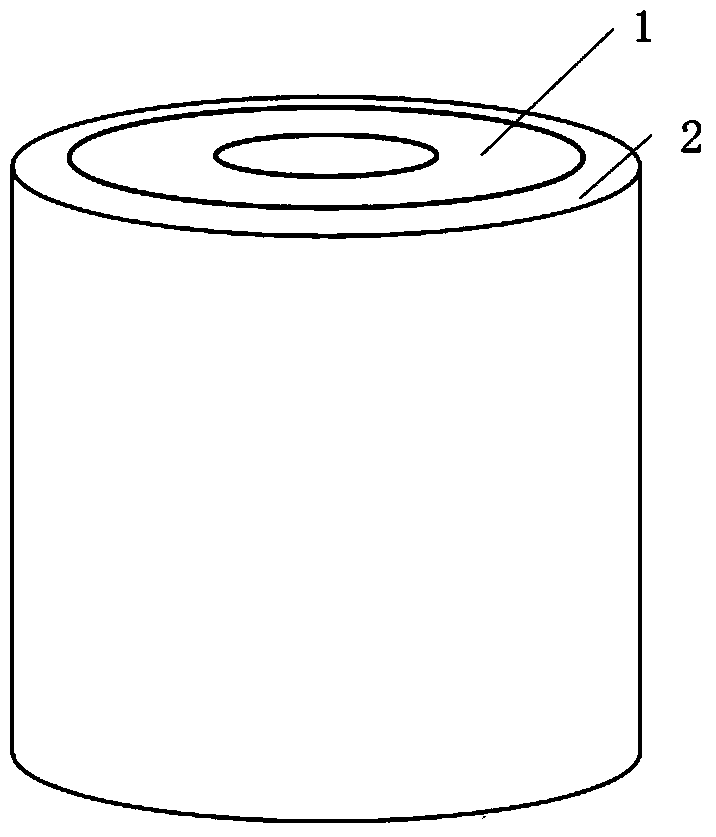

[0042] The sintered permeable piles are arranged with pipe piles, each section is 1-3m, connected by taper threads, the compressive strength of the piles is not less than 15MPa, and the permeability coefficient is not less than 0.01mm / s. Press the pi...

Embodiment 2

[0045] For a 10,000-ton wharf project, the foundation is composed of a 6.0m-thick loose layer of silt-containing medium-sand and gravel-containing silt, and an upper part of 9.0m-thick blown sand and gravel fill (reclaimed from the sea half a year ago). It is a typical weak foundation, which has the characteristics of high water content, high pore water, high compressibility, high sensitivity, high creep, low strength, low water permeability and inhomogeneity, so sintered permeable piles can be used to The foundation is treated.

[0046] The sintered permeable piles are arranged with pipe piles, each section is 1-3m, connected by taper threads, the compressive strength of the piles is not less than 15MPa, and the permeability coefficient is not less than 0.01mm / s. Press the pile body into the foundation with a pile driver, cover the pile cap, lay a gravel cushion on the surface of the foundation, with a thickness of 30-50cm, and then use geogrid and specific graded aggregates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com