Sintering furnace with silicon wafer capable of being dried in suspended manner

A technology of sintering furnace and drying furnace, which is applied in the direction of drying, dryer, furnace, etc., can solve the problems of low drying efficiency and high energy consumption, and achieve the purpose of improving drying efficiency, ensuring drying effect, and drying air flow Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

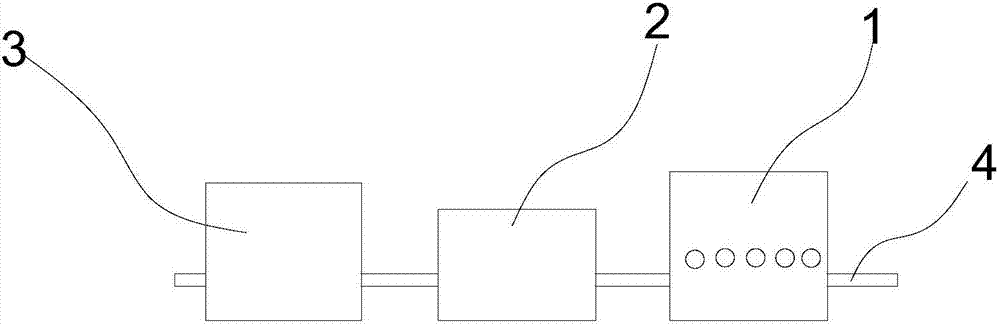

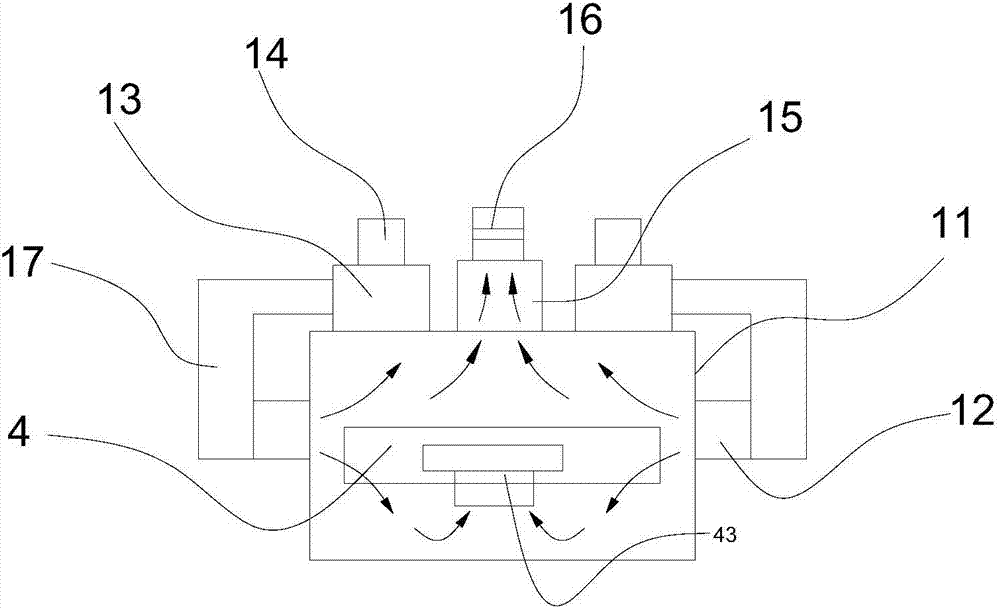

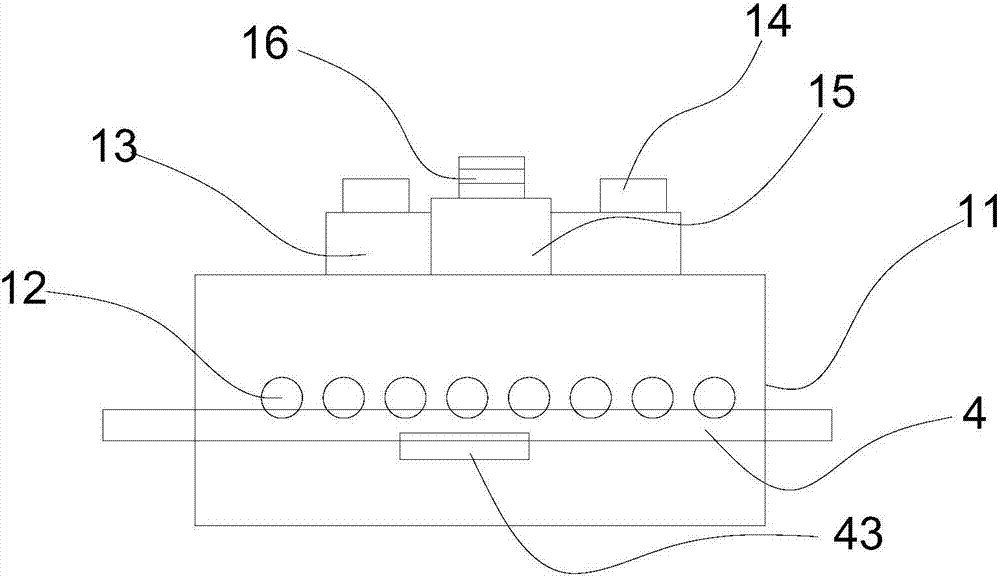

[0035] Such as Figure 1 to Figure 3 As shown, the sintering furnace for drying silicon wafers in the air according to the present invention includes a drying furnace area 1, a sintering furnace area 2, a cooling furnace area 3 and a conveying device 4, and the conveying device 4 runs through the drying furnace area in sequence 1. Sintering furnace area 2, cooling furnace area 3;

[0036] The conveying device 4 located in the drying furnace area 1 is provided with an air injection device 43; the conveying device 4 includes two driving rollers 41 and a supporting seat before and after; the driving roller 41 is supported by a supporting seat 48, and the driving roller 41 A conveyor belt 42 is wound on it, and the conveyor belt 42 is a conveyor net; the support base 48 is provided with a drive device 5 for driving the drive roller 41 to rotate;

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com