Reactor for realizing suspension of biofilm carriers under low aeration quantity

A technology of biofilm carrier and aeration rate, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve the problems of complex water quality of production wastewater, secondary pollution, low B/C value, etc., and achieve stable and short-term nitrification Advantages, improved impact load resistance, and the effect of maintaining fluidization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

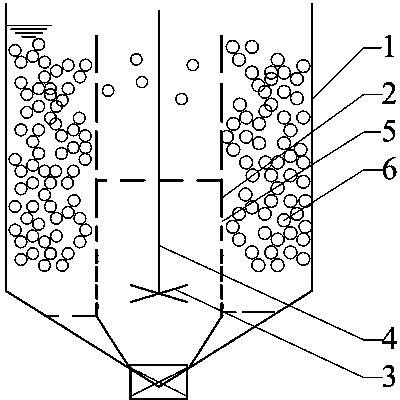

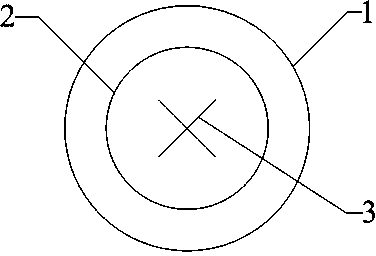

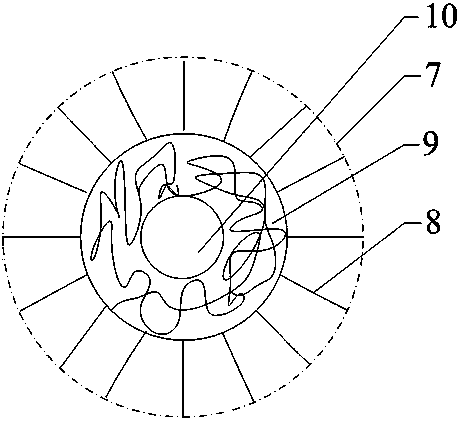

[0022] see figure 1 , figure 2 and image 3 , the present invention provides a reactor for realizing biofilm carrier suspension under low aeration rate, mainly used for treating oil refinery catalyst wastewater, comprising a vertical cylindrical shell 1 coaxially arranged with a vertical Hollow cylinder 2, stirring paddle 3 is installed in the described hollow cylinder, the drive shaft 4 of described stirring paddle can be positioned on the axis of described hollow cylinder, the rotating speed of described stirring paddle is preferably 90rpm, the cylinder wall of described hollow cylinder Several through holes 5 are opened on the top, the bottom end of the hollow cylinder is fixedly connected with the bottom end of the housing, and the annular space between the hollow cylinder and the housing is filled with a biofilm carrier 6, so The bottom end of the hollow cylinder and the bottom end of the housing can be sealed, or a gap can be left, the size of the gap does not allow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com