Novel liquid spot-spray torch and spot-spray method thereof

A liquid and new technology, applied in the direction of liquid injection device, injection device, etc., can solve the problems of low injection frequency, easy clogging of nozzles, difficult cleaning, etc., and achieve the effects of high control accuracy, improved production efficiency, and fast dynamic response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

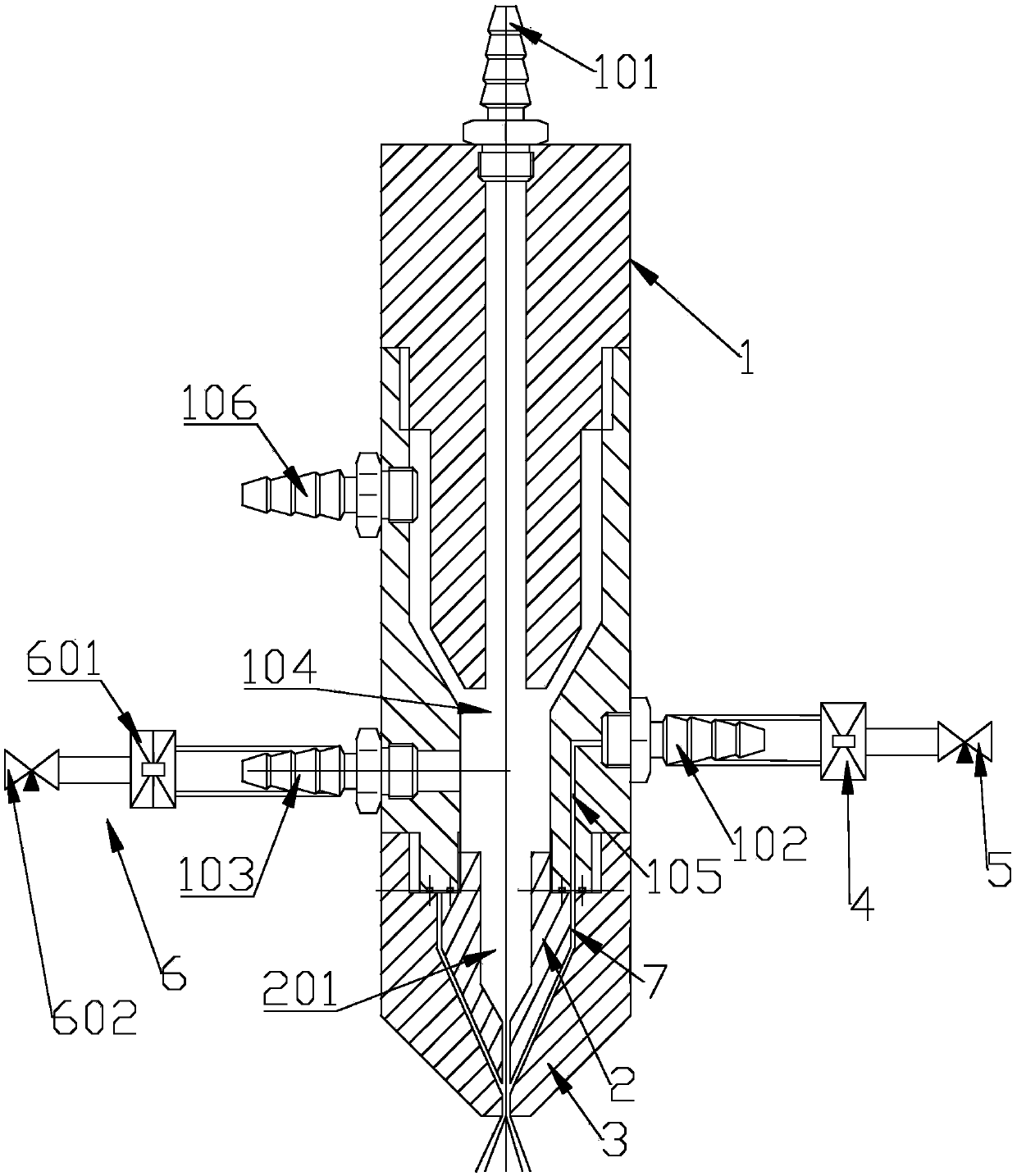

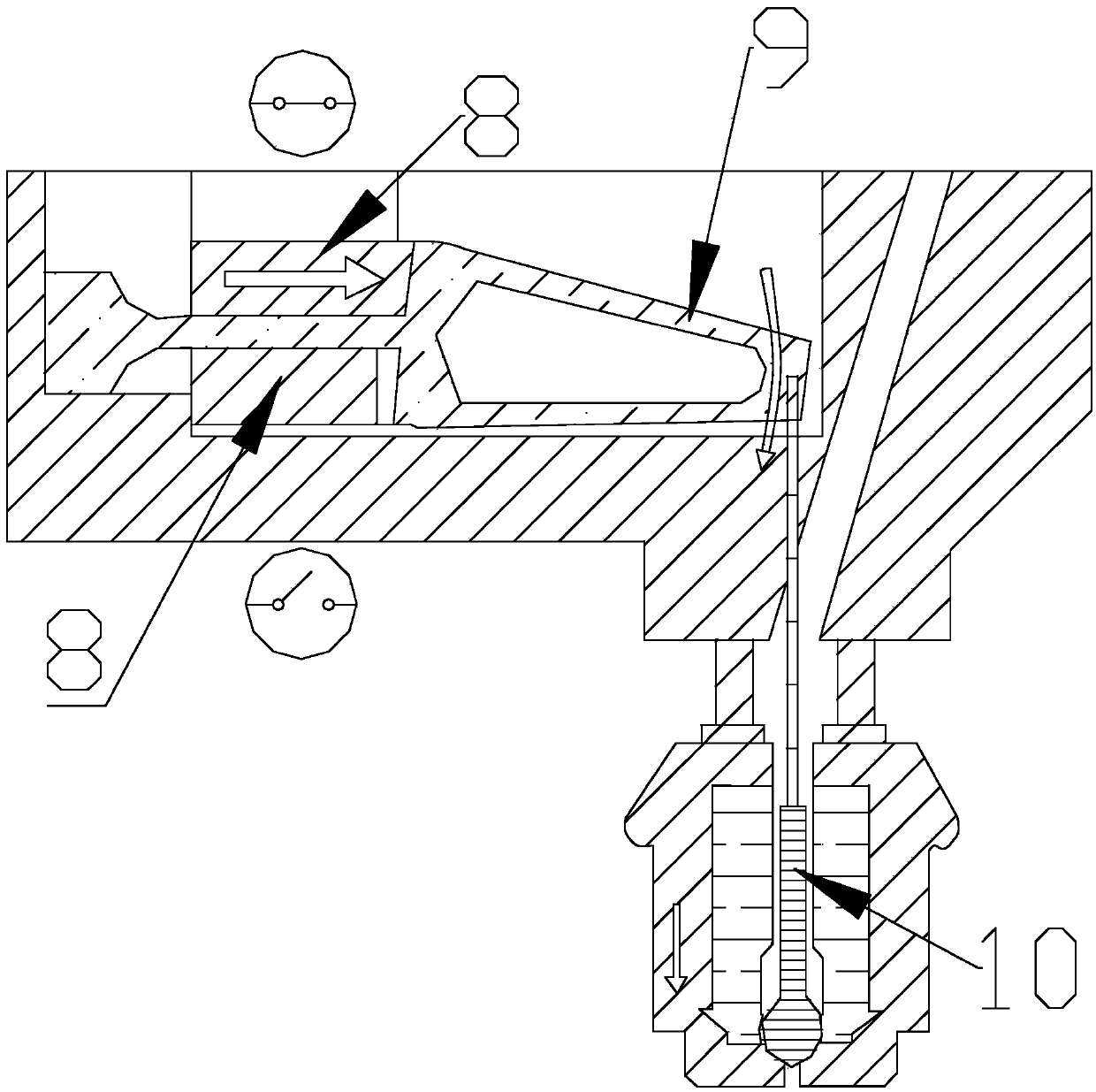

[0018] Figure 1 ~ Figure 2 A novel liquid spot spray gun according to one embodiment of the present invention is schematically shown. Such as figure 1 As shown, the new liquid point spray gun includes a spray gun body 1, an air guide cone 2 and a nozzle 3. The spray gun body 1 is provided with a liquid inlet 101, an air inlet 102, and a negative pressure port 103. The inside of the spray gun body 1 is provided with a first A liquid storage chamber 104, a first air chamber 105, the liquid inlet 101 communicates with the first liquid storage chamber 104, one end of the air inlet 102 communicates with the first air chamber 105, and the other end of the air inlet 102 communicates with the piezoelectric ceramic direct drive The valve 4 is connected, the piezoelectric ceramic direct drive valve 4 is connected with the first pressure regulating valve 5, the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com