A gas-liquid separation device

A gas-liquid separation device and gas-liquid separation technology, which are applied in the field of analytical chemistry, can solve the problems of low separation efficiency, limit the optimization of gas-liquid separators, affect the sensitivity and detection limit of gaseous sampling, and achieve separation efficiency. High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

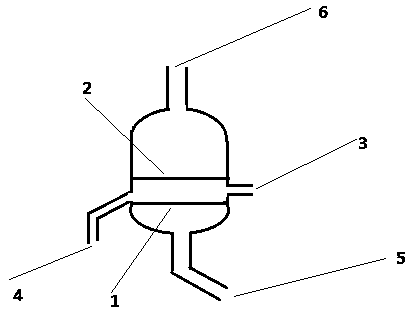

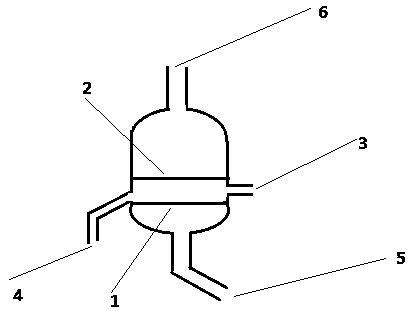

[0027] A gas-liquid separation device, the inner diameter of the device is 3 centimeters. There are two air-permeable filter plates with micropores inside, and the pore size of the first air-permeable filter plate below is 10 microns, which is used to pass the carrier gas from below to make the solution bubbling for gas-liquid After separation, the separated volatiles are carried by the carrier gas through the upper second filter plate (with a pore size of 80 microns), and then enter the atomic spectrometer to be detected. The solution cannot pass through the upper filter plate, but is excluded on the side between the two filter plates. Wherein the vertical distance between the first filter plate and the second filter plate is 1.5 cm.

Embodiment 2

[0029] A gas-liquid separation device, the inner diameter of the device is 3.5 cm. There are two air-permeable filter plates made of sintered glass cores with micropores inside, the first air-permeable filter plate below has a pore size of 15 microns, which is used to pass the carrier gas from below to make the air-permeable filter plate above The solution is bubbled for gas-liquid separation, and the separated volatiles are carried by the carrier gas through the upper second filter plate (with 100 micron pores), and then enter the atomic spectrometer for detection. The solution cannot pass through the upper filter plate, but is excluded on the side between the two filter plates. Wherein the vertical distance between the first filter plate and the second filter plate is 1 cm.

Embodiment 3

[0031] Use a peristaltic pump to mix 0.4% sodium ethylenediamine dithiocarbamate (Na-DDTC) and a sample solution containing 2ppb zinc at an equal flow rate online, and the mixed solution enters a gas-liquid separator with the following parameters from tube 3 Device (see attached picture):

[0032] The inner diameter of the gas-liquid separator is 3.5 cm. There are two air-permeable filter plates made of sintered glass core with microporous inside, the pore diameter of the first air-permeable filter plate below is 5-15 microns, and the pore diameter of the second one above is 40-80 Micron. The vertical distance between the first filter plate and the second filter plate is 0.5 cm.

[0033] The volatile zinc-DDTC in the solution is immediately separated by the carrier gas (argon) bubbling from below, and the separated volatiles are carried by the carrier gas through the second fast gas-liquid separation filter plate above, and then carried The volatiles of gas and zinc are ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com