Patents

Literature

51 results about "Arsenic product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arsenic is a trace element. It is found in several foods including seafood, poultry, grains (especially rice), bread, cereal products, mushrooms, and dairy products. Some forms of arsenic are used as medicine.

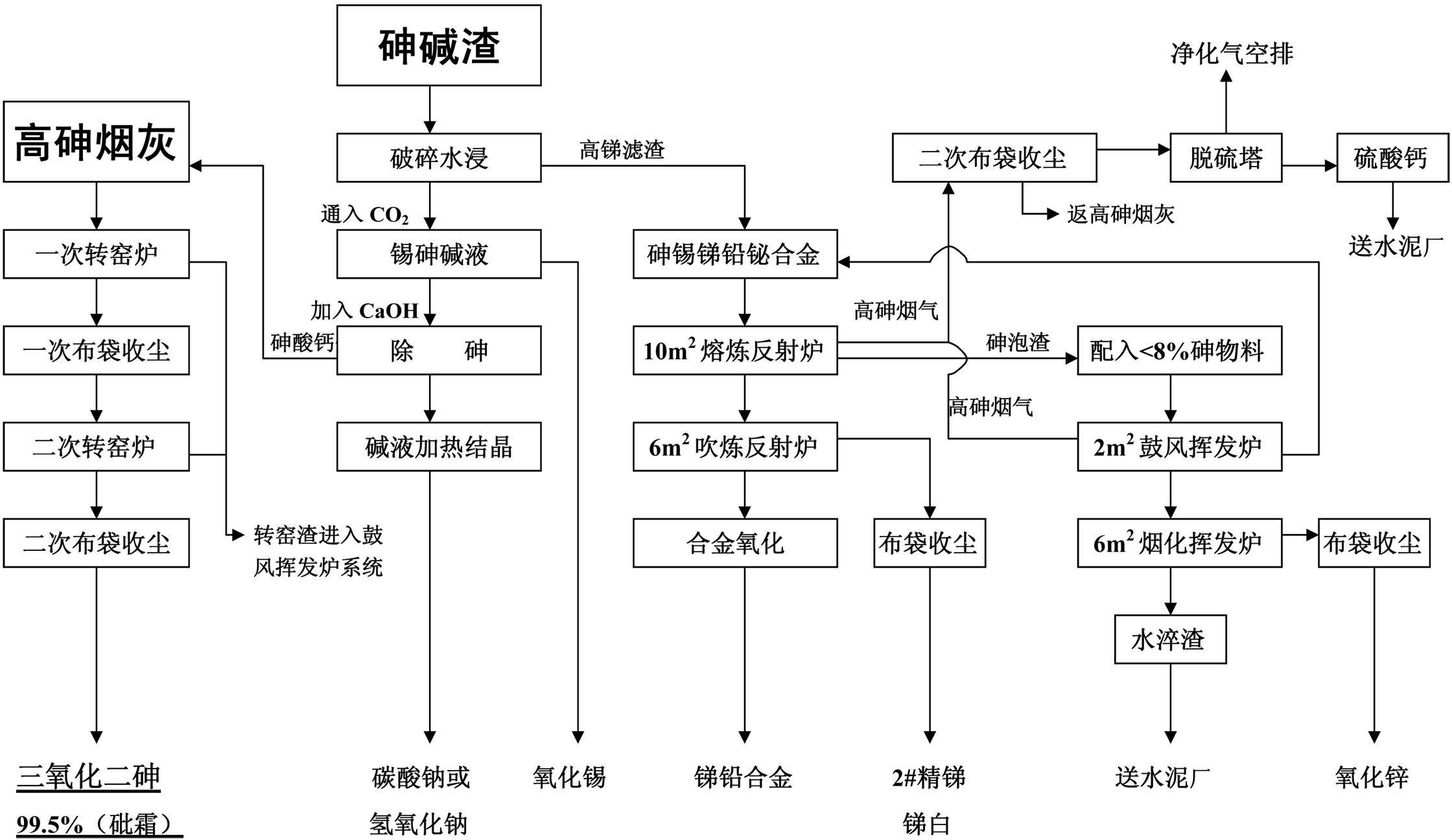

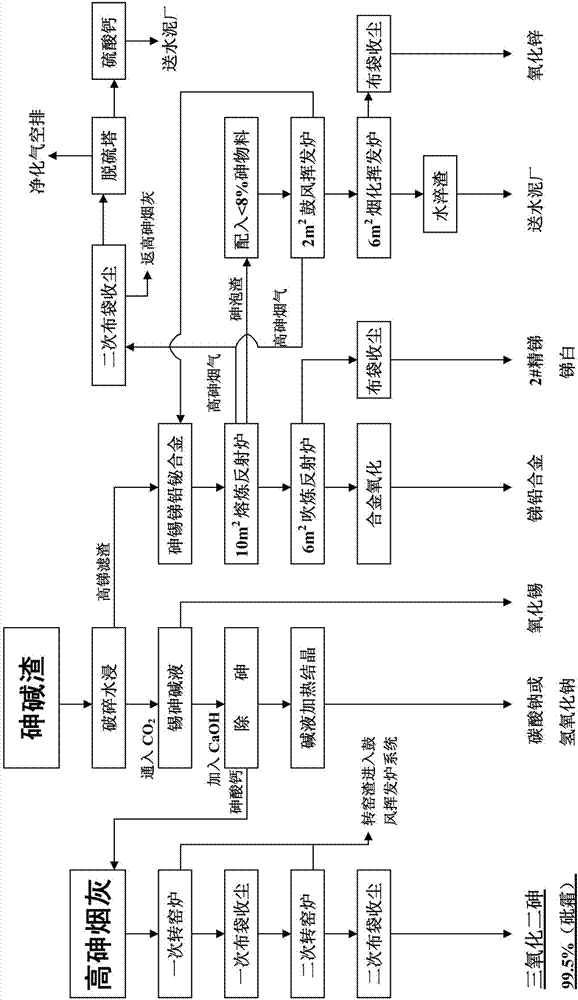

A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

ActiveCN102286665ANo pollutionCement productionProcess efficiency improvementRecovery methodTin dioxide

Disclosed is a comprehensive recovery method for a complex material containing arsenic and valuable metal slags, comprising passing the materials containing arsenic through a primary rotating kiln to volatilize the arsenic, and through a secondary rotating kiln to purify the arsenic, so that an arsenic product containing 99.5% As 2 O 3 is produced; reduction smelting slags from the primary and secondary rotating kilns in a blowing volatilization furnace, with the resultant highly arsenious dust being returned to the primary rotating kiln for treatment, and the slags being used as a raw material in a cement manufactory and a raw material for zinc after undergoing strongly reductive dearsenization and volatilization of zinc in a fuming furnace; the resultant alloy containing arsenic being subjected to basic oxidizing refinement, and the oxidized / refined alloy after dearsenizations containing Pb > 72%, Sb > 12%, As 2 O 3 <0.02%, being sold as a lead-antimony alloy; the basic slags from the refinement, containing As 2 O 3 10%-20%, being subjected to crushing, dissolution in base, and filtration, with the slags thereof being returned to a blowing volatilization furnace for treatment; precipitating tin from the basic solution containing tin and arsenic by blowing in CO 2 , with the filtered tin oxide being sold as a raw material for tin; adding Ca(OH) 2 into the basic filtrate containing arsenic to precipitate arsenic, returning the filtered slags of calcium arsenate to the primary rotating kiln for treatment, and evaporating the remaining basic solution to concentrate and recover the base.

Owner:LEIYANG YANXIN NON FERROUS METALS

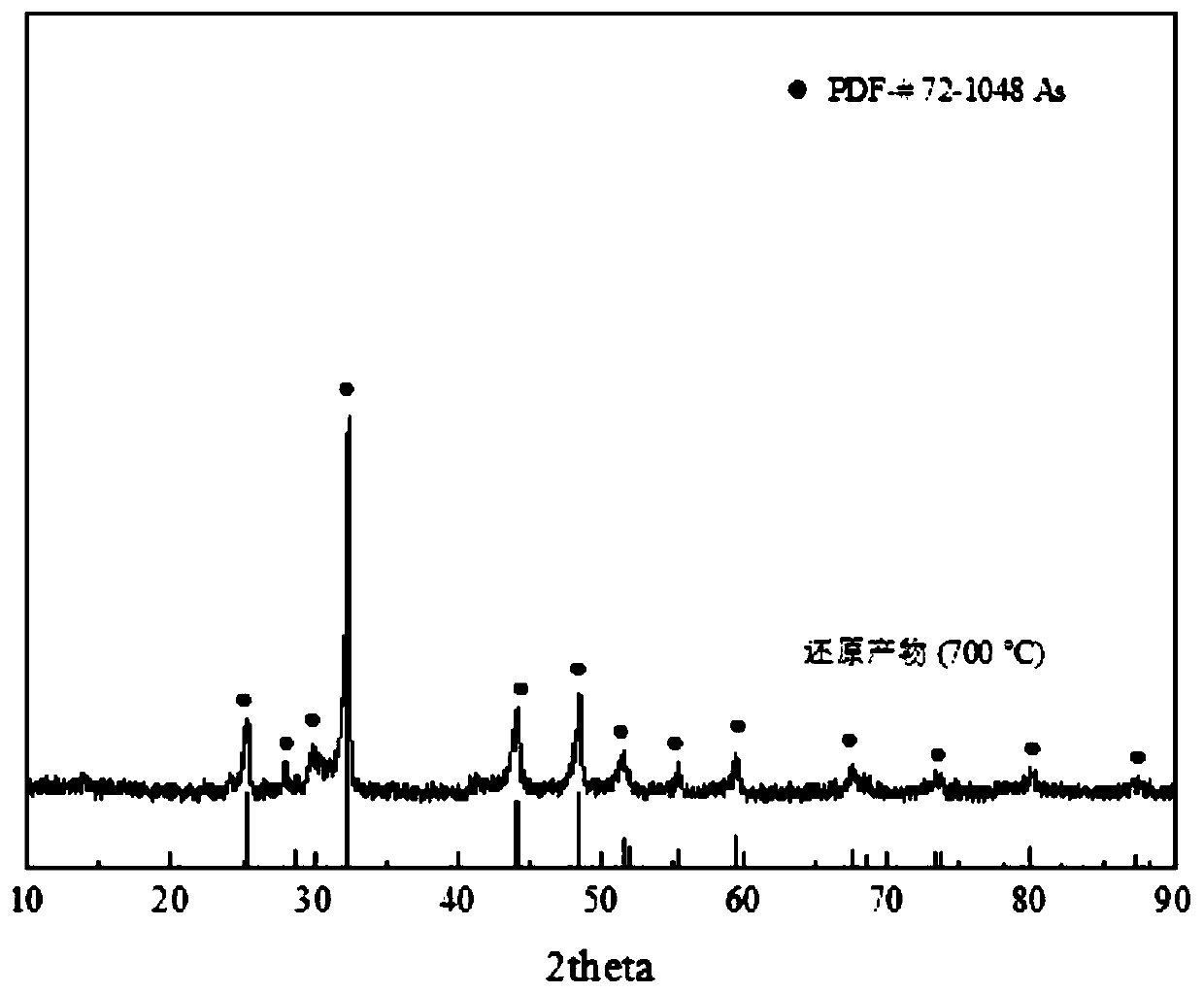

Method for preparing arsenic by direct reduction and roasting of arsenic-containing material

The invention discloses a method for preparing arsenic by direct reduction and roasting of an arsenic-containing material. The method comprises the following steps: taking arsenate as a raw material, uniformly mixing the arsenate material with a carbonaceous reducing agent to obtain a mixture, putting the mixture into an inert or reducing atmosphere, carrying out reduction and roasting under a negative pressure condition, and collecting roasting flue gas to obtain an arsenic product. According to the method, the arsenic-containing material which is commonly used in a metallurgical process and takes the arsenate as a main component is reduced into chemically stable elementary arsenic; the elementary arsenic is nontoxic, can be used as a raw material in the semiconductor and alloy industries, and has a certain market value; weight reduction, harmlessness and recycling of the toxic arsenic-containing material are realized in the reduction process and are the most reasonable development direction of arsenic; and therefore, the method has a large popularization value.

Owner:CENT SOUTH UNIV

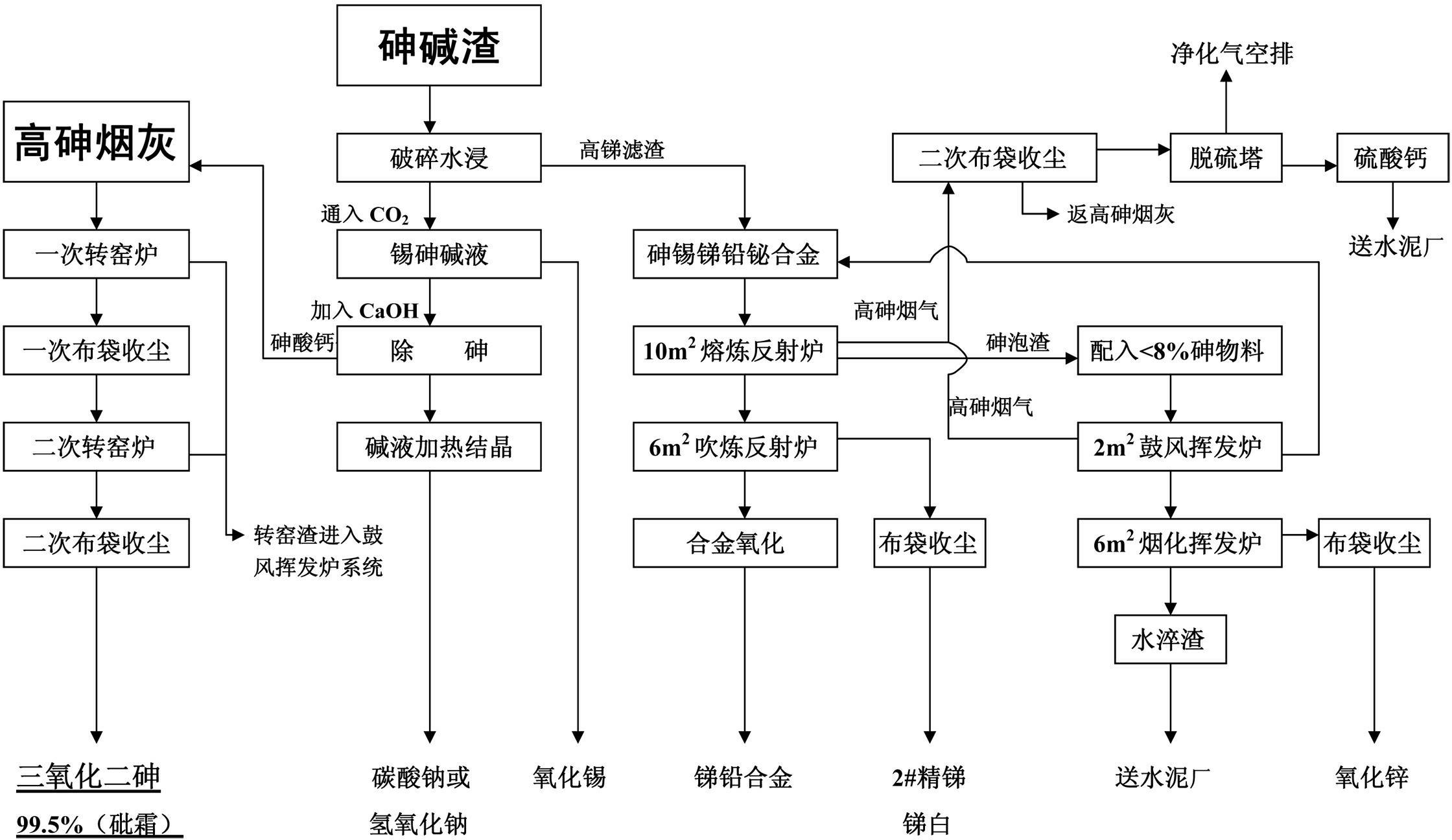

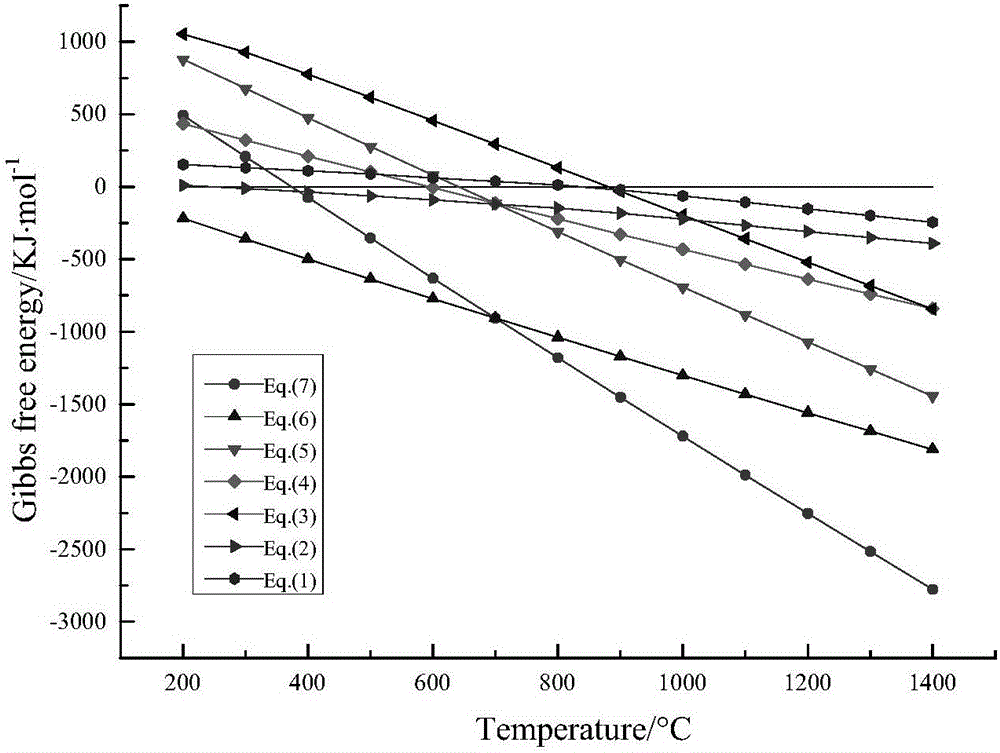

Arsenic-alkali slag reduction smelting treatment method

ActiveCN108220626ASolve disposal problemsSolve environmental problemsProcess efficiency improvementAlkali metal carbonatesSlagWater immersion

The invention discloses an arsenic-alkali slag reduction smelting treatment method. The method comprises the following steps: mixing arsenic-alkali slag and a carbon reducing agent and performing reduction smelting to obtain arsenic steam, crude antimony and reducing slag; after condensing the arsenic steam, obtaining a metal arsenic product, wherein a main component of the reducing slag is Na2CO3, can be directly used as an arsenic removal agent to be returned back to an antimony refining and arsenic removal procedure, and also can be subjected to a water immersion-concentration-crystallization technology to obtain an Na2CO3 crystal. According to the arsenic-alkali slag reduction smelting treatment method, metal arsenic and the crude antimony are prepared through one-step reduction; meanwhile, the Na2CO3 is regenerated; compared with an existing technology, a flow is simplified and the production cost is reduced; reduction, harmlessness and recycling of the arsenic are realized and the environment protection difficulty is solved; considerable economic benefits are generated and the arsenic-alkali slag reduction smelting treatment method is suitable for being industrially popularized.

Owner:湖南锐异资环科技有限公司

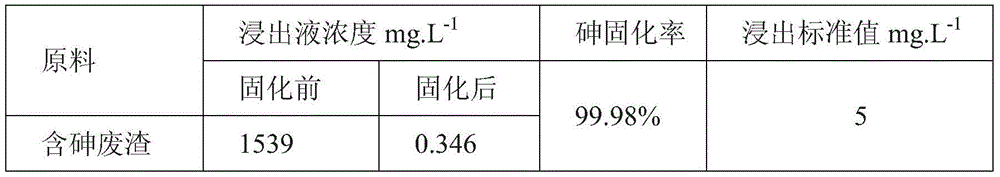

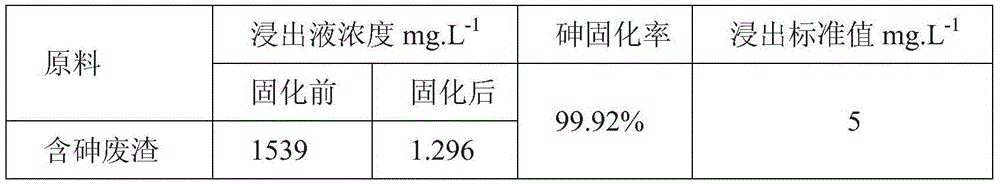

Method for curing arsenic-containing waste residues through industrial waste residues

ActiveCN105537247AImprove adsorption capacityImprove stabilitySolid waste disposalTransportation and packagingNonferrous metalSlag

The invention discloses a method for curing arsenic-containing waste residues through industrial waste residues. The method includes the following steps that (1) the arsenic-containing waste residues are thrown into a stirring tank, and water is added for slurrying, so that slurry is obtained; (2) an arsenic curing agent is added into the stirring tank for a curing reaction, and the arsenic curing agent is smelting slag or magnetic iron concentrate obtained through ball-milling and magnetic separation of smelting slag; and (3) neutralizing slag is added into the stirring tank for stirring, and finally casting molding and natural curing are conducted, so that solid arsenic products are obtained. According to the method, the waste residues generated by a nonferrous metal smelting plant are utilized, the material cost is basically zero, and meanwhile the excellent effect of dealing with waste by waste can be achieved. Through the method for treatment the arsenic-containing waste residues, the curing rate of arsenic in the arsenic-containing waste residues reaches 94% or more.

Owner:HUNAN RES INST FOR NONFERROUS METALS

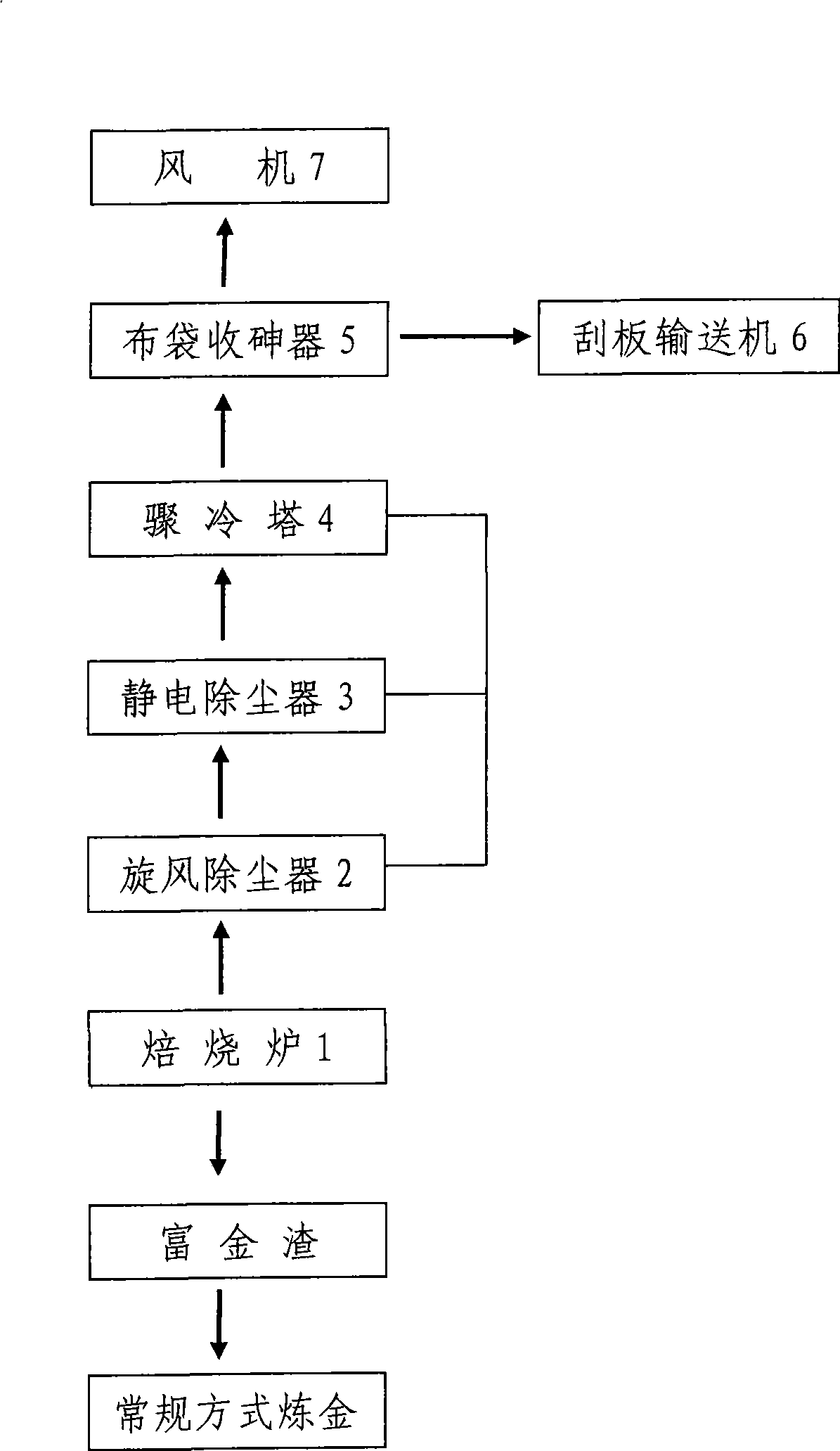

Method for extracting arsenic trioxide from roasting dust of arsenic-containing gold concentrate powder

ActiveCN101412538AHigh purityThe process is easy to controlArsenic compoundsArsenic pollutionCyclonic spray scrubber

The invention discloses a method for extracting arsenic trioxide from gold concentrate powder roasted fume containing arsenic. The method adopts a staged gradually-heating purification process and a quenching extraction process. The purification process is to volatilize impurities with low melting points in materials under the condition of different temperatures. The purified materials are insulated at a temperature of between 500 and 550 DEG C for more than 150 minutes, so that the arsenic is oxidized into arsenic trioxide gas; the gas is purified through a cyclone dust collector and an electrostatic precipitator in sequence; the purified high-temperature arsenic trioxide gas directly enters a quenching tower of which the temperature is between 120 and 140 DEG C to be crystallized into arsenic trioxide microparticles; and powdery arsenic trioxide collected by a bag arsenic collector is outputted via a scraper conveyor. The method has the advantages that the process procedure is arranged reasonably, controllably and stably, and the rate of extracting the arsenic trioxide from fume is high, and the purity of the extracted arsenic product is high, and the method well solves the problem of arsenic pollution in the gold smelting industry.

Owner:JIANGSU KANGJIE ENVIRONMENT ENG

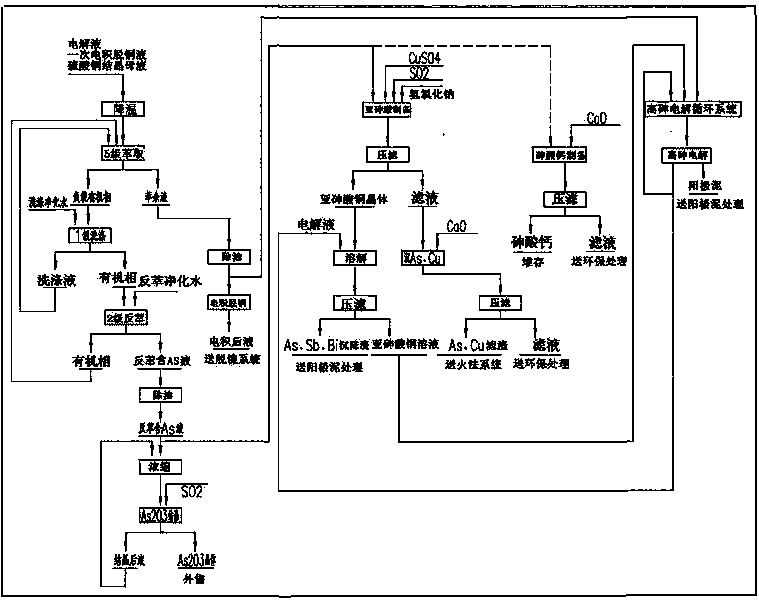

Compound technology for removing As, Sb, Bi by utilizing copper electrolyte

ActiveCN104018185AReduce power consumptionReduce energy consumptionElectrolysis componentsPhotography auxillary processesElectrolytic agentArsenic product

The invention discloses a compound technology for removing, Sb, Bi by utilizing copper electrolyte. A process for removing As by means of solvent extraction and a process of removing Sb and Bi by means of solution self-purification are combined; copper arsenite crystals are prepared by As in a back-extraction solution and is used as a high arsenic electrolytic additive; during high arsenic electrolysis, Sb and Bi in the solution can be effectively removed through As (III), and a majority of Sb and Bi in an anode plate enter anode mud. According to the compound technology, the aims of removing As, Sb and Bi can be fulfilled; meanwhile, an electro-deposition induced decoppering and dearsenification method is eliminated in the main process, and a small quantity of nickel removal liquid in the auxiliary process needs to be subjected to electro-deposition treatment. The compound technology is low in power consumption; the amount of H3As gas, black copper plates and black copper powder is obviously reduced; a dearsenification product is sold in a form of As2O3 or stacked in a form of calcium arsenate. According to the method, the operating environment is optimized, the defects that the As removal product contains a large amount of copper in the electro-deposition induced decoppering and dearsenification method and needs to be returned to a pyrogenic process system for separating copper and arsenic are overcome; the electro-deposition during the main impurity removal process is avoided, and the energy consumption is obviously reduced.

Owner:CHINA NERIN ENG

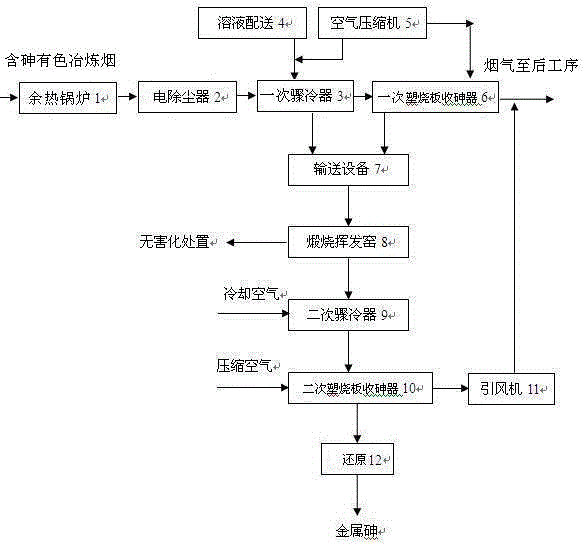

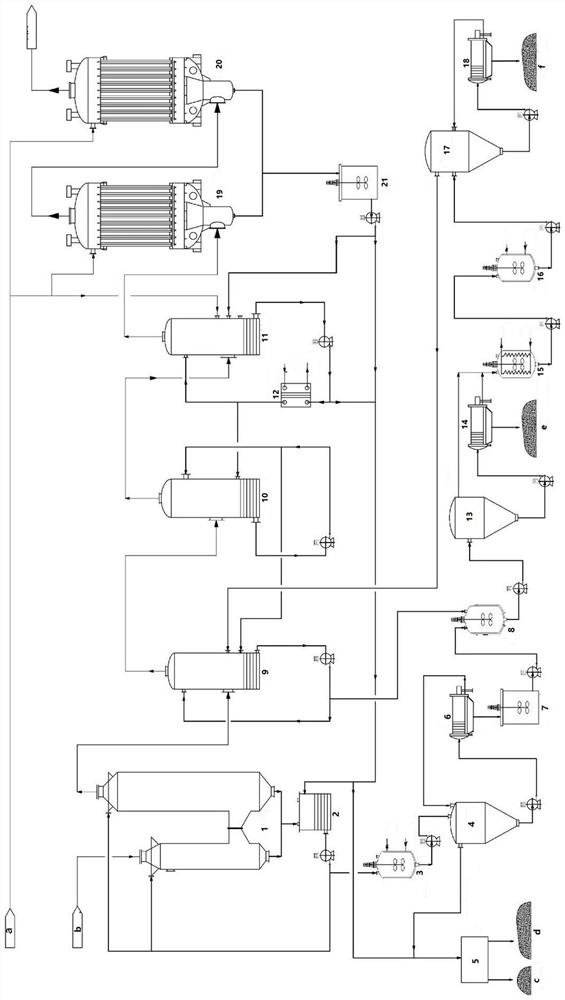

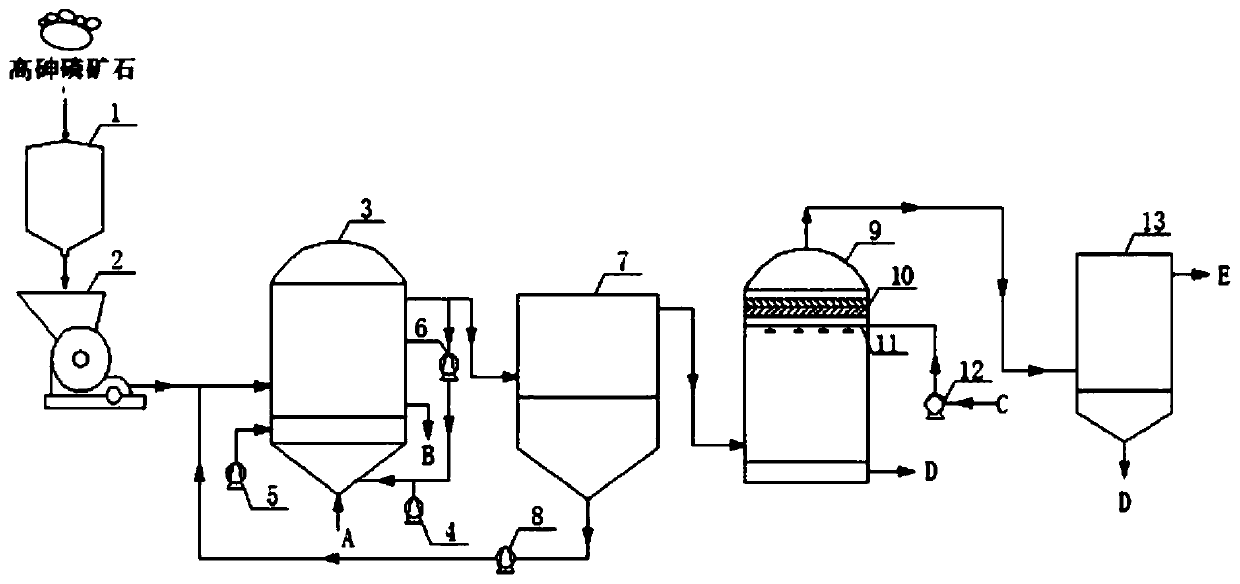

Clean production technological method and device for extracting arsenic

The invention discloses a clean production technological method and device for extracting arsenic. The method comprises the specific steps that the high-quality product As2O3 is recycled from arsenic-containing nonferrous metal materials or arsenic-containing nonferrous metal metallurgical off-gas through a continuous two-time arsenic purification technology, and the elementary substance arsenic or metal arsenic product is further reduced and produced; low-dew-point acid gas SO3 in flue gas is removed through a gas phase neutralization technology, a high-efficiency sinter-plate dust removing apparatus is adopted, and finally the cost spent by treating acid-containing and arsenic-containing waste water in a subsequent procedure is greatly reduced. The clean production technological method and device are the integrated arsenic recovery, purification, productization and harmless technology and equipment, and belongs to the typical clean production technology.

Owner:JIANGSU CHENGTIAN ENVIRONMENTAL PROTECTION TECH CO LTD

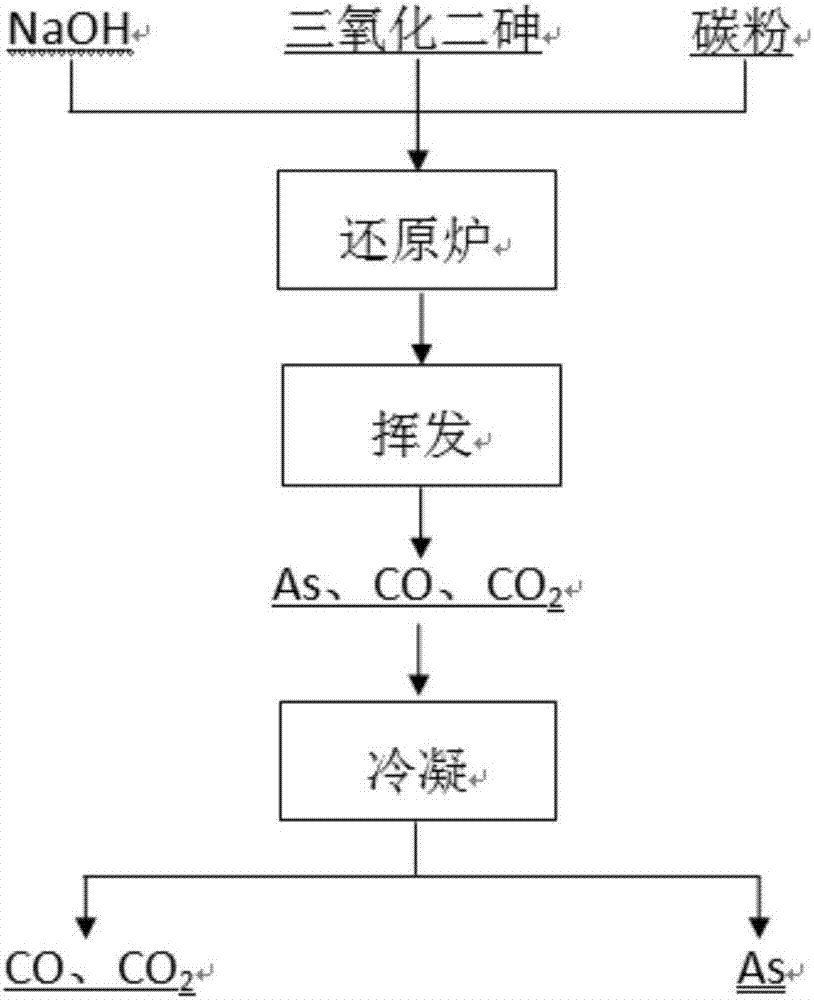

Method for preparing metallic arsenic through As2O3 reduction

The invention discloses a method for preparing metallic arsenic through As2O3 reduction. The method comprises the steps that As2O3, a carbonaceous reducing agent and strong alkali are mixed to be uniform and then put into a closed environment for reduction roasting, after reduction roasting is completed, arsenic steam is collected and condensed, and metallic arsenic is obtained. According to the method, the metallic arsenic product with the higher value is obtained under the closed condition by taking As2O3 as a raw material, no poisonous gas is generated in the process, the problems that a traditional preparation method is poor in operating environment, serious in pollution and the like are solved, and a very good application prospect is achieved.

Owner:CENT SOUTH UNIV

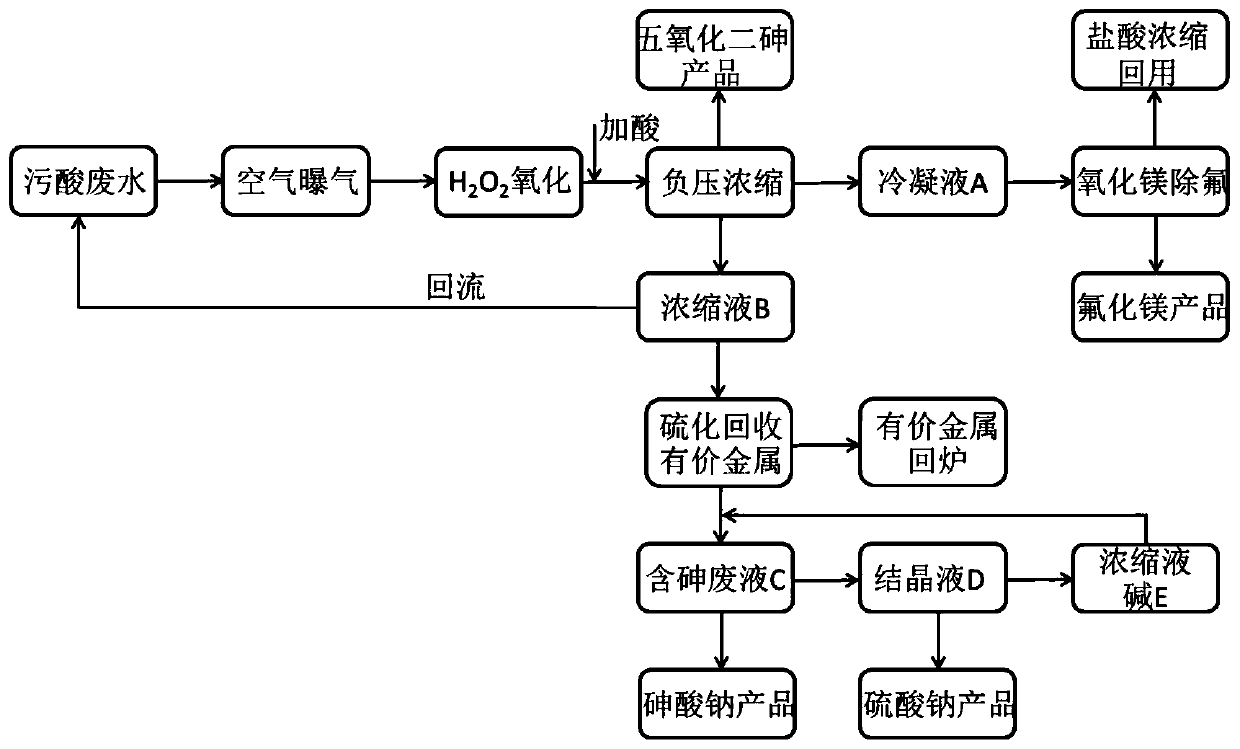

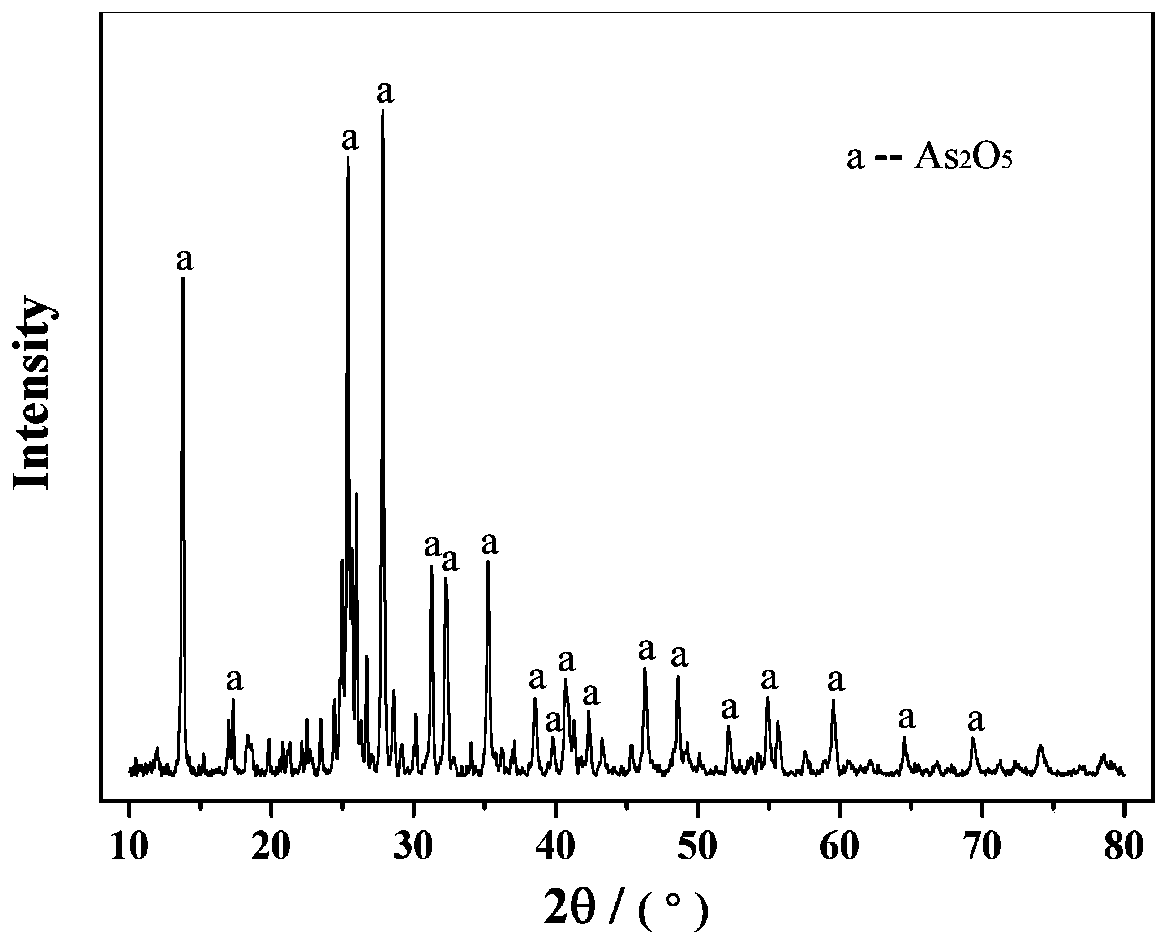

Method for resource utilization of waste sulfuric acid wastewater produced in copper smelting and acquisition of arsenic-containing products

ActiveCN111018229ANothing producedIncrease the areaMagnesium fluoridesChlorine/hydrogen-chloride purificationArsenic oxideArsenic pentoxide

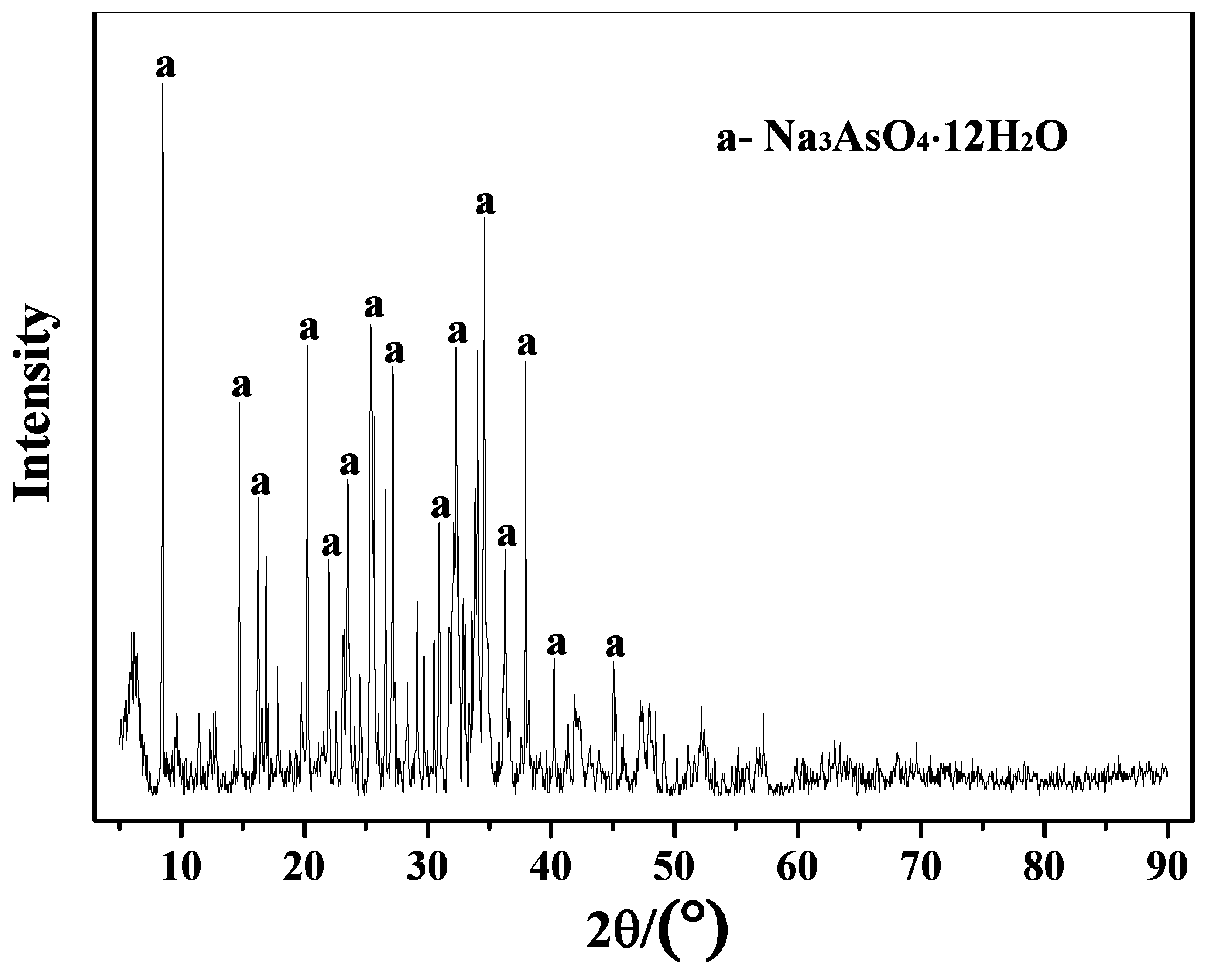

The invention belongs to the technical field of industrial sewage treatment, and particularly discloses a method for resource utilization of waste sulfuric acid wastewater produced in copper smeltingand acquisition of arsenic-containing products. The method comprises the following steps: 1, oxidization of trivalent arsenic: oxidizing the waste sulfuric acid wastewater by air and hydrogen peroxidein sequence; 2, separation of arsenic from fluorine and chlorine: carrying out negative pressure evaporation after oxidation to obtain a condensate A containing fluorine and chlorine, a concentratedsolution B and arsenic pentoxide crystals; 3, separation of fluorine and chlorine: absorbing the condensate A with magnesium oxide to obtain a magnesium fluoride product and diluted hydrochloric acid;4, recovery of valuable metal: adding a sodium sulfide solution into the concentrated solution B to obtain a valuable metal precipitate and arsenic-containing waste liquid C, and returning the valuable metal precipitate to a furnace for refining; and 5, crystallization: adding caustic soda flakes or recycled concentrated alkali liquor E into the arsenic-containing waste liquor C, adjusting a pH value to 13.5-14.0 to obtain a sodium arsenate product and a crystallized filtrate D, filtering the crystallized filtrate D, and conducting concentrating to obtain a sodium sulfate product and the concentrated alkali liquor E. According to the method, waste sulfuric acid wastewater is subjected to resource recycling, and arsenic pentoxide and sodium arsenate products are obtained.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

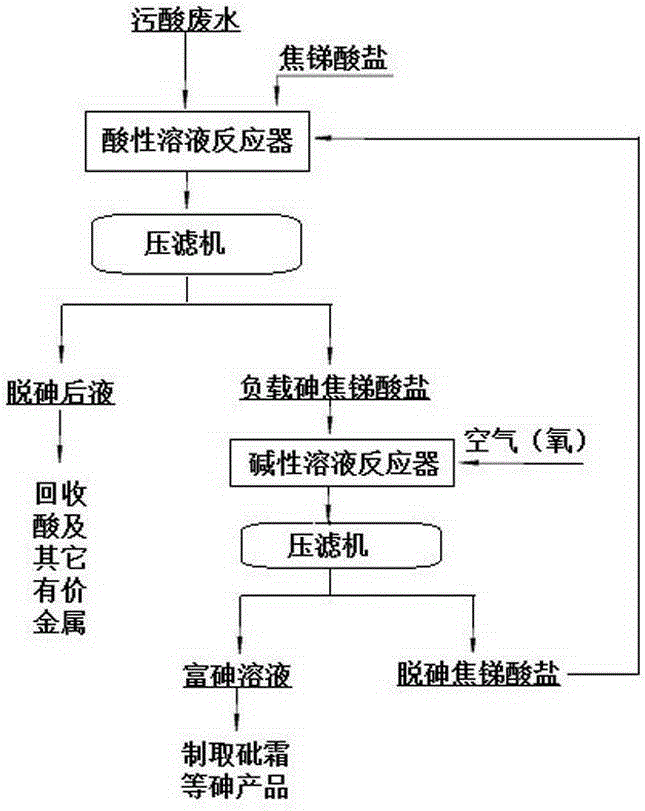

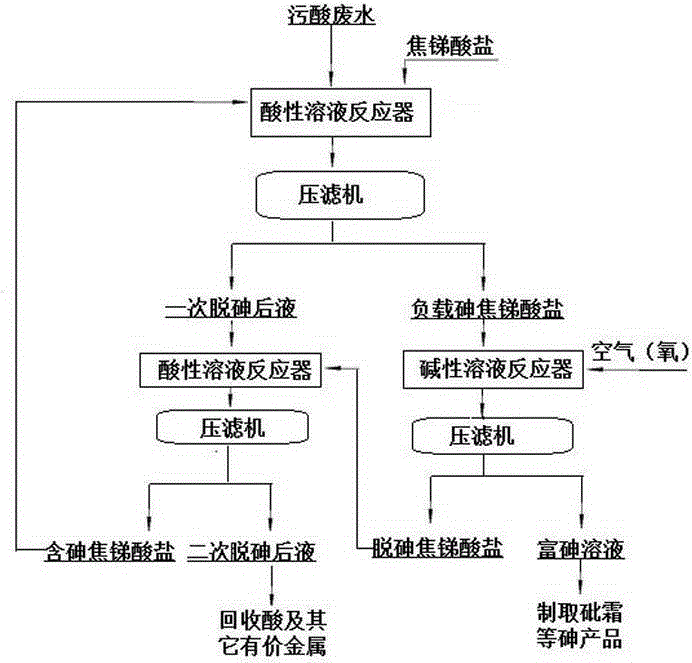

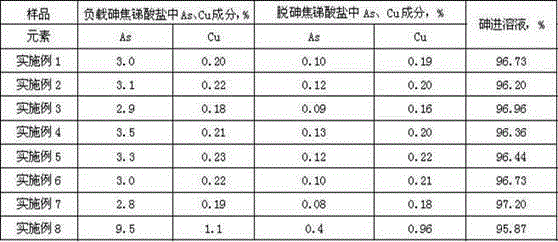

Method for precipitating and separating arsenic from waste acid wastewater

ActiveCN105347544AReduce generationEasy to separateWater contaminantsTreatment involving filtrationLiquid ratioFiltration

The invention discloses a method for precipitating and separating arsenic from waste acid wastewater. The method comprises the following steps: pumping the waste acid wastewater into an acidic solution reactor, adding pyroantimonate according to a liquid-to-solid ratio of 4-10mL:1g, heating to 45-60DEG C, reacting for 15-20min, pumping the obtained reaction solution to a filter press, carrying out press filtration, allowing the obtained arsenic removal filtrate to flow to an acid and valuable metal recovery process, adding arsenic-supported pyroantimonate filter residues into an alkaline solution reactor according to a solid-to-liquid ratio of 1g:3-8mL, introducing air, heating to 78-90DEG C, stirring and reacting for 60-100min, pumping the obtained reaction solution to the filter press, carrying out press filtration, allowing the obtained press-filtered arsenic-rich filtrate to flow to a process for preparing arsenic trioxide and other arsenic products, and returning the arsenic removed pyroantimonate filter residues to the acidic solution reactor. The method has the following advantages: pyroantimonate has a good arsenic removal effect as an arsenic removal medicine; arsenic removal pyroantimonate can be reused, so the treatment cost is low; and the amount of generated dangerous solid wastes is small, so no secondary pollution is realized.

Owner:JIANGXI COPPER

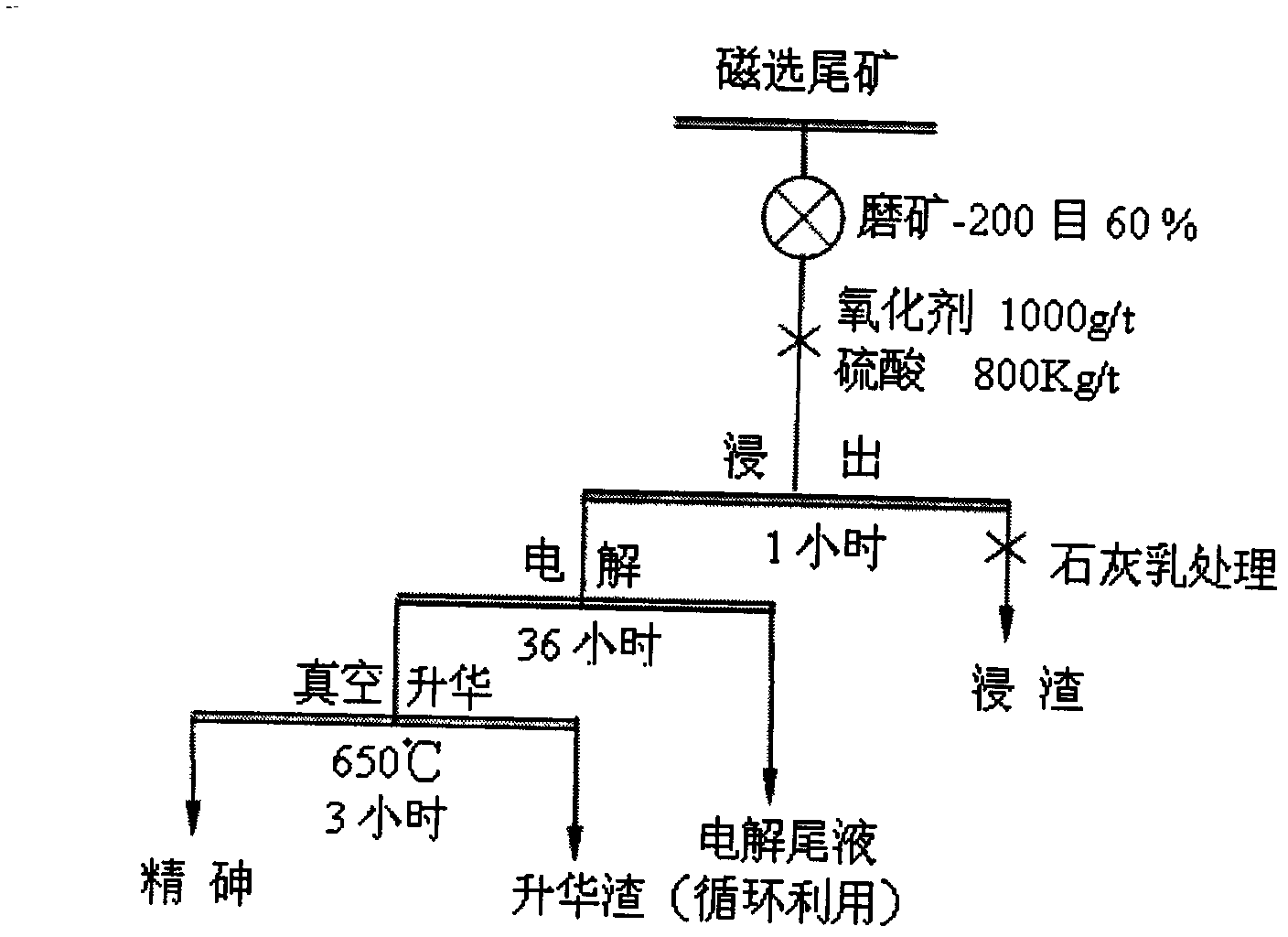

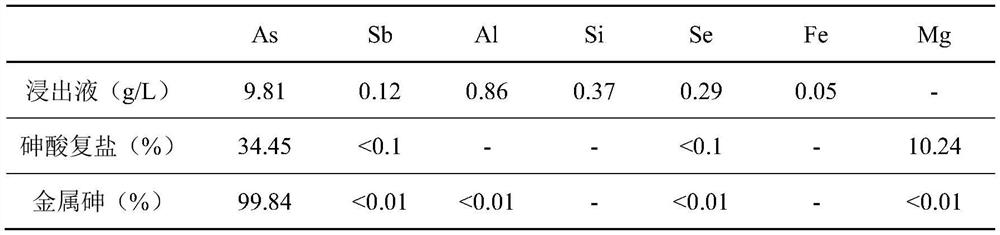

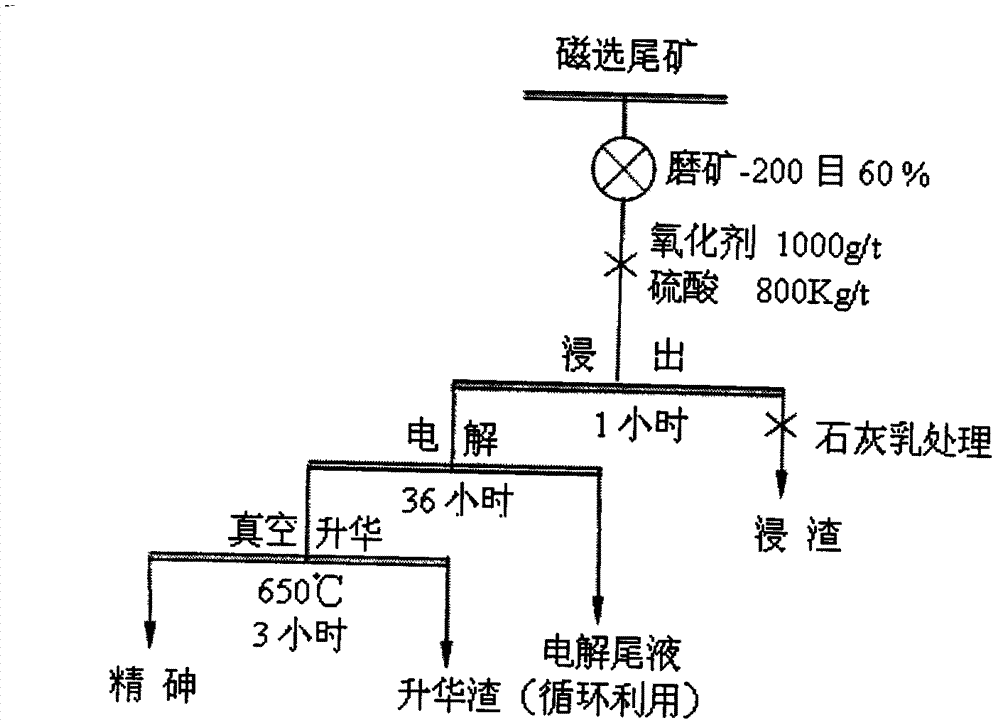

Combined extraction method for arsenic in high-arsenic manganese ore tailings

InactiveCN102181668AHigh recovery rateImprove product qualityProcess efficiency improvementPregnant leach solutionElectrolysis

The invention discloses a combined extraction method for arsenic in high-arsenic manganese ore tailings, which is characterized by comprising the following steps of: dissolving arsenic minerals in the high-arsenic manganese ore tailings which have the arsenic grade weight of between 9 and 11 percent and serve as a raw material by an acid leaching-electrolysis-sublimation process combined process and a wet-type chemical leaching process, reducing arsenic in leachate to form simple substance arsenic by an electrolysis method, and purifying by a sublimation method further to obtain an arsenic product. By the method for extracting the arsenic, the recovery rate is high, the leaching rate of arsenic weight is more than or equal to 95 percent, the purity of the arsenic product weight is more than or equal to 80 percent, and the quality of the product is high; waste water of electroreduction operation returns the leaching operation to be recycled, so water for production is saved, and the environment is protected; leaching slag is processed by using alkali, and sublimation slag meets the discharge standard, so the method is environment-friendly, and has the good economic, social and ecological benefits. The method is suitable for producing high-purity arsenic products by arsenic ore tailings which are similar to fluorine-containing adelite CaMg(F / AsO4).

Owner:广西壮族自治区地质矿产测试研究中心

Arsenic removing technology for zinc hydrometallurgy

InactiveCN105734290AAvoid the phenomenon of agglomeration clogging pipesEliminate generationProcess efficiency improvementSlagHydrometallurgy

The invention discloses an arsenic removing technology for zinc hydrometallurgy. The arsenic removing technology includes the following steps that under the normal-temperature condition, a neutralizing agent is added into a leaching agent in the metallurgical process to adjust the pH value of the leaching agent to be the constant value; and then an oxidizing agent is added to remove iron ions in the solution, the pH value of the leaching agent is kept at the constant value by adjusting the adding amount of the neutralizing agent, sediment is filtered out and removed, and filtrate generated after iron removing and arsenic removing is obtained. By means of the method, the neutralizing agent of lead-zinc oxide ore is used for replacing a neutralizing agent of calcium carbonate or whitewash used traditionally, generation of arsenic and iron slag is eliminated, zinc in lead zinc ore can be recycled through the wet process, zinc sulfate products are produced, produced lead, arsenic and iron ore sediment is rich in valuable metal such as lead and iron, lead bullion and arsenic products can be produced through a pyrogenic process, the production cost is reduced, and the phenomenon that a pipeline is blocked due to agglomeration of whitewash in the using process is avoided.

Owner:HUBEI DABEIJIANG ENVIRONMENTAL TECH CO LTD

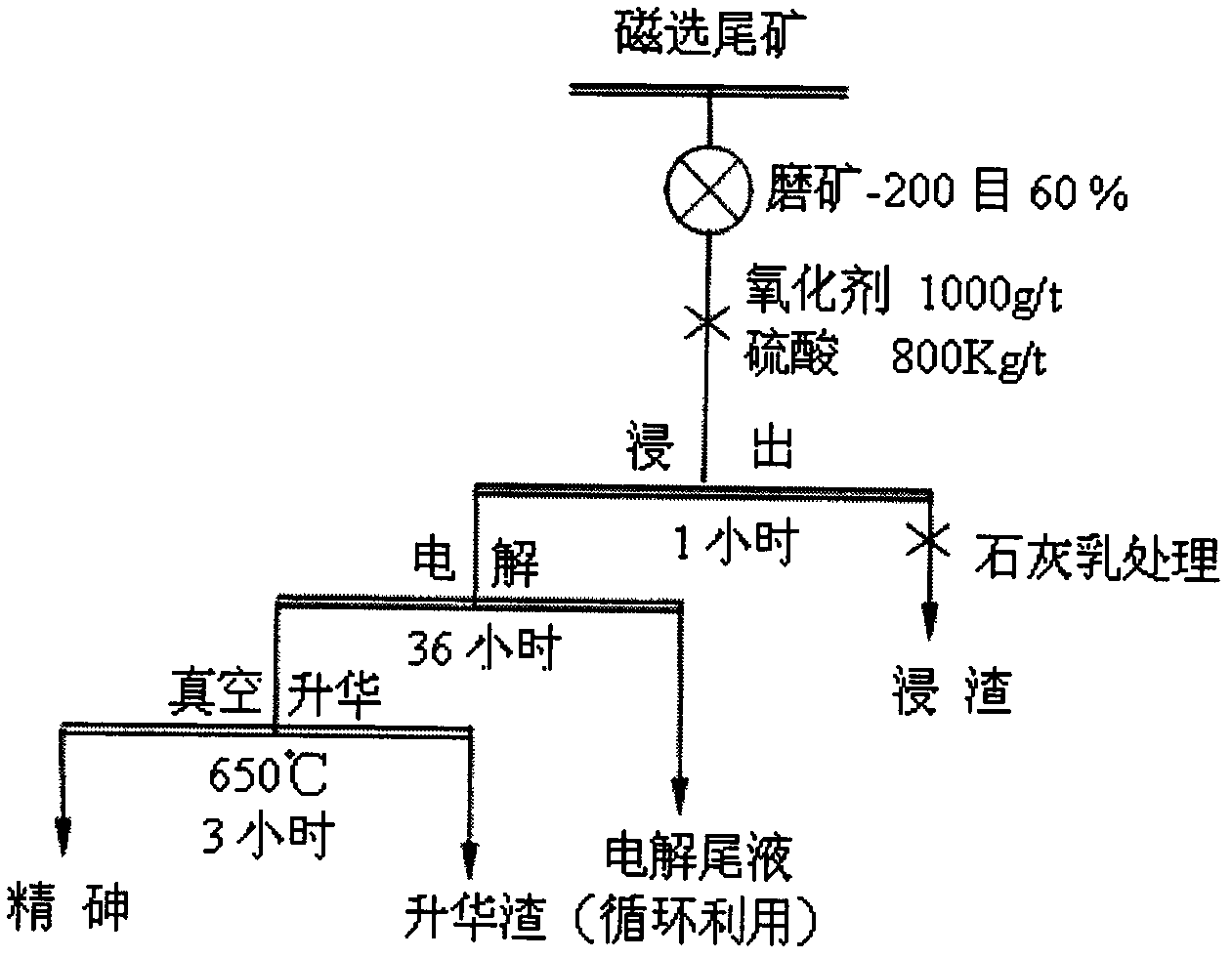

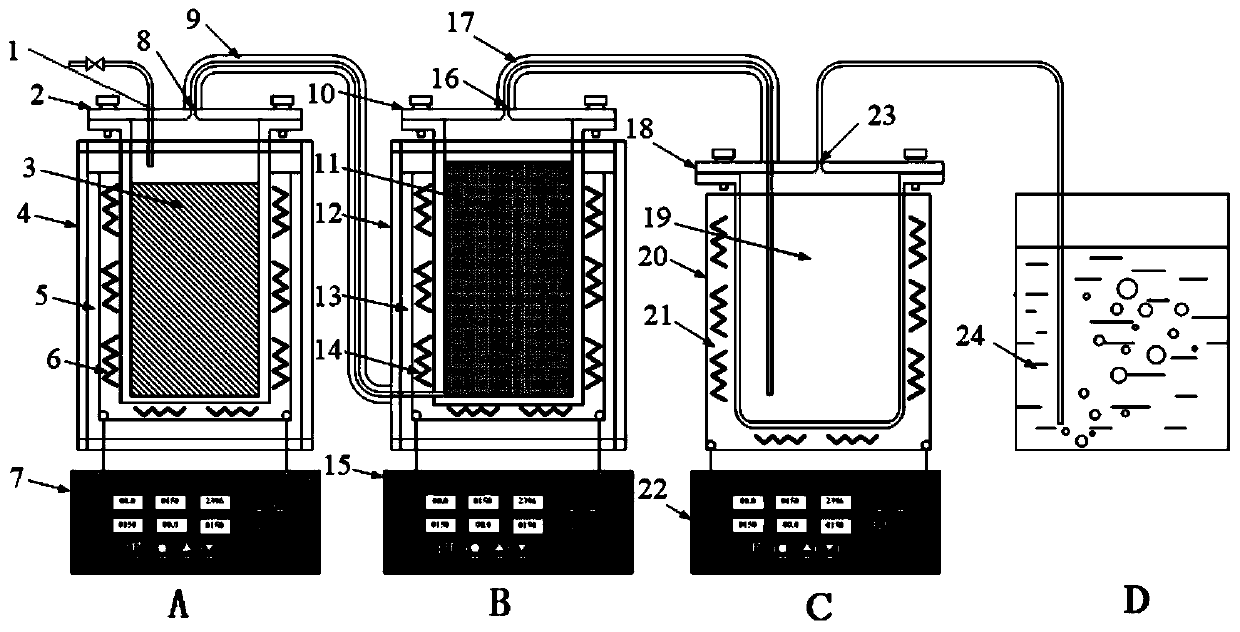

Method and equipment for recovering arsenic from titanium-arsenic slag

ActiveCN111304447AReduce energy consumptionAvoid energy consumptionProcess efficiency improvementElectrolytic agentSlag

The invention discloses a method for recovering arsenic from titanium-arsenic slag. The method comprises the following steps of (1) pyrolyzing the titanium-arsenic slag to obtain arsenic oxide steam,wherein the pyrolysis temperature ranges from 700 DEG C to 1200 DEG C; (2) reducing the arsenic oxide steam to obtain arsenic steam; and (3) condensing the arsenic vapor to obtain elemental arsenic. The invention further discloses equipment for recovering arsenic from the titanium-arsenic slag. The equipment comprises a pyrolysis device, a reduction device and a condensation device, wherein the pyrolysis device comprises a pyrolysis furnace chamber, the reduction device comprises a reduction furnace chamber, and the condensation device comprises a condensation furnace chamber; the top of the pyrolysis furnace chamber is in communication with the lower part of the reduction furnace chamber through a pipeline; the top of the reduction furnace chamber is in communication with the condensationfurnace chamber through a pipeline. According to the method, arsenic in the titanium-arsenic slag is reduced into an elemental arsenic product under the process condition of a short process, and theprocess and the equipment provide a technical basis for arsenic removal of the copper electrolyte and short-process cyclic utilization of the titanium-arsenic slag.

Owner:JIANGXI UNIV OF SCI & TECH

Comprehensive utilization method for high-arsenic pyrite

InactiveCN101260458ASolve environmental problemsOther heat production devicesSulfur compoundsFlue gasSlag

The invention belongs to the environment protection technical field. A sulfurous iron ore with high arsenic content is calcined inside a furnace in fluid bed with high temperature and low oxygen content to remove arsenic and sulfur to prepare qualified slag products; most part of the mine dust of the flue gas is removed by a dedusting device; the outgoing flue gas is cooled and dedusted; the outgoing flue gas is cooled down and the arsenic is removed, and then the flue gas enters an acid making system to prepare concentrated sulphuric acid. The invention not only avoids the environmental pollution of the sulfurous iron ore with high arsenic content but also makes the best of the resources of sulfurous iron ore with high arsenic content to prepare qualified sulphuric acid, iron slag, steam and arsenic products. The invention has sufficient recycle, small causticity to the device, stable and continuous technique, good safety and good environment protection value and economic values.

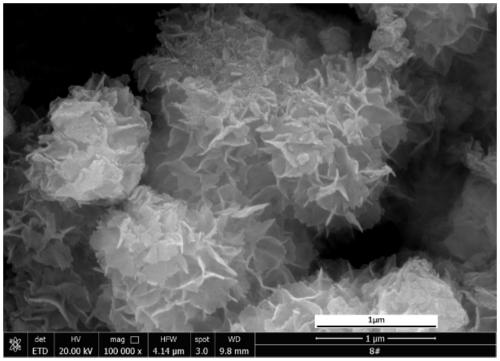

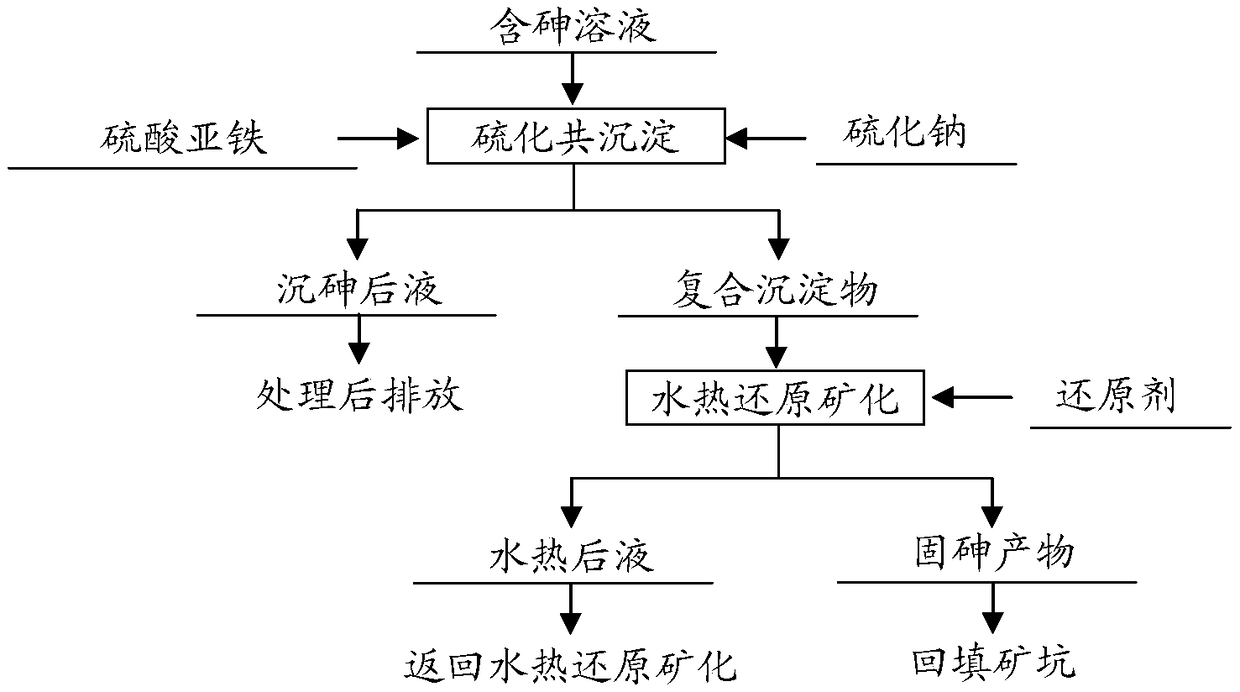

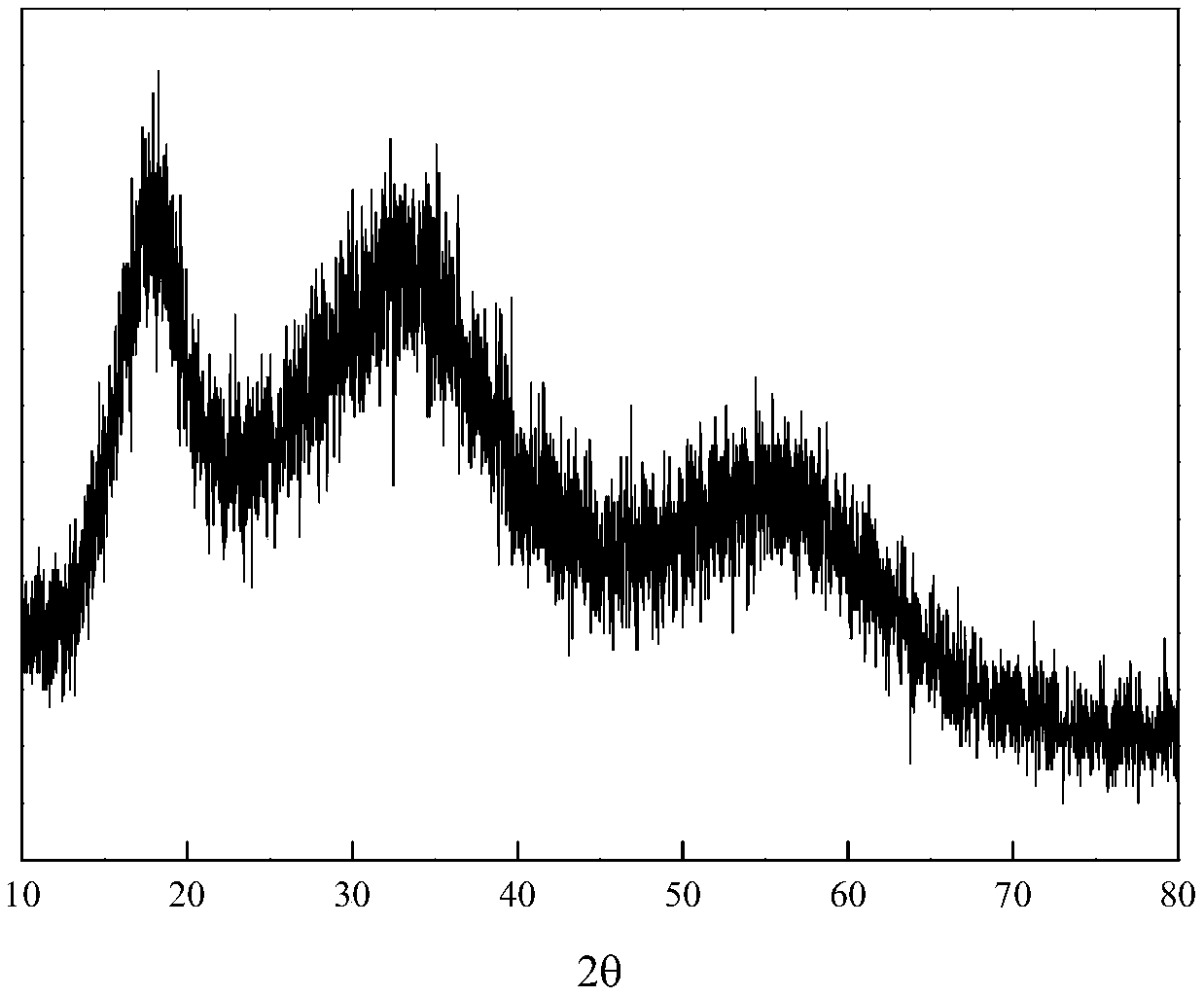

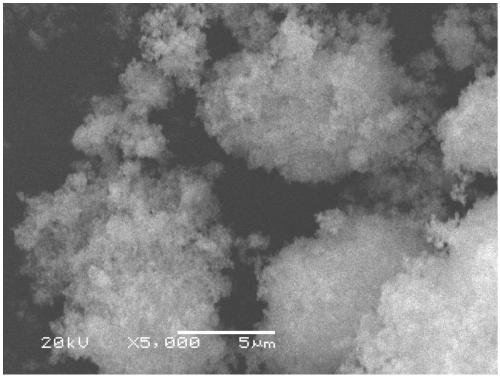

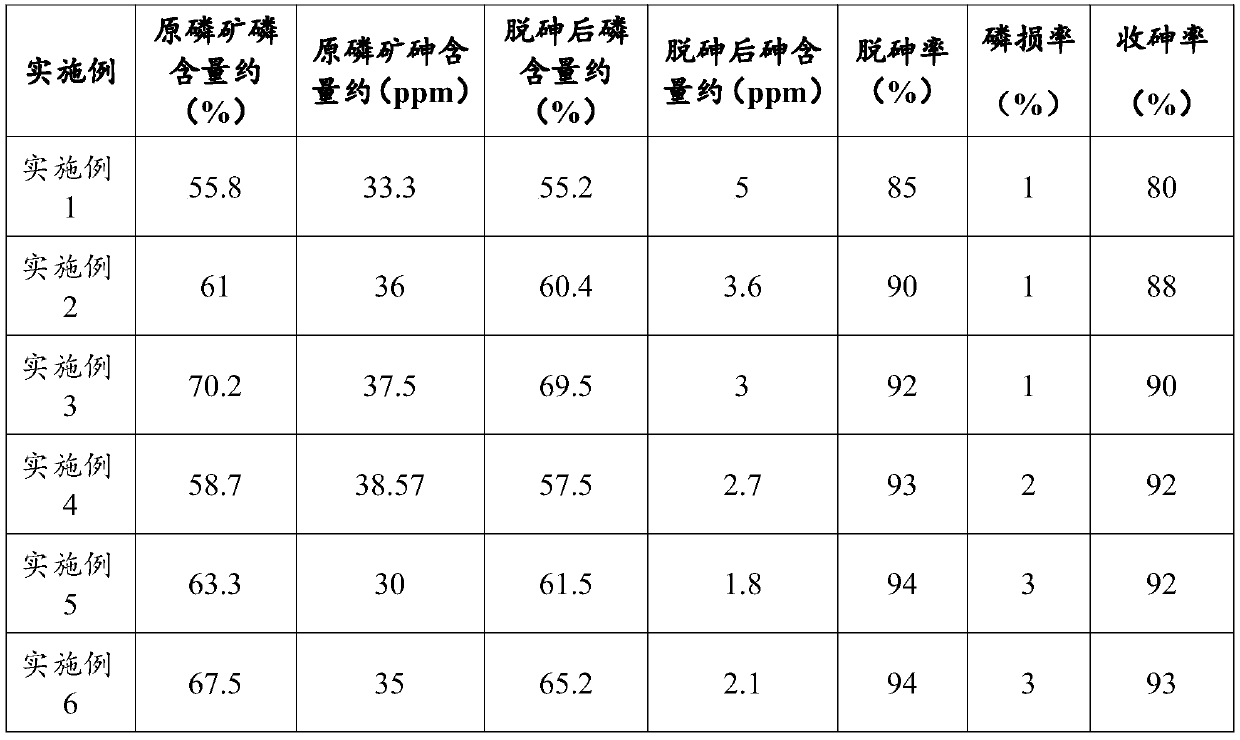

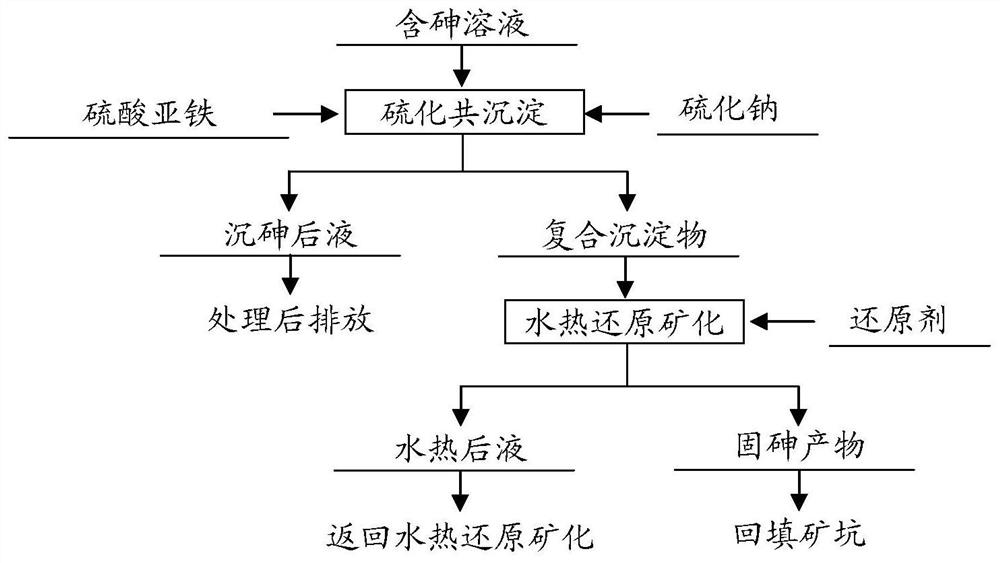

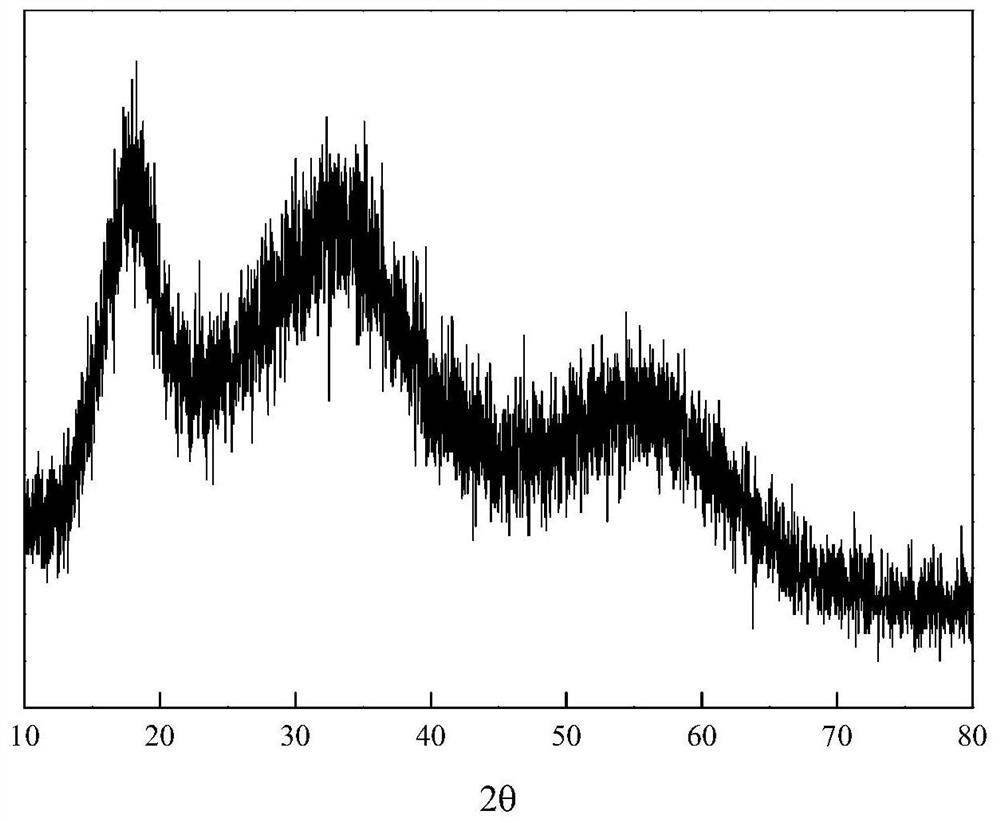

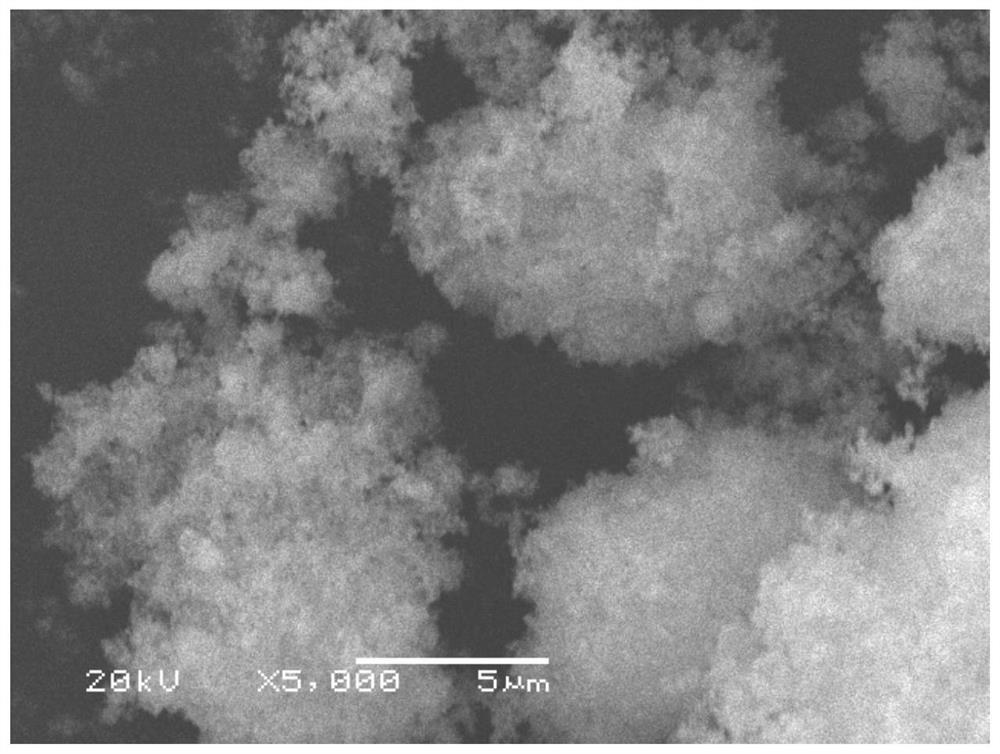

Method for carrying out hydrothermal reduction on mineralized synergistic fixed arsenic

ActiveCN109095576AReduce the toxicity of dissolutionLight in massArsenic sulfidesUnderground miningVulcanizationDissolution

The invention discloses a method for carrying out hydrothermal reduction on mineralized synergistic fixed arsenic. According to the method, ferrous sulfate is added into arsenic-bearing solution; under a required pH value, sodium sulfate is added to precipitate an arsenic sulfide-ferrous sulfide composite precipitate; the compound precipitate and a reducing agent are made into size by using waterand then added into a high-pressure reaction kettle; and the temperature is controlled to carry out reaction for a certain time so as to ensure that the compound precipitate is converted into a solidarsenic product with a mineral crystal form, so that the aim of reducing solid arsenic product dissolution toxicity is finally realized. According to the method, the synergistic fixing of arsenic is realized through two processes: vulcanization co-precipitation and hydrothermal reaction mineralization, so that the double aims of improving the arsenic content in solid arsenic products and reducingthe arsenic dissolution toxicity are achieved. The method has the advantages of being low in dissolution toxicity, small in solid arsenic product mass and stable in technical index.

Owner:CENT SOUTH UNIV

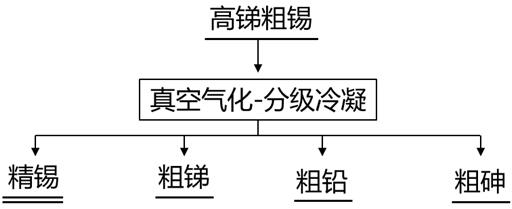

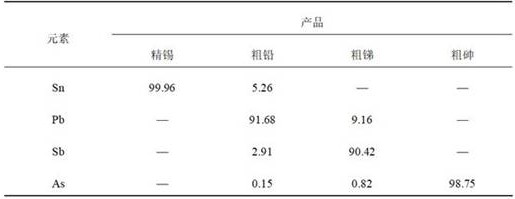

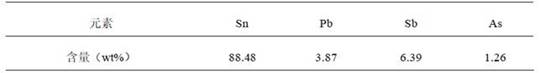

Method for separating and purifying high-antimony crude tin

ActiveCN113737007AImprove recycling efficiencySolve the loop problemProcess efficiency improvementRefining (metallurgy)Arsenic product

The invention relates to a method for separating and purifying high-antimony crude tin, and belongs to the technical field of non-ferrous metal pyrometallurgy. Vacuum gasification treatment is carried out on the high-antimony crude tin, volatile impurity elements in the crude tin are gasified to the maximum extent, and mixed metal vapor is formed through gasification and volatilization; and the obtained mixed metal steam is guided into a grading condenser connected with a vacuum gasification furnace, the temperatures of condensing areas of the grading condenser are controlled to be 550-700 DEG C, 300-450 DEG C and 100-250 DEG C respectively, and crude lead, crude antimony and crude arsenic products, and refined tin products left by gasification and volatilization are obtained respectively. The method solves the problem of circulation of the antimony element in a tin refining system, has the advantages of short flow, no generation of three wastes, maximum recovery of valuable metals, low treatment cost, high metal recovery rate, direct recovery rate, good operation environment and safe and controllable process.

Owner:KUNMING UNIV OF SCI & TECH

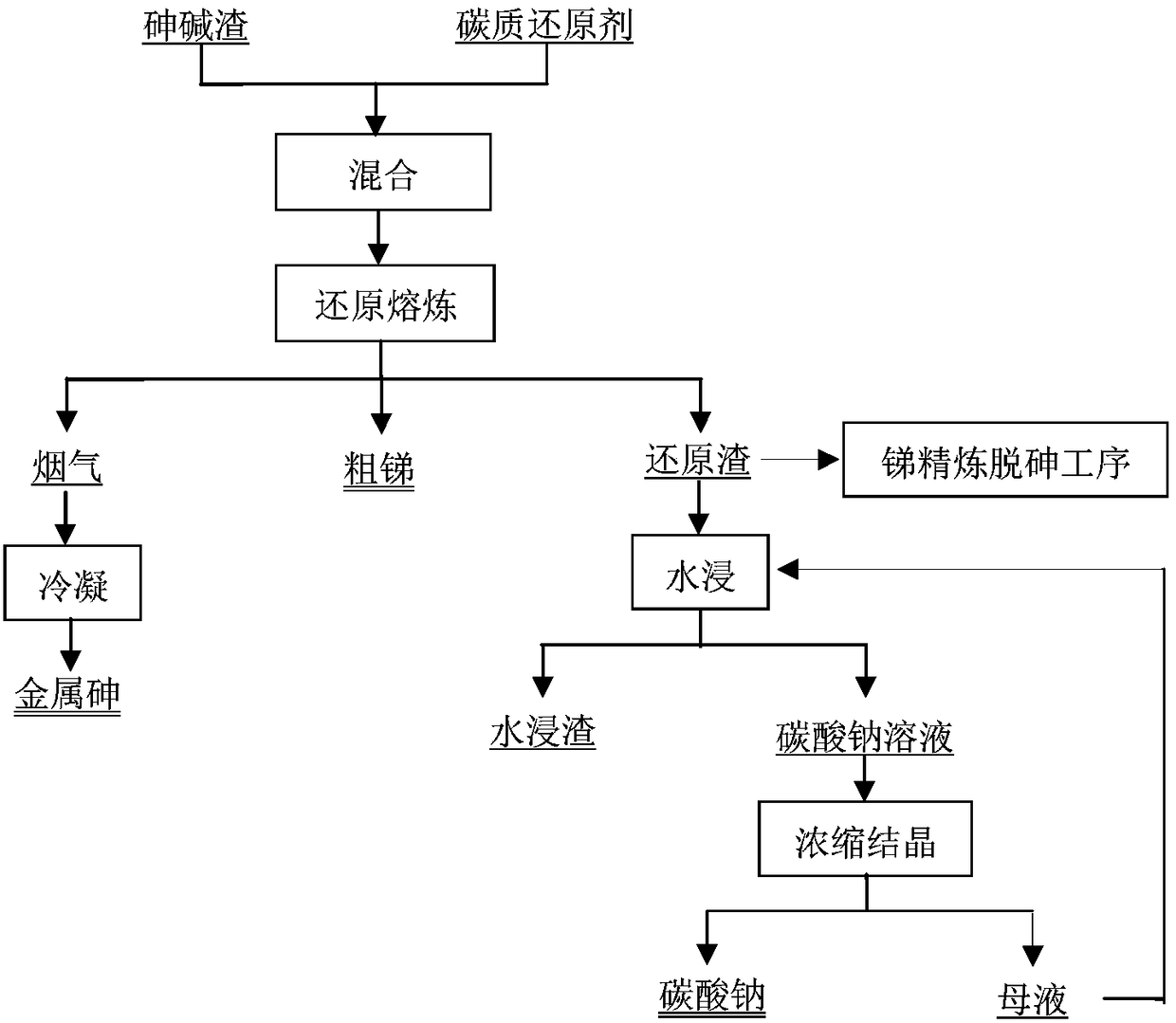

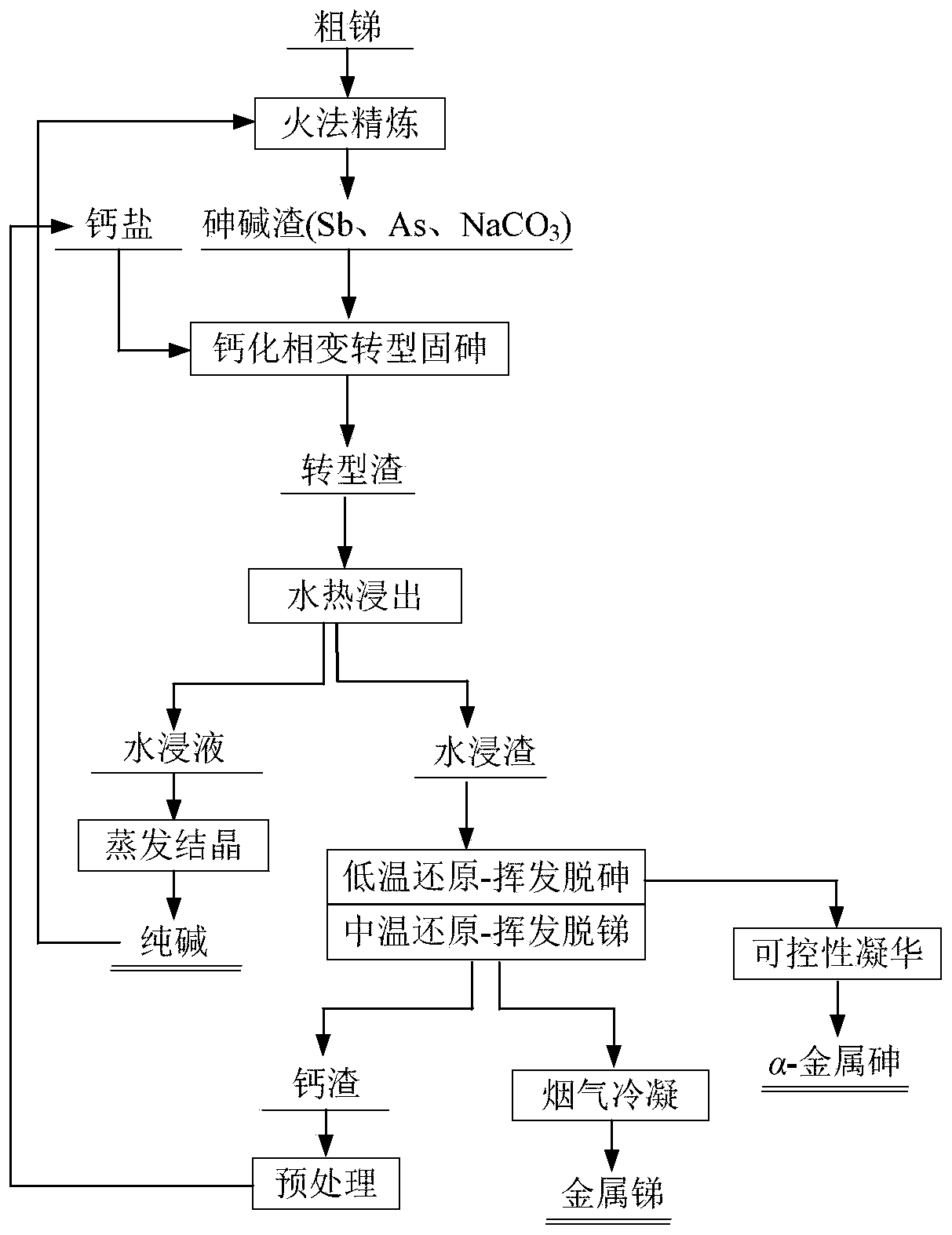

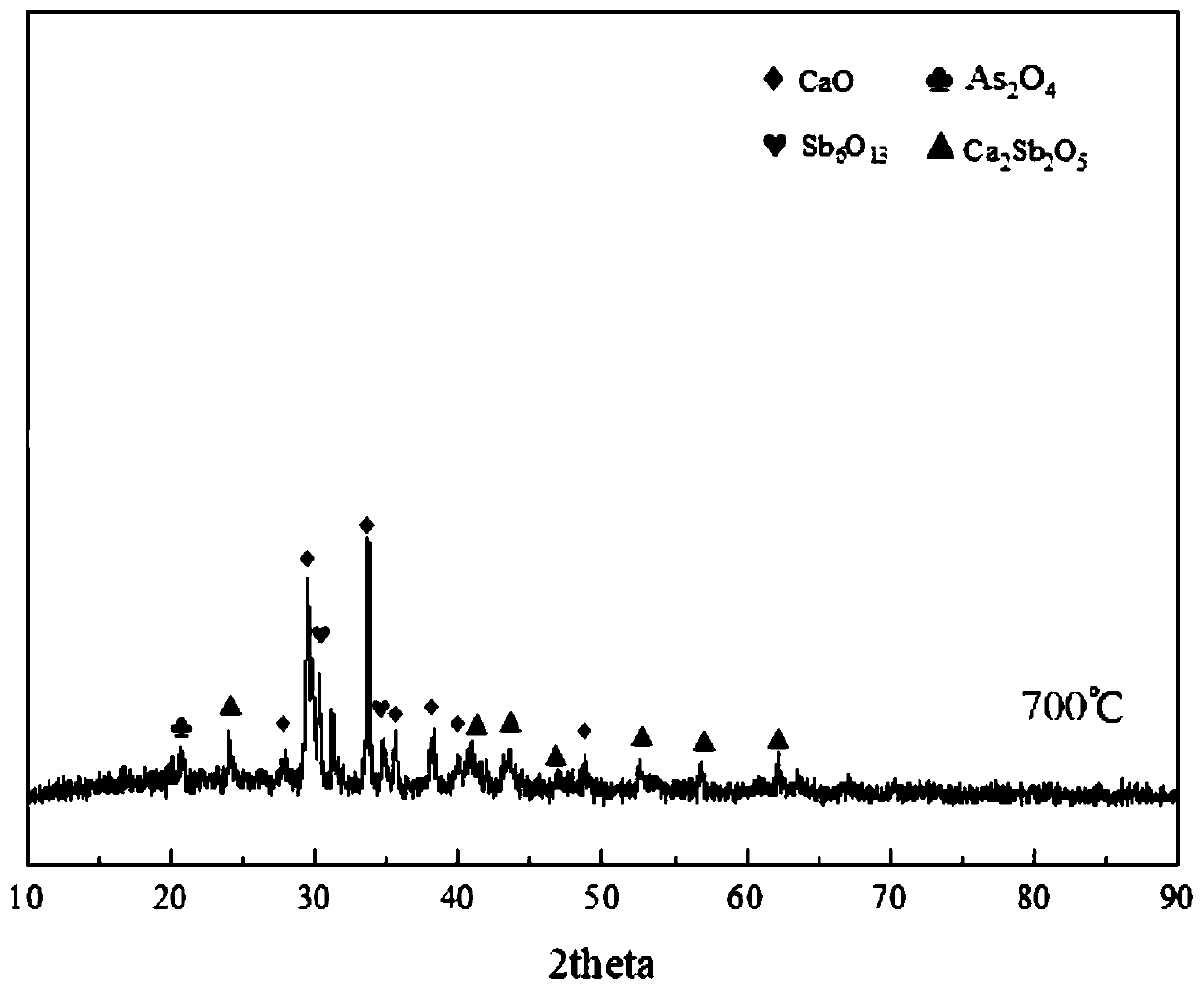

Method for recovering antimony, arsenic and alkali selectively from arsenic alkali residue

ActiveCN111334673ASolve the separation problemClever fixedProcess efficiency improvementAlkali metal carbonatesArsenic productGravity separation

The invention discloses a method for recovering antimony, arsenic and alkali selectively from arsenic alkali residue. The method comprises the steps that (1) the arsenic alkali residue is subjected toball-milling until the specification is 30-100 [mu]m; (2) gravity separation is performed on the arsenic alkali residue subjected to ball-milling, and gravity separation tailings and antimony residueare obtained; (3) the gravity separation tailings and calcium salt are mixed and heated to obtain calcified transformation residue; (4) the calcified transformation residue is subjected to water leaching to achieve solid-liquid separation, and water leaching alkali liquor and water leaching residue are obtained; and (5) the water leaching residue and a carbon-based reductive agent are mixed and heated to 600-800 DEG C, condensate gas is collected to obtain a metal arsenic product, then a mixture is heated to 900-1000 DEG C, reductive residue is obtained, and condensate gas is collected to obtain a crude antimony product. The processing method provided by the invention can be used for processing arsenic alkali residue produced by different antimony smelting enterprises, efficient separating of antimony, arsenic and alkali is achieved, the antimony and arsenic recovery rates can reach up above 95%, almost all alkali can be recycled, the process is simple and convenient to operate, and the production efficiency can be improved easily.

Owner:JIANGXI UNIV OF SCI & TECH

Comprehensive recovery method for complicated materials containing arsenic and valuable metal slag dust

ActiveCN102286665BNo pollutionCement productionProcess efficiency improvementTin dioxideRecovery method

Owner:LEIYANG YANXIN NON FERROUS METALS

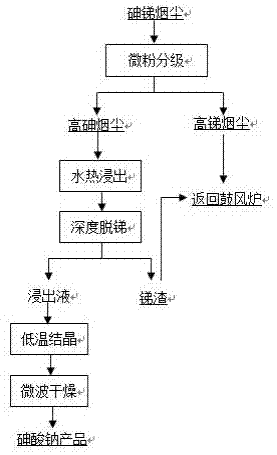

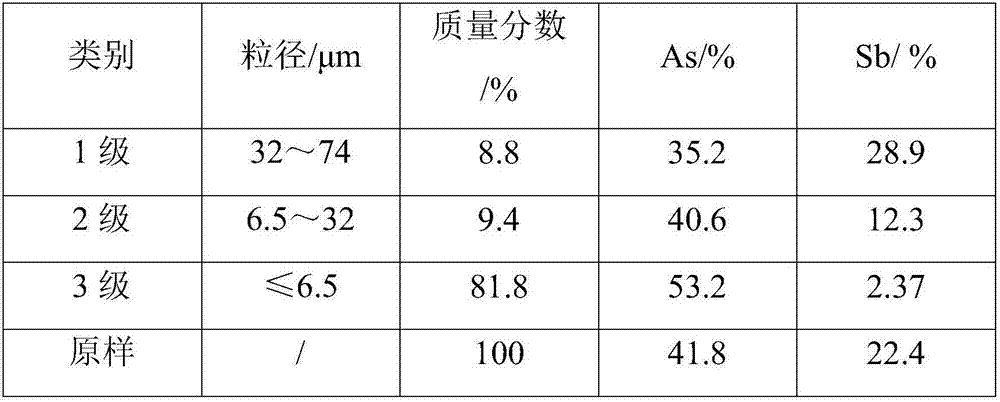

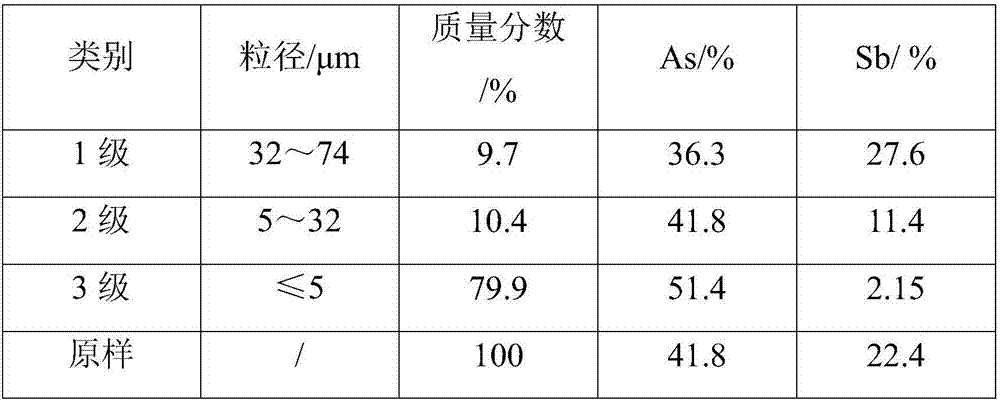

Efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke

ActiveCN107365913AReduce Pollution PotentialEliminate Pollution PotentialProcess efficiency improvementSodium saltArsenic product

The invention relates to an efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke and belongs to the technical field of non-ferrous metallurgy. The method comprises the specific steps that the arsenic and antimony smoke is subjected to stge treatment, fine powder smoke obtained through separation is put into hot water according to the formula that the liquid-solid ratio is 5:1, agitation leaching is conducted for 60 min at the temperature is 85 DEG C, and solid-liquid separation is conducted after leaching; an oxidizing agent is slowly added into leaching liquid, the volume percentage of the oxidizing agent is 3%, stirring is continuously conducted for 60 min, and arsenic-containing leaching post-liquid and antimony-containing leaching residues are obtained after filtering; a sodium salt solution is added into the leaching post-liquid, the mixture is subjected to low-temperature concentration and crystallization under the microwave condition after sufficient stirring, sodium arsenate crystals are obtained after centrifugal filtering, and crystallization mother liquor is used circularly; and the sodium arsenate crystals are sent to microwave drying equipment to be dried, and products are obtained after drying. According to the method, the arsenic and antimony smoke is subjected to stage treatment according to the grain size, enrichment and separation of arsenic and antimony can be achieved, operation is easy, and the cost is effectively reduced; and separated arsenic-enriched smoke is leached, refined and crystallized, arsenic products are formed for export sales, antimony-containing materials return to the procedure, and resource recycling is achieved.

Owner:红河绿地环保科技发展有限公司

Method for recovering antimony, arsenic and alkali from secondary arsenic alkaline residue

InactiveCN110541078APromote sustainable developmentQuick resultsAlkali metal oxidesProcess efficiency improvementCrucibleProcess engineering

The invention relates to a method for recovering antimony, arsenic and alkali from secondary arsenic alkaline residue. The method comprises the following steps of (1), adding the secondary arsenic alkali residue and a reducing agent into a crucible, conducting mixing, putting the mixture into a reaction furnace, introducing inert gas, and conducting stirring and heating; and (2), receiving arsenicsteam containing antimony in the upper part of the reaction furnace, conducting cooling, crystallizing and dust collecting to obtain an antimony-containing crude arsenic product, discharging reactionalkali residue from the outlet of the lower part of the reaction furnace, and cooling to obtain sodium oxide. The method can be used for effectively, thoroughly and harmlessly treating the secondaryarsenic alkali residue, can accelerate the treatment of a large amount of secondary arsenic alkali residue which is overstocked currently, and has good environmental protection benefits and social benefits; the sodium oxide obtained through the method can be used as a glass manufacturing raw material and has relatively good economic benefits; and meanwhile, the method is short in technological process, convenient to operate, free of secondary pollution, less in investment, fast in effectiveness and suitable for industrial treatment of the secondary arsenic alkali residue.

Owner:锡矿山闪星锑业有限责任公司

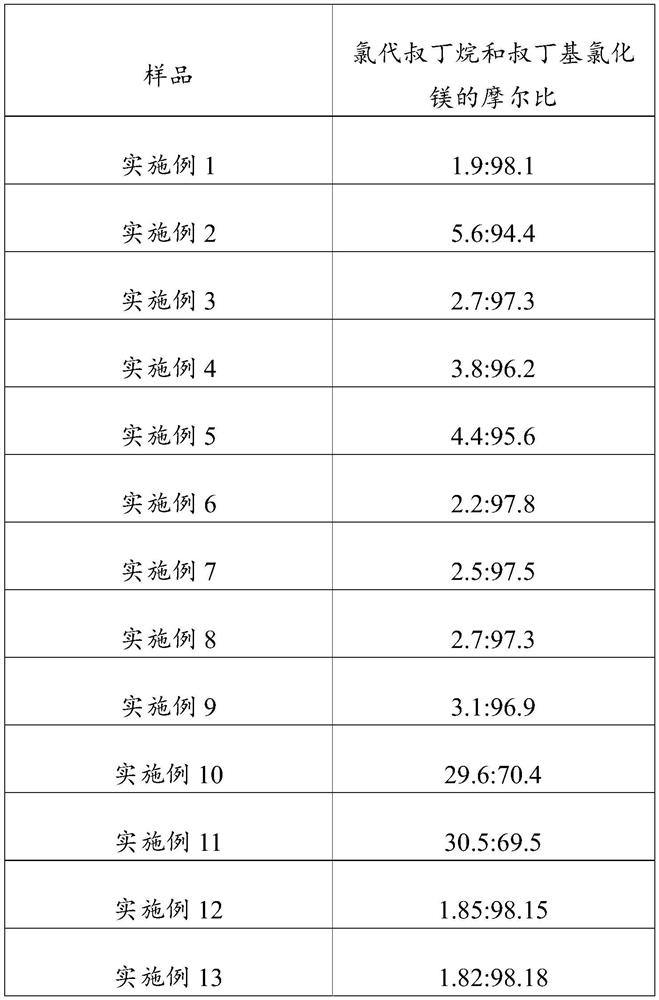

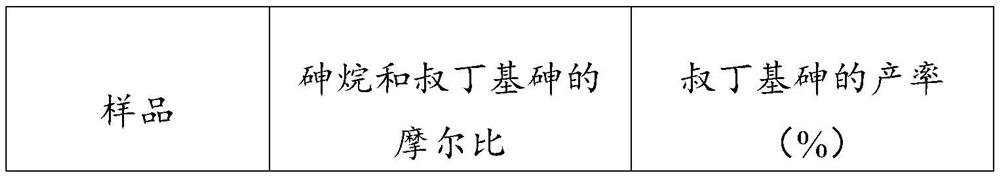

Preparation method of tert-butyl arsenic

PendingCN112159431AHigh purityImprove conversion rateGroup 5/15 element organic compoundsMagnesium organic compoundsArsineTert-Butyl chloride

The invention provides a preparation method of tert-butyl arsenic, which comprises the following steps that (1) under the protection of inert gas, magnesium and chlorotert-butane react at 60-80 DEG Cto generate tert-butyl magnesium chloride, carrying out the reaction of magnesium and chlorotert-butane under the condition of an initiator, wherein the initiator is organic aluminum or inorganic aluminum, and the weight ratio of the initiator to magnesium is (3-7): 100; (2) stirring and reacting arsenic trichloride and tert-butyl magnesium chloride at the temperature of 10 DEG C or below to obtain tert-butyl arsenic dichloride; (3) stirring tert-butyl arsenic dichloride and a reducing agent to react at the temperature of 10 DEG C or below to obtain a tert-butyl arsenic crude product; (4) purifying the tert-butyl arsenic crude product obtained in the step (3). According to the method, the reaction efficiency of magnesium and chlorotert-butane is improved, the purity of the intermediate product tert-butyl magnesium chloride is improved, the conversion rate of arsenic trichloride is increased, and arsenic trichloride is prevented from generating side reaction to generate arsine in subsequent reaction, and therefore the purity of the crude tert-butyl arsenic product is improved.

Owner:广东先导微电子科技有限公司

Method for separating and recovering copper and arsenic from zinc hydrometallurgy copper and arsenic slag

ActiveCN113621813AHigh recovery rateAchieve separationProcess efficiency improvementSlagPhysical chemistry

The invention relates to a method for separating and recovering copper and arsenic from zinc hydrometallurgy copper and arsenic slag, and belongs to the technical field of metallurgical engineering. A method for separating the copper and arsenic through high-temperature volatilization is adopted for the zinc hydrometallurgy copper and arsenic slag containing 40-60 wt% of copper and 10-20 wt% of arsenic, and specifically comprises the steps that the zinc hydrometallurgy copper and arsenic slag is put into an intermediate frequency furnace lined with a graphite device, heated to the temperature of 1100-1300 DEG C in the intermediate frequency furnace and subjected to heat preservation for 30-60 min, so that the zinc hydrometallurgy copper and arsenic slag is molten; and in the electromagnetic disturbance of an electromagnetic field and a reducing atmosphere formed by a graphite device in the furnace, arsenic in the zinc hydrometallurgy copper and arsenic slag forms elemental arsenic, and the elemental arsenic is volatilized and separated to obtain a crude copper product containing more than 95 wt% of copper and a metal arsenic product containing more than 90 wt% of arsenic. The method can directly realize high-efficiency separation of copper and arsenic from the zinc hydrometallurgy copper and arsenic slag, can obtain high-quality copper and arsenic products, and has the characteristics of simple operation, short process flow, high valuable metal recovery rate, clean and efficient treatment process and the like.

Owner:KUNMING UNIV OF SCI & TECH

Reduction efficient treatment method for arsenious flue dust

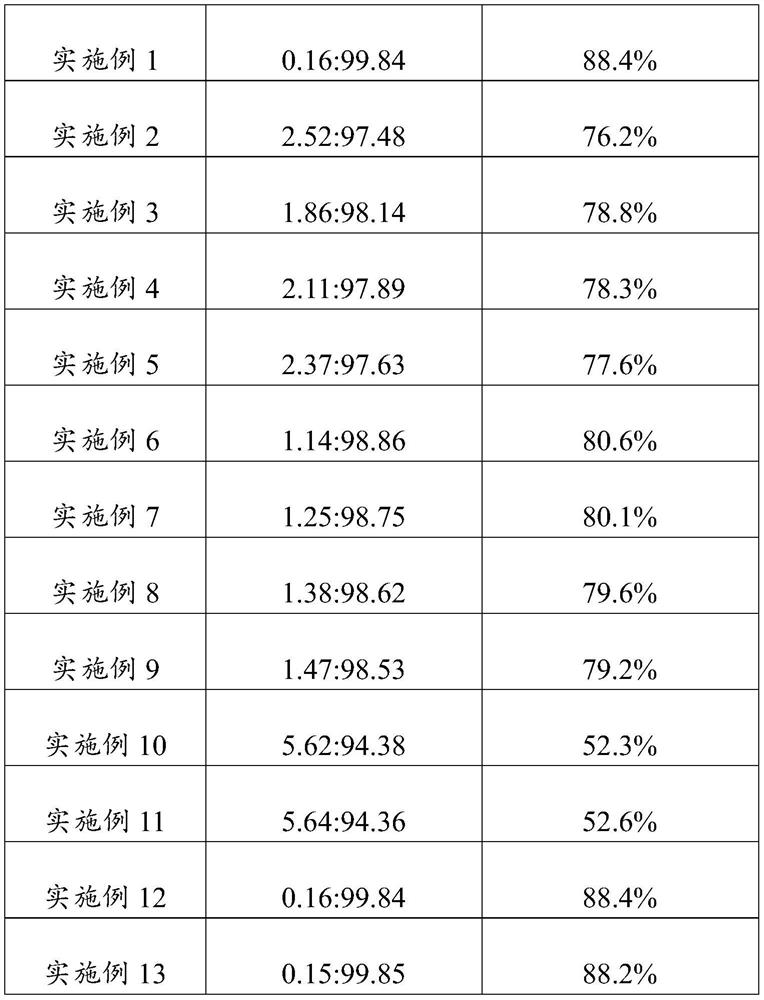

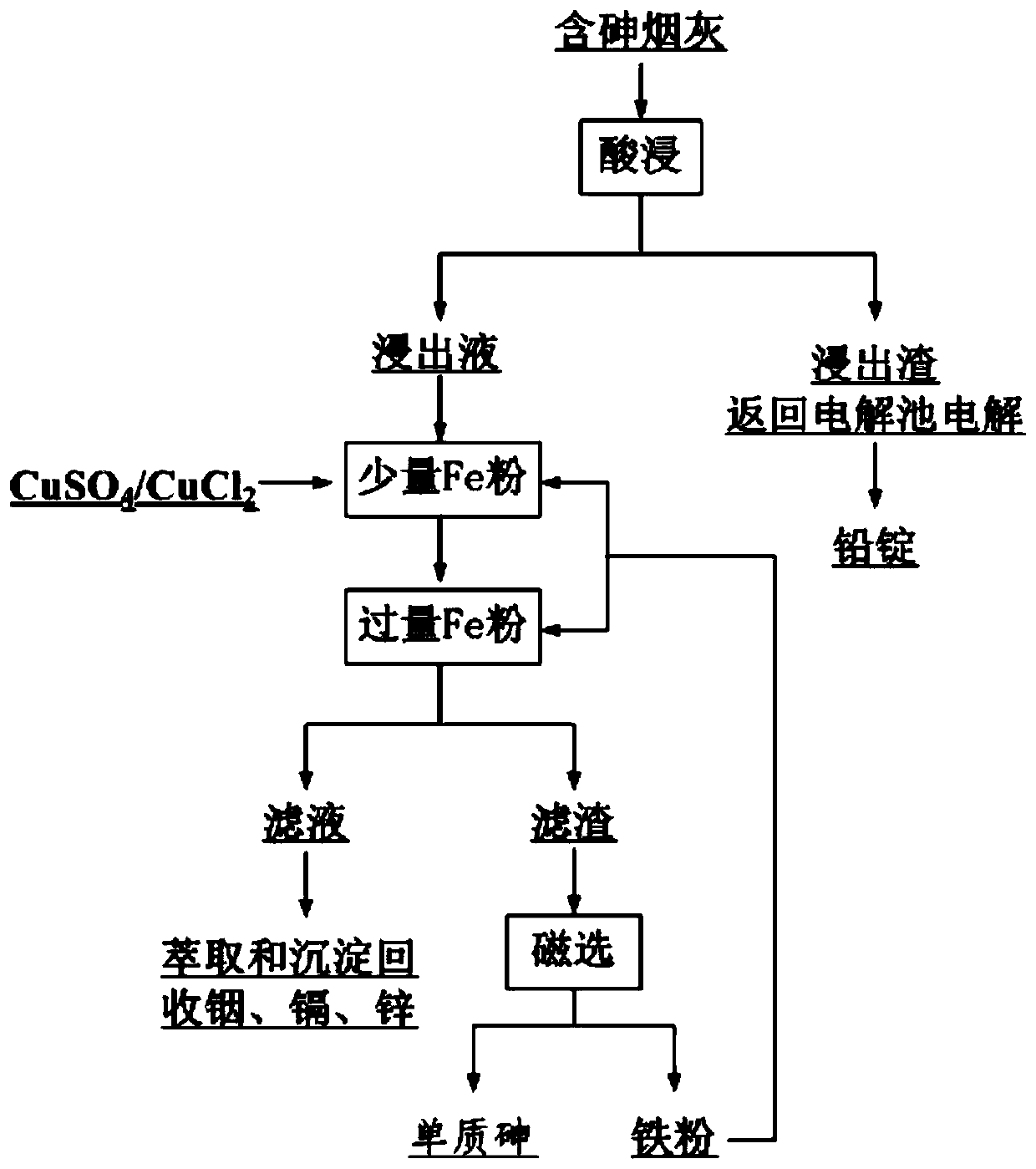

ActiveCN110172583AAchieve separationAlleviate passivationProcess efficiency improvementIndiumReduction treatment

The invention discloses a reduction efficient treatment method for arsenious flue dust. The reduction efficient treatment method for the arsenious flue dust mainly includes following steps: (1) performing acid leaching on the arsenious flue dust so as to obtain an acid leaching solution and acid leaching slags; (2) using iron powder for reducing arsenic in the acid leaching solution step by step, using Cu2+ as an activating agent during the reduction process, and obtaining a filtrate and filter residues after reaction completes; (3) performing magnetic separating on the obtained filter residues, separating iron from the arsenic in the filter residues, and obtaining a high purity simple substance arsenic product. The reduction efficient treatment method for the arsenious flue dust first performs the acid leaching so as to enable the arsenic, zinc, indium and cadmium to enter the acid leaching solution, achieves separation of valuable metals of the arsenic, the zinc, the indium, the cadmium and the like from other metals, uses the iron powder for reducing the arsenic in the acid leaching solution into the single substance arsenic, and accordingly not only can effectively recycle the arsenic, but also can reduce preservation content of the arsenic in the arsenic product, and achieves reduction treatment of the arsenious flue dust. The reduction efficient treatment method for the arsenious flue dust is simple to operate, low in cost and high in efficiency.

Owner:CENT SOUTH UNIV +1

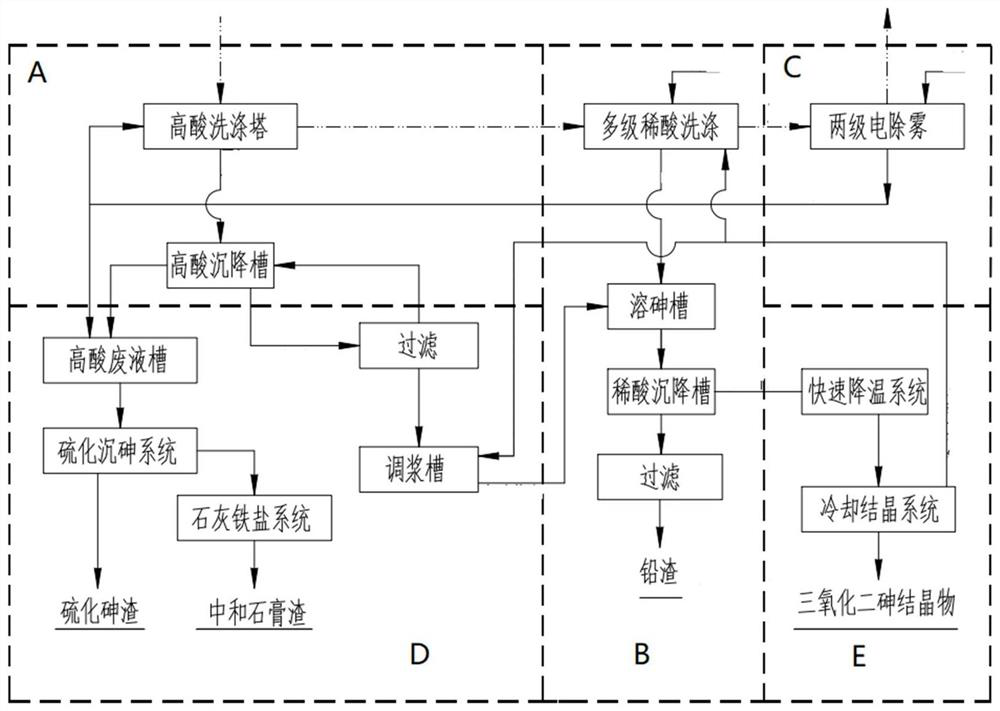

Method and system for wet dearsenification of smelting flue gas

InactiveCN112370951AReduce consumptionReduce processing costsGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention belongs to the technical field of flue gas dearsenification, and particularly relates to a method and a system for wet dearsenification of smelting flue gas. The method for wet dearsenification of smelting flue gas comprises the following steps of: washing the smelting flue gas with high-concentration sulfuric acid so as to remove most of sulfur trioxide; and washing the flue gas washed by the high-concentration sulfuric acid with low-concentration sulfuric acid so as to remove most As2O3; wherein the mass fraction of sulfuric acid in the high-concentration sulfuric acid is 40% or above, and the mass fraction of sulfuric acid in the low-concentration sulfuric acid is 20% or below. The method for wet dearsenification of smelting flue gas has the advantages of small hazardous waste residue amount, low agent consumption, low treatment cost and high purity of main arsenic products.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

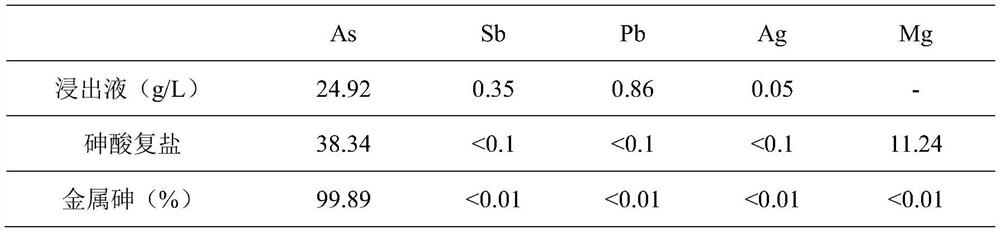

Method for preparing high-purity metal arsenic from non-ferrous smelting arsenic-containing solid waste in short process

ActiveCN114836635AAchieve deep separationLow costProcess efficiency improvementAmmonium compoundsCarboxyl radical

The invention discloses a short-process method for preparing high-purity metal arsenic from non-ferrous smelting arsenic-containing solid waste. The method comprises the following steps: carrying out oxidation alkaline leaching on the non-ferrous smelting arsenic-containing solid waste to obtain an arsenic-containing alkaline leaching solution; sequentially adding a mixed magnesium ammonium reagent consisting of a water-soluble polymer organic matter containing carboxyl and / or hydroxyl, a magnesium compound and an ammonium compound and a hydrophobic polymer organic matter with a periodic geometric structure into the arsenic-containing alkaline leachate, and stirring for reaction to obtain an arsenic acid double salt crystal wrapped by the organic matter; and roasting the arsenic acid double salt crystal wrapped by the organic matter, then mixing the arsenic acid double salt crystal with carbon powder, carrying out reduction roasting, and condensing and recovering the metal arsenic from the flue gas. According to the method, safe treatment of the non-ferrous smelting arsenic-containing solid waste can be achieved, the arsenic component in the non-ferrous smelting arsenic-containing solid waste can be recycled to prepare the high-purity metal arsenic product, and the method is simple, rapid, efficient and low in cost and meets industrial production.

Owner:CENT SOUTH UNIV

Combined extraction method for arsenic in high-arsenic manganese ore tailings

InactiveCN102181668BHigh recovery rateImprove product qualityProcess efficiency improvementPregnant leach solutionElectrolysis

The invention discloses a combined extraction method for arsenic in high-arsenic manganese ore tailings, which is characterized by comprising the following steps of: dissolving arsenic minerals in the high-arsenic manganese ore tailings which have the arsenic grade weight of between 9 and 11 percent and serve as a raw material by an acid leaching-electrolysis-sublimation process combined process and a wet-type chemical leaching process, reducing arsenic in leachate to form simple substance arsenic by an electrolysis method, and purifying by a sublimation method further to obtain an arsenic product. By the method for extracting the arsenic, the recovery rate is high, the leaching rate of arsenic weight is more than or equal to 95 percent, the purity of the arsenic product weight is more than or equal to 80 percent, and the quality of the product is high; waste water of electroreduction operation returns the leaching operation to be recycled, so water for production is saved, and the environment is protected; leaching slag is processed by using alkali, and sublimation slag meets the discharge standard, so the method is environment-friendly, and has the good economic, social and ecological benefits. The method is suitable for producing high-purity arsenic products by arsenic ore tailings which are similar to fluorine-containing adelite CaMg(F / AsO4).

Owner:广西壮族自治区地质矿产测试研究中心

Method and system used for high arsenic phosphorus ore pre-dearsenization

ActiveCN110240135AEfficient use ofSimple processArsenic oxides/hydroxides/oxyacidsRaw phosphate material treatmentHigh concentrationOxygen

The invention belongs to the technical field of phosphorus ore purification, and provides a method used for high arsenic phosphorus ore pre-dearsenization. The method comprises following steps: first, high arsenic phosphorus ore is subjected to high temperature treatment, arsenic in high arsenic phosphorus ore powder and oxygen are reacted at 420 to 550 DEG C to generate gaseous state arsenic trioxide, and gas solid phase separation is adopted to separate arsenic from the phosphorus ore powder; and furthermore, in order to obtain pure arsenic product, flue gas containing a small amount of ore powder is subjected to dedusting and cooling crystallization to generate arsenic trioxide for recycling. The method is capable of increasing dearsenization rate of high arsenic phosphorus ore to be 80% or higher, and phosphorus loss rate is lower than 3%. The technology process is simple; arsenic trioxide can be recycled, and waste is changed into valuables; and the application prospect is promising. According to the method, heat energy generated in combustion of high concentration CO in yellow phosphorus tail gas is adopted in high temperature hot treatment of high arsenic phosphorus ore, so that cost is reduced further. The invention also provides a system used for high arsenic phosphorus ore pre-dearsenization. The system is simple in structure; and industrialized production is convenient to realize through adoption of the system in high arsenic phosphorus ore pre-dearsenization.

Owner:KUNMING UNIV OF SCI & TECH

A method for synergistic arsenic fixation by hydrothermal reduction and mineralization

ActiveCN109095576BReduce the toxicity of dissolutionLight in massArsenic sulfidesUnderground miningSulfateSulfidation

A method for synergistic arsenic fixation by hydrothermal reduction mineralization, adding ferrous sulfate to the arsenic-containing solution, adding sodium sulfide at a required pH value to precipitate arsenic sulfide-ferrous sulfide composite precipitate, the composite precipitate and reduction After the agent is mixed with water, it is added to the high-pressure reactor, and the temperature is controlled for a certain period of time to convert the composite precipitate into an arsenic-fixed product with a mineral crystal form, and finally achieve the purpose of reducing the dissolution toxicity of the arsenic-fixed product. The essence of the present invention is to realize the synergistic solidification of arsenic by using two processes of sulfide co-precipitation and hydrothermal reduction mineralization, so as to achieve the dual purposes of increasing the arsenic content in the arsenic-fixed product and reducing the toxicity of arsenic dissolution. The invention has the advantages of low dissolution toxicity, small quality of arsenic-fixed product, stable technical index and the like.

Owner:CENT SOUTH UNIV

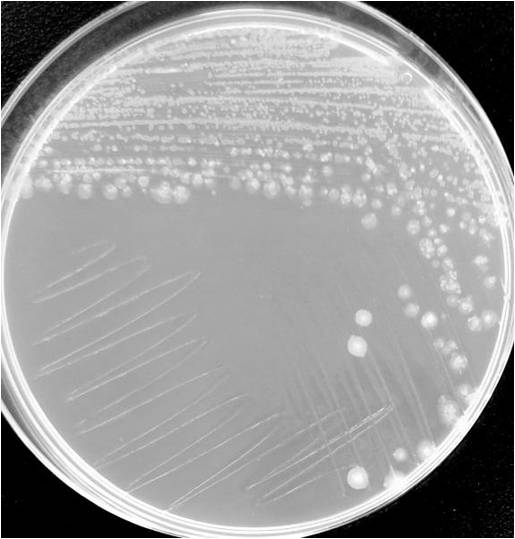

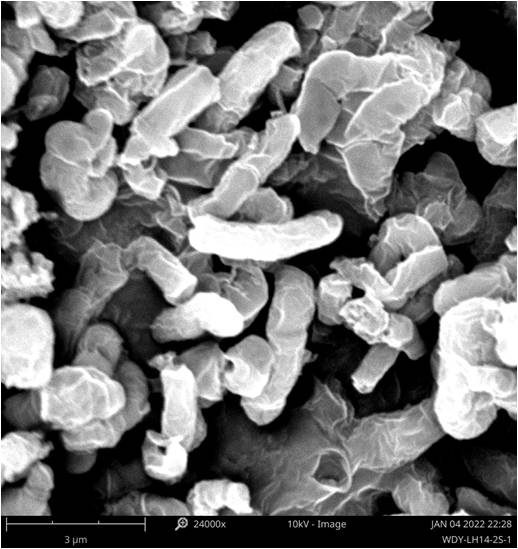

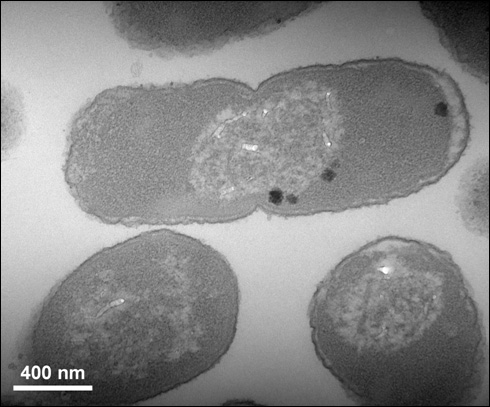

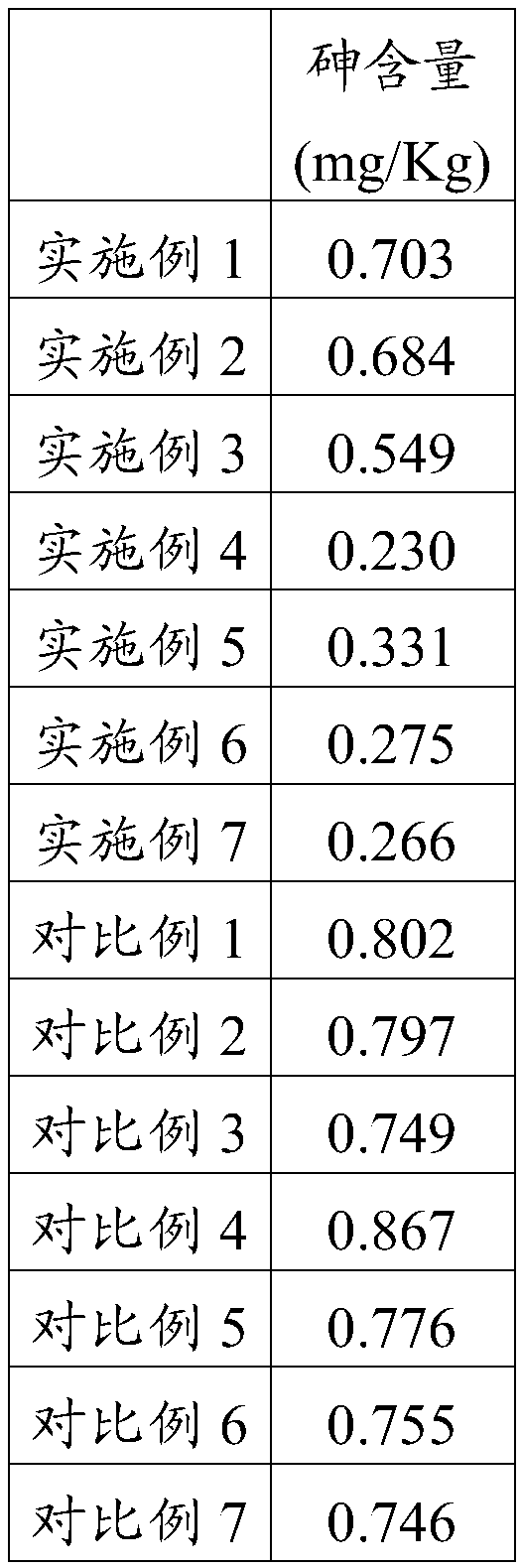

Bacillus with aerobic arsenic methylation and volatilization functions and application thereof

ActiveCN114410553ALow toxicityWeak toxicityPlant growth regulatorsBiocideArsenic pollutionBacterial strain

The invention discloses bacillus with aerobic arsenic methylation and volatilization functions and application thereof, and belongs to the technical field of microorganisms. The name of the bacterial strain is bacillus subtilis LH14, the bacterial strain is preserved in Guangdong Microbial Culture Collection Center (GDMCC) on December 2, 2021 in No.59 building, No.100 Courtyard, Xianlie Middle Road, Guangzhou City, Guangdong Province, and the preservation number is GDMCC No: 62092. The bacillus LH14 has an obvious methylation effect on inorganic trivalent arsenic, a main methyl arsenic product is trimethyl arsenic, a secondary methyl arsenic product is dimethyl arsenic, and double detoxification functions of arsenic methylation and arsenic oxidation can be synchronously realized. The bacillus LH14 can obviously reduce the content of highly toxic inorganic arsenic, generates organic arsenic with low toxicity and volatile arsenic, and has important application potential in treatment and remediation of arsenic polluted environment, especially treatment and remediation of arsenic polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Treatment method and application of arsenic removal material

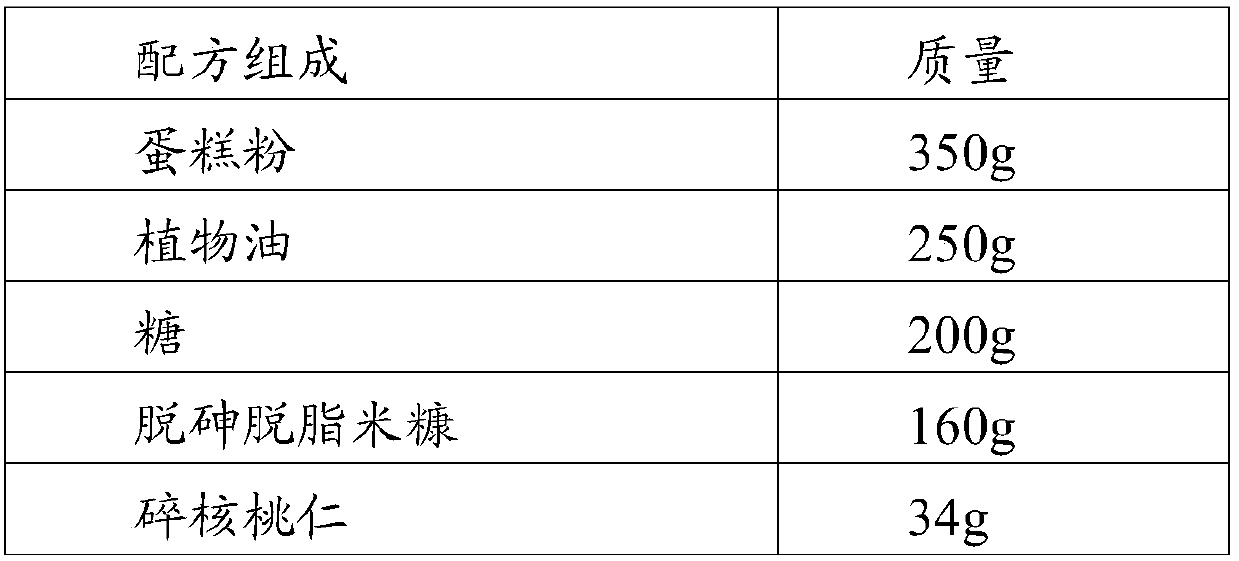

PendingCN111345431ALow in arsenicRich in mineralsSugar food ingredientsFood ultrasonic treatmentEnvironmental engineeringArsenic product

The present invention provides a treatment method of an arsenic removal material. The method comprises the following steps of performing reducer treatment on the arsenic removal material, and optionally performing ultrasonic treatment and / or alcohol stabilizer treatment on the arsenic removal material. The present invention also provides the treated arsenic removal material obtained with the method and an application of the arsenic removal material. The present invention also provides a method for performing arsenic removal treatment on a substance to be subjected to arsenic removal, and an arsenic removal product prepared with the method and an application of the arsenic removal product.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com