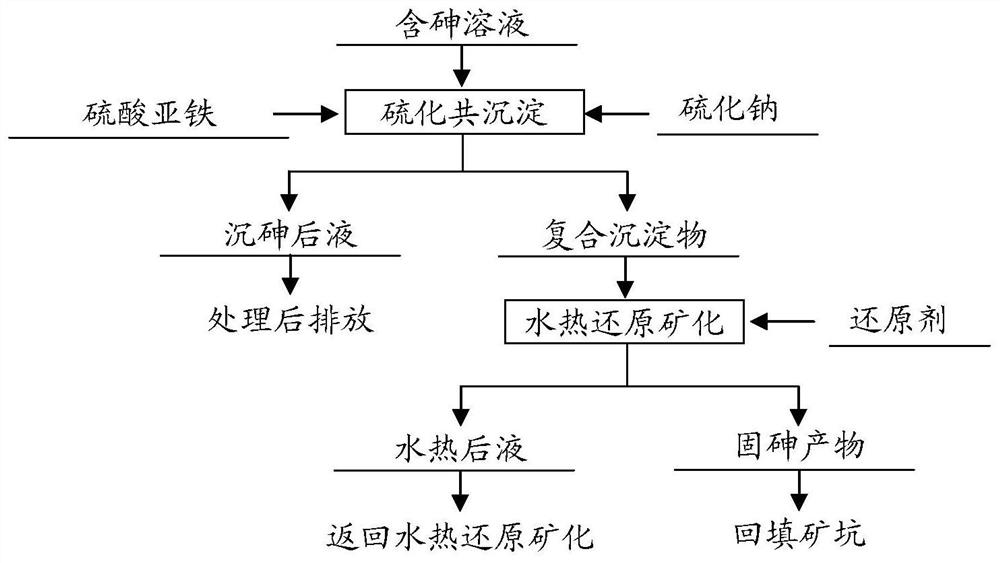

A method for synergistic arsenic fixation by hydrothermal reduction and mineralization

A hydrothermal and sodium sulfide technology, applied in chemical instruments and methods, arsenic sulfide, reduced water/sewage treatment, etc., can solve the problems of high leaching rate of solidified body, poor durability, low arsenic content, etc., and reduce storage space demand, reduce dissolution toxicity, and stabilize technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

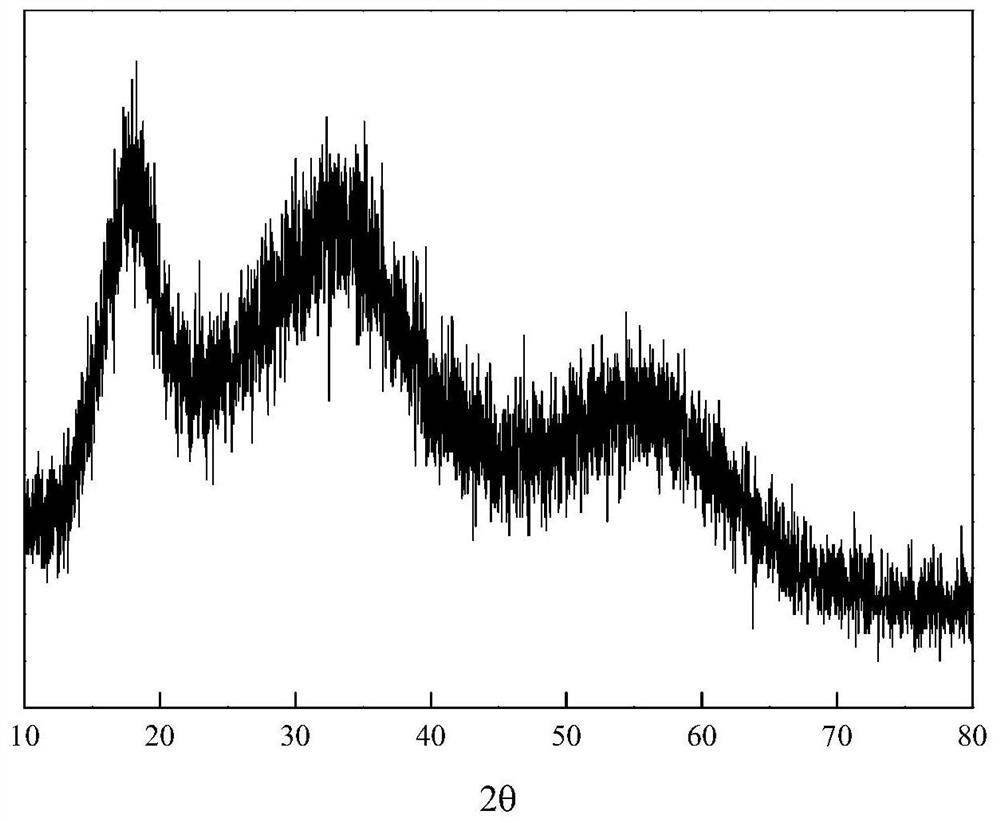

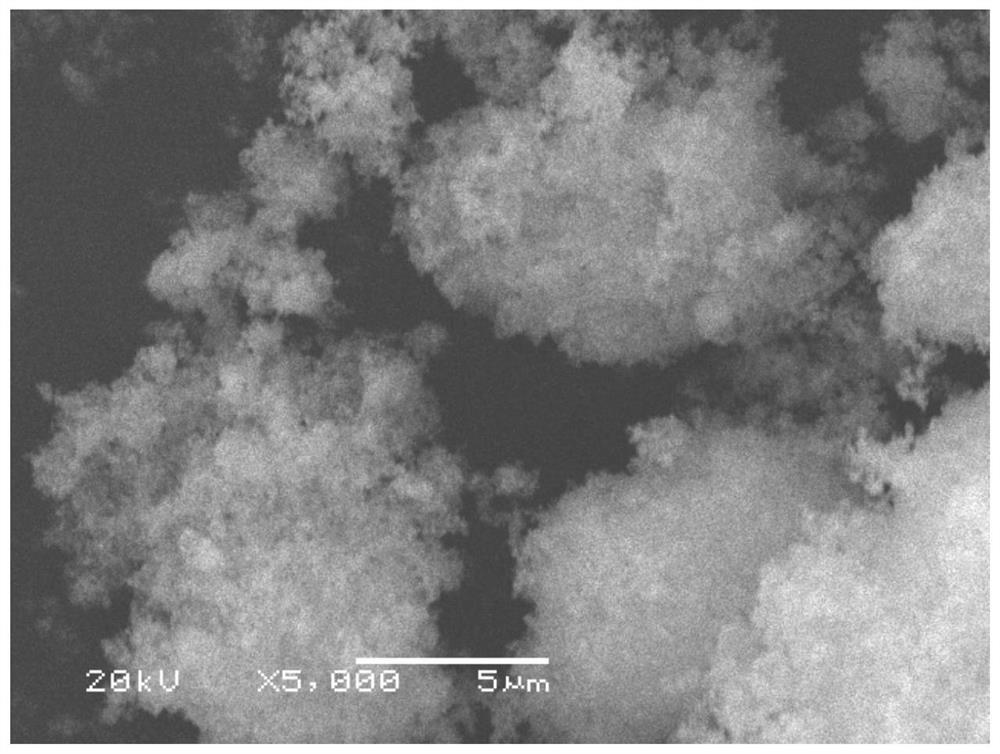

Embodiment 1

[0026]The arsenic concentration in the arsenic-containing solution is 11000mg / L, the pH is 0.3, ferrous sulfate, concentrated sulfuric acid, sodium hydroxide, sodium sulfide and glucose are all industrial grade reagents. Add ferrous sulfate to the arsenic-containing solution, control the molar ratio of Fe / As in the solution to 0.5 / 1, and then use a sodium sulfide solution with a concentration of 100g / L to control the molar ratios of sodium sulfide, arsenic and iron to 1.5 / 1 respectively and 1.0 / 1, add concentrated sulfuric acid to adjust the pH of the solution to 4.5, and react at a temperature of 60°C for 60 minutes. After the reaction, vacuum filtration is used to separate the liquid from the solid; Slurry with water at a ratio of 3 to 10 / 1, then add glucose with a weight of 2.0% of the composite sediment as a reducing agent, add the mixed slurry into a stainless steel high-pressure reactor, and feed nitrogen into the reactor to discharge residual air. Ventilate for 2 minute...

Embodiment 2

[0028] The concentration of arsenic in the solution containing arsenic is 12500 mg / L, the pH is 0.1, ferrous sulfate, concentrated sulfuric acid, sodium hydroxide, sodium sulfide and glucose are all industrial grade reagents. Add ferrous sulfate to the arsenic-containing solution, control the molar ratio of Fe / As in the solution to 0.7 / 1, and then use a sodium sulfide solution with a concentration of 100g / L to control the molar ratios of sodium sulfide, arsenic and iron to 1.7 / 1 respectively and 1.0 / 1, add concentrated sulfuric acid to adjust the pH of the solution to 4.0, react at a temperature of 60°C for 60 minutes, and separate the liquid and solid by vacuum filtration after the reaction; Slurry with water at a ratio of 3 to 10 / 1, then add glucose with a weight of 2.5% of the composite sediment as a reducing agent, add the mixed slurry into a stainless steel high-pressure reactor, and feed nitrogen into the reactor to discharge the residual air. Ventilate for 2 minutes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com