Method for preparing high-purity metal arsenic from non-ferrous smelting arsenic-containing solid waste in short process

A short-process, metal arsenic technology, which is applied in the direction of improving process efficiency, can solve problems such as the difficulty of separating arsenic from similar impurities, and achieve the effects of industrial production, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

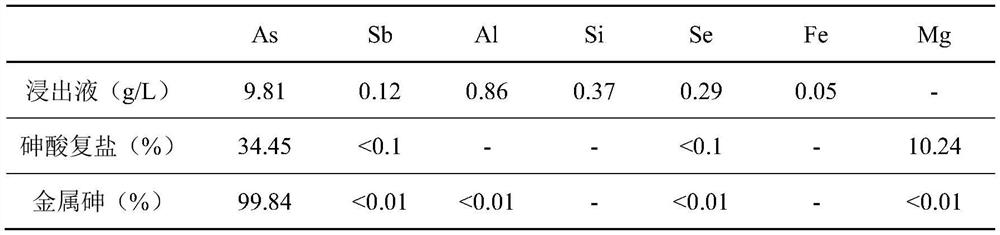

Embodiment 1

[0027] Take 5kg arsenic alkali slag (main components are As: 4.29%, Sb: 1.62%, Al: 2.41%, Fe: 0.89%, alkali (mainly sodium carbonate): 54.71%) and mix it with 20L water, because the arsenic alkali slag itself It contains alkali, so only an appropriate amount of hydrogen peroxide is added during the leaching process, instead of sodium hydroxide or sodium carbonate. The leaching temperature is controlled at 50 ° C, the stirring intensity is 500 rpm, and the leaching time is 1.5 h. After the leaching is completed, the solid-liquid separation is performed to obtain alkali The main components of the arsenic-containing leaching solution are shown in Table 1, of which the arsenic leaching rate is 92.15%.

[0028] After mixing magnesium oxide and ammonium bicarbonate according to a molar ratio of n(Mg / N)=0.5, then mixing sodium polyacrylate and the mixed agent according to a mass ratio of 5 mg / g to prepare a mixed magnesium ammonium reagent. Chitosan was mixed with 100°C hot water at ...

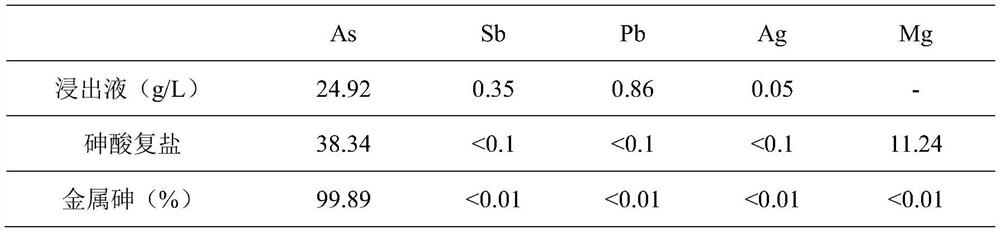

Embodiment 2

[0043] Take 5kg of lead anode slime (the specific components are Pb: 12.88%, As: 27.53%, Sb: 24.92%, Ag: 5.08%, in which arsenic mainly exists in the form of elemental substance and oxidation state) to carry out oxidative alkali leaching, add an appropriate amount during the leaching process Hydrogen peroxide was used as the oxidant, the liquid-solid ratio was controlled to be 10mL:1g, the dosage of sodium carbonate and sodium hydroxide were both 1mol / L, the temperature was 60°C, the leaching time was 2h, and the stirring speed was 500rpm. After the leaching reaction was completed, the solid-liquid Separation to obtain alkaline arsenic-containing leaching solution, the main components are shown in Table 2, wherein the arsenic leaching rate is 90.47%.

[0044] After mixing magnesium chloride and ammonium chloride according to a molar ratio of n(Mg / N)=0.4, then mixing polyethylene glycol with the mixed agent according to a mass ratio of 8 mg / g to prepare a mixed magnesium-ammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com