Method for preparing high-purity pyrite through flotation mass transfer kinetics regulation and control

A high-purity sulfur and kinetic technology, applied in flotation, solid separation and other directions, can solve the problems of not reaching high-purity pyrite, complicated process design, complicated process, etc., and achieve easy industrial production, reasonable process structure, The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Target of treatment: Copper-sulfur flotation separation tailings of Yunnan polymetallic oxygen-sulfur mixed mine

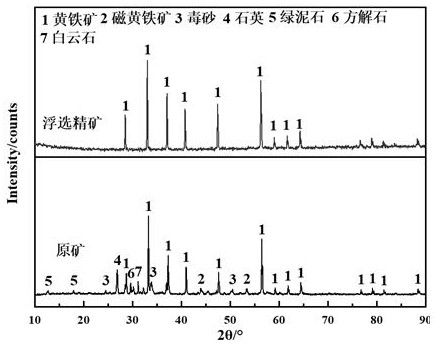

[0024] Copper-sulfur flotation separation tailings is the product in the tank obtained by floating copper sulfide minerals as foam products. Its main chemical components are: S 34.25%, As 5.2%, Fe 30.26%, Cu 0.13%, The main minerals are pyrite, arsenopyrite, pyrrhotite, quartz, calcite, chlorite, etc., specifically as figure 2 shown. The particle size of copper-sulfur flotation separation tailings is -74μm, accounting for 96.5%, of which -18μm accounts for 47.8%, which belongs to fine-grained minerals.

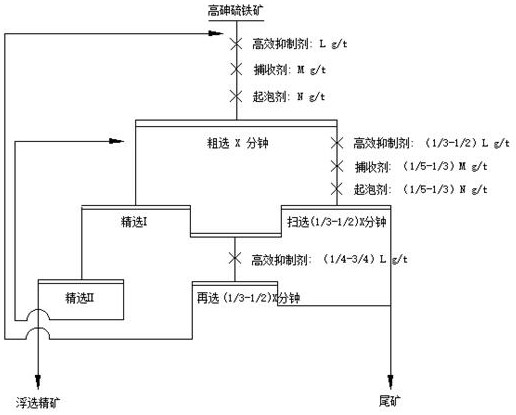

[0025] Mix the ore sample and water in the mixing drum, feed 2 L / min of nitrogen, control the rotation speed at 200 r / min, and mix for 5 minutes to prepare a uniform slurry with a solid mass concentration of 21%, creating a new environment for flotation kinetics. condition. Add 950 g / t of high-efficiency inhibitor, 115 g / t of butyl xanthate and 40 g / t o...

Embodiment 2

[0028] Target of treatment: Inner Mongolia polymetallic sulfide ore flotation tailings

[0029] Flotation tailings is the product in the tank obtained after the copper, lead and zinc sulfide minerals are floated out as foam products. Its main chemical components are: S 33.72%, As 4.6%, Fe 28.79%, Pb 0.15%, Zn 0.35%, the main minerals are pyrite, arsenopyrite, pyrrhotite, quartz, dolomite, etc. The particle size of high-arsenic pyrite is -74μm, accounting for 92.5%, of which -18μm accounts for 45.2%. It is a kind of fine-grained high-arsenic pyrite that is easily oxidized. The ore sample was mixed with water in the mixing drum, 1.5 L / min of nitrogen gas was introduced, and the rotational speed was controlled at 180 r / min. After mixing for 6 minutes, a uniform slurry with a solid mass concentration of 18.5% was prepared to create a good buoyancy. Select the mass transfer kinetics conditions; add 1100 g / t of high-efficiency inhibitor, 155 g / t of xanthate and 45 g / t of terpineol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com