Patents

Literature

37results about How to "Achieve deep separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-water separating device and method

ActiveCN101972559AWith deep separationAchieve deep separationNon-miscible liquid separationOil waterPolypropylene

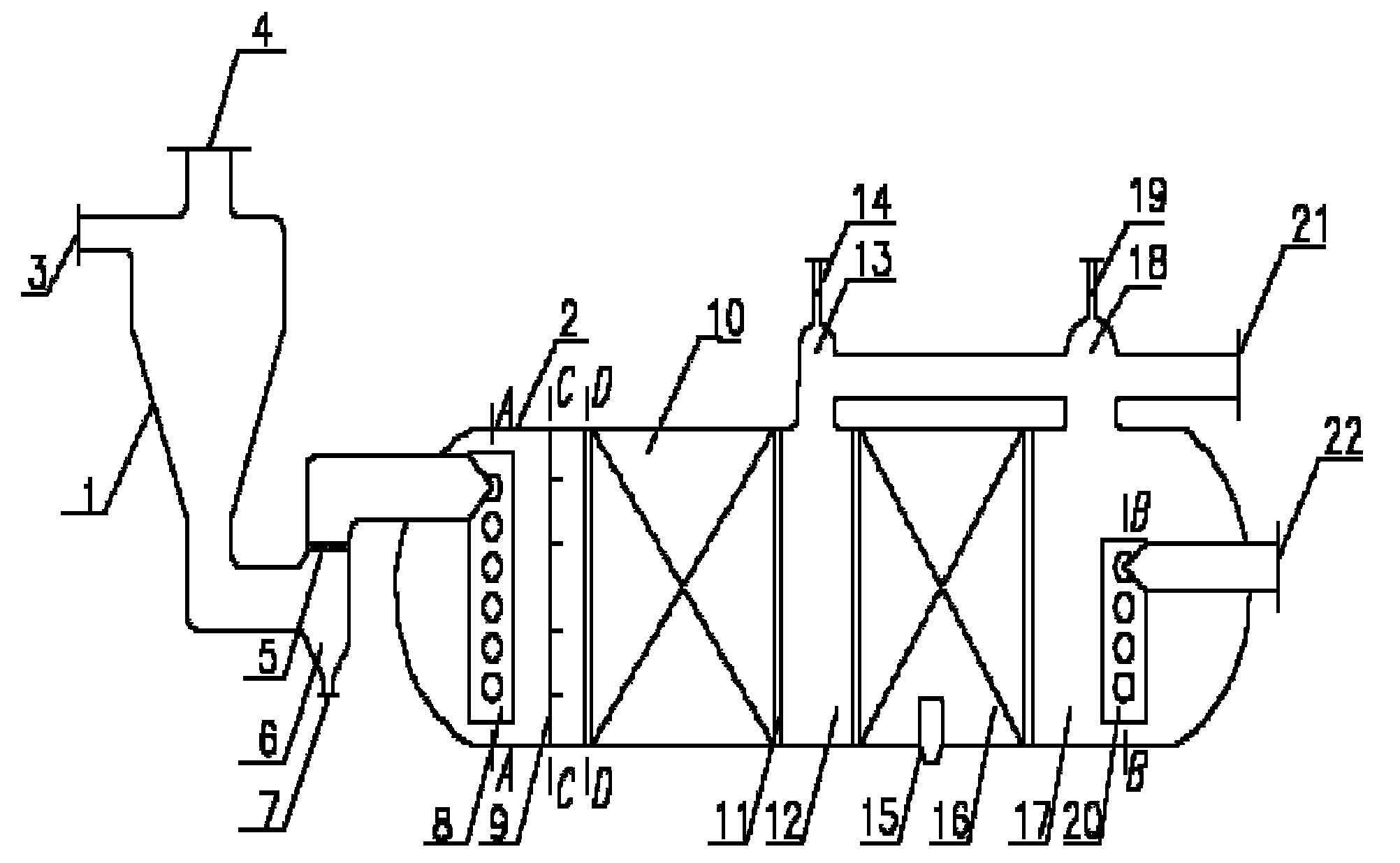

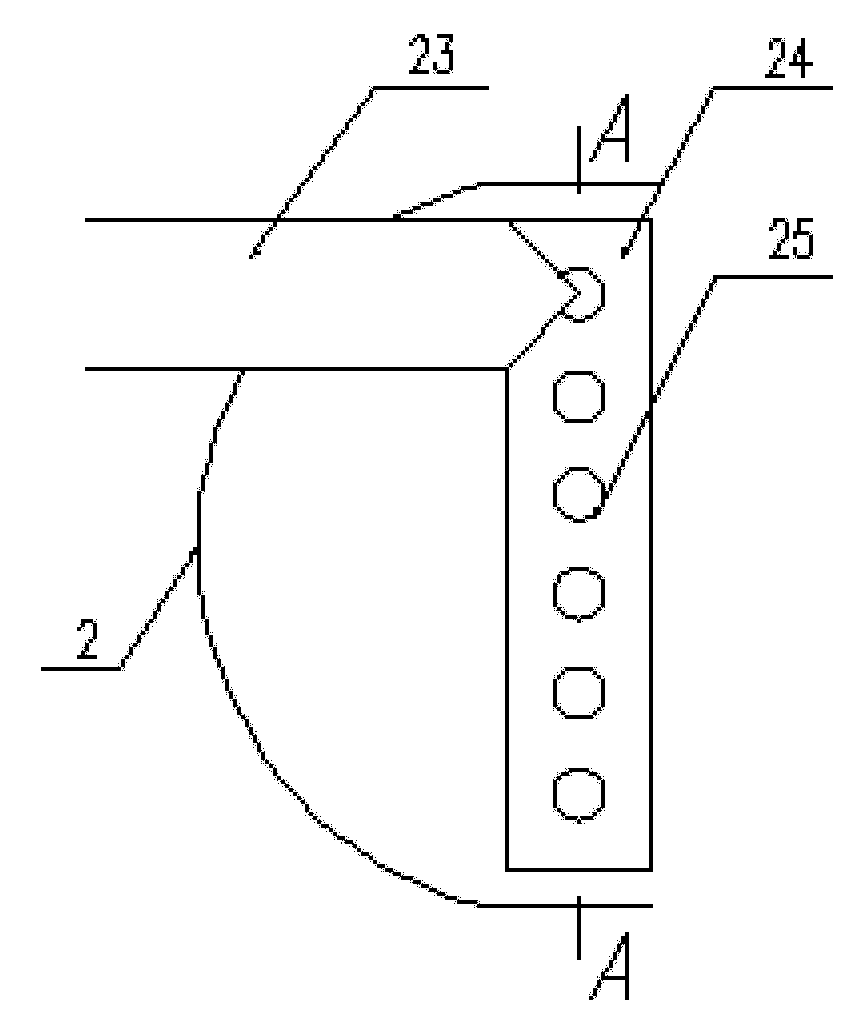

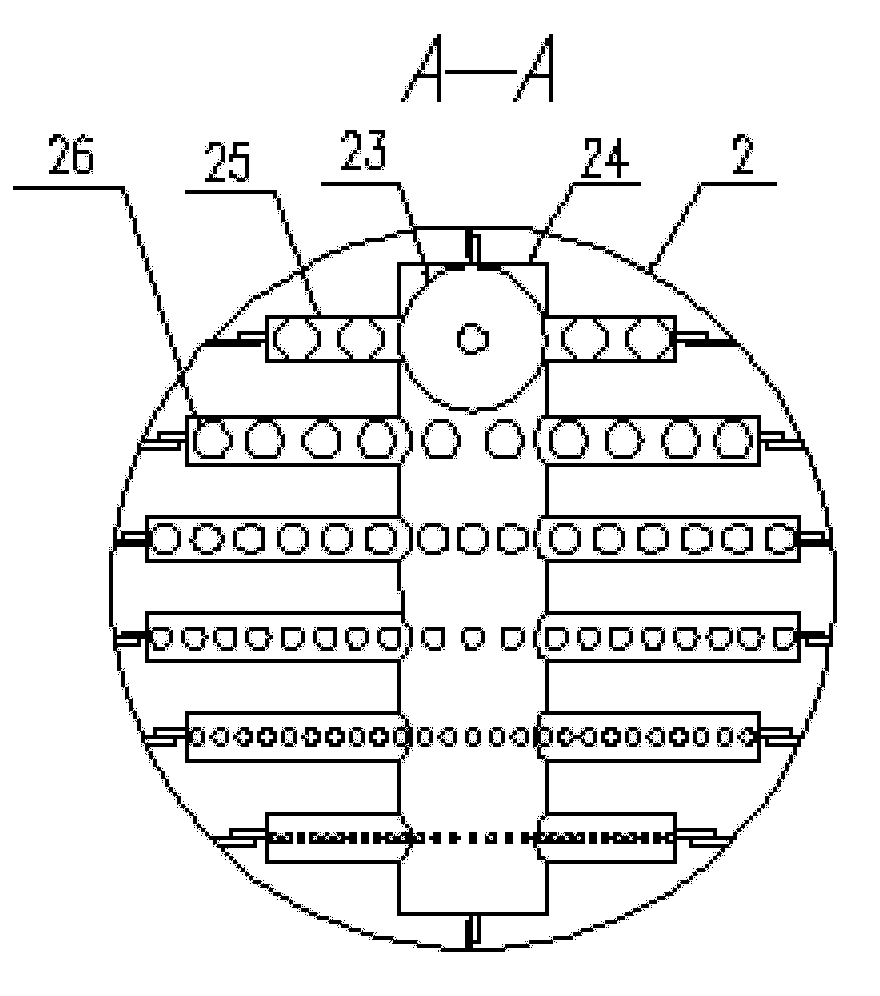

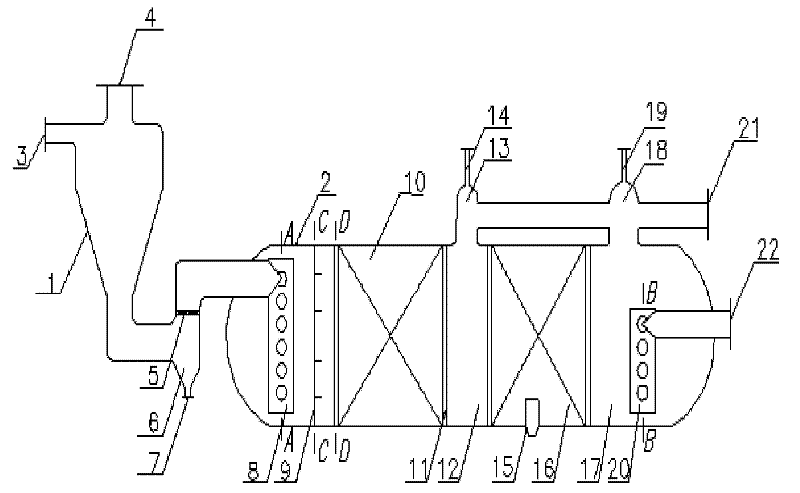

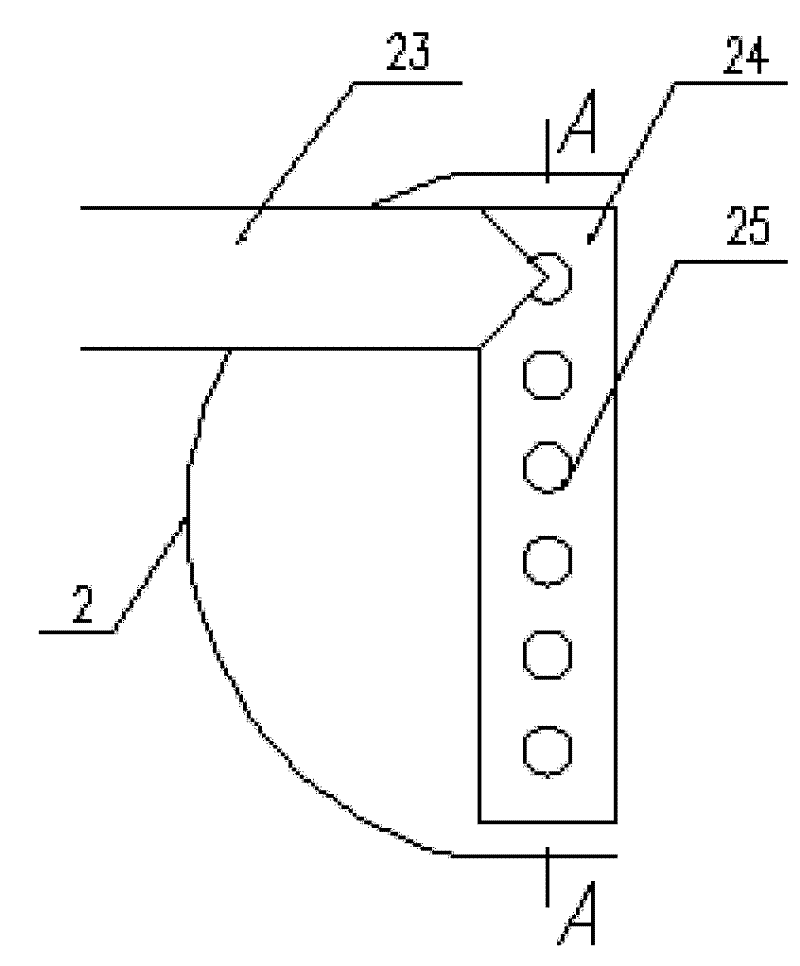

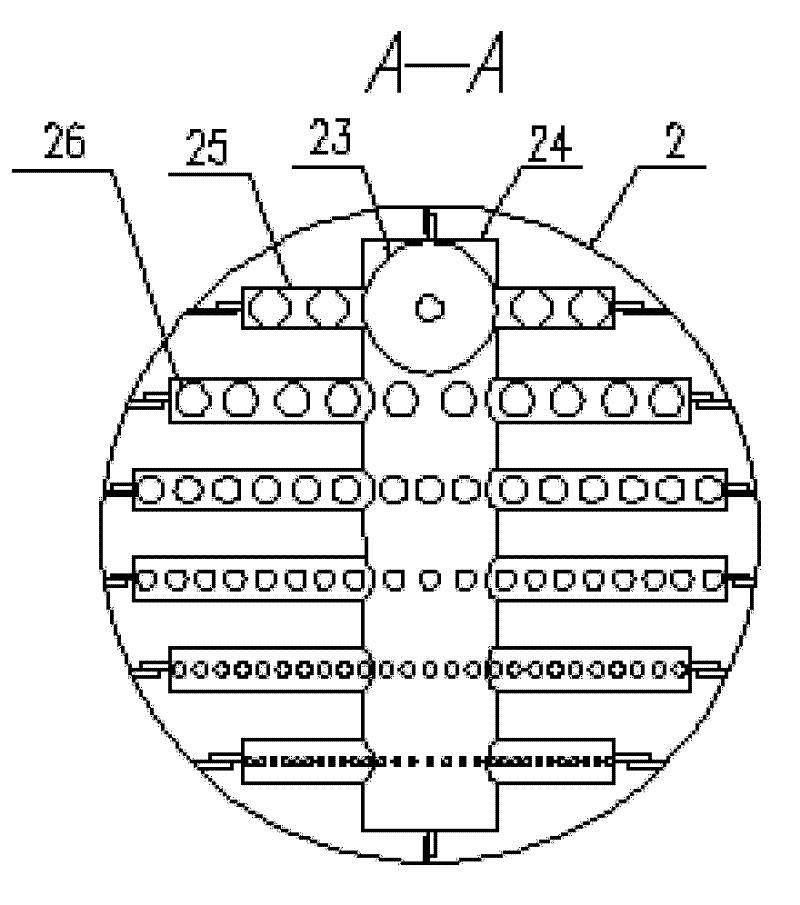

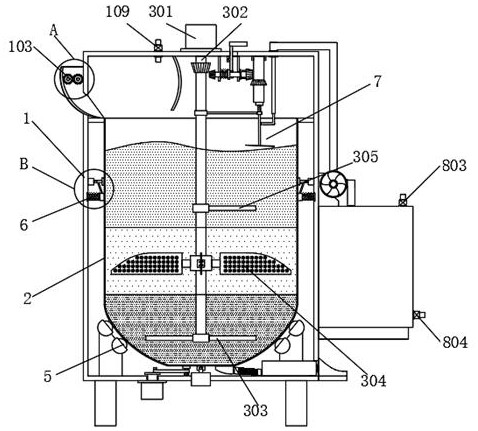

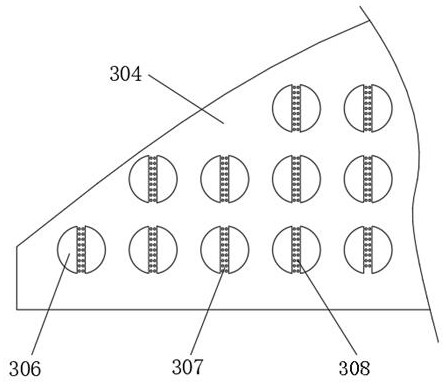

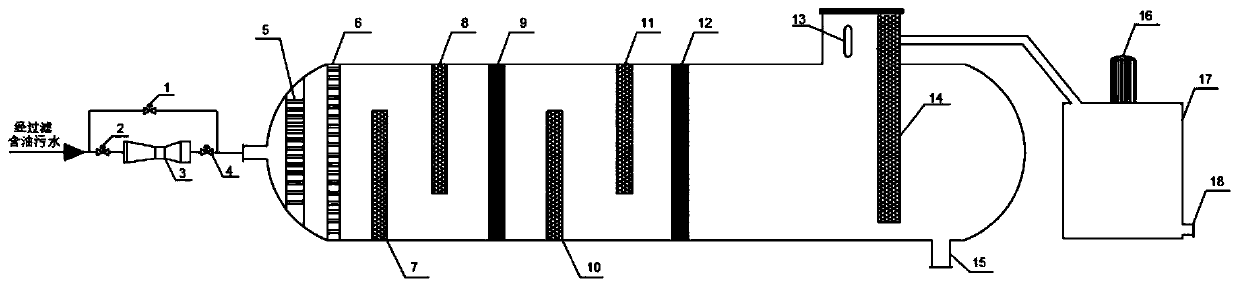

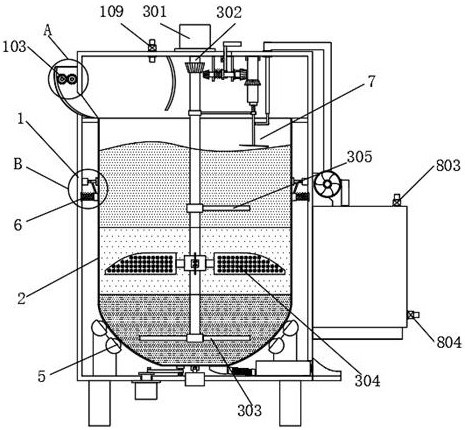

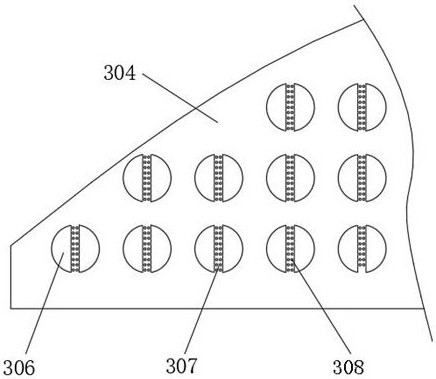

The invention discloses oil-water separating device and method. The oil-water separating device comprises a swirler and a horizontal type agglutinating oil-water separator, wherein a bottom flow pipe of the swirler is in a U shape; the horizontal type agglutinating oil-water separator has the liquid uniform distributing function; an inlet liquid distributor, a rectifying sieve plate, a stainless steel plate ripple filler, a polypropylene gauze ripple filler, an outlet liquid collector, and the like are sequentially arranged in the horizontal type agglutinating oil-water separator, and the stainless steel plate ripple filler and the polypropylene gauze ripple filler are fixed by a limit grid plate; the U-shaped bottom flow pipe of the swirler and a filter screen arranged in the swirler can filter a small number of solid impurities contained in liquid so as to prevent the blockage of agglutinated fillers; the inlet liquid distributor and the outlet liquid collector ensure that the liquid is uniformly distributed; the rectifying sieve plate reduces the flow rate of the liquid to form lamellar flow; the stainless steel plate ripple filler provides a place for agglutinating and separating oil drops; and the polypropylene gauze ripple filler with an air floating device can further agglutinate and separate residual fine oil drops. The combination simultaneously has the effects of whirl, agglutination and air floatation and can realize the deep separation of oil and water.

Owner:TIANJIN UNIV

Method for separating and recycling vanadium and chromium from vanadate-chromate-containing solution

InactiveCN102676810AAchieve deep separationHigh recovery rateProcess efficiency improvementIon exchangeIon-exchange resin

The invention relates to a method for separating and recycling vanadium and chromium from a vanadate-chromate-containing solution, which is characterized in that by using the difference of between anion exchange potentials formed by hexavalent chromium and quintavalent vanadium in water solutions by weak alkali and strong alkali anion exchange resins, saturation adsorption is utilized to implement deep separation of vanadium and chromium, thereby obtaining the vanadium and chromium products. The invention has the characteristics of short technological process, favorable separating effect, environment friendliness and the like, and is simple to operate. The invention can effectively shorten the technological process for separating and recycling vanadium and chromium from the vanadate-chromate-containing solution, enhance the separating effect of vanadium and chromium, lower the recycling cost of vanadium and chromium, and save the reagent consumption; and vanadium and chromium in the solution are deeply separated through ion exchange and are respectively recycled. The invention is suitable for industrialized application.

Owner:CENT SOUTH UNIV

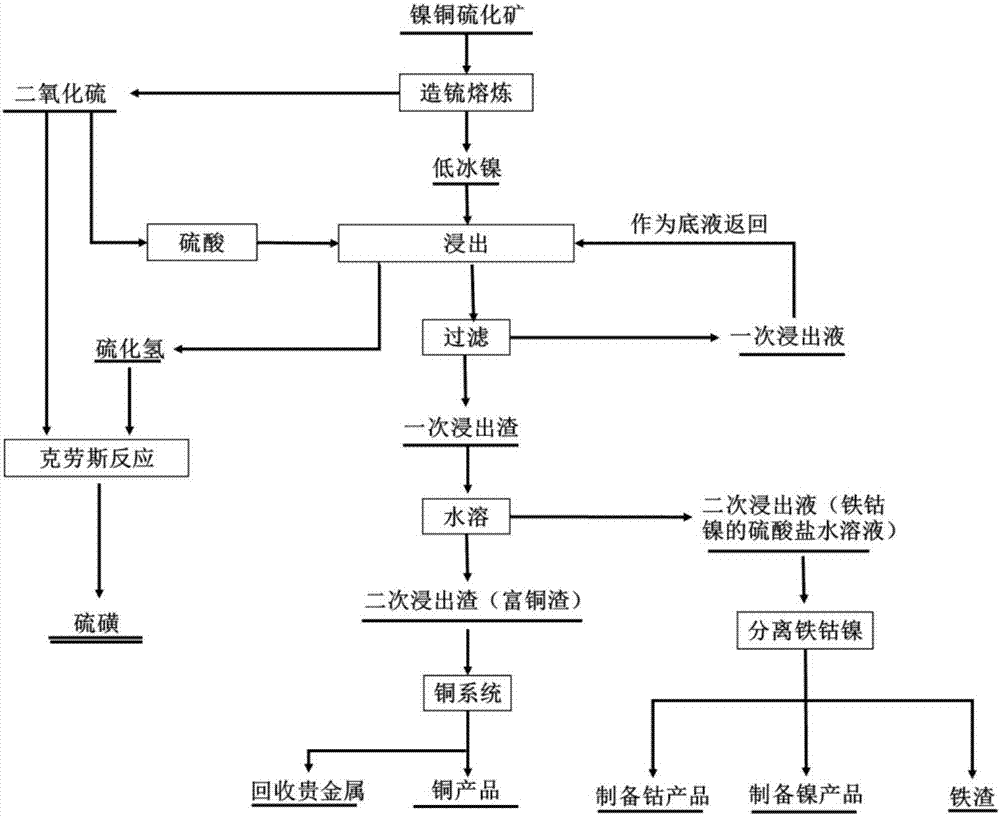

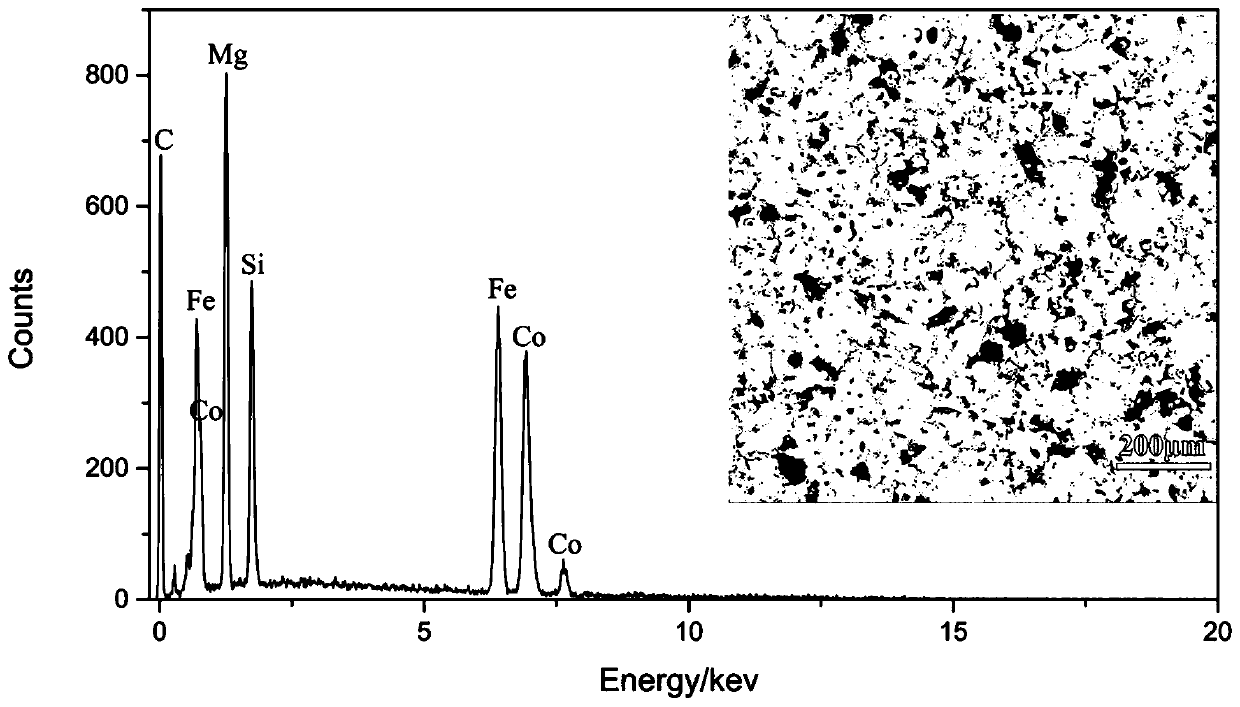

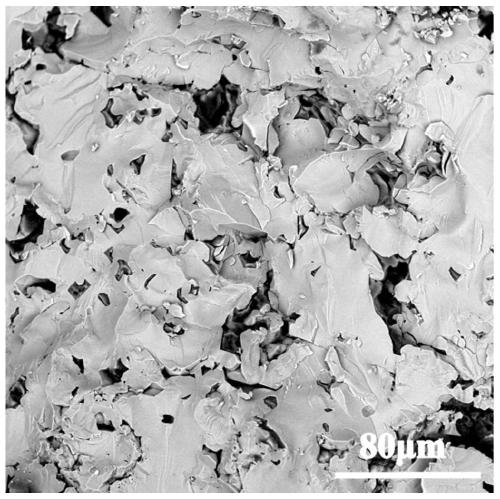

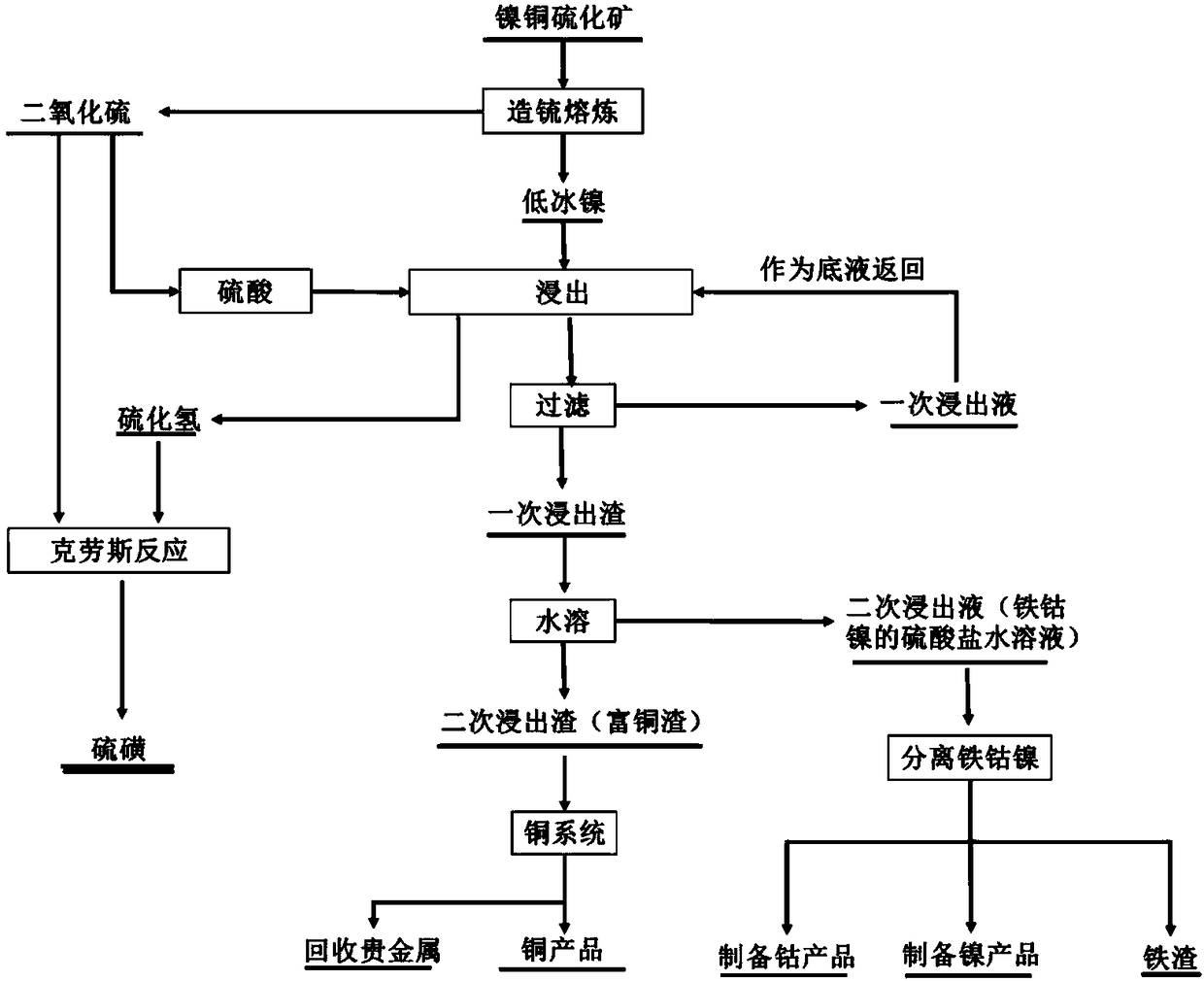

Method and system for recovering main associated elements from copper-nickel sulfide ore

ActiveCN107012324AAchieve deep separationImprove efficiencyProcess efficiency improvementSlagNickel sulfide

The invention provides a method and system for recovering main associated elements from copper-nickel sulfide ore. The method comprises the following steps: 1, continuously adding low-grade nickel matte and a leaching reaction solution into a reaction base solution, carrying out selective leaching, and collecting hydrogen sulfide gas, a first leaching solution and a first leaching residue, wherein the leaching reaction liquid is sulfuric acid with the mass fraction being 60-95%; 2, adding water into the first leaching residue for dissolving the first leaching slag, and collecting a second leaching solution and a second leaching residue; and 3, removing iron from the second leaching solution, collecting an iron-removed solution used for extracting nickel and cobalt and an iron-removed residue used for iron making, and / or sending the second leaching residue to a copper smelting device for smelting to obtain copper and noble metal. According to the method, deep separation of the nickel and the copper can be realized, and recovery of the nickel, the copper, the cobalt, the noble metal and sulfur can be effectively realized. The method is simple in process, short in flow and high in efficiency, is a clean and efficient element recovery process and is easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

Oil-water separating device and method

ActiveCN101972559BWith deep separationAchieve deep separationNon-miscible liquid separationOil waterPolypropylene

The invention discloses oil-water separating device and method. The oil-water separating device comprises a swirler and a horizontal type agglutinating oil-water separator, wherein a bottom flow pipe of the swirler is in a U shape; the horizontal type agglutinating oil-water separator has the liquid uniform distributing function; an inlet liquid distributor, a rectifying sieve plate, a stainless steel plate ripple filler, a polypropylene gauze ripple filler, an outlet liquid collector, and the like are sequentially arranged in the horizontal type agglutinating oil-water separator, and the stainless steel plate ripple filler and the polypropylene gauze ripple filler are fixed by a limit grid plate; the U-shaped bottom flow pipe of the swirler and a filter screen arranged in the swirler canfilter a small number of solid impurities contained in liquid so as to prevent the blockage of agglutinated fillers; the inlet liquid distributor and the outlet liquid collector ensure that the liquid is uniformly distributed; the rectifying sieve plate reduces the flow rate of the liquid to form lamellar flow; the stainless steel plate ripple filler provides a place for agglutinating and separating oil drops; and the polypropylene gauze ripple filler with an air floating device can further agglutinate and separate residual fine oil drops. The combination simultaneously has the effects of whirl, agglutination and air floatation and can realize the deep separation of oil and water.

Owner:TIANJIN UNIV

Method for deeply separating molybdenum and vanadium in solution containing molybdenum and vanadium

InactiveCN105692698ASimple processShort processVanadium compounds preparationMolybdeum compounds preparationIonIon exchange

The invention relates to a method for deeply separating molybdenum and vanadium in a solution containing the molybdenum and the vanadium. The method includes: regulating the acidity [H<+>] of the solution containing the molybdenum and the vanadium to be 0.0003-10mol / L, and then using the compound of Mo(IV) or / and Mo(V) as the reducing agent to selectively reduce the vanadium in the solution to obtain liquid after reduction; regulating the pH of the liquid after reduction to be 4-7, settling the vanadium, and using an ion exchanging method or extraction method to enrich the molybdenum; or regulating the pH of the liquid after reduction to be 2-4, using an ion exchanging method or extraction method to enrich the molybdenum, then regulating the pH to 4-7, and settling the vanadium. The method has the advantages that the E<0>Mo(VI) / Mo(V) and E<0>V(V) / V(IV) potential differences under an acidic condition are utilized, the compound of Mo(IV) or / and Mo(V) as the reducing agent to selectively reduce the V(V) in the solution into V(IV), and the maximum differentiation of the properties of the molybdenum and the vanadium in the solution is achieved; the property that anion exchange resin or basic extractant can only selectively enrich the Mo(VI) in the solution and cannot absorb the V(IV) is utilized to deeply separate the molybdenum and the vanadium; the method is simple in process, short in process flow, convenient to operate, good in molybdenum-vanadium separation effect, low in treatment cost, environmental friendly, suitable for industrial application, and the like.

Owner:CENT SOUTH UNIV

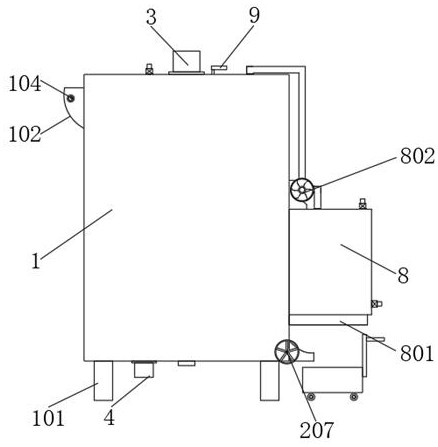

Oil-sludge separation equipment for oil field based on oil-sludge treatment and separation method of oil-sludge separation equipment

ActiveCN113321398AEasy to separateEfficient separationSludge treatmentSpecific water treatment objectivesOil fieldProcess engineering

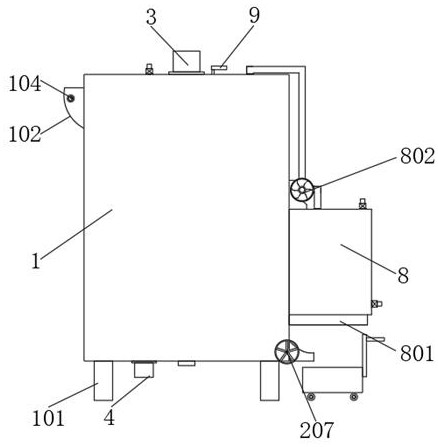

The invention relates to the technical field of oil-sludge separation equipment, and in particular, relates to oil-sludge separation equipment for an oil field based on oil-sludge treatment and a separation method of the oil-sludge separation equipment. The oil-sludge separation equipment comprises a shell, a separation tank, a feeding grinding assembly, an oil-sludge separation structure, a vibration separation structure, a deflection protection universal ball, a vibration stabilizing structure, a telescopic oil nozzle assembly, an evaporation box and a transmission switch assembly. Deep separation of the sludge is realized through grinding of large particles of the oil sludge, high-speed stirring and mixing, low-speed stirring and separation, oscillation separation and collection and recovery, so that the oil sludge is layered and separated more thoroughly, the equipment operation is simpler, the oil sludge separation is more efficient, and the problem that traditional equipment can only remove sludge on a surface layer by means of calcination evaporation and is low in efficiency is solved.

Owner:东营金昱技术开发有限公司

Oil-water separation device and oil-water separation method

ActiveCN111450576ASimple structureImprove separation efficiencyNon-miscible liquid separationSeparation technologyWaste oil

The invention provides an oil-water separation device and an oil-water separation method, belonging to an oil-water separation technology in the field of environmental protection. The oil-water separation device is simple in structure, high in separation efficiency and capable of operating for a long period. The oil-water separation device comprises an oil-water separation unit, wherein a liquid distributor, a liquid rectifier, an oil drop gathering partition plate, an oil-water layering strengthening partition plate and a dirty oil leading-out partition plate are arranged in the oil-water separation unit; and multiple structures in the oil-water separation unit are orderly arranged, so separation of oil and water in oily wastewater is facilitated. The oil-water separation device providedby the invention is high in oil-water separation efficiency, and can realize deep separation of oily wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

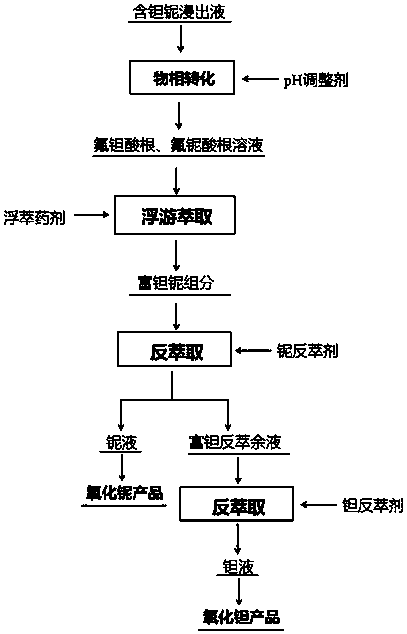

Method for selectively separating tantalum and niobium step by step based on floating extraction

ActiveCN111286608ASelective step-by-step separationEfficient enrichmentFlotationProcess efficiency improvementNiobiumPhysical chemistry

The invention discloses a method for selectively separating tantalum and niobium step by step based on floating extraction. The method comprises the following steps of adding hydrofluoric acid to a solution containing tantalum and niobium to convert tantalum and niobium in the solution into fluorotantalate and fluoroniobate; adding a floating extraction agent and a bubble dispersant to the solution and introducing air to form microbubbles, promoting the hydrophobic mineralization of bubbles to form fluorine tantalum / niobate-floating extraction agent-bubble microdroplets, and finally enrichingtantalum and niobium components by floating extraction; adding a pH adjuster and a niobium stripping agent to the tantalum-niobium-enriched component to obtain niobium liquid after stripping; and thenadding a pH adjuster and a tantalum stripping agent to a stripping raffinate and stripping to obtain a tantalum solution. The method has good selective separation effect on tantalum and niobium, simple process flow and low operation cost, effectively overcomes the shortcomings of multi-stage solvent extraction and stripping, and is particularly suitable for deep separation of tantalum and niobium.

Owner:ZHENGZHOU UNIV

Purification method of byproduct sodium chloride in betaine or betaine hydrochloride production

ActiveCN109134287AHigh purityAchieve recyclingOrganic compound preparationAmino-carboxyl compound preparationPurification methodsBetaine Hydrochloride

The invention relates to a purification method of the byproduct sodium chloride in betaine or betaine hydrochloride production. The method includes: preprocessing reaction mother liquor, preliminarilyseparating betaine and crude sodium chloride, performing secondary purification and separation, combining betaine and purifying, combining with the sodium chloride and purifying, refining and the like. The method has the advantages that the method is suitable large-scale industrial separation and purification and high in economic performance and environment protection performance and does not need procedures such as electrodialysis; the purified sodium chloride can meet feed grade standards, byproduct recycling is achieved, and the method is simple and does not generate secondary pollution.

Owner:山东祥维斯生物科技股份有限公司

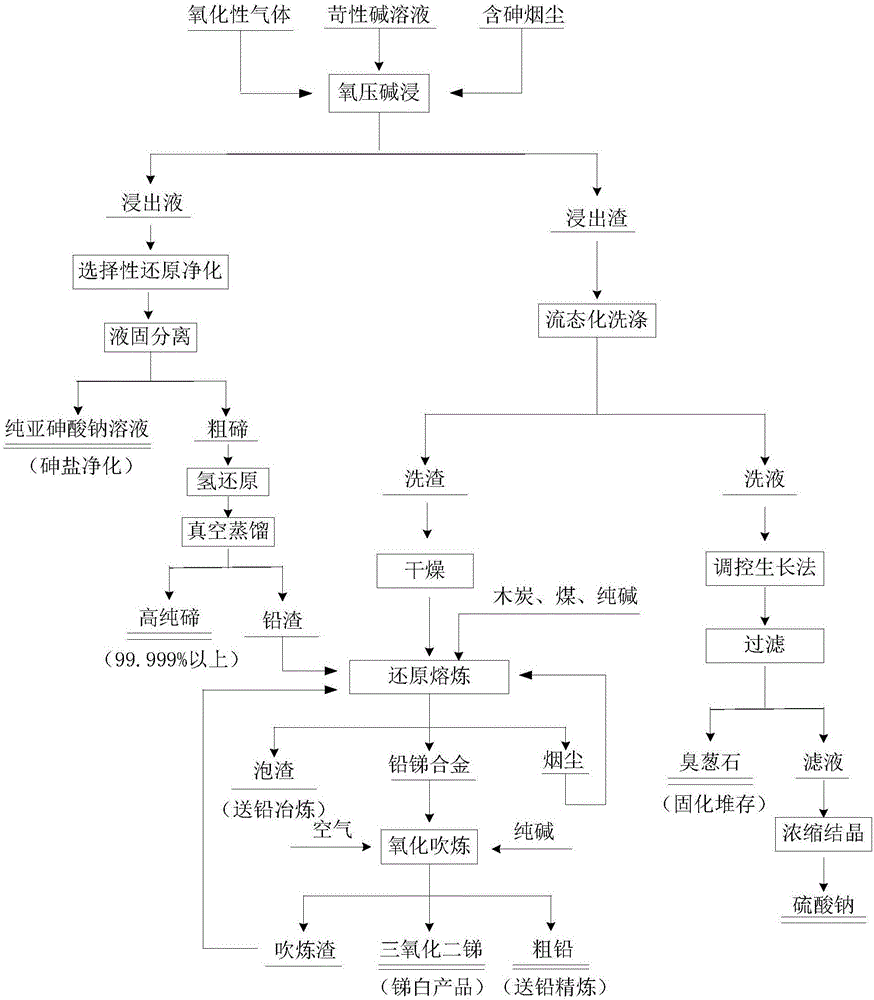

Harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke

The invention provides a harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke. All valuable elements are recycled and utilized through the procedures of carrying out oxygen pressure leaching via caustic alkali; carrying out selective reduction purification on leachate; during purification, carrying out hydrogen reduction and vacuum distillation on obtained crude tellurium so as to obtain high-purity tellurium; after purification, obtaining a pure sodium arsenite solution, and using the solution for the arsenic salt purification of a zinc sulfate solution so as to remove cobalt and nickel; carrying out fluidization washing on leaching residues; after washing, solidifying arsenic in the solution, and carrying out reduction smelting on the residues; and carrying out oxidization blowing and the like. The arsenic is removed from the smoke, stibium, lead, bismuth, stannum and the like are kept in the residues from which the arsenic is removed as much as possible, and the deep separation of the arsenic and the stibium is realized. The obtained pure sodium arsenite solution is used for the arsenic salt purification of the zinc sulfate solution used for wet-process zinc smelting so as to remove the cobalt and nickel raw materials, part of sodium arsenate with high impurity content is solidified, the arsenic is precipitated, the harmless recycling of the arsenic resource is realized, and the valuable elements, such as the tellurium, the stibium, the lead and the bismuth are recycled. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved.

Owner:CENT SOUTH UNIV

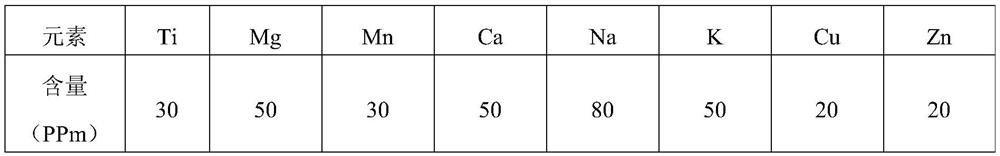

Method for deeply purifying titanium dioxide copperas

The invention belongs to the field of comprehensive utilization of titanium dioxide byproducts, and particularly relates to a method for deeply purifying titanium dioxide copperas. The technical problem to be solved by the invention is to provide a method for deeply purifying titanium dioxide copperas, and the method comprises the following steps of: A. dissolving a titanium dioxide byproduct copperas in sulfuric acid, adding iron powder, performing heating to boiling, keeping boiling, and carrying out solid separation to obtain a liquid 1; B. adding ammonium hydrogen sulfide or ammonium sulfide and ammonium phosphate into the liquid 1, adding ammonia water to adjust the pH value to 3-4, adding a flocculating agent, performing aging for layering, and conducting separating to obtain a liquid 2; and C, adding sulfuric acid into the liquid 2 to adjust the pH value to 2-3, conducting heating, concentrating, cooling and crystallizing to obtain the high-purity ferrous sulfate. According to the basic principle that the solubility of a double salt is smaller than that of a single salt, magnesium ions are precipitated and separated in the form of the double salt, deep separation of magnesium ion impurities is achieved, and the method has the advantages of simple process, high iron yield and good impurity removal effect.

Owner:PANZHIHUA UNIV

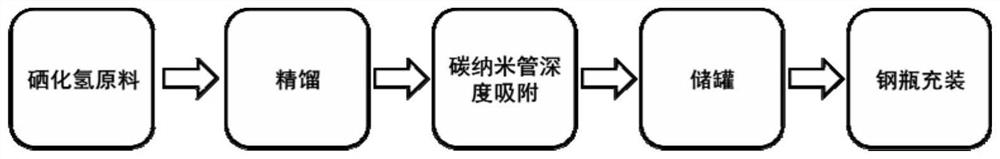

High-purity hydrogen selenide purification process utilizing carbon nanotubes

InactiveCN112142015AReduce pressure dropImprove the purification effectBinary selenium/tellurium compoundsActivated carbonSelenium hydride

Owner:SUZHOU JINHONG GAS CO LTD

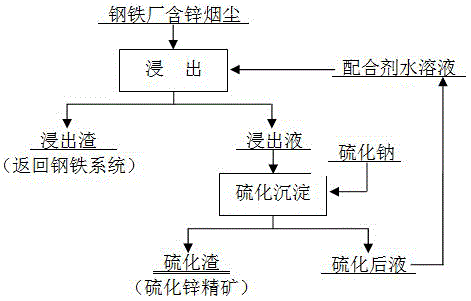

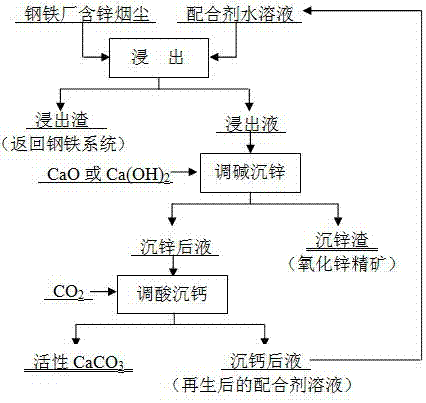

Method for treating steel plant zinc-containing smoke dust through wet process to realize enrichment of zinc sulfide concentrate

InactiveCN104946897ASmall side effectsAchieve deep separationProcess efficiency improvementSlagMaterials science

The invention relates to the field of comprehensive utilization of solid waste resources in a steel plant, in particular to a method for treating steel plant zinc-containing smoke dust through a wet process. According to the method, the steel plant zinc-containing smoke dust is leached through a compounding ingredient aqueous solution with glycine ions Gly<-> as ligand under weak-base conditions, during a leaching process, iron, carbon, calcium, magnesium and silicon are not dissolved and stay in leaching slag, and lead and cadmium enter leaching liquid with zinc; and the leaching slag is returned to a steel system for compounding sintering after water washing, the leaching liquid can be returned to the leaching process to be used after being subjected to sulfide precipitation, and obtained sulfide slag is zinc sulfide concentrate. According the invention, the process is short, and the operation is simple; a leaching system is mild, requirements for corrosion prevention of equipment are low, and less toxic and side effects on human bodies and the environment are realized; ultralow zinc grade zinc-containing smoke dust with high iron content can be treated to realize deep separation of iron and zinc; and toxic heavy-metal elements Zn, Pb and Cd in the steel plant zinc-containing smoke dust can be effectively removed.

Owner:JIANGSU UNIV

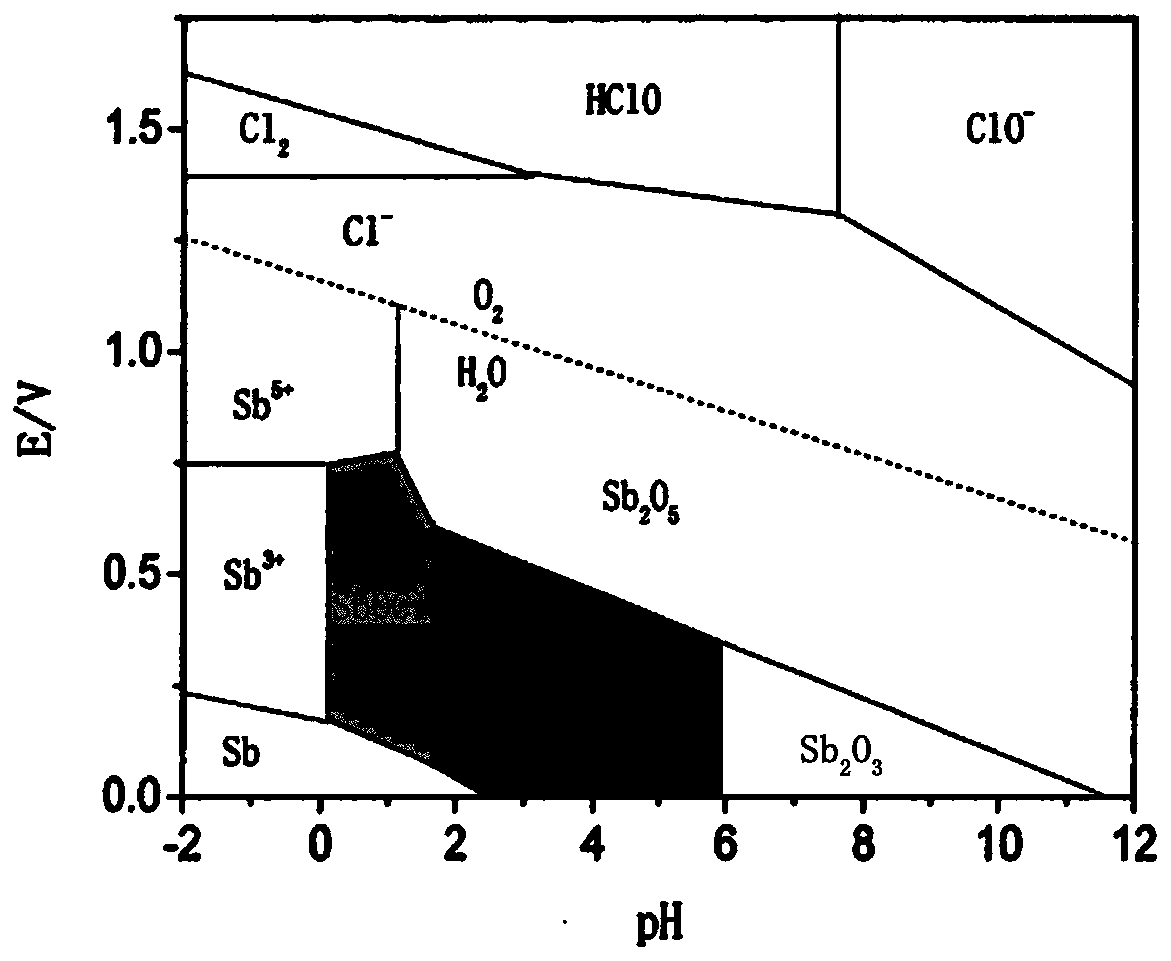

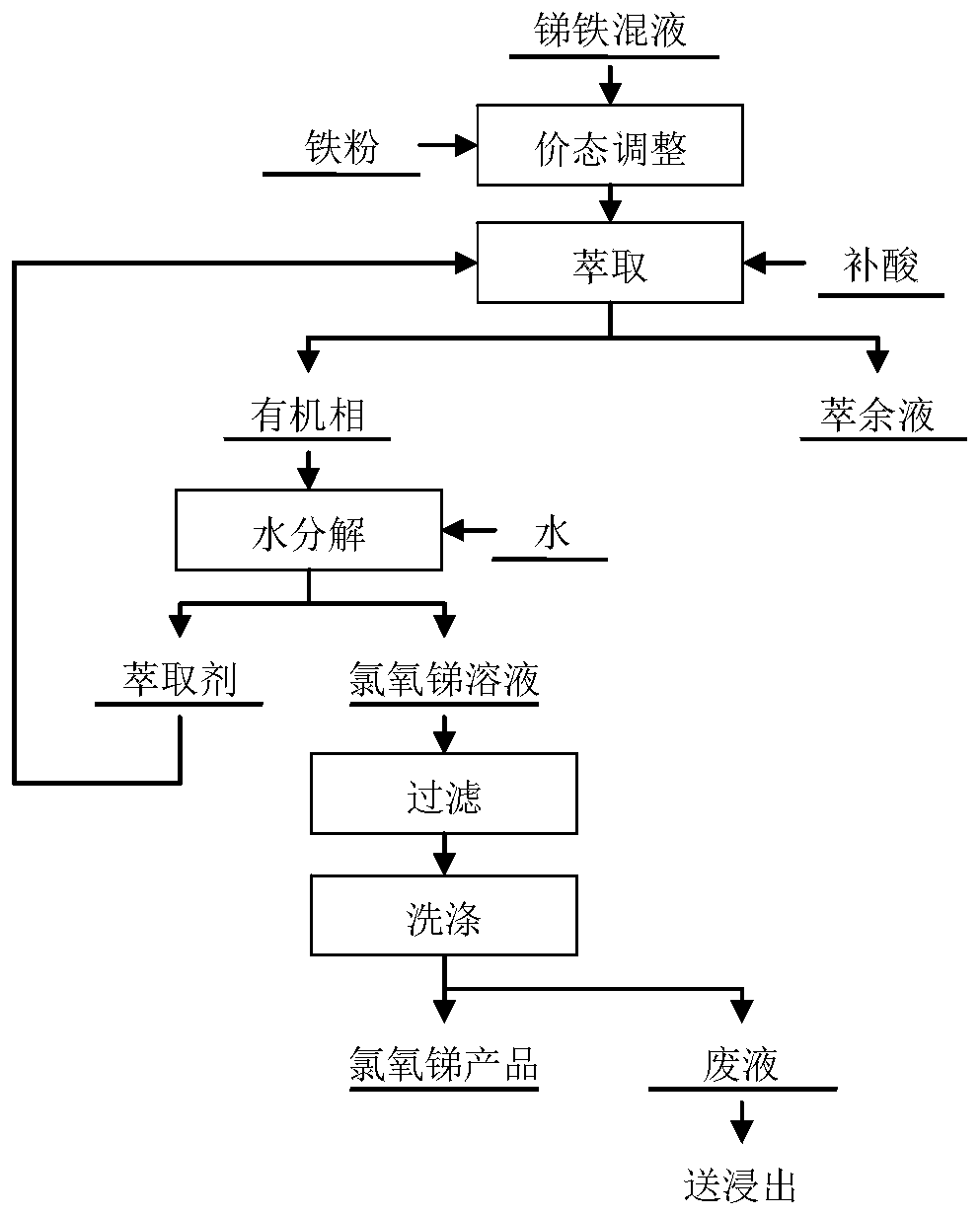

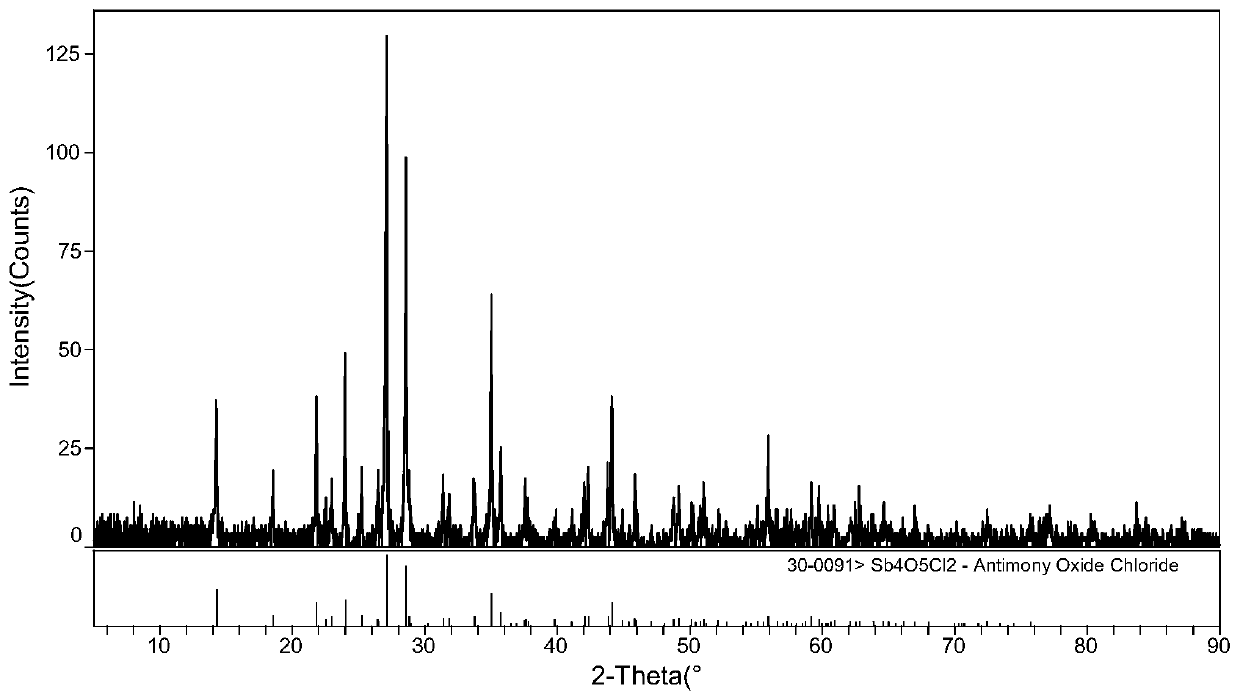

Method for separating antimony and iron by extraction-water decomposition in a mixed solution of antimony and iron

ActiveCN108728643BAchieve deep separationReduce consumptionProcess efficiency improvementIron powderDecomposition

The invention discloses a method for extracting-water-splitting and separating antimony and iron in an antimony-iron mixed solution, belonging to the field of non-ferrous metal metallurgy. The method firstly uses iron powder to reduce high-valent antimony iron ions in an antimony-iron mixed solution to a low-valent iron Divalent iron ion and trivalent antimony ion are filtered and separated to obtain low-valent antimony iron solution, and then use quaternary ammonium salt extractant to extract and separate antimony from it, to obtain antimony-rich organic phase and ferrous raffinate, the latter can be directly opened; The antimony-rich organic phase does not carry out back extraction, but is directly water-decomposed to generate antimony oxychloride, and at the same time, the quaternary ammonium salt extractant is regenerated. The method realizes the separation problem of antimony and iron through valence adjustment and extraction process, and the separation of antimony and iron is complete; and the innovative water splitting step is used to directly complete the dissociation of antimony, which cancels the traditional stripping process and obtains antimony products in one step. and regeneration extraction agent, simplifying the process, reducing the consumption of reagents, and solving the problem of separation and separate utilization of antimony iron solution in the antimony hydrometallurgy process.

Owner:杨婷

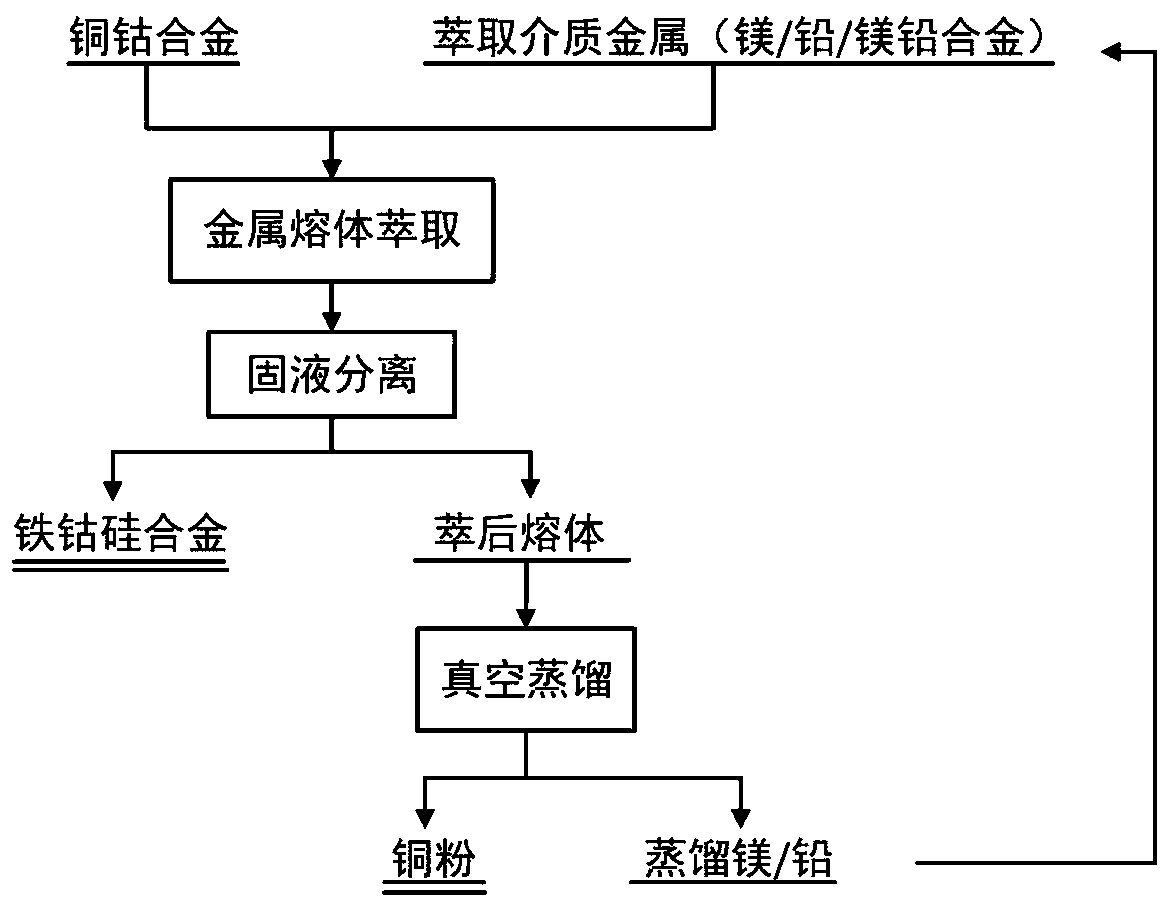

Method for extraction treating of copper-cobalt alloy by using metal melt

PendingCN111172399AHigh extraction rateImprove efficiencyCrucible furnacesProcess efficiency improvementSilicon alloyCrucible

The invention discloses a method for extraction treating of a copper-cobalt alloy by using metal melt. The method comprises the following steps that (1) a to-be-treated copper-cobalt alloy and a metalextraction medium are put into a crucible, heating is conducted under an inert protective atmosphere to melt the metal extraction medium, heat preservation is conducted, and solid-liquid separationis conducted after copper in the alloy enters the metal melt to obtain a residual alloy and an extracted melt; and (2) vacuum distillation is conducted on the extracted melt to separate the extractionmedium and the copper, and the copper is extracted. According to the method, the metal copper separated from extraction treating of the copper-cobalt alloy by using the metal melt can be used as a high-quality raw material for producing copper products, separated porous iron-cobalt-silicon alloy particles have large specific surface area and are extremely easy to break, and the leaching effect isgood when acid leaching is adopted subsequently.

Owner:CENT SOUTH UNIV

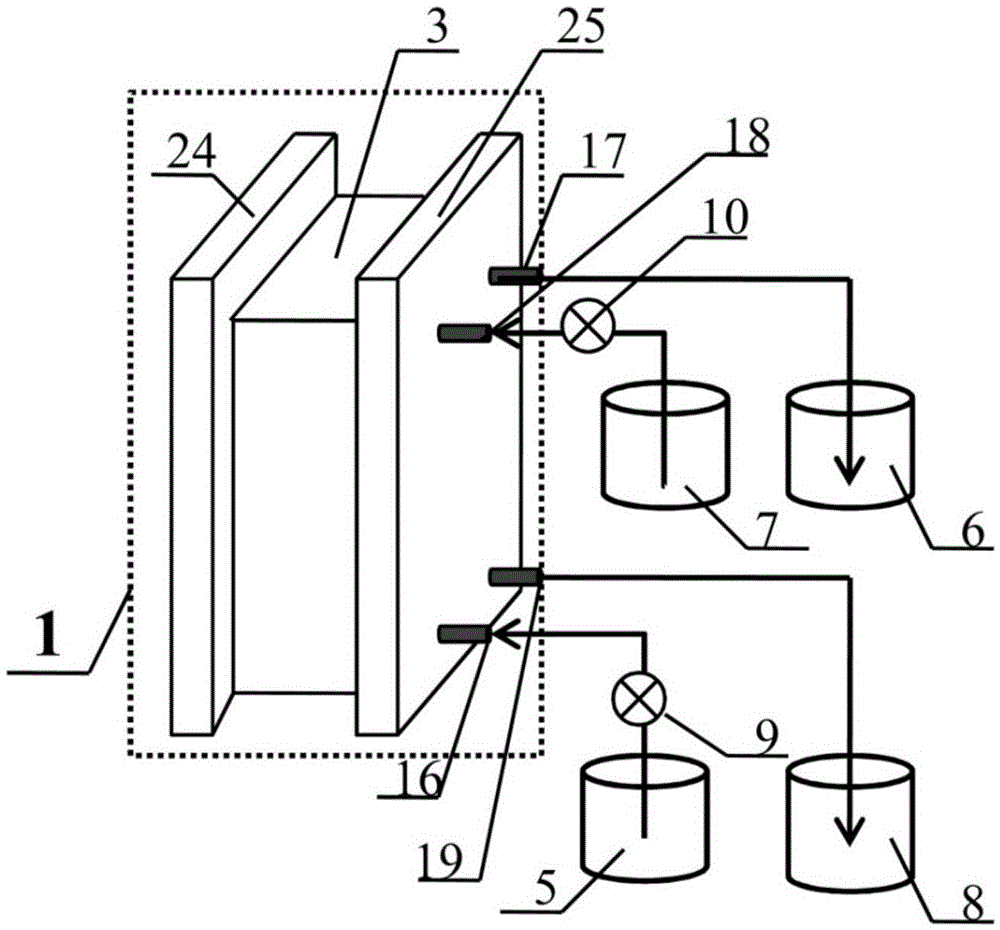

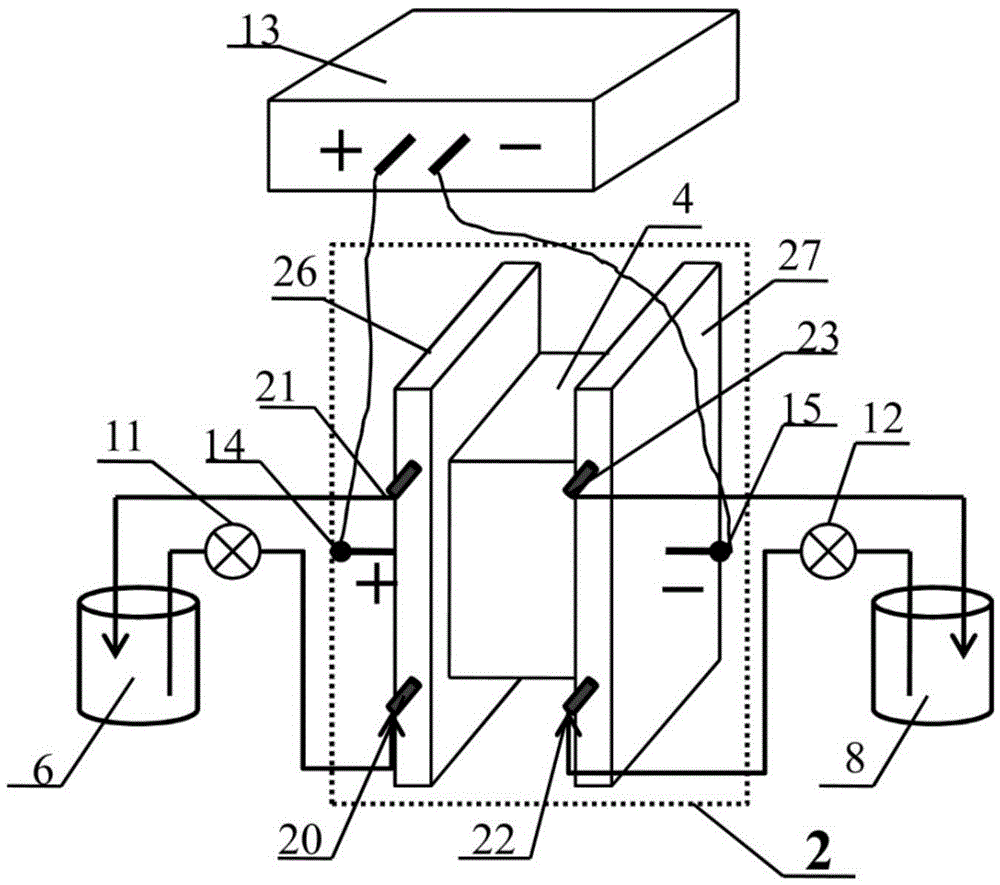

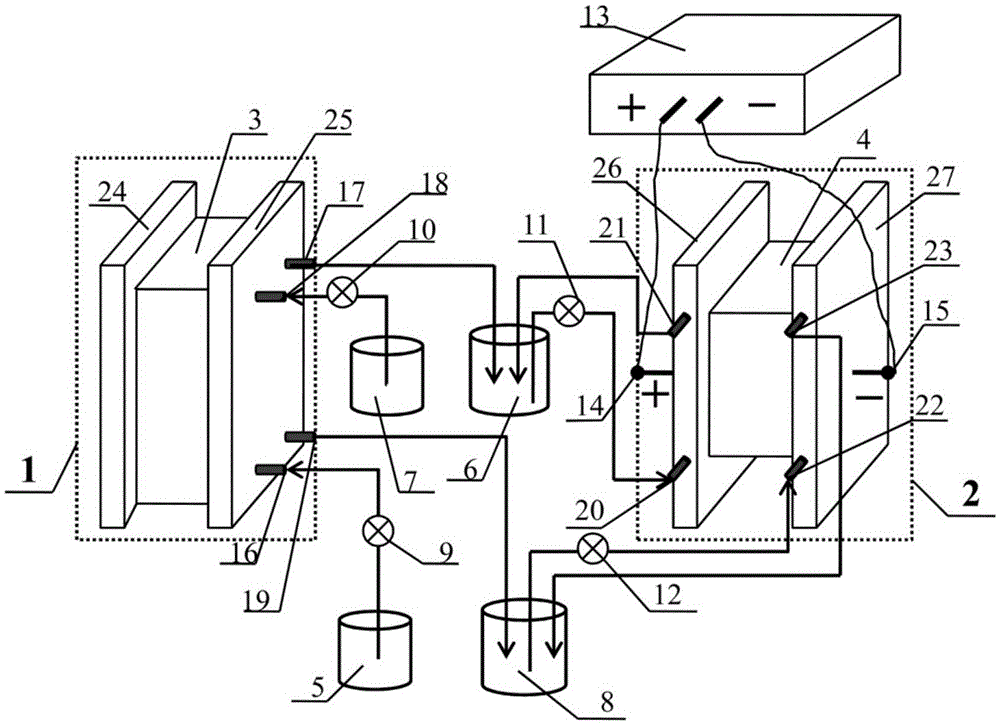

Device and method for conducting diffusion dialysis and electrolysis electrodialysis integrated treatment on vanadium-alkali feed liquid in alkali method vanadium extraction process

InactiveCN105463505ASimple processFast separationPhotography auxillary processesProcess efficiency improvementLeakage rateElectrodialysis

The invention discloses a device and method for conducting diffusion dialysis and electrolysis electrodialysis integrated treatment on vanadium alkali feed liquid in the alkali method vanadium extraction process. The device is characterized in that a retentate tank of a diffusion dialysis device is combined with an anode liquor tank of an electrolysis electrodialysis device, a dialysate tank of the diffusion dialysis device is combined with a cathode liquor tank of the electrolysis electrodialysis device, and the device for conducting integrated treatment on the vanadium-alkali feed liquid in the alkali method vanadium extraction process is formed; and primary separation is conducted on vanadium-alkali feed liquid through the diffusion dialysis device in the integrated treatment device, and retentate generated after diffusion dialysis is deeply separated through electrolysis electrodialysis. According to the method, in combination with the diffusion dialysis device which has the advantages of being large in treatment capacity, low in energy consumption, low in film pollution, high in electrolysis electrodialysis zero-vanadium leakage rate and efficiency and the like, the vanadium-alkali feed liquid is treated in the alkali method vanadium extraction process with the lower energy consumption, the concentration of the recycled alkali liquor is high, the former working procedure can be directly executed, vanadium extraction can be conducted again, and circulating use is achieved.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

Steelmaking slag separation method

InactiveCN104313208AAchieve deep separationIncrease profitRecycling and recovery technologiesSteelmakingMagnetic separation

The invention relates to the metallurgy field, and in particular relates to a steelmaking slag separation method, aiming at solving a technical problem of providing a steelmaking slag separation method which can realize separation and recycling of steelmaking slag with high efficiency. The steelmaking slag separation method is characterized by comprising the following steps: a, conducting hot-simmering treatment on steelmaking slag; b, putting the steelmaking slag to a stock bin and sieving the steelmaking slag; c, obtaining over-sized materials and under-sized materials after being sieved by a bin roller screen, wherein the under-sized materials are sieved by a two-layer flat screen; d, obtaining materials in three specifications, and sequentially processing the materials in three specifications through a semi-permanent magnetic roller; and e, obtaining concentrate, tailing, magnetic separation material and tailing powder through the semi-permanent magnetic roller. The separation method disclosed by the invention realizes deep separation of the steelmaking slag and sufficiently recovers various components in the steelmaking slag, thus improving a utilization rate of the steelmaking slag; and the method disclosed by the invention is especially suitable for a separation process for metallic iron in the steelmaking slag.

Owner:PANZHIHUA GANGCHENG GROUP

A method for deep separation of molybdenum and vanadium in molybdenum-vanadium-containing solution

InactiveCN105692698BAchieve deep separationEasy to separateVanadium compounds preparationMolybdeum compounds preparationPotential differenceIon exchange

Owner:CENT SOUTH UNIV

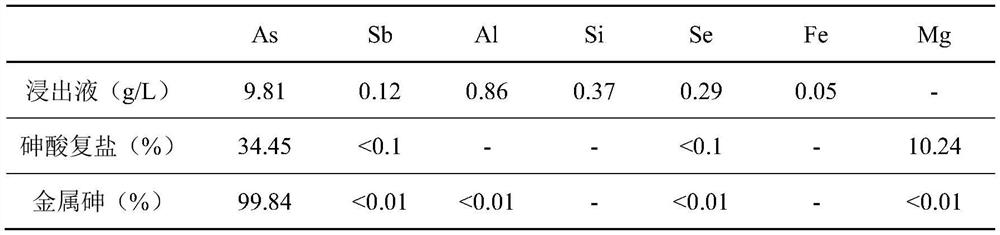

Method for preparing high-purity metal arsenic from non-ferrous smelting arsenic-containing solid waste in short process

ActiveCN114836635AAchieve deep separationLow costProcess efficiency improvementAmmonium compoundsCarboxyl radical

The invention discloses a short-process method for preparing high-purity metal arsenic from non-ferrous smelting arsenic-containing solid waste. The method comprises the following steps: carrying out oxidation alkaline leaching on the non-ferrous smelting arsenic-containing solid waste to obtain an arsenic-containing alkaline leaching solution; sequentially adding a mixed magnesium ammonium reagent consisting of a water-soluble polymer organic matter containing carboxyl and / or hydroxyl, a magnesium compound and an ammonium compound and a hydrophobic polymer organic matter with a periodic geometric structure into the arsenic-containing alkaline leachate, and stirring for reaction to obtain an arsenic acid double salt crystal wrapped by the organic matter; and roasting the arsenic acid double salt crystal wrapped by the organic matter, then mixing the arsenic acid double salt crystal with carbon powder, carrying out reduction roasting, and condensing and recovering the metal arsenic from the flue gas. According to the method, safe treatment of the non-ferrous smelting arsenic-containing solid waste can be achieved, the arsenic component in the non-ferrous smelting arsenic-containing solid waste can be recycled to prepare the high-purity metal arsenic product, and the method is simple, rapid, efficient and low in cost and meets industrial production.

Owner:CENT SOUTH UNIV

A kind of purification method of by-product sodium chloride in the production of betaine or betaine hydrochloride

ActiveCN109134287BImprove solubilityIncrease polarityOrganic compound preparationAmino-carboxyl compound preparationHydrochlorideElectrodialysis

Owner:山东祥维斯生物科技股份有限公司

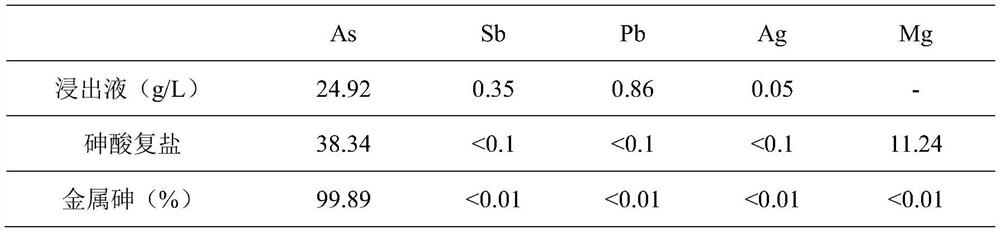

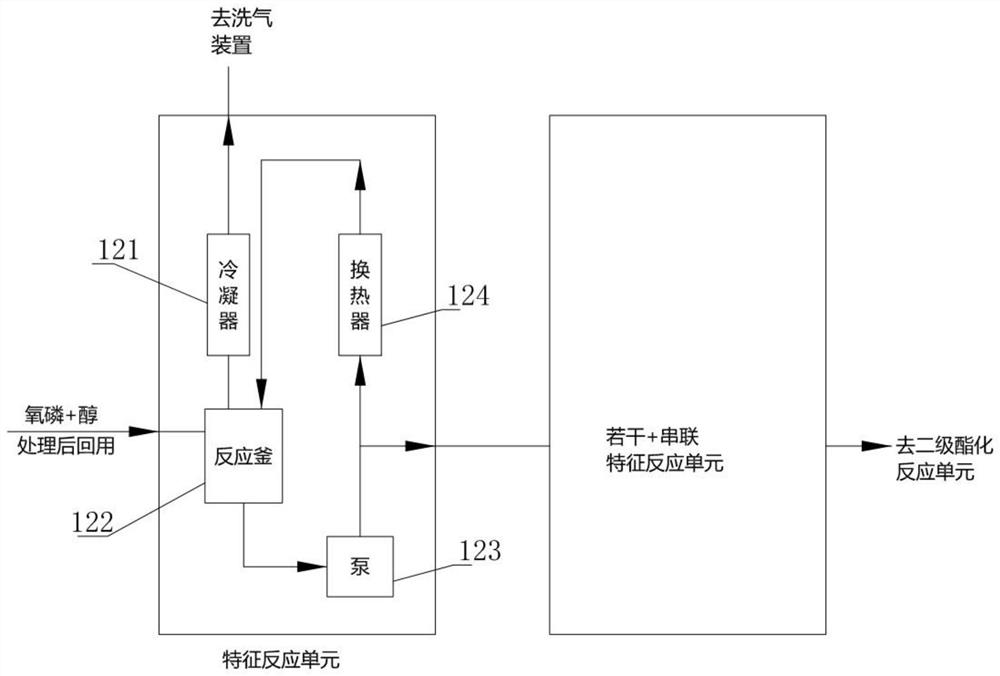

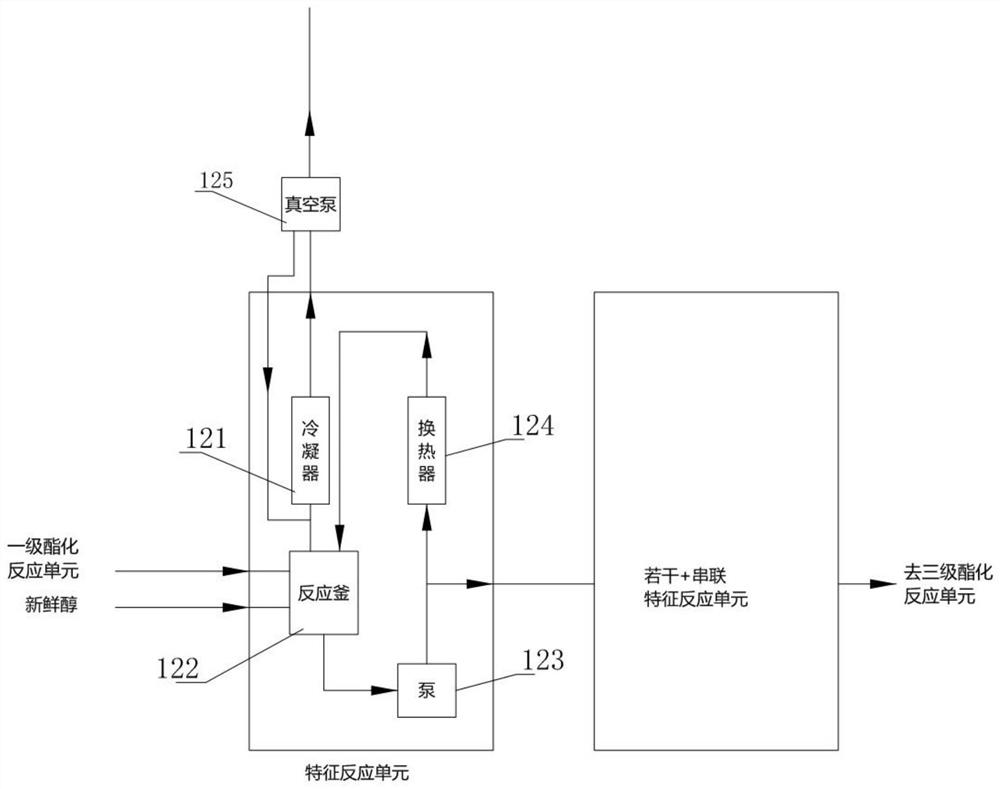

Phosphate preparation equipment and preparation method thereof

PendingCN112745346AReduce wasteReduce outputGroup 5/15 element organic compoundsPhosphoric Acid EstersPhosphate

The invention relates to phosphate preparation equipment and a preparation method thereof. The equipment comprises a multi-stage esterification reaction unit, a dealcoholization device and a gas washing device for recovering hydrogen chloride and monohydric alcohol, and the multi-stage esterification reaction unit is formed by connecting a plurality of esterification reaction units in series in sequence; wherein a raw material input port of the esterification reaction unit at the head part is connected with a raw material output port of a gas washing device, and a mixture input port of the gas washing device is used for being connected with the esterification reaction units and the mixture output port of the dealcoholization device in parallel; and the raw material input port of the dealcoholization device is connected with one esterification reaction unit positioned at the tail part. According to the invention, unreacted monohydric alcohol entrained during volatilization of hydrogen chloride is recovered by utilizing the gas washing device, phosphorus oxychloride entrained in absorption liquid during volatilization of hydrogen chloride is absorbed by industrial hydrochloric acid water, and then volatile hydrogen chloride is absorbed by industrial water, so that industrial-grade qualified byproduct hydrochloric acid can be prepared, waste of raw materials is reduced, and the yield of waste gas, waste water and solid waste is also reduced.

Owner:邓华萍

Method for directly preparing zinc oxide by wet treatment of zinc-containing fumes in iron and steel plants

ActiveCN105967222BSmall side effectsAchieve deep separationZinc oxides/hydroxidesPrecipitationMaterials science

Owner:桂阳县皓钰新材料有限公司

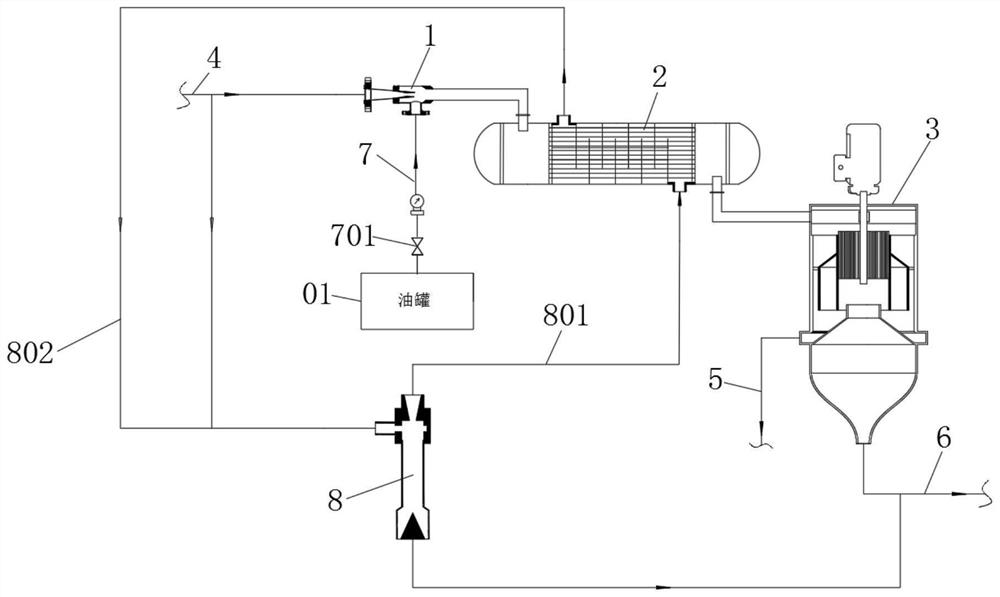

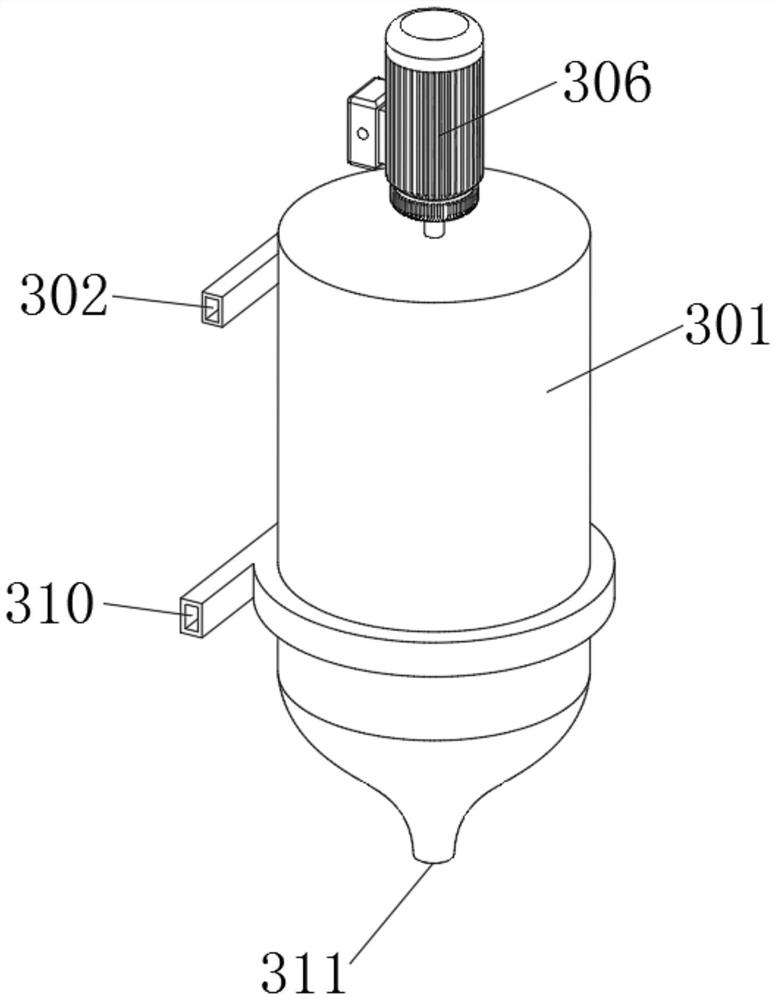

Oilfield sludge separation equipment and separation method based on sludge treatment

ActiveCN113321398BEasy to separateEfficient separationSludge treatmentSpecific water treatment objectivesFiberThermodynamics

The present invention relates to the technical field of oil sludge separation equipment, in particular to oil sludge separation equipment for oil fields based on oil sludge treatment and a separation method thereof, including a shell, a separation tank, a feed grinding assembly, an oil sludge separation structure, an oscillation separation structure, and a deflection protection Universal ball, vibration and stable structure, telescopic oil nozzle assembly, evaporation box and transmission switch assembly; the present invention realizes the deep layer of sludge through grinding large particles of sludge, high-speed stirring and mixing, low-speed stirring and separation, vibration separation and collection and recovery. Separation makes the sludge layered and separated more thoroughly, the operation of the equipment is simpler, and the separation of the sludge is more efficient, which solves the problem that the traditional equipment can only remove the sludge on the surface by calcination and evaporation, and the efficiency is low.

Owner:东营金昱技术开发有限公司

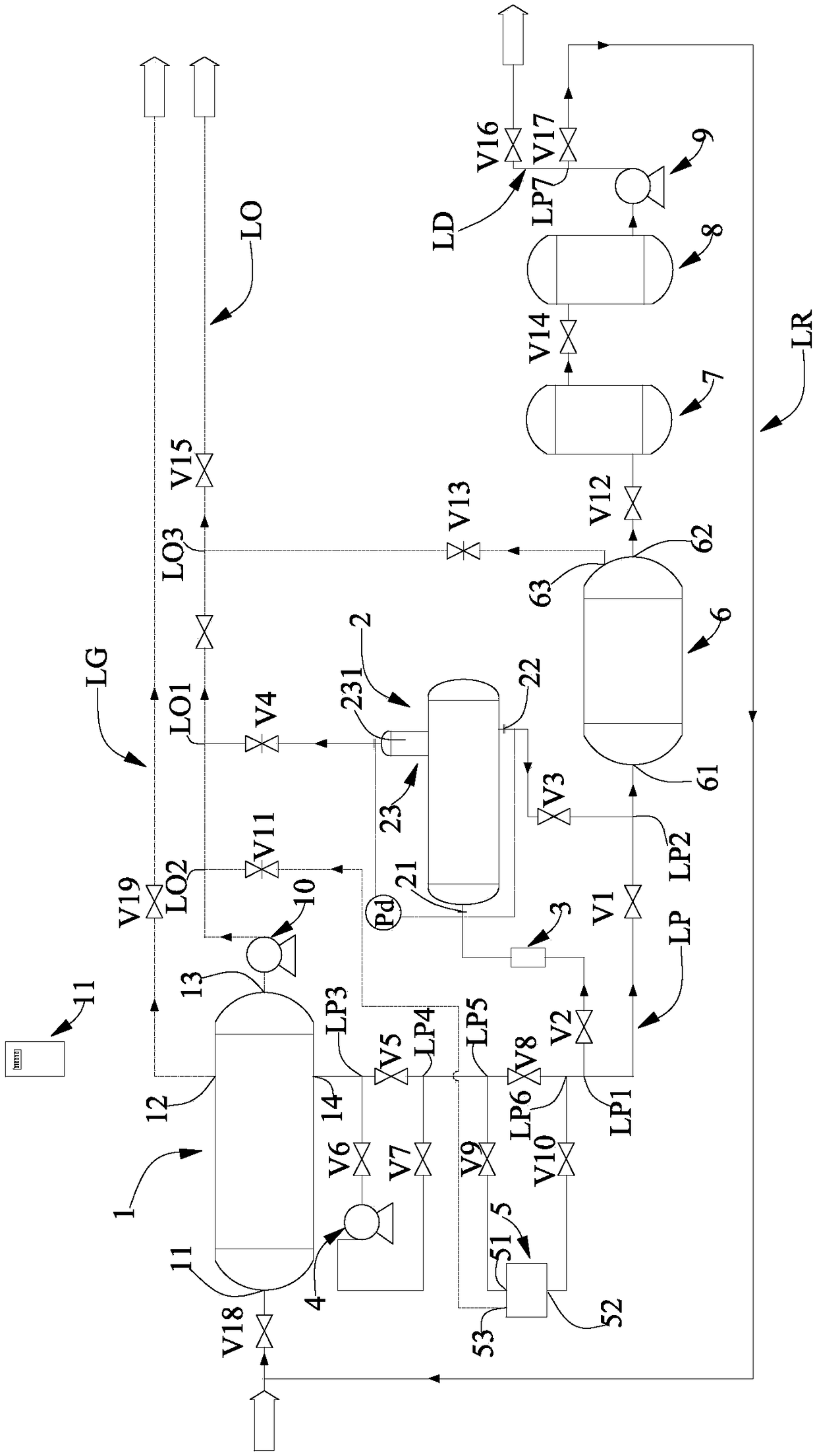

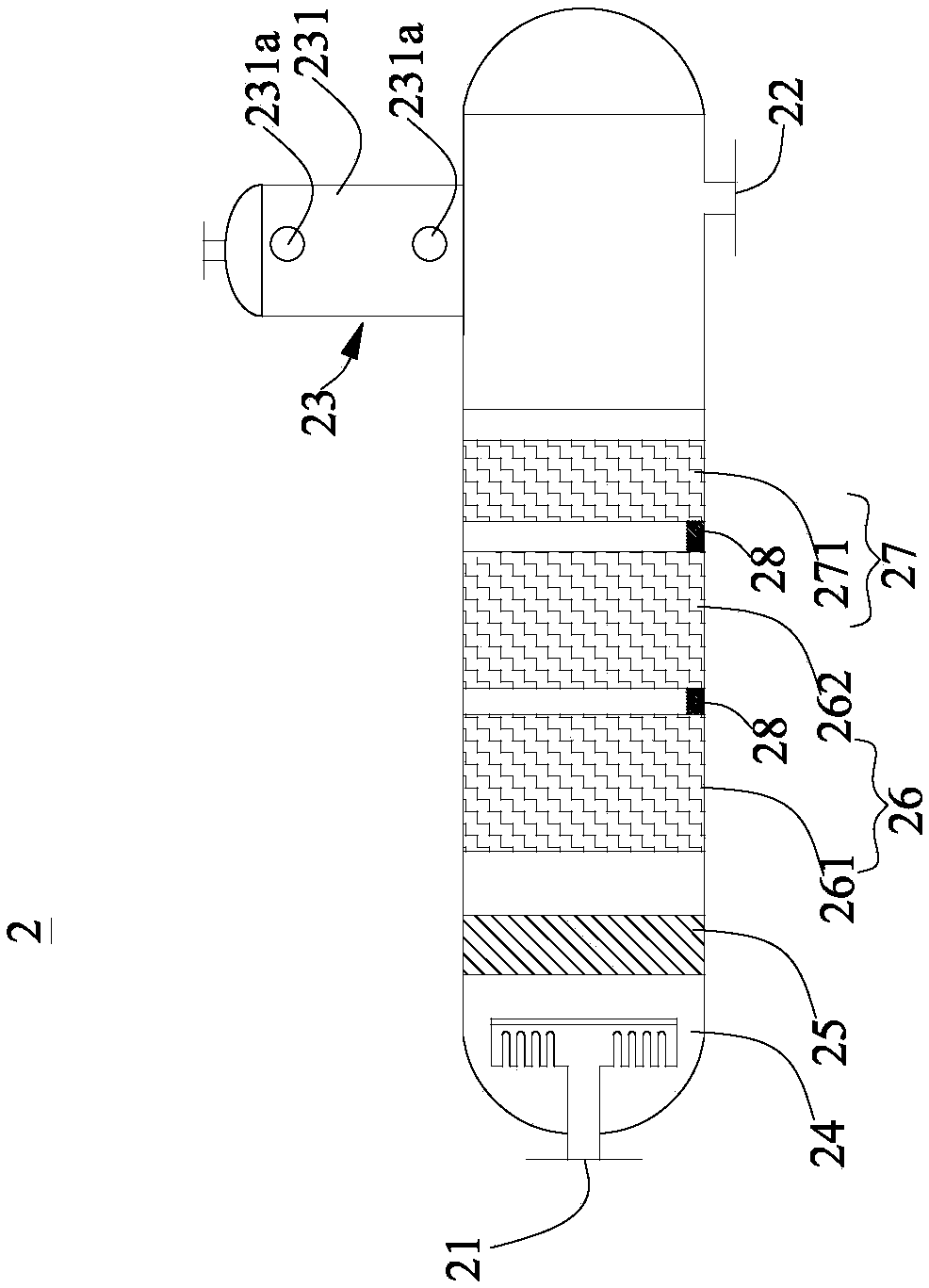

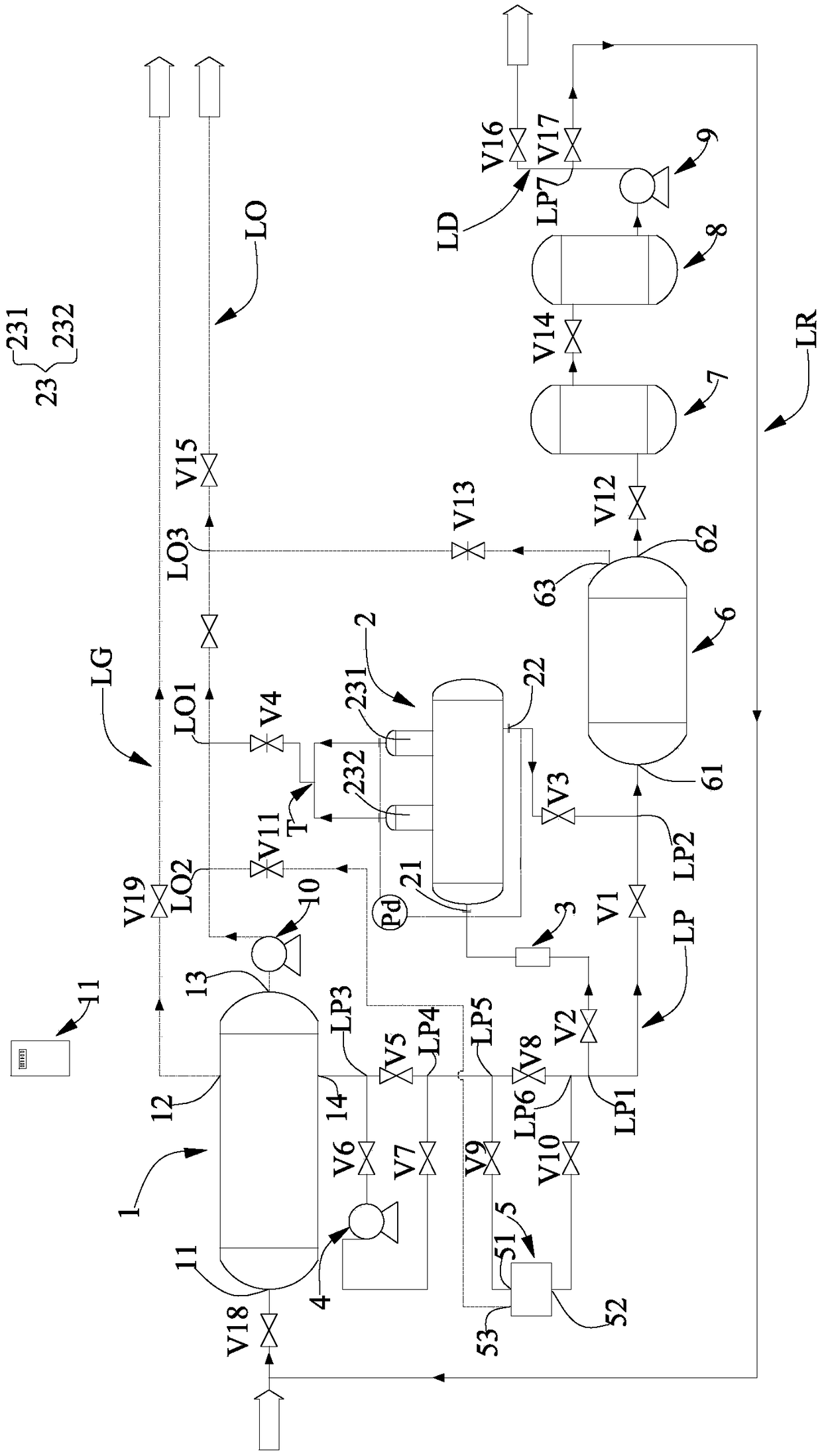

System for recovering heavy hydrocarbon in VOCs in storage tank

ActiveCN112920832AReduce lossIncrease profitDispersed particle separationLiquid hydrocarbon mixture recoveryHeating furnaceMechanics

The invention discloses a system for recovering heavy hydrocarbon in VOCs in a storage tank. The system comprises an ejector, a heat exchanger and a micro-channel cyclone separator, a working fluid inlet of the ejector is connected with a fuel gas pipe of the heating furnace, and an ejection fluid inlet of the ejector is communicated with an upper gas cavity in the oil tank through an ejection pipe; a mixed fluid outlet of the ejector is connected with a heat source medium inlet of the heat exchanger; a heat source medium outlet of the heat exchanger is connected with a tangential inlet of the micro-channel cyclone separator; a cold source medium inlet of the heat exchanger is connected with a cold flow outlet of the vortex tube; a cold source medium outlet of the heat exchanger is connected with an inlet of the vortex tube; an inlet of the vortex tube is connected with a heating furnace fuel gas tube; and a liquid phase tangential outlet of the micro-channel cyclone separator is connected with a heavy hydrocarbon recovery pipeline, and a gas phase outlet of the micro-channel cyclone separator is connected with a fuel gas inlet of the heating furnace. A cold source in the heat exchanger is directly obtained by decomposing fuel gas of a heating furnace in a factory area through the vortex tube, and materials are convenient to obtain.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

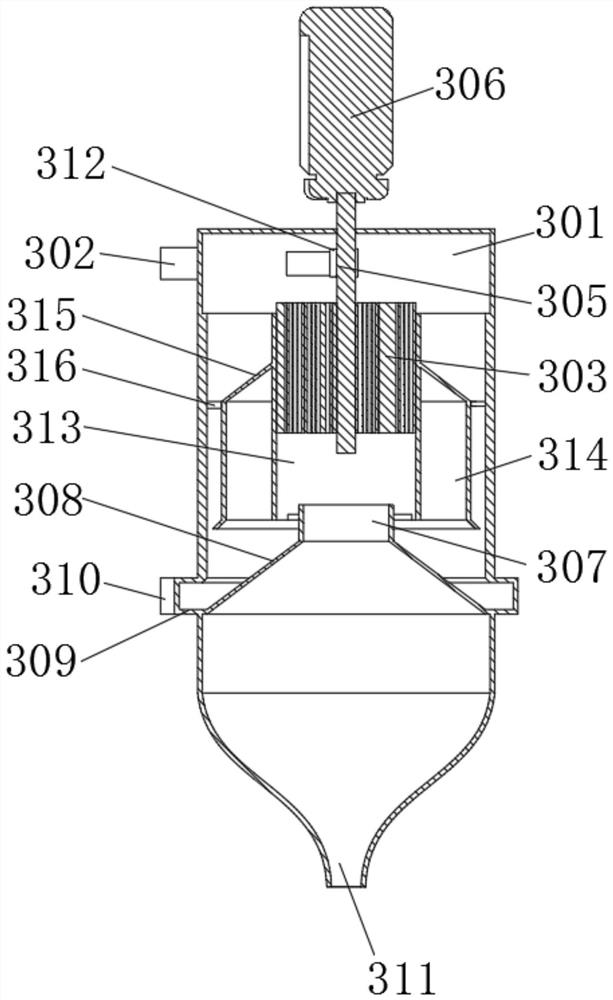

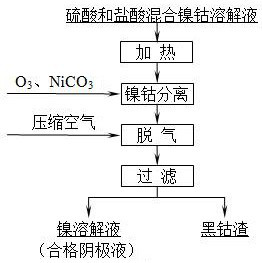

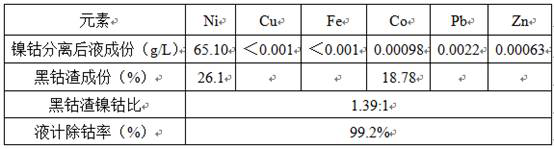

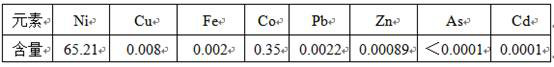

Production method for realizing nickel-cobalt separation by utilizing ozone under mixed acid system

ActiveCN113512649AStrong oxidation abilityAchieve deep separationProcess efficiency improvementSoil scienceCobalt

The invention discloses a production method for realizing nickel-cobalt separation by utilizing ozone under a mixed acid system. The production method for realizing nickel-cobalt separation by utilizing the ozone under the mixed acid system comprises the following steps that a pH value is adjusted to 4.0-5.0, a solution is heated to 45-65 DEG C, stirring is started, ozone gas with the concentration of 50-180 mg / L is introduced into the solution, nickel carbonate is added simultaneously and continuously to control the pH value of a reaction system to 4.0-5.0, the temperature of the solution is kept to be 45-65 DEG C; the flow of the ozone is adjusted to control the oxidation-reduction potential of the reaction system to be 1000-1080 mV, the ozone introduction time is 40-60 min, a nickel-cobalt separation reaction is carried out, Co < 2 + > ions in a mixed solution are oxidized into Co < 3 + > ions by the ozone, and Co (OH) 3 precipitates are formed. The ozone is used as an oxidizing agent, the nickel carbonate is used as a neutralizing agent, and no new zwitterions are introduced into a system in the whole process; the ozone has strong oxidizability, and can quickly and effectively realize deep separation of nickel and cobalt.

Owner:JINCHUAN GROUP LIMITED +1

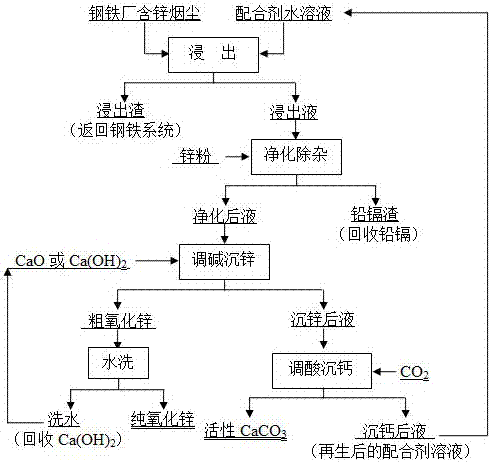

Method for enriching zinc oxide concentrate by wet treatment of zinc-containing dust in iron and steel plant

The invention relates to the field of comprehensive utilization of steel plant solid waste resources, particularly a method for treating steel plant zinciferous smoke dust by a wet process. The method comprises the following steps: a compounding agent water solution using aminoacetate ions as a ligand is utilized to leach steel plant zinciferous smoke dust under weakly alkaline conditions, wherein in the leaching process, iron, carbon, calcium, magnesium and silicon are insoluble and reside in leaching slag, lead and cadmium in the smoke dust enter the leach solution along with the zinc, and the leaching slag is subjected to water washing and returns to an iron and steel system to perform proportioning and sintering; the obtained leach solution is subjected to alkali regulation and zinc precipitation by using CaO or Ca(OH)2, so that the zinc precipitates in the form of zinc oxide, and the lead and cadmium coprecipitate along with the zinc and are enriched in the zinc oxide concentrate; and the zinc precipitation solution is subjected to acid regulation and calcium precipitation by using CO2 gas so as to remove calcium ions introduced in the zinc precipitation process and regenerate the compounding agent, and the regenerated compounding agent solution can return to the leaching process for direct use, wherein an active CaCO3 byproduct can be produced in the calcium precipitation process.

Owner:桂阳县皓钰新材料有限公司

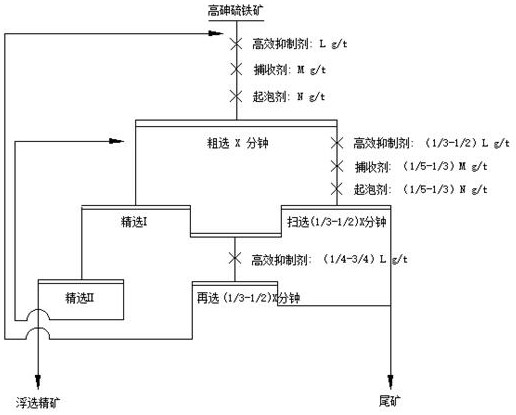

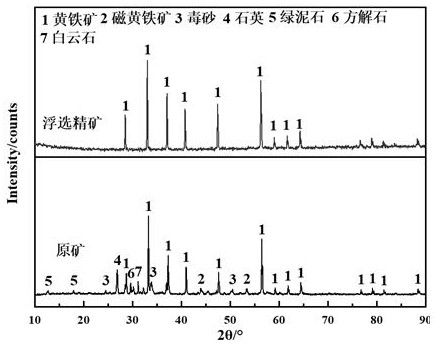

Method for preparing high-purity pyrite through flotation mass transfer kinetics regulation and control

PendingCN113976331AHigh recovery rateReasonable process structureFlotationProcess efficiency improvementOre concentrateSulfidation

The invention discloses a method for preparing high-purity pyrite through flotation mass transfer kinetics regulation and control, which comprises the steps of slurrying micro-fine-particle high-arsenic pyrite, fully stirring in an inert atmosphere to uniformly disperse particles, transferring into a flotation machine, sequentially adding an efficient inhibitor, a sufficient amount of collecting agent and a foaming agent for roughing, scavenging and finely selecting, well controlling the scavenging operation frequency, the reagent dosage and the flotation time, and finally conducting closed-loop flotation. Products in a first-time fine selection groove and foam products obtained through first-time scavenging are combined and re-selected and then return to roughing operation, and mass transfer dynamics regulation and control blind areas and foam mechanical entrainment are made up. Finally, high-purity pyrite concentrate with the sulfur content greater than 52%, the iron content greater than 44% and the arsenic content less than 0.3% is obtained, and the recovery rate of sulfur is 55-65%. The method has the advantages of being easy to regulate and control, low in medicament consumption, remarkable in economic benefit and the like, and can be widely applied to fine separation of complex non-ferrous metal sulfide minerals.

Owner:KUNMING UNIV OF SCI & TECH

A method and system for recovering main and associated elements from copper-nickel sulfide ore

ActiveCN107012324BAchieve deep separationImprove efficiencyProcess efficiency improvementPregnant leach solutionSlag

The invention provides a method and system for recovering main and associated elements from copper-nickel sulfide ore, the method comprising: 1) continuously adding low-matte and leaching reaction solution into the reaction bottom liquid, selectively leaching, and collecting hydrogen sulfide Gas, the first leaching solution and the first leaching slag, wherein the leaching reaction solution is sulfuric acid with a mass fraction of 60%-95%; 2) adding water to the first leaching slag for dissolution, and collecting the second leaching solution and the second leaching slag; 3) removing iron from the second leaching solution, collecting the iron-removing solution and iron-removing slag, the iron-removing solution is used for the extraction of nickel and cobalt, and the iron-removing slag is used for ironmaking; and / or, sending the second leaching slag to copper The smelting device smelts to obtain copper and precious metals respectively. The method proposed by the invention can realize the deep separation of nickel and copper, and effectively realize the recovery of nickel, copper, cobalt, precious metals and sulfur. The invention has simple process, short process and high efficiency, is a clean and efficient element recovery process, and is easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

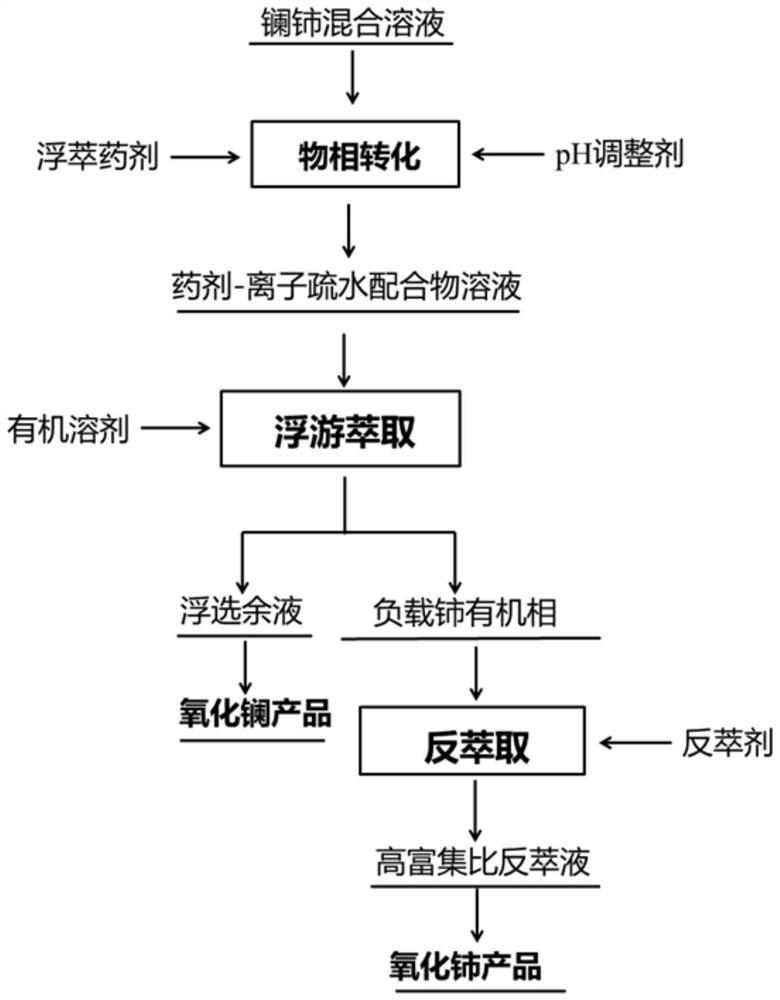

Floating extraction agent for strengthening floating extraction separation of lanthanum and cerium and method for selectively separating lanthanum and cerium

ActiveCN112662873AImprove capture abilityAchieve deep separationLanthanum oxide/hydroxidesCerium oxides/hydroxidesPhosphoric acidCerium

The invention discloses a floating extraction agent for strengthening floating extraction separation of lanthanum and cerium and a method for selectively separating lanthanum and cerium. The floating extraction agent comprises long-chain alkyl sulfonate (sulfate) and an organophosphate compound. The method for selectively separating lanthanum and cerium by using the floating extraction agent comprises the following steps that a solution containing lanthanum ions and cerium ions is reacted with the floating extraction agent to selectively convert the cerium ions into a floating extraction agent-cerium ion hydrophobic complex to obtain a reaction mixed solution; floating extraction is carried out on the reaction mixed solution to obtain an organic phase loaded with the cerium ions, and the lanthanum ions are enriched in the reaction mixed solution; and reverse extraction is carried out on the organic phase loaded with the cerium ions through a reverse extraction agent to obtain a cerium ion enriched solution. The method for selectively separating lanthanum and cerium is simple to operate, low in floating extraction agent cost and high in separation efficiency of similar rare earth metal lanthanum and cerium ions, is particularly suitable for deep separation of lanthanum and cerium in a low-concentration system, and has a relatively high industrial application prospect.

Owner:ZHENGZHOU UNIV

Oily sewage treatment system

PendingCN109502786AAchieve deep separationWaste water treatment from quariesFatty/oily/floating substances removal devicesEngineeringSewage treatment

The invention provides an oily sewage treatment system. The oily sewage treatment system comprises a production separator, an air conveying line, an oil conveying line, a production water conveying line and a coalescence oil removal device, wherein the oil conveying line is provided with a first connecting point, the production water conveying line is provided with a first access point and a second access point, and a first control valve is arranged between the first access point and the second access point; the coalescence oil removal device is arranged between the first access point and thesecond access point in a bypass way, and is provided with an inlet, a water outlet and an oil collection bag; a distributor, a flow arrangement device, a coalescence separation module, and a reinforced settlement module are arranged in the coalescence oil removal device along the flowing direction of the production water; a second control valve is connected between the inlet of the coalescence oilremoval device and the first access point of the production water conveying line; a third control valve is connected between the water outlet of the coalescence oil removal device and the second access point of the production water conveying line; a fourth control valve is connected between the oil collection bag of the coalescence oil removal device and the first connecting point of the oil conveying line.

Owner:中石化石油工程技术服务有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com