High-purity hydrogen selenide purification process utilizing carbon nanotubes

A carbon nanotube, hydrogen selenide technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of hydrogen sulfide adsorbent deactivation and difficult removal, and achieve the effect of reducing pressure drop and improving purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019]Example 1:

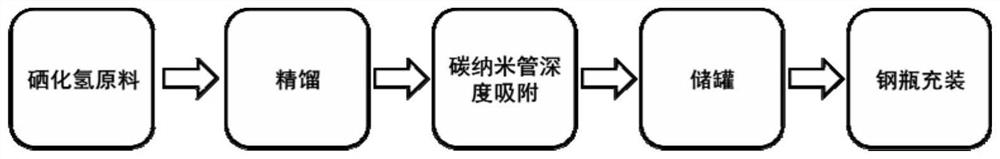

[0020]A purification process of high-purity hydrogen selenide using carbon nanotubes includes the following steps:

[0021]S1. Lead the hydrogen selenide raw material into the primary distillation tower in liquid form for preliminary distillation;

[0022]S2, the hydrogen selenide material after preliminary distillation in step S1 is introduced into the secondary distillation tower for secondary distillation;

[0023]S3. Pass the hydrogen selenide material after the second rectification in step S2 through the adsorption column in gaseous form, and the adsorption column is filled with a mixture of carbon nanotubes and activated carbon for adsorption treatment;

[0024]S4. The hydrogen selenide material after the adsorption treatment in step S3 is pressurized to 1.5Mpa through the pressure treatment of the compressor, cooled to -10°C, and stored in the storage tank through cooling and liquefaction. Finally, the filling pipeline is used Fill it up.

[0025]Wherein, the working conditi...

Example Embodiment

[0027]Example 2:

[0028]A purification process of high-purity hydrogen selenide using carbon nanotubes includes the following steps:

[0029]S1. Lead the hydrogen selenide raw material into the primary distillation tower in liquid form for preliminary distillation;

[0030]S2, the hydrogen selenide material after preliminary distillation in step S1 is introduced into the secondary distillation tower for secondary distillation;

[0031]S3. Pass the hydrogen selenide material after the second rectification in step S2 through the adsorption column in gaseous form, and the adsorption column is filled with a mixture of carbon nanotubes and activated carbon for adsorption treatment;

[0032]S4. The hydrogen selenide material after the adsorption treatment in step S3 is pressurized to 1.5Mpa through the pressure treatment of the compressor, cooled to -10°C, and stored in the storage tank through cooling and liquefaction. Finally, the filling pipeline is used Fill it up.

[0033]Wherein, the working conditi...

Example Embodiment

[0035]Example 3:

[0036]A purification process of high-purity hydrogen selenide using carbon nanotubes includes the following steps:

[0037]S1. Lead the hydrogen selenide raw material into the primary distillation tower in liquid form for preliminary distillation;

[0038]S2, the hydrogen selenide material after preliminary distillation in step S1 is introduced into the secondary distillation tower for secondary distillation;

[0039]S3. Pass the hydrogen selenide material after the second rectification in step S2 through the adsorption column in gaseous form, and the adsorption column is filled with a mixture of carbon nanotubes and activated carbon for adsorption treatment;

[0040]S4. The hydrogen selenide material after the adsorption treatment in step S3 is pressurized to 1.5Mpa through the pressure treatment of the compressor, cooled to -10°C, and stored in the storage tank through cooling and liquefaction. Finally, the filling pipeline is used Fill it up.

[0041]Wherein, the working conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com