A method and system for recovering main and associated elements from copper-nickel sulfide ore

A technology of associated elements and sulfide ore, applied in the field of non-ferrous metal metallurgy, can solve problems such as ineffective realization, and achieve the effects of facilitating transportation and storage, improving recovery rate and effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

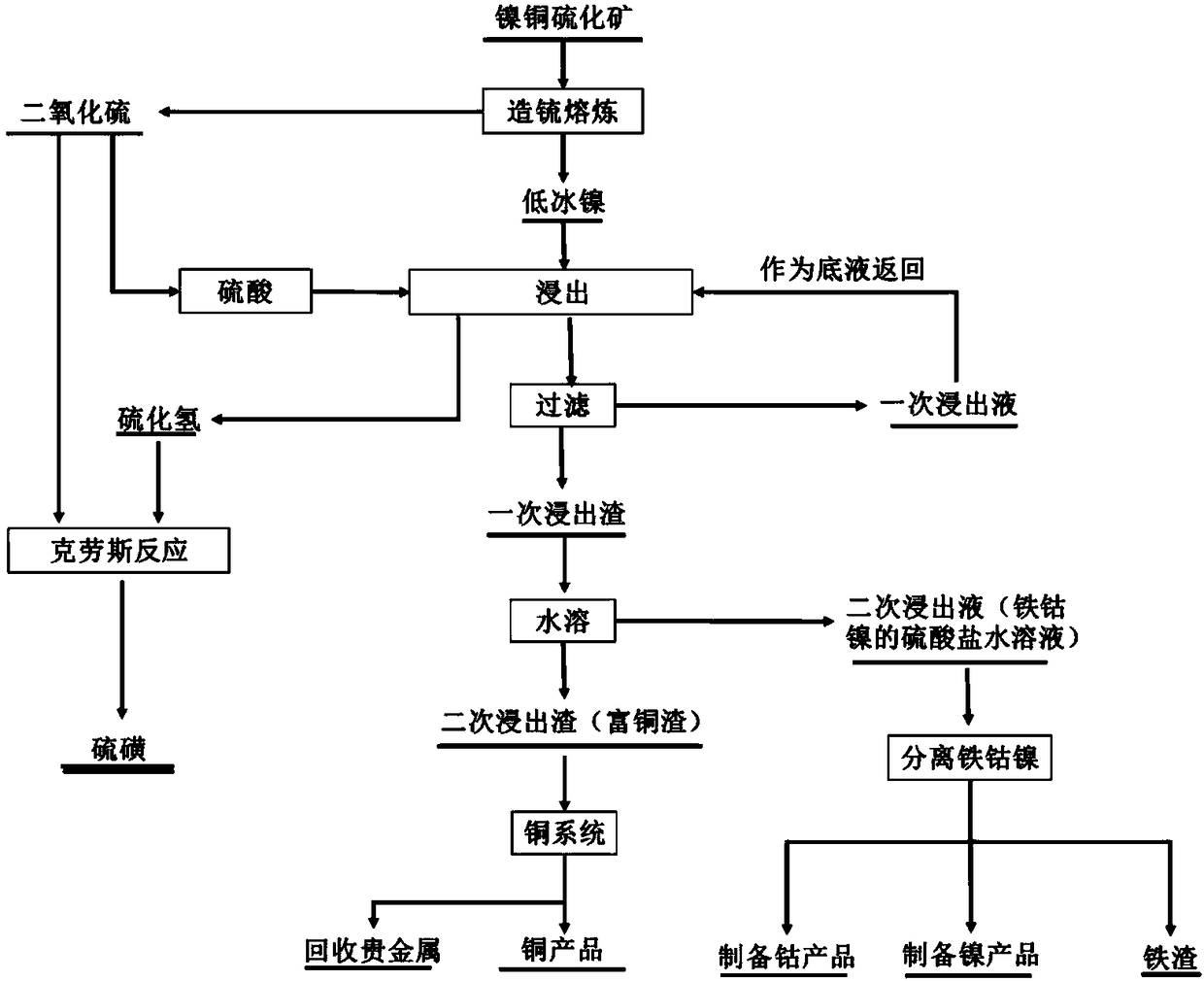

[0069] like figure 1 As shown, in this example, the copper-nickel sulfide ore is smelted by matte making to obtain low nickel matte, the main element content: Ni20.21%, Cu 10.52%, Fe37.44%, Co 0.78%, precious metal about 10g / t, At the same time, sulfur dioxide is generated.

[0070] A solution with a mass fraction of sulfuric acid of 30% was prepared as the reaction bottom solution; at the same time, a solution with a mass fraction of sulfuric acid of 90% was prepared as a leaching reaction solution. Fill the reaction bottom liquid of total kettle volume 40% in reactor; Add low matte and reaction leaching liquid in reactor simultaneously and react, and keep the consumption of sulfuric acid in the reactor consistent with the addition; Continuous feed reacts, until Stop feeding when the slurry in the reaction kettle reaches 80% of the total kettle volume, continue the reaction for 1 hour, and collect the hydrogen sulfide gas generated during the reaction.

[0071] After the re...

Embodiment 2

[0074] Copper-nickel sulfide ore is smelted with matte to obtain low-matte nickel. The main element content is: Ni 13.25%, Cu 8.32%, Fe38.44%, Co 0.64%, precious metal about 8g / t, and sulfur dioxide is generated at the same time.

[0075] A solution with a mass fraction of sulfuric acid of 40% was prepared as the reaction bottom solution; at the same time, a solution with a mass fraction of sulfuric acid of 85% was prepared as a leaching reaction solution. Fill the reaction bottom liquid of 45% of total kettle volume in reactor; Add low matte nickel and reaction leaching solution in reactor simultaneously and react, and maintain the consumption of sulfuric acid in the reactor consistent with the addition; Continuous feed reacts, until Stop feeding when the slurry in the reaction kettle reaches 80% of the total kettle volume, continue the reaction for 1.5h, and collect the hydrogen sulfide gas generated during the reaction.

[0076] After the reaction is completed, the slurry i...

Embodiment 3

[0079] Copper-nickel sulfide ore is smelted with matte to obtain low nickel matte. The main element content is: Ni 16.55%, Cu 10.32%, Fe 33.44%, Co 0.34%, precious metal about 11g / t, and sulfur dioxide is formed at the same time.

[0080] A solution with a mass fraction of sulfuric acid of 20% was prepared as the reaction bottom solution; at the same time, a solution with a mass fraction of sulfuric acid of 60% was prepared as a leaching reaction solution. Fill the reaction bottom liquid of total still volume 30% in reactor; Add low matte nickel and reaction leaching liquid in reactor simultaneously and react, and keep the consumption of sulfuric acid in the reactor consistent with the addition; Continuous feed reacts, until Stop feeding when the slurry in the reaction kettle reaches 80% of the total kettle volume, continue the reaction for 0.5h, and collect the hydrogen sulfide gas generated during the reaction.

[0081] After the reaction is completed, the slurry is cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com