Oily sewage treatment system

A sewage treatment system and oil technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problem of exceeding separation capacity, excessive oil content in production water, and increased gas phase flow And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The drawings illustrate embodiments of the invention and it is to be understood that the disclosed embodiments are merely examples of the invention, which may be embodied in various forms; therefore, specific details disclosed herein should not be construed as limiting, but rather The claims are presented merely as a basis and as a representative basis for teaching one of ordinary skill in the art to variously practice the invention.

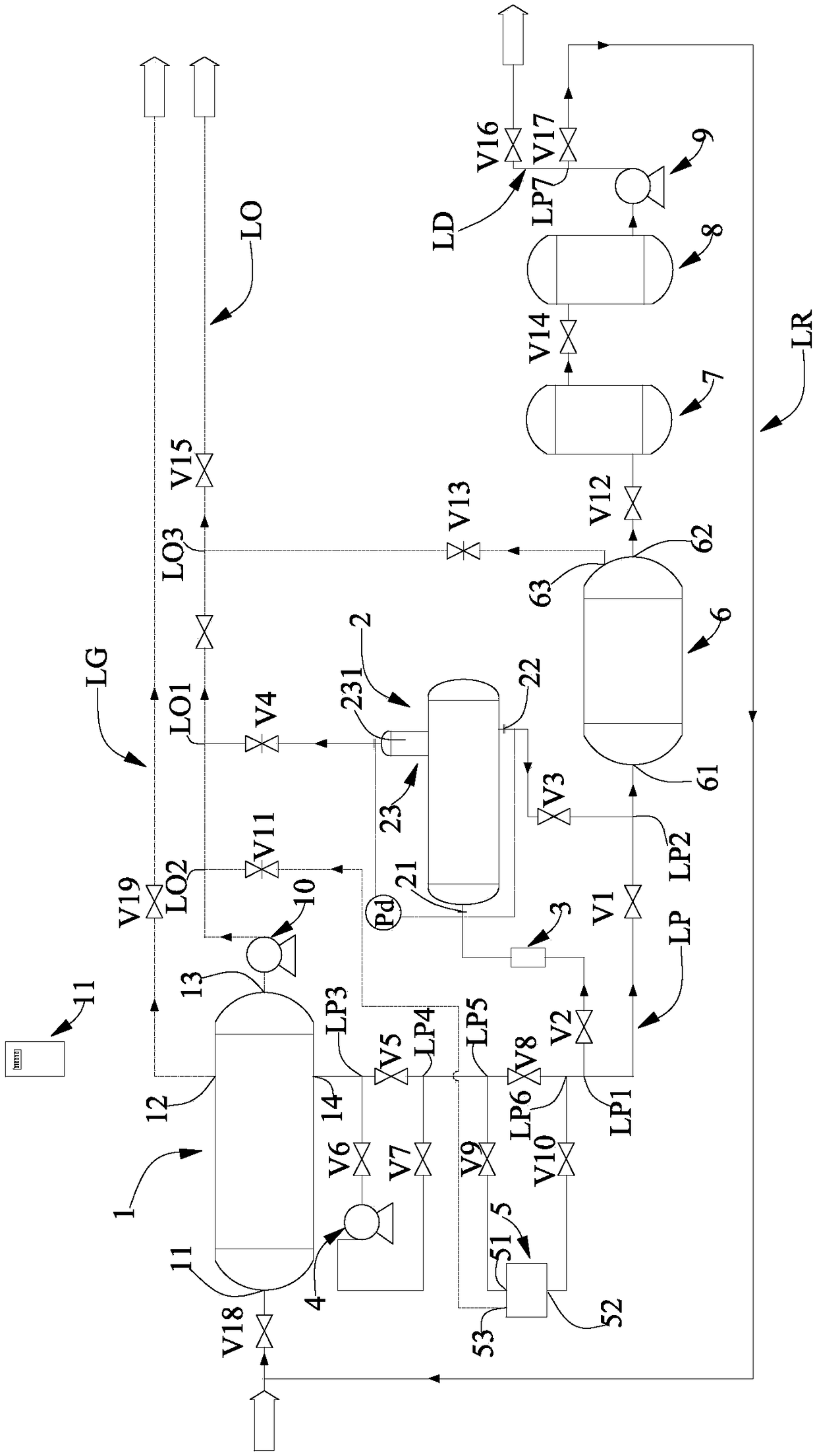

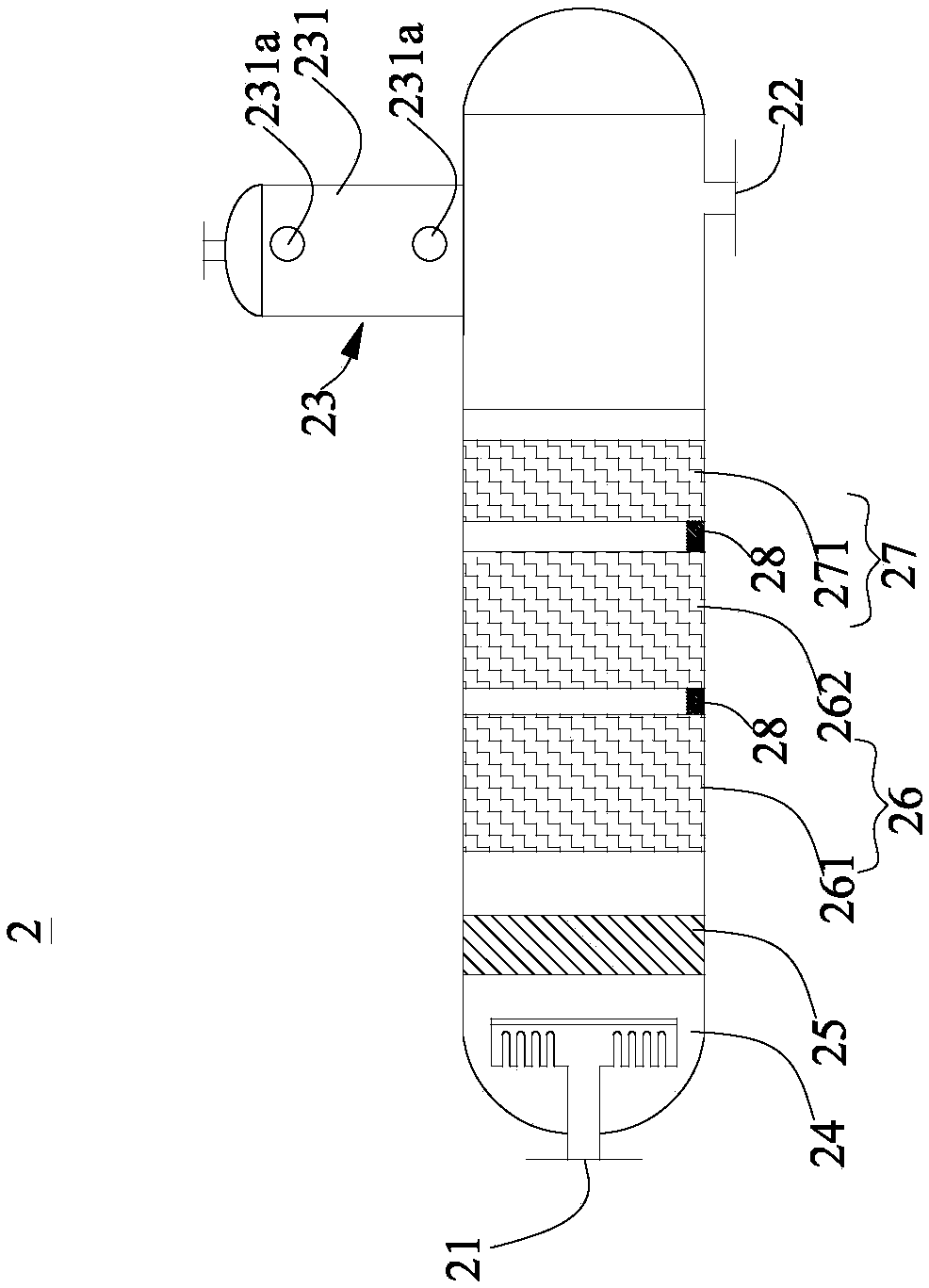

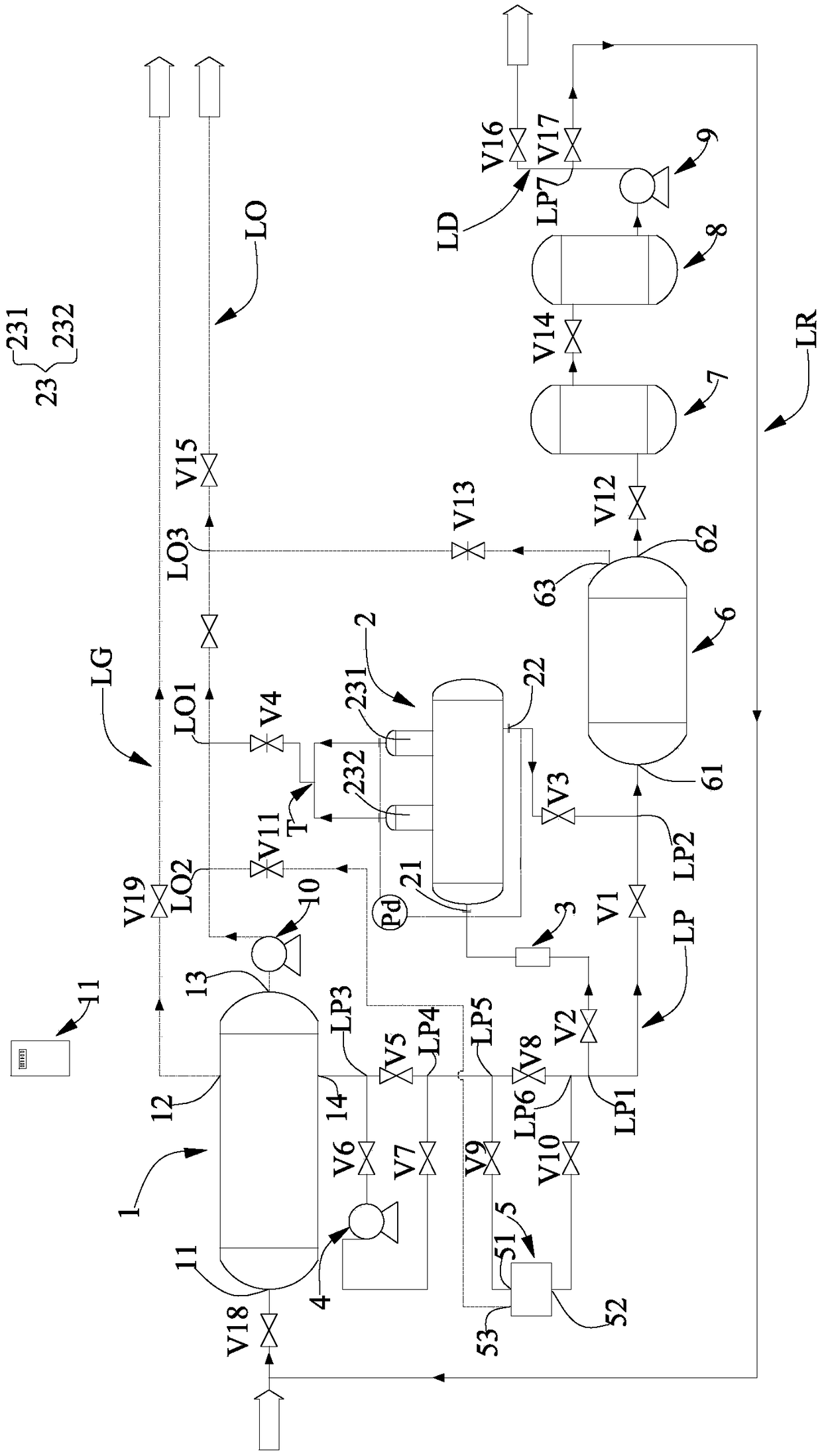

[0047] figure 1 is a schematic diagram of the first embodiment of the oily sewage treatment system according to the present invention. figure 2 Yes figure 1 Schematic diagram of the coalescence degreasing unit of the oily wastewater treatment system. image 3 is a schematic diagram of the second embodiment of the oily sewage treatment system according to the present invention. Figure 4 Yes image 3 Schematic diagram of the coalescence degreasing unit of the oily wastewater treatment system.

[0048] refer to figure 1 and figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com