Production method for realizing nickel-cobalt separation by utilizing ozone under mixed acid system

A production method and ozone technology, applied in the direction of improving process efficiency, can solve the problems of long reaction time, many reaction tanks, large processing capacity, etc., and achieve low entrainment of valuable metal nickel, reduction of processing costs, and entrainment of nickel. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

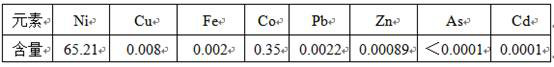

[0024] Table 1: Nickel-cobalt mixed acid solution composition (g / L) used in embodiment 1

[0025]

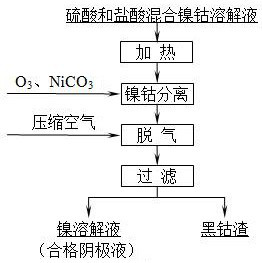

[0026] The specific implementation process: take a certain amount of sulfuric acid and hydrochloric acid mixed nickel-cobalt solution, pH=4.8, after the electric heating plate is heated to 60°C, turn on the stirring speed of 400r / min, adjust the ozone concentration to 50mg / L, the process is controlled by adding nickel carbonate The pH of the reaction slurry is 4.8, and the aeration reaction time is 60 minutes. After the aeration is completed, compressed air is blown in for 5 minutes, and the reaction solution is filtered to obtain nickel mixed acid solution and black cobalt slag. Table 2 shows the ratio of nickel and cobalt in the liquid, black cobalt slag and liquid meter cobalt removal rate after cobalt removal.

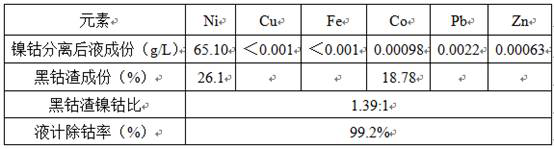

[0027] Table 2: Example 1 Nickel-Cobalt Separation and Analysis Results

[0028]

Embodiment 2

[0030] Table 3: Nickel-cobalt mixed acid solution composition (g / L) used in embodiment 2

[0031]

[0032] The specific implementation process: Take a certain amount of sulfuric acid and hydrochloric acid mixed with nickel-cobalt solution, pH=4.5, after the electric heating plate is heated to 55°C, turn on the stirring speed of 400r / min, adjust the ozone concentration to 150mg / L, the process is controlled by adding nickel carbonate The pH of the reaction slurry is 4.5, and the aeration reaction time is 50 minutes. After the aeration is completed, compressed air is blown in for 5 minutes, and the reaction liquid is filtered to obtain nickel mixed acid solution and black cobalt slag. After cobalt removal, the ratio of nickel to cobalt in the liquid, black cobalt slag and the cobalt removal rate in liquid meter are shown in Table 4.

[0033] Table 4: Example 2 Nickel-Cobalt Separation and Analysis Results

[0034]

Embodiment 3

[0036] Table 5: Nickel-cobalt mixed acid solution composition (g / L) used in embodiment 3

[0037]

[0038] Take a certain amount of nickel-cobalt solution mixed with sulfuric acid and hydrochloric acid, pH=5.0, heat up the electric heating plate to 45°C, turn on the stirring speed at 400r / min, adjust the ozone concentration to 110mg / L, and control the pH of the reaction slurry by adding nickel carbonate to 5.0, the ventilation reaction time is 60 minutes, and the compressed air is blown in for 5 minutes after the ventilation is completed, and the liquid after the reaction is filtered to obtain the mixed acid solution of nickel and black cobalt slag. After cobalt removal, the ratio of nickel to cobalt in the liquid, black cobalt slag and the cobalt removal rate of the liquid meter are shown in Table 6.

[0039] Table 6: Example 3 Nickel-Cobalt Separation and Analysis Results

[0040]

[0041] Based on the above three embodiments, it can be seen that the ratio of nickel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com