Floating extraction agent for strengthening floating extraction separation of lanthanum and cerium and method for selectively separating lanthanum and cerium

A selective and flotation technology, applied in the direction of lanthanum oxide/lanthanum hydroxide, cerium oxide/cerium hydroxide, process efficiency improvement, etc., to achieve the effect of strong hydrophobicity and relative stability, easy formation and easy dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

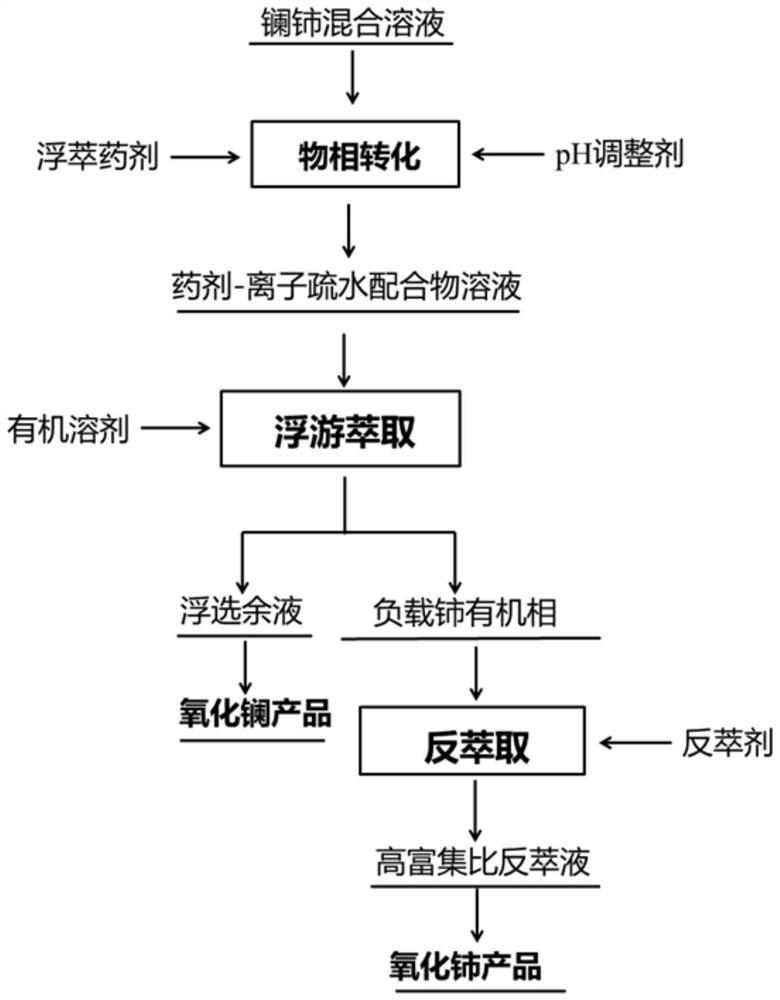

[0031] The invention discloses a method for selectively separating lanthanum and cerium with a floating extraction agent, which is composed of the following parts by mass: 20 parts by mass of sodium lauryl sulfate; and 80 parts by mass of P204. The floating extraction process is as follows:

[0032] (1) To 500mL La 3+ The concentration is 0.1mol / L, Ce 3+ In the solution with a concentration of 0.02 mol / L, a 6 mol / L HCl pH regulator was added to adjust the pH of the solution to 2. Then add 1.5 times the theoretical amount of cerium floating extraction agent, and stir at 600r / min for 30min. Ce 3+ Form a hydrophobic complex with the floating extraction agent P204 and combine with sodium dodecyl sulfate to become a drug-ion micro-droplet with stronger hydrophobicity.

[0033](2) Move the above-mentioned mixed solution into the flotation column, ventilate and adjust the gas velocity to be 50ml / min, add 20ml organic solvent in the upper layer of the solution, and the organic pha...

Embodiment 2

[0038] The invention discloses a method for selectively separating lanthanum and cerium with a floating extraction agent, which is composed of the following parts by mass: 30 parts by mass of sodium dodecylsulfonate; 70 parts by mass of P507. The floating extraction process is as follows:

[0039] (1) To 500mL La 3+ The concentration is 0.05mol / L, Ce 3+ In the solution with a concentration of 0.01 mol / L, 6 mol / L of HCl pH regulator was added to adjust the pH of the solution to 2.5. Then add 1.5 times the theoretical amount of cerium floating extraction agent, and stir at 600r / min for 30min. Ce 3+ Form a hydrophobic complex with the floating extraction agent P507 and combine with sodium dodecylsulfonate to become a drug-ion micro-droplet with stronger hydrophobicity.

[0040] (2) Move the above-mentioned mixed solution into the flotation column, ventilate and adjust the gas velocity to be 50ml / min, add 20ml organic solvent in the upper layer of the solution, and the organic...

Embodiment 3

[0045] The invention discloses a method for selectively separating lanthanum and cerium with a floating extraction reagent, which is composed of the following parts by mass: 40 parts by mass of sodium octadecyl sulfate; 60 parts by mass of P204. The floating extraction process is as follows:

[0046] (1) To 500mL La 3+ The concentration is 0.08mol / L, Ce 3+ In the solution with a concentration of 0.01 mol / L, 6 mol / L of HCl pH adjuster was added to adjust the pH of the solution to 3. Then add 1.8 times the theoretical amount of cerium floating extraction agent, and stir at 600r / min for 30min. Ce 3+ Form a hydrophobic complex with the floating extraction agent P204 and combine with sodium octadecyl sulfate to become a drug-ion micro-droplet with stronger hydrophobicity.

[0047] (2) Move the above-mentioned mixed solution into the flotation column, ventilate and adjust the gas velocity to be 50ml / min, add 20ml organic solvent in the upper layer of the solution, and the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com