Corrugated wall honeycomb structure and production method thereof

A corrugated wall and honeycomb technology, applied in ceramic products, internal combustion piston engines, adding non-fuel substances to fuel, etc., can solve the problem of difficult contact between fluid and wall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Best Mode for Carrying Out the Invention

[0071] Embodiments of the present invention are explained below with reference to the drawings, and it goes without saying that the present invention is not limited to the following embodiments.

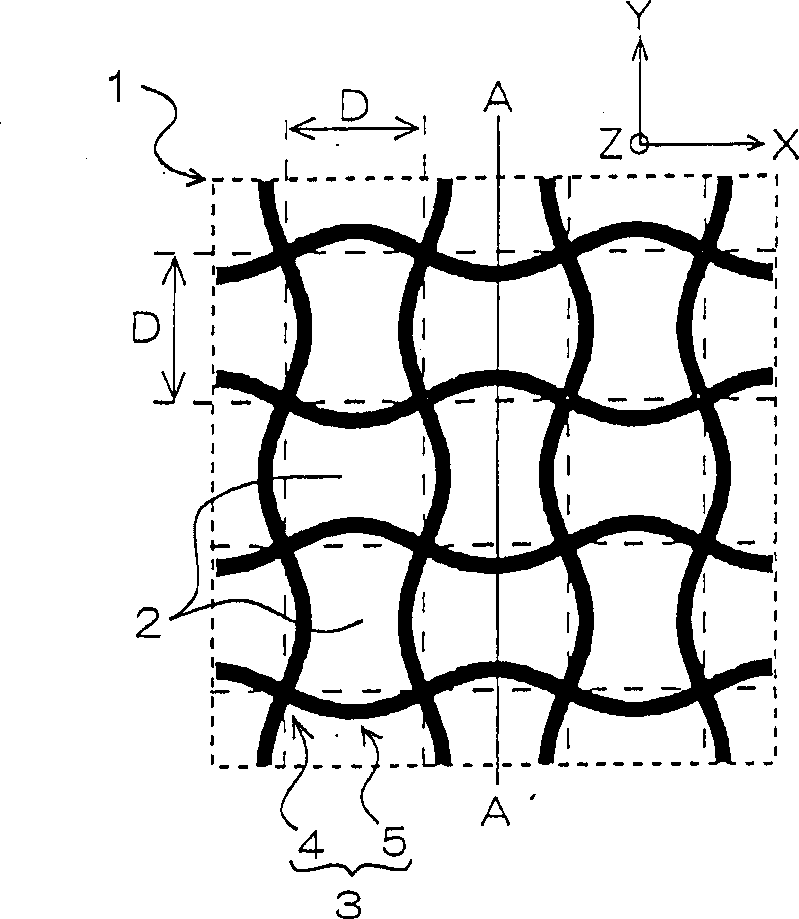

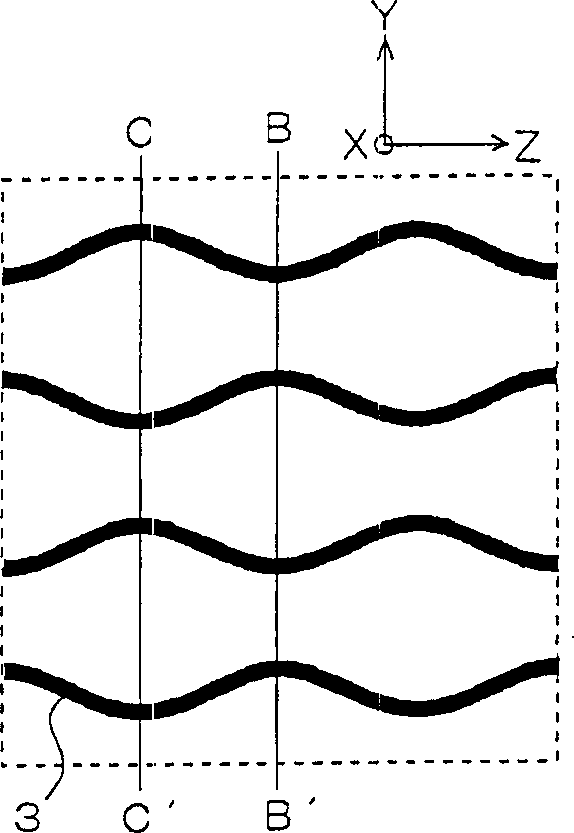

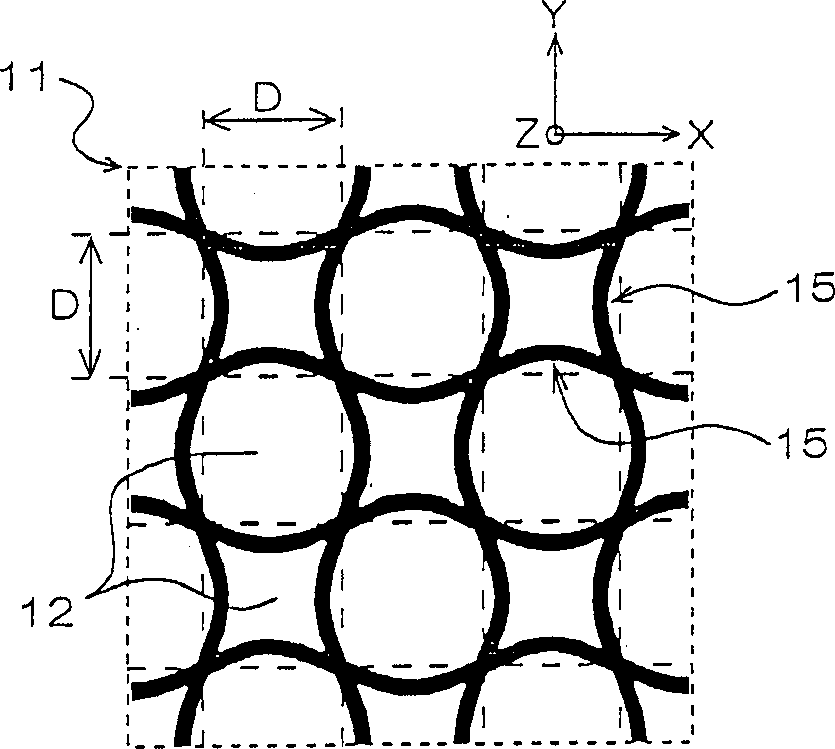

[0072] 1 (a) and (b) illustrate an embodiment of the undulated-wall honeycomb structure according to the present invention, wherein the cross section (hereinafter referred to as "cell channel cross section") and the cell channel direction (referring to the channel direction of the cell channel) The walls of a vertical, general honeycomb structure having a quadrangular (square) cell shape are made in a corrugated shape. The normal honeycomb structure is hereinafter referred to as "normal honeycomb structure" or "flat-walled honeycomb structure". The "corrugated-wall honeycomb structure" means a honeycomb structure having corrugated walls, and also includes a structure in which all walls are made as corrugated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com