Method for preparing TCPP (Tris(Chloroisopropyl)Phosphate) flame retardant

A flame retardant and oxidant technology, applied in the field of TCPP flame retardant preparation, can solve problems such as affecting product quality, reducing TCPP yield, increasing product acid value, etc., and achieving the effects of convenient operation, low odor and favorable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

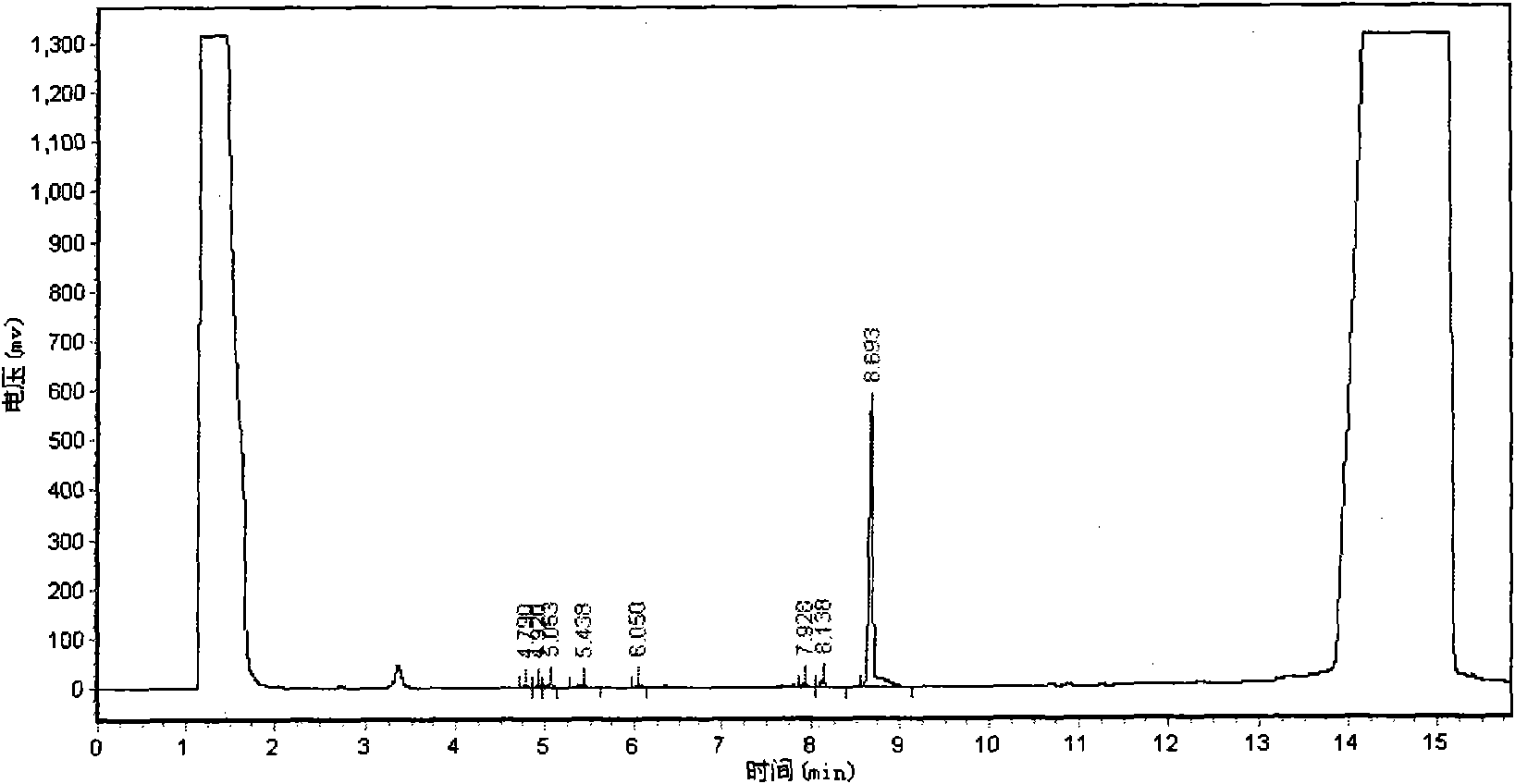

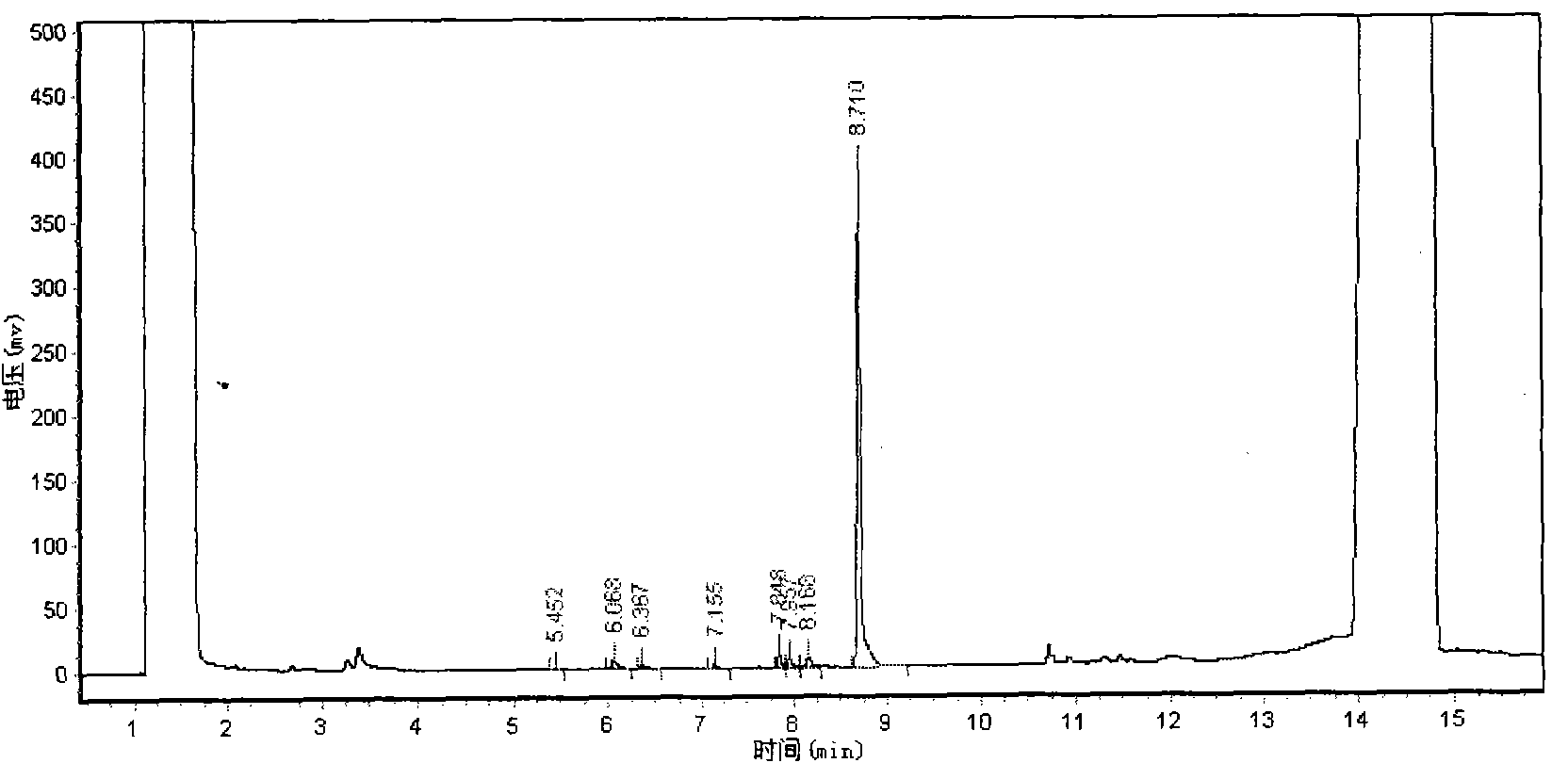

[0016] Embodiment 1: in the 1000ml four-necked flask that thermometer, stirrer are housed, add 600g above-mentioned TCPP crude products that make, stir and heat up to 50 ℃, add 100g concentration and be the potassium perchlorate solution acidified with sulfuric acid of 0.1%, keep 50 ℃ The mixture was stirred and reacted for 30 minutes. After liquid separation, it was washed once with alkali and twice with water. The water layer was separated, and the water was removed by vacuuming to obtain the finished product TCPP. The aldehyde content was determined to be 7.4 ppm by gas chromatography. Gas Chromatography See figure 2 , see Table 2 for the peak data.

Embodiment 2

[0017] Embodiment 2: in the 1000ml four-necked flask that thermometer is housed, add 600g above-mentioned TCPP crude products that make above, stir and be warmed up to 60 ℃, add the potassium chlorate solution that 129g concentration is 0.1% sulfuric acid acidification, keep stirring under 60 ℃ React for 30 minutes, wash with alkali and water after liquid separation, separate the water layer, and vacuumize to remove water to obtain the finished product TCPP. The aldehyde content measured by gas chromatography is 5.3 ppm.

Embodiment 3

[0018] Embodiment 3: in the 1000ml four-necked flask that thermometer is housed, add 600g above-mentioned TCPP crude products that make above, stir and be warming up to 70 ℃, add the sodium chlorate solution that 290g concentration is 0.05% sulfuric acid acidification, keep 70 ℃ Stir and react for 30 minutes, after liquid separation, wash with alkali and water, separate the water layer, and vacuumize to remove water to obtain the finished product TCPP. The aldehyde content measured by gas chromatography is 0.7ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com