Purification method for preparing ethylene glycol from coal-based synthesis gas

A coal-based synthesis gas and ethylene glycol technology, which is applied in the separation/purification of hydroxyl compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem that the UV value and aldehyde content of ethylene glycol are difficult to meet the standards, and the product quality indicators are up to standard Problems such as less than the national standard for superior products, affecting the UV value of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The purification unit is used to purify the ethylene glycol extracted from the side line of the coal-based synthesis gas to ethylene glycol product tower. The purification unit includes two 1# resin towers (1 open and 1 standby), 1 2# resin tower, 1# The resin tower and the 2# resin tower are connected in series.

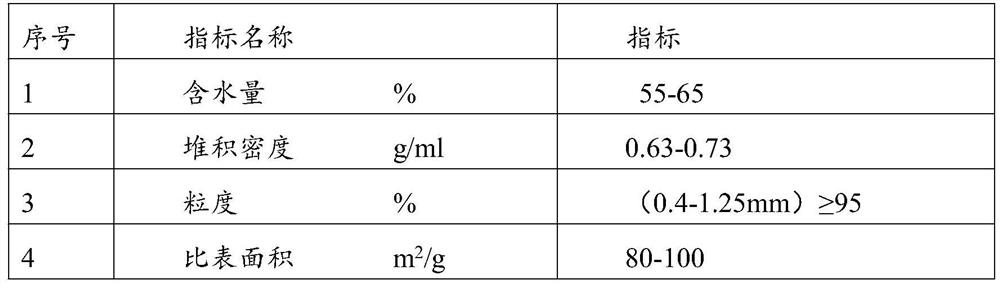

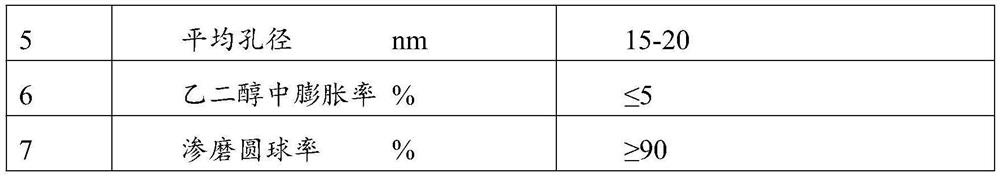

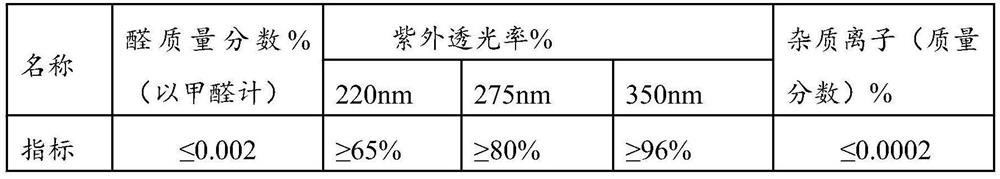

[0044] The ethylene glycol indicator that product tower side draws out is shown in Table 3:

[0045] Table 3 Ethylene glycol index before purification

[0046]

[0047] The ethylene glycol extracted from the side line of the product tower is passed into the 1# resin tower and the 2# resin tower in turn, and then the purified ethylene glycol is extracted from the outlet of the 2# resin tower. The operating parameters of the 1# resin tower are: The operating temperature is 35-50°C, the flow rate is 4m / h, the inlet pressure is 0.5-0.85MPa, the operating pressure difference is ≤0.18MPa, and the filling volume of SQYJ-2 enhanced UV resin in 1# resin tower is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com