Negative pressure mash tower degassing, aldehyde-discharging and acid-discharging device for fuel ethanol and edible alcohol

A technology for edible alcohol and fuel ethanol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. It can solve the problems of heavy load on towers, low PH value, and influence on product quality, so as to improve comprehensive Quality, reduce aldehyde content and acidity, reduce the effect of impurity discharge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

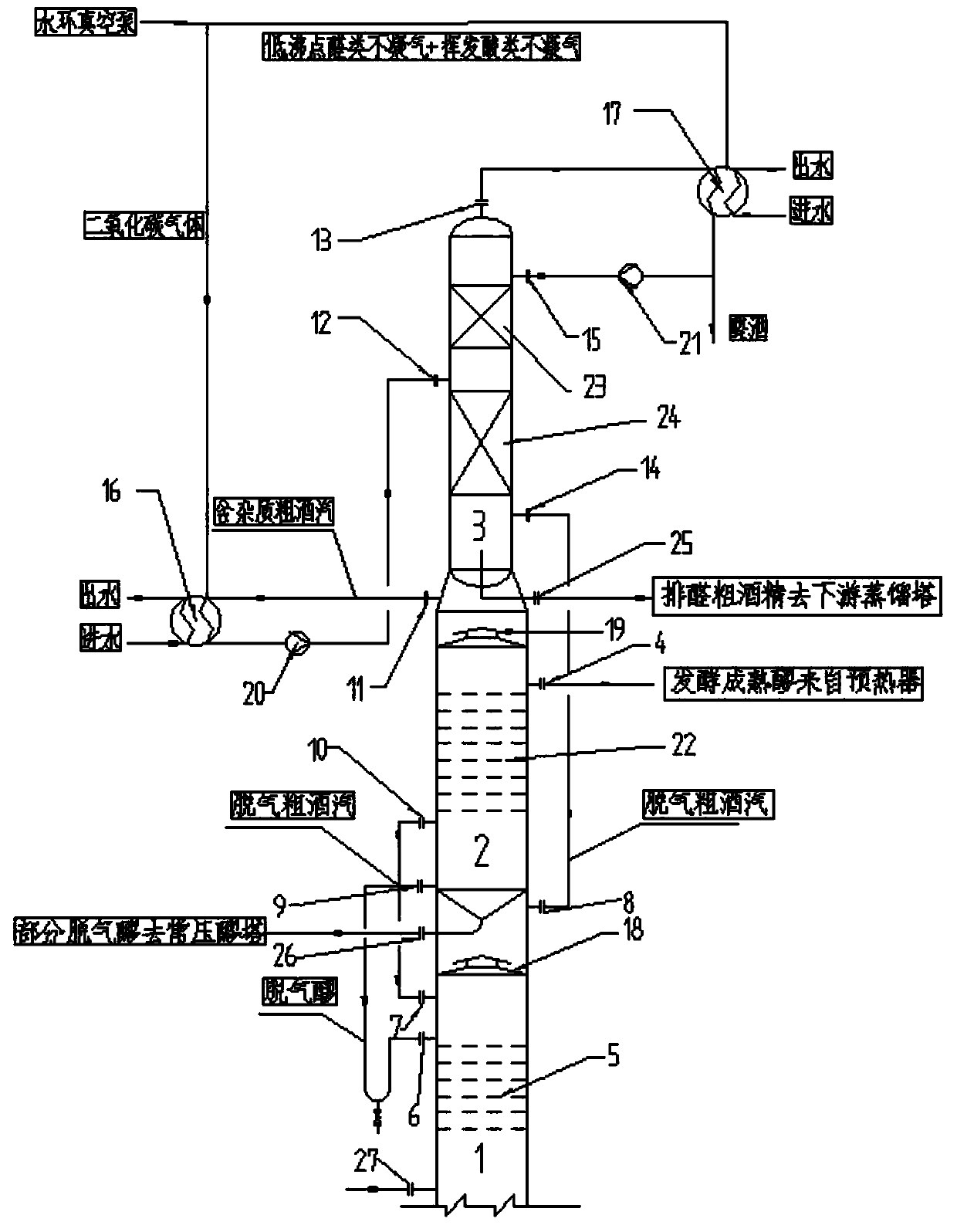

[0048] Negative pressure mash tower degassing and degassing and degassing devices for fuel ethanol and edible alcohol, such as figure 1 Shown:

[0049] (1) steam enters the negative pressure mash tower from the steam inlet 27, and the degassed mash is distilled by the first tray 5 in the mash tower 1 to obtain degassed crude wine gas;

[0050] (2) The fermented mature mash enters from the mature mash inlet 4 of the degassing section 2, and the degassed crude wine gas in the degassed section 2 is distilled through the second plate 22 to the fermented matured mash to obtain impurity-containing crude wine gas and degassed alcohol. mash. A part of degassed mash enters the normal pressure mash tower through the second degassed mash outlet 26; another part of degassed mash enters the degassed mash inlet 6 from the first degassed mash outlet 9, and then enters the negative pressure mash tower 1 to carry out step (1 ) distillation; the degassed crude wine gas obtained by distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com