Patents

Literature

134results about How to "The method flow is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering lithium from lithium-containing electrode waste material

InactiveCN108220607AShort leaching timeHigh recovery rateLithium oxides/hydroxidesLithium carbonates/bicarbonatesSlagScrap

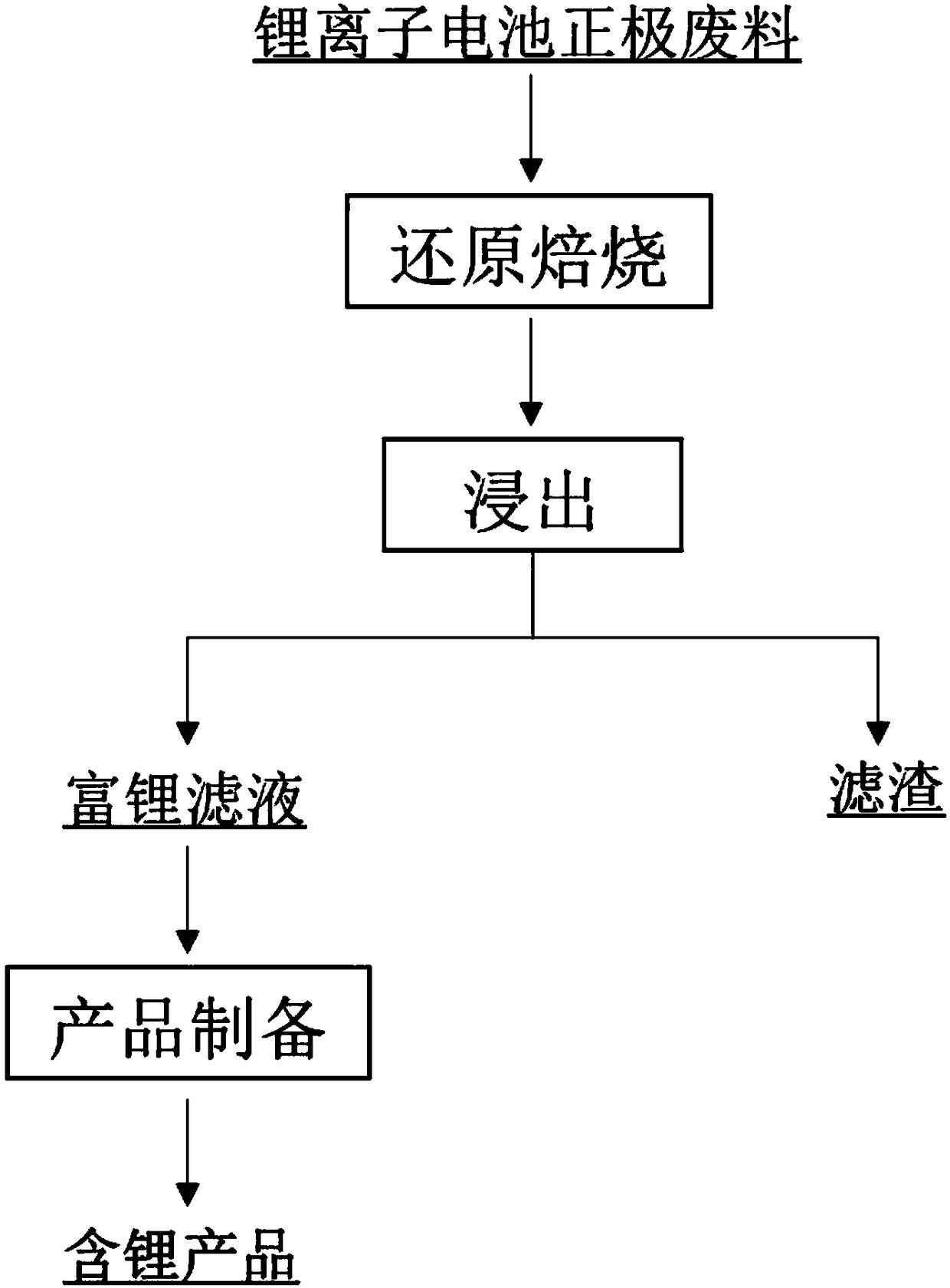

The invention provides a method for recovering lithium from a lithium-containing electrode waste material. The method comprises the following steps of (1) roasting the lithium-containing electrode waste material under a reducing atmosphere, after roasting, cooling under a protective atmosphere to obtain a reduced material, leaching the reduced material through a leaching agent, and carrying out solid-liquid separation to obtain a lithium-containing solution and solid slags; (2) preparing the lithium-containing solution in the step (1) into a lithium-containing product. According to the methodprovided by the invention, a reducing gas is adopted for reducing roasting, so that the roasting temperature is low, and the energy consumption is less; and one-step leaching is carried out after reducing, so that high-efficient separation of lithium and other metal elements can be realized, the concentration of the lithium in the leaching agent is high, the recovery rate of the lithium is greatlyimproved, the recovered lithium-containing product has high purity, and in addition, other transition metal elements in the waste electrodes can be further recovered. The method provided by the invention is short in flow, low in cost, and easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for preparing fraction oil hydrogenation treatmnt catalyst

InactiveCN1458232APromote formationModulation of surface propertiesHydrocarbon oils refiningDistillates petroleumActive component

The preparation process of fraction oil hydrogenation treatment catalyst includes assistant adding modification of gamma-alumina precursor and subsequent conventional preparation process. The fraction oil hydrogenation treatment catalyst includes gamma-alumina precursoe prepared through carbonation process, aluminum nitrate process, aluminum sulfate process or aluminum chloride process; F an / or Bas assistant and W and Ni as active component. Compared with available technology, the present invention has the advantages of simple preparation process, low cost, low power consumption, and excellent catalyst performance. The catalyst of the present invention is suitable for hydrogenation treatment of 130-390 deg.c fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for selectively recycling positive electrode materials for lithium ion batteries

ActiveCN108832215AImplement selective extractionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLiquid wasteSlag

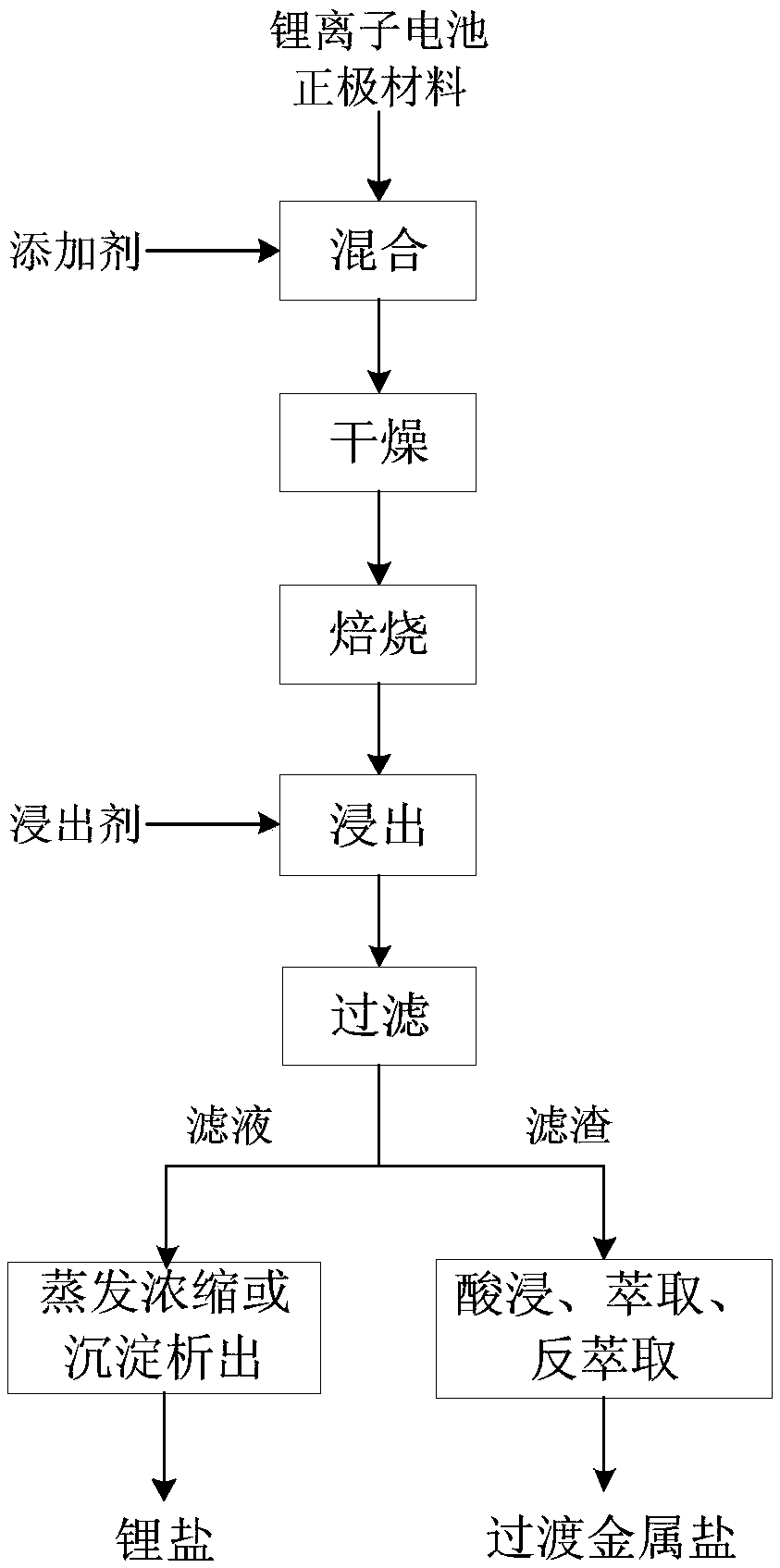

The invention provides a method for selectively recycling positive electrode materials for lithium ion batteries. The method comprises the following steps: carrying out transformation processing aftermixing the recycling positive electrode materials for lithium ion batteries with an additive; leaching an obtained transformation product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and a solid slag; and preparing the obtained lithium-rich solution into a lithium salt and the obtained solid slag into a transition metal salt. According to the method, recycling of valuable metals in the positive electrode materials for lithium ion batteries is realized by using in situ crystal transformation and mild leaching methods, particularly, selectiveextraction for lithium is realized, the recycle rate reaches 95% or above, and the recycle rate of other valuable metals such as nickel, cobalt and manganese reaches 98% or above; the method is shortin flow, other impurity ions are not introduced, the product purity is high, secondary pollution and liquid waste disposal can also be avoided, the recycle cost is saved, and the method is easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recovering organic effluent brine

InactiveCN102633398AIncrease expansionIncrease its valueElectrolysis componentsMultistage water/sewage treatmentFiltrationEvaporation

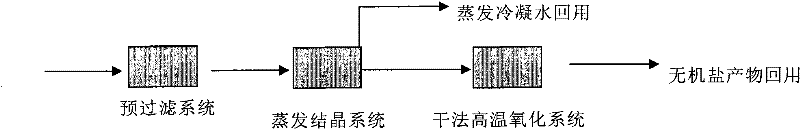

The invention discloses a method for recovering organic effluent brine. The method comprises the following steps: introducing organic effluent brine containing inorganic salts and organic matter into a prefiltration system, an evaporation crystallization system and a dry-method high temperature oxidation reaction system, after filtration, evaporation, and oxidation treatment, allowing the obtained inorganic salt product to be dissolved to become saturated brine, wherein the total organic carbon TOC is less than 10 ppm. With the method of the invention, more than 90% of water and inorganic salts can be recovered, and the zero discharge standard for waste water is basically reached; the recovery rate for the recycling of organic effluent brine is effectively increased; and great benefits are generated for environment protection and resource recovery; additionally, the obtained inorganic salt product can be used as an industrial raw material for recycling in ionic membrane electrolytic devices.

Owner:凯膜过滤技术(上海)有限公司

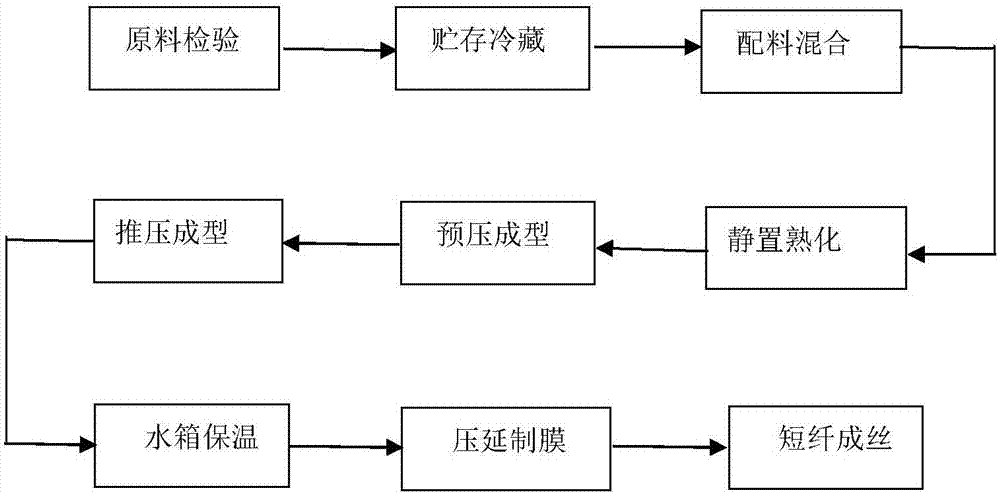

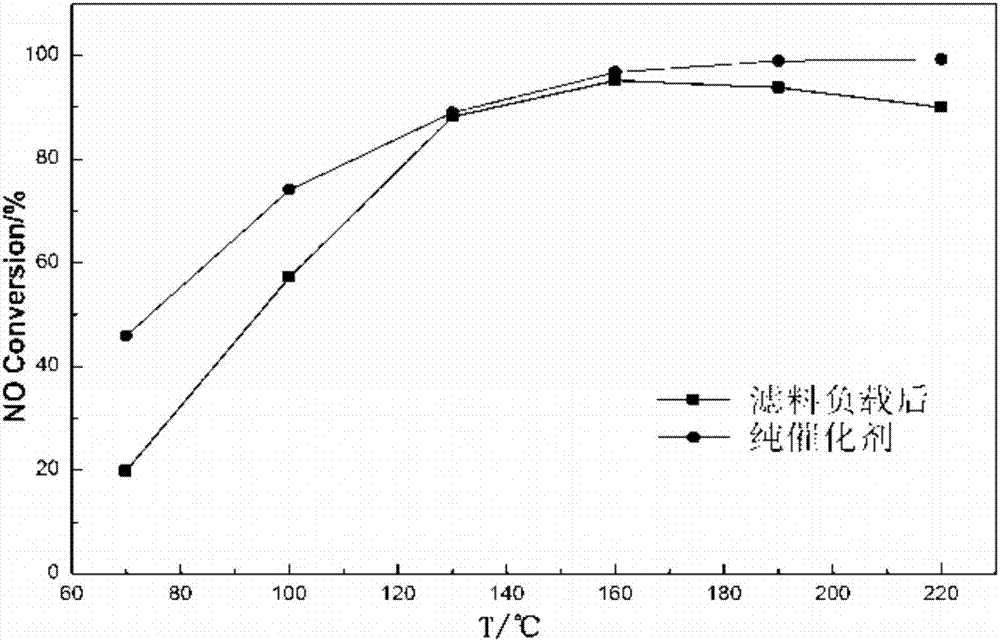

PTFE (polytetrafluoroethylene) fiber for denitration and preparation method of PTFE (polytetrafluoroethylene) fiber

InactiveCN107475795AShort processThe denitrification function is more stable and moreFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentFilamentationFilter material

The invention discloses a PTFE (polytetrafluoroethylene) fiber for denitration. The fiber is prepared from PTFE dispersion resin, aviation kerosene and manganese catalyst powder. The invention further provides a preparation method of the PTFE fiber for denitration. The method comprises the steps of raw material inspection, storage and refrigeration, ingredient mixing, standing and curing, prepressing forming, pushing forming, heat preservation in a water tank, rolling for film forming and filamentation of short fibers. The PTFE fiber and the preparation method have the advantages that a functional filter material for dedusting and denitration can be directly prepared from the PTFE fiber; the preparation method of the PTFE fiber is short in process, a denitration catalyst is evenly dispersed in the fiber, and the denitration function is stable and efficient.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Preparation method for bamboo fiber

The invention provides a method for rapid extraction of bamboo fiber from bamboo, and the bamboo fiber fully meets textile requirements. The preparation method for bamboo fiber belongs to the textile field. The preparation method for bamboo fiber comprises the steps of: bamboo sheet preparation, bamboo sheet cooking, crushing decomposition, bamboo filament cooking, bio-enzyme degumming, and after-treatment. The preparation method for bamboo fiber provided by the invention has the advantages of simplicity, short process, no pollution, environmental protection, low energy consumption, and obvious economic benefits.

Owner:QINGDAO BAIZHONG CHEM TECH

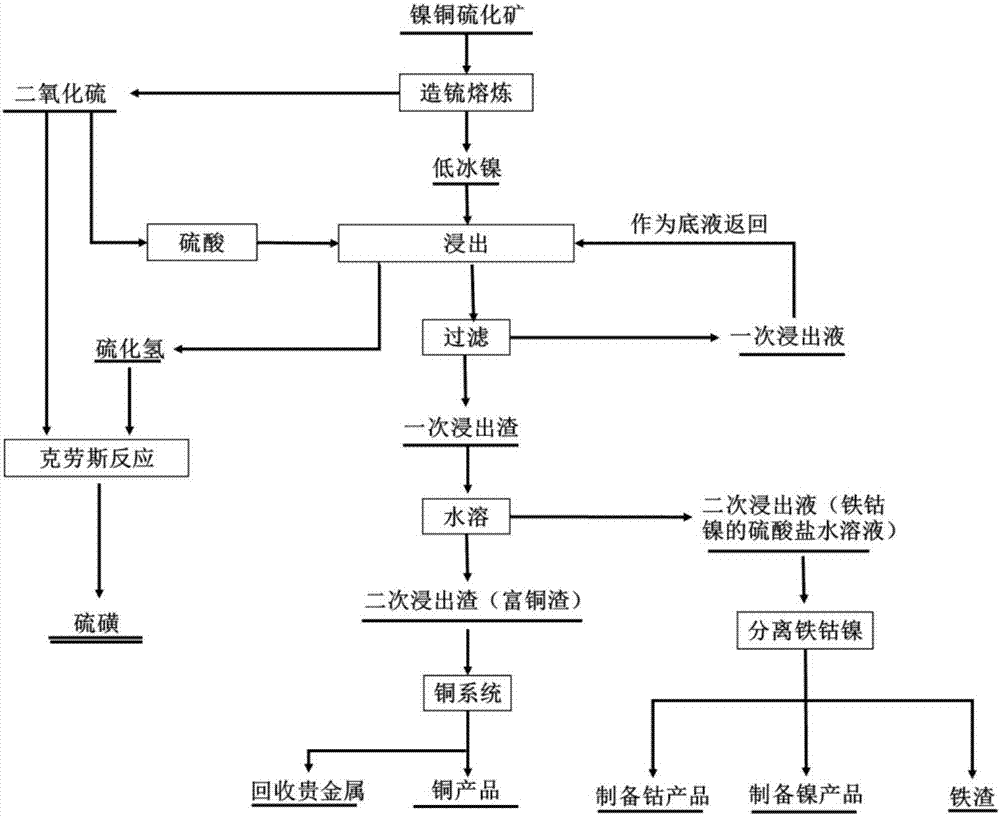

Method and system for recovering main associated elements from copper-nickel sulfide ore

ActiveCN107012324AAchieve deep separationImprove efficiencyProcess efficiency improvementSlagNickel sulfide

The invention provides a method and system for recovering main associated elements from copper-nickel sulfide ore. The method comprises the following steps: 1, continuously adding low-grade nickel matte and a leaching reaction solution into a reaction base solution, carrying out selective leaching, and collecting hydrogen sulfide gas, a first leaching solution and a first leaching residue, wherein the leaching reaction liquid is sulfuric acid with the mass fraction being 60-95%; 2, adding water into the first leaching residue for dissolving the first leaching slag, and collecting a second leaching solution and a second leaching residue; and 3, removing iron from the second leaching solution, collecting an iron-removed solution used for extracting nickel and cobalt and an iron-removed residue used for iron making, and / or sending the second leaching residue to a copper smelting device for smelting to obtain copper and noble metal. According to the method, deep separation of the nickel and the copper can be realized, and recovery of the nickel, the copper, the cobalt, the noble metal and sulfur can be effectively realized. The method is simple in process, short in flow and high in efficiency, is a clean and efficient element recovery process and is easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

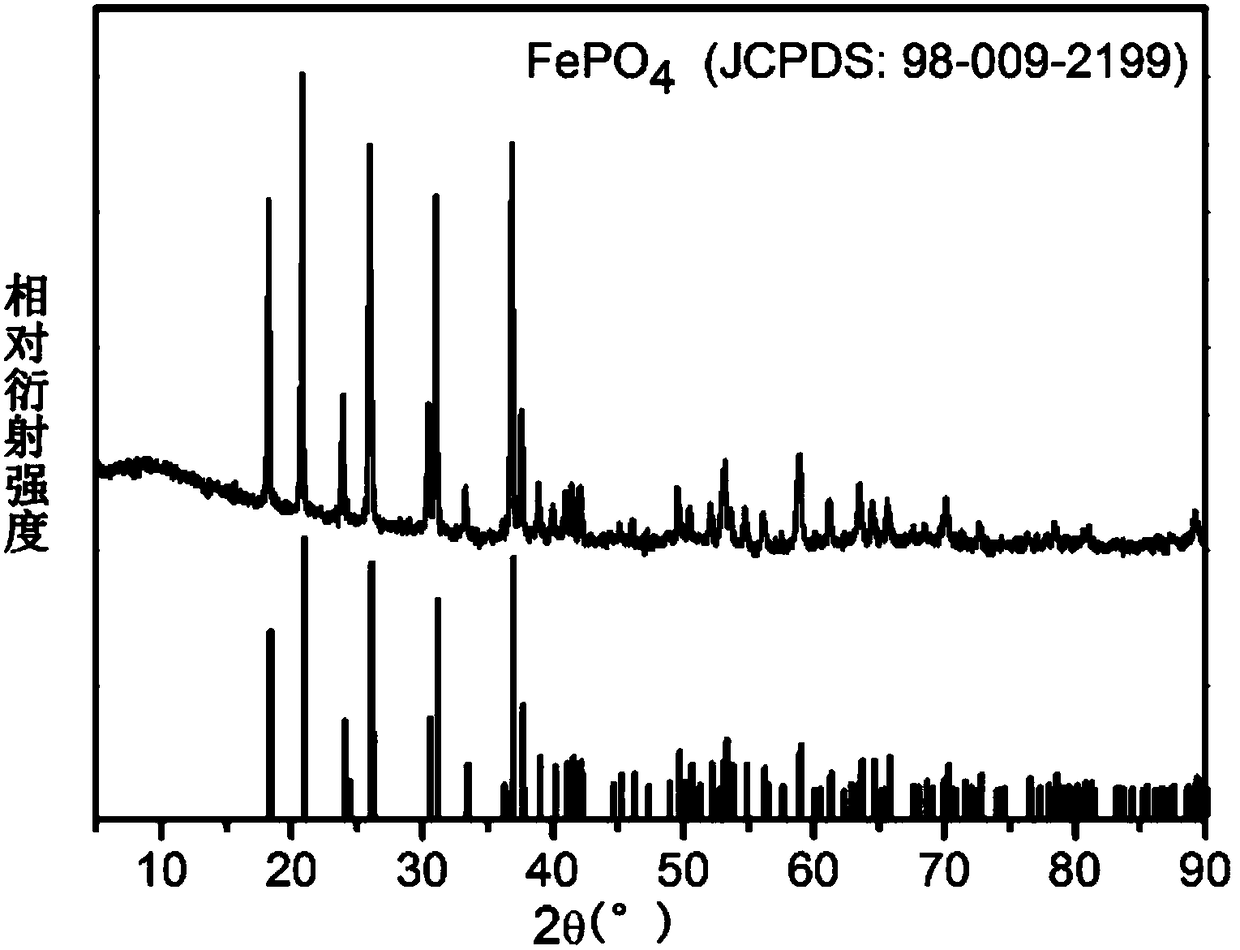

Method for extracting lithium in waste lithium ion phosphate anode material

InactiveCN108461857AIncrease profitImprove heating efficiencyWaste accumulators reclaimingBattery recyclingLithium iron phosphateMicrowave

The invention provides a method for extracting lithium in a waste lithium ion phosphate anode material. The method comprises the following steps: (1) mixing the waste lithium ion phosphate anode material with an extracting agent solution to obtain mixed slurry; (2) extracting the mixed slurry in the step (1) under the microwave condition and performing solid-liquid separation after extracting to obtain solid containing lithium leachate and FePO4. According to the method disclosed by the invention, the lithium in the waste extracting agent anode material is extracted out through microwave assistance, so that an energy utilization rate and a heating efficiency are high; by means of the method, a lithium extracting rate can reach 95% or more, selectivity and a recovery rate of lithium can respectively reach 98% and 95% or more, and iron is precipitated in a FePO4 mode; the method has the advantages of short process flow, simpleness in operation and easiness in industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

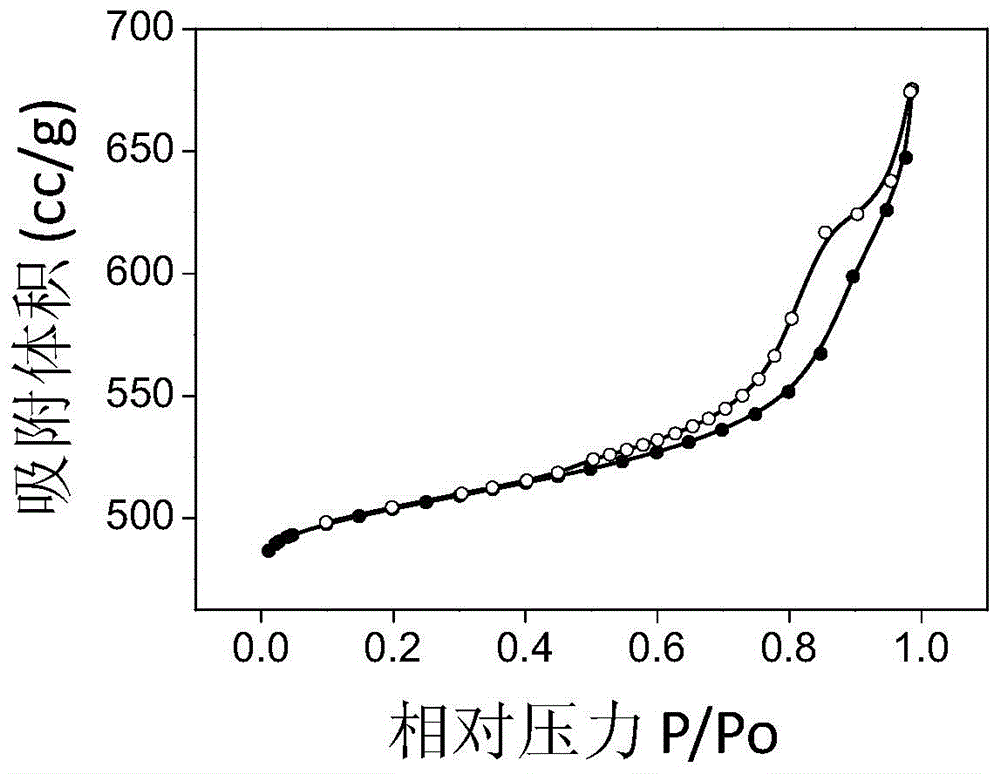

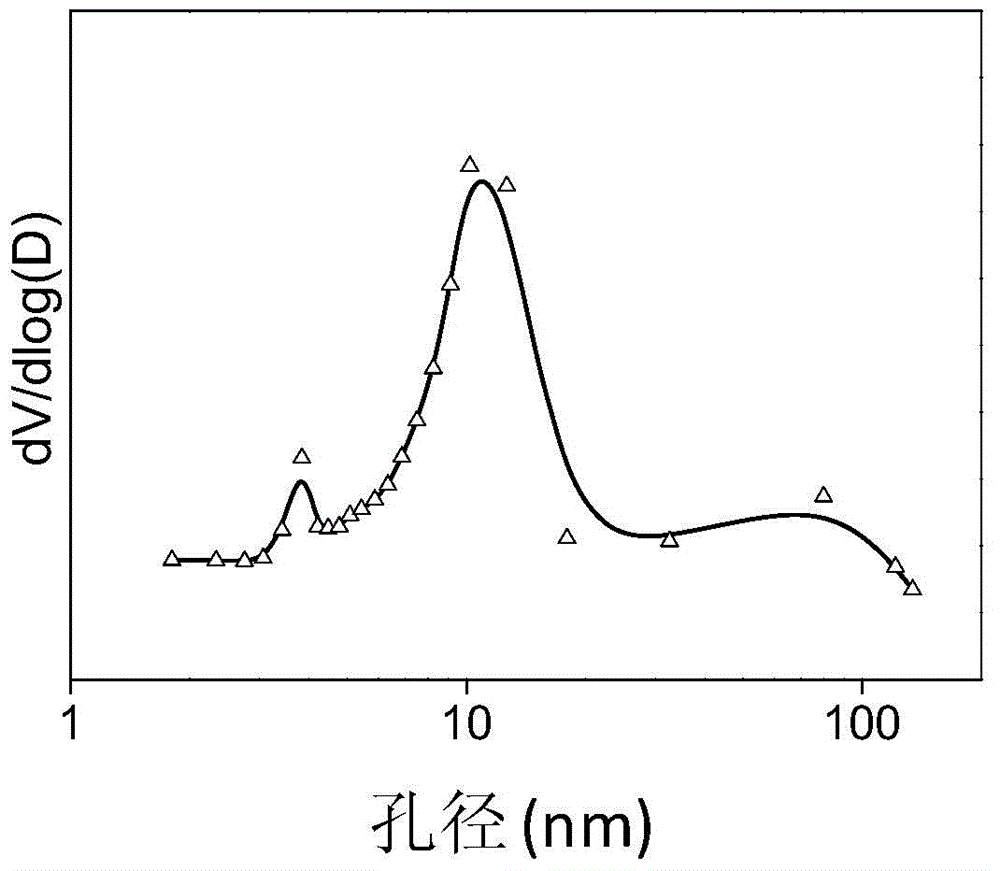

A lithium iron phosphate with high compact density and a preparation method thereof

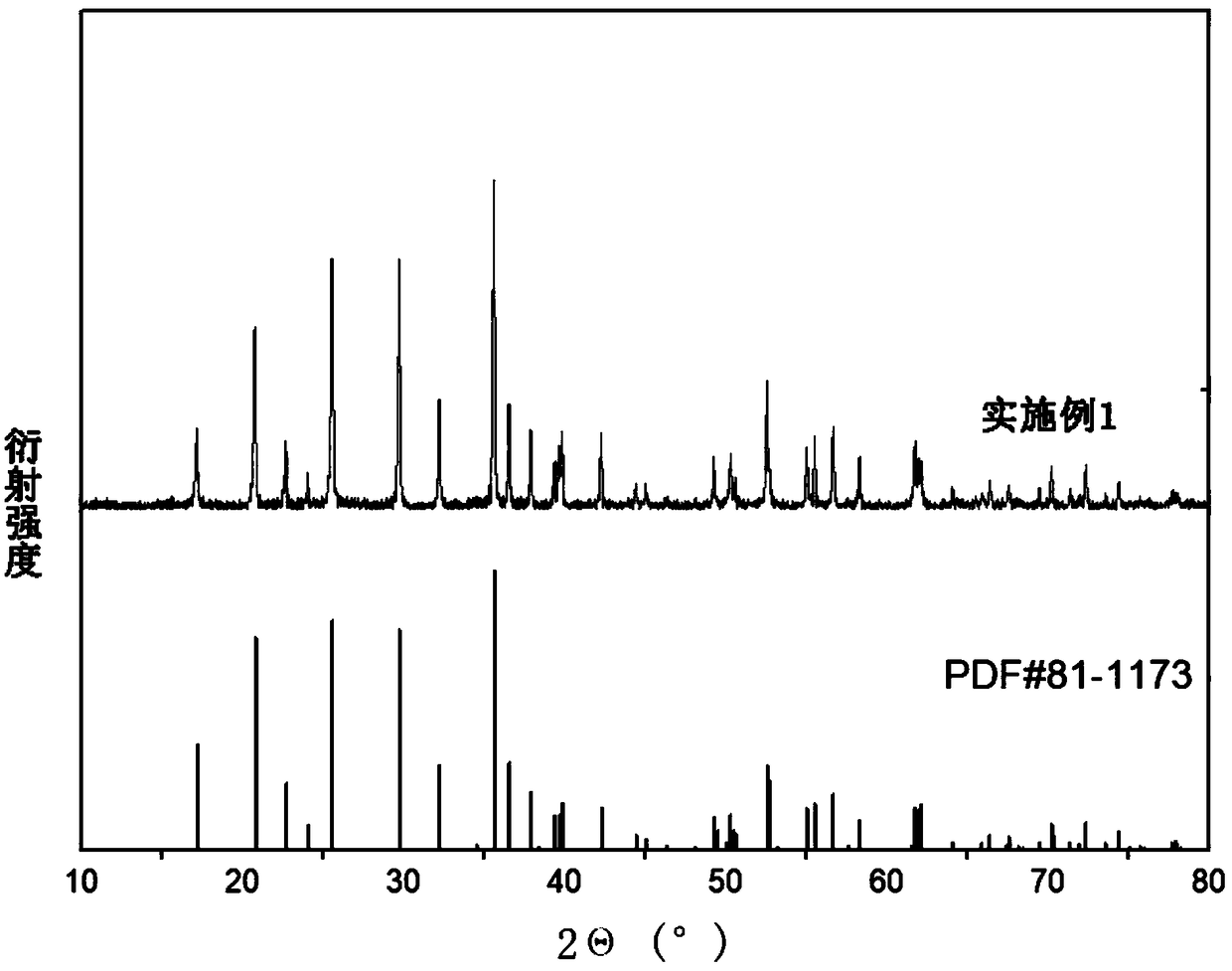

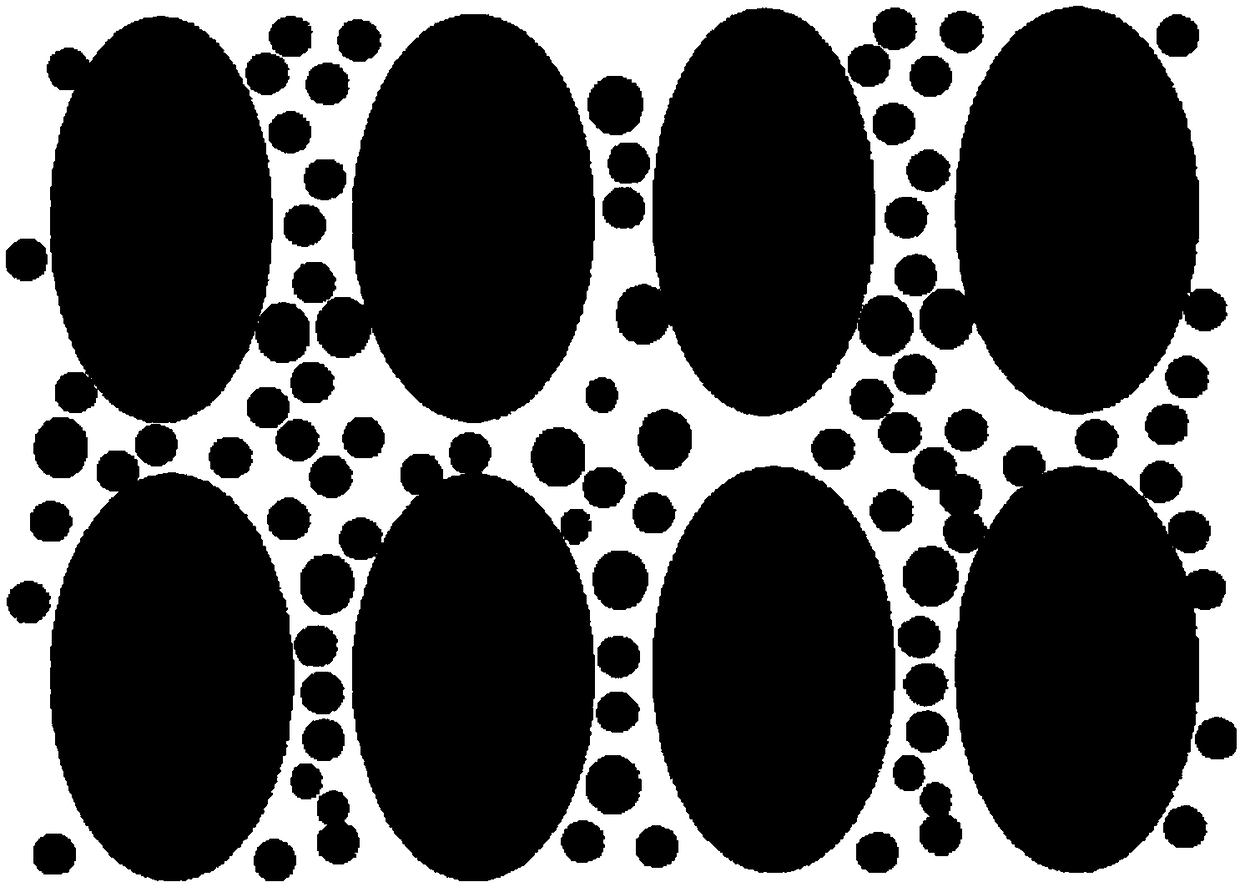

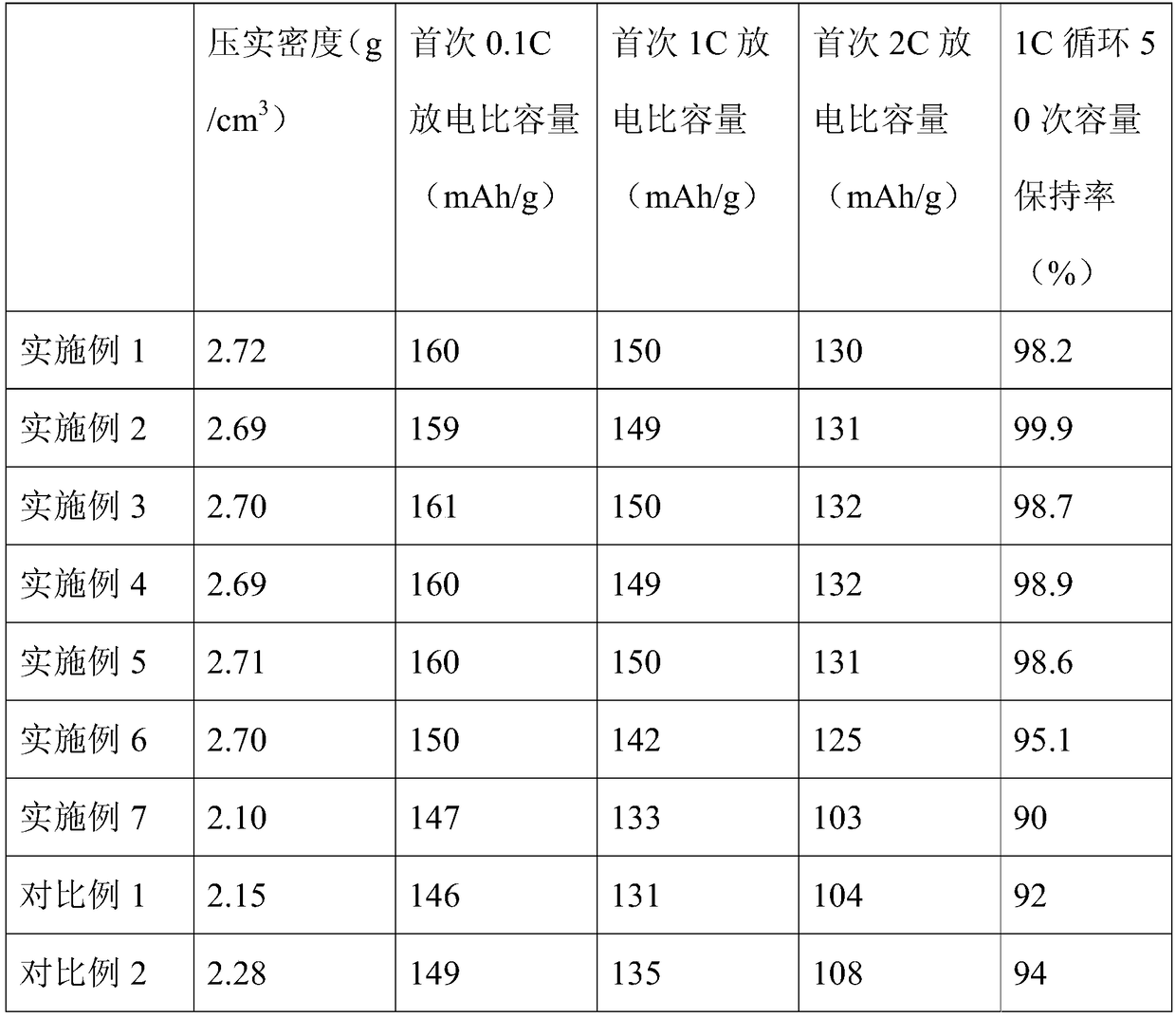

ActiveCN109192948AIncrease compaction densityReduce porosityCell electrodesSecondary cellsLithium iron phosphateThree stage

The invention provides a lithium iron phosphate with high compact density and a preparation method thereof. The lithium iron phosphate positive electrode material comprise large particles of lithium iron phosphate and small particle of lithium iron phosphate, wherein that small particles of lithium iron phosphate are filled in the voids between the large particle of lithium iron phosphate, and theshape of the small particles of lithium iron phosphate comprises a spherical shape. A method for prepare that lithium iron phosphate precursor comprises sinter the lithium iron phosphate precursor ina protective gas atmosphere, wherein the sintering is three-stage sintering, the sintering temperature of the three-stage sintering is sequentially increased, and aft the three-stage sintering is finished, the lithium iron phosphate positive electrode material is obtained; Wherein the shape of the lithium iron phosphate precursor comprises a spherical shape. The compaction density of the lithiumiron phosphate with high compaction density provided by the invention can reach 2.7 g / cm3, the electrochemical performance is excellent, the first discharge specific capacity of 1C can reach 150 mAh / g, and the capacity retention rate of 50 cycles of 1C can reach 99.9%.

Owner:SHENZHEN DYNANONIC

Method for preparing babbitt alloy from residue containing silver of copper anode slime

InactiveCN102312097AEasy to separateLow costProcess efficiency improvementElectrolytic agentAntimony potassium tartrate

The invention relates to a method for preparing a babbitt alloy from residue containing silver of copper anode slime. The method comprises the following steps:1, adding sodium carbonate, powdered carbon and borax according to the mass of the residue containing silver, and uniformly mixing; 2, melting to obtain a crude alloy containing lead; 3, preparing an electrolyte from fluosilicic acid, lead fluorosilicate, stannous oxide and potassium antimonyl tartrate, and adding with gelatin and ethyl naphthol; 4, treating the crude alloy as an anode and a stainless steel plate as a cathode, and taking the cathode plate (the stainless steel plate) and peeling cathode products each 12h; and 5, adding lead, antimony and copper or tin, antimony and copper to the cathode products, and melting to obtain the lead-based or tin-based babbitt alloy. The method which has the advantages of short flow, low cost, and strong practicality and allows the lead-based or tin-based babbitt alloy to be prepared from the residue containing silver of the copper anode slime is especially suitable for anode slime processing in electrolyzing electronic wastes with regenerated copper, and has the characteristics of simple and feasible operation, and high recovery rate of valuable metals.

Owner:广东省资源综合利用研究所

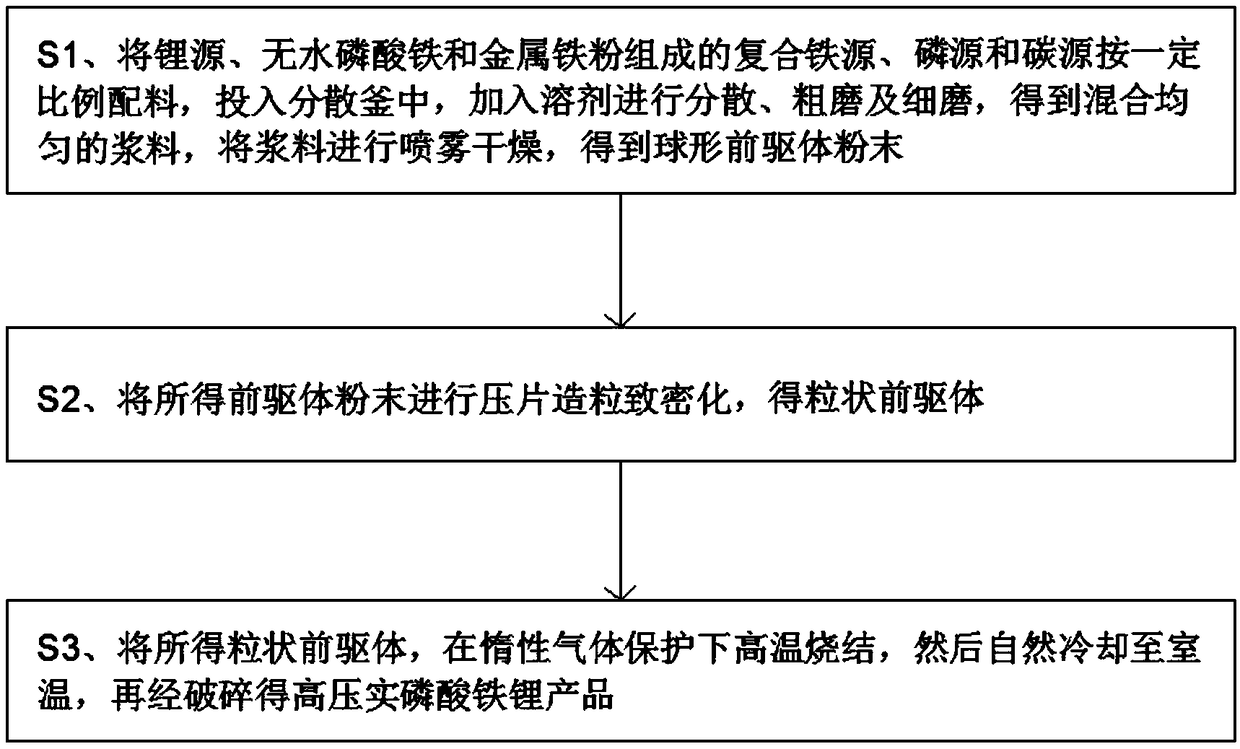

Preparation method of positive electrode material lithium iron phosphate for high-compaction lithium ion battery

The invention provides a preparation method of a positive electrode material lithium iron phosphate for a high-compaction lithium ion battery. The preparation method comprises the following steps thatS1, a lithium source, a composite iron source composed of ferric pyrophosphate and metal iron powder, a phosphorus source and a carbon source are prepared according to a certain proportion and put into a dispersion kettle, a solvent is added for dispersion, coarse grinding and fine grinding to obtain uniformly-mixed slurry, and the slurry is subjected to mist spraying and drying to obtain spherical precursor powder; S2, the obtained precursor powder is tableted, granulated and densified to obtain a granular precursor; S3, the obtained granular precursor is sintered at a high temperature underthe protection of inert gas, and then naturally cooled to the room temperature and pulverized to obtain a high-compaction lithium iron phosphate product. According to the preparation method, the composite iron source is adopted, the density of the metal iron powder is high, and in cooperation of nanoscale ferric pyrophosphate, synthesized lithium iron phosphate has excellent electrochemical performance and higher tap density; the precursor powder obtained by mist spraying and drying is tableted, granulated and densified, and therefore the sintering production efficiency and the density of thelithium iron phosphate material are improved.

Owner:江西省金锂科技股份有限公司

Comprehensive recovery method for tungsten accompanying fluorite resources

The invention discloses a comprehensive recovery method for tungsten accompanying fluorite resources. The method comprises the steps that tungsten accompanying fluorite ore is broken and ground and then is subjected to magnetic separation deferrization and flotation desulfuration; the desulfured tailings are subjected to flotation separation I through a combined inhibitor composed of sodium silicate, bake glue and gallotannic acid and a collecting agent fatty acid to obtain tungsten and fluorite bulk concentrate; the bulk concentrate is subjected to flotation separation II through an inhibitor amino phosphonate after being subjected to acid decalcification treatment, the foam product is fluorite concentrate, and the tailings product is tungsten concentrate. By means of the method, the comprehensive recovery rate of tungsten and fluorite resources is greatly improved, the flow is short, the medicament is simple, operation is convenient, the labor intensity is low, energy consumption is low, environmental protection and high efficiency are achieved, and the ore dressing cost is greatly reduced.

Owner:CENT SOUTH UNIV

Preparation method of metal base nanometer composite powder material for added material manufacturing

InactiveCN108015295AEvenly distributedGood dispersionMaterial nanotechnologyTransportation and packagingNanoparticleMetal powder

The invention relates to a preparation method of a metal base nanometer composite powder material for added material manufacturing, and belongs to the technical field of preparation of metal powder. Nanometer reinforcing particles are introduced in the atomization powder preparation process, so that atomization powder preparation and nanometer particle reinforcement are synchronously finished to realize metallurgical bonding of a basal body and nanometer particles. Compared with the prior art, the method can efficiently prepare the nanometer composite powder material with high sphericity and good fluidity, and is more suitable for industrial preparation of the composite powder material for added material manufacturing.

Owner:BEIJING COMPO ADVANCED TECH

Bank ATM machine high-strength anti-knock steel plate and manufacture method

The invention aims at market requirement of high-strength steel plate technology used by a bank ATM automatic teller machine, disadvantages of insufficient low-grade steel strength and anti-knock anti-fall bulletproof performances can be changed, the low carbon and manganese content are designed, a proper amount of niobium vanadium titanium copper microalloy element can be added, a converter is used for rapidly smelting, the steel is refined outside the furnace and is refined through degassing, the molten steel purity degree is improved, and the invention provides a bank ATM machine high-strength anti-knock steel plate and a manufacture method, through a high rigidity four-roll reversible rough rolling / refine rolling temperature control controlled rolling technology, the steel strength, toughness and steel plate flatness are improved, and a pearlite and ferrite microstructure can be obtained. The method has the advantages of short flow, high efficiency, easy operation, easy welding and low cost, the plate flatness control can satisfy the manufacture and usage of the bank system ATM automatic teller machine.

Owner:JIGANG GRP

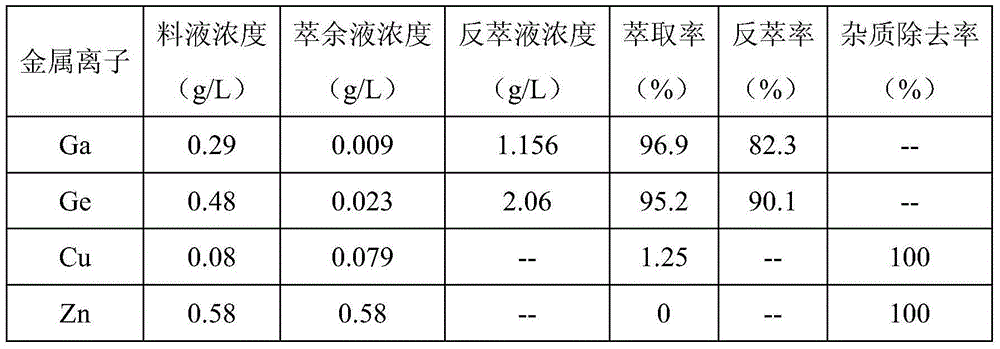

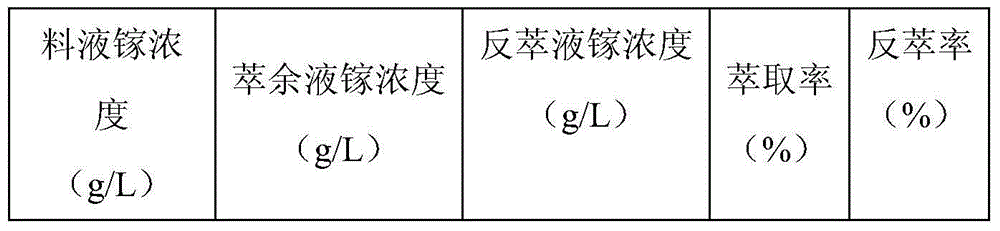

Method for selective extraction of gallium and germanium from oxalic acid solution containing gallium and germanium

The invention discloses a method for selective extraction of gallium and germanium from an oxalic acid solution containing gallium and germanium. The method comprises the following steps of carrying out single-stage or multistage countercurrent extraction on the oxalic acid solution containing gallium and germanium by an organic phase, carrying out single-stage or multistage countercurrent selective gallium-back-extraction on the carrying organic phase obtained by the above single-stage or multistage countercurrent extraction to extract gallium, and carrying out germanium back-extraction on the organic phase obtained by the gallium-back-extraction by an alkali solution to respectively obtain a gallium-containing aqueous solution and a germanium-containing aqueous solution. The method effectively realizes separation of gallium and germanium from impurities such as copper and zinc, has a short flow process, small chemical reagent consumption and a low cost and can easily realize industrialization.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

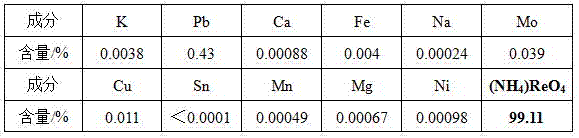

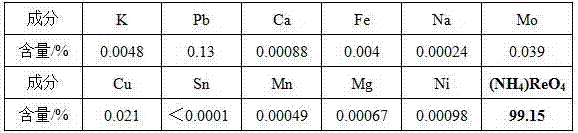

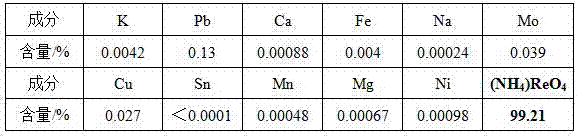

Method for removing tungsten, vanadium, phosphor and arsenic from molybdate solution by deposition

ActiveCN101492181AHigh depth of impurity removalMolybdenum loss is smallMolybdeum compoundsChemistryTungsten

The invention provides a method for removing tungsten, vanadium, phosphorus and arsenic from a molybdenate solution by deposition. The method comprises that: a reagent is added into the molybdenate solution to generate a precipitator in the solution, and by the precipitator, the impurities of tungsten, vanadium, phosphorus and arsenic in the solution are removed. The method has the advantages of removing various impurities at the same time and having high impurity removing degree, along with little loss of molybdenum, short flow, simple equipment, easy implementation, low cost and no environmental pollution.

Owner:CENT SOUTH UNIV

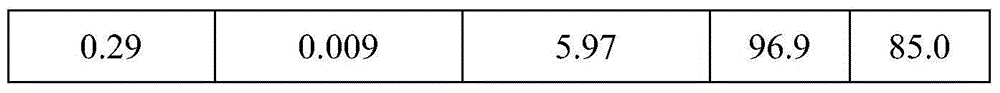

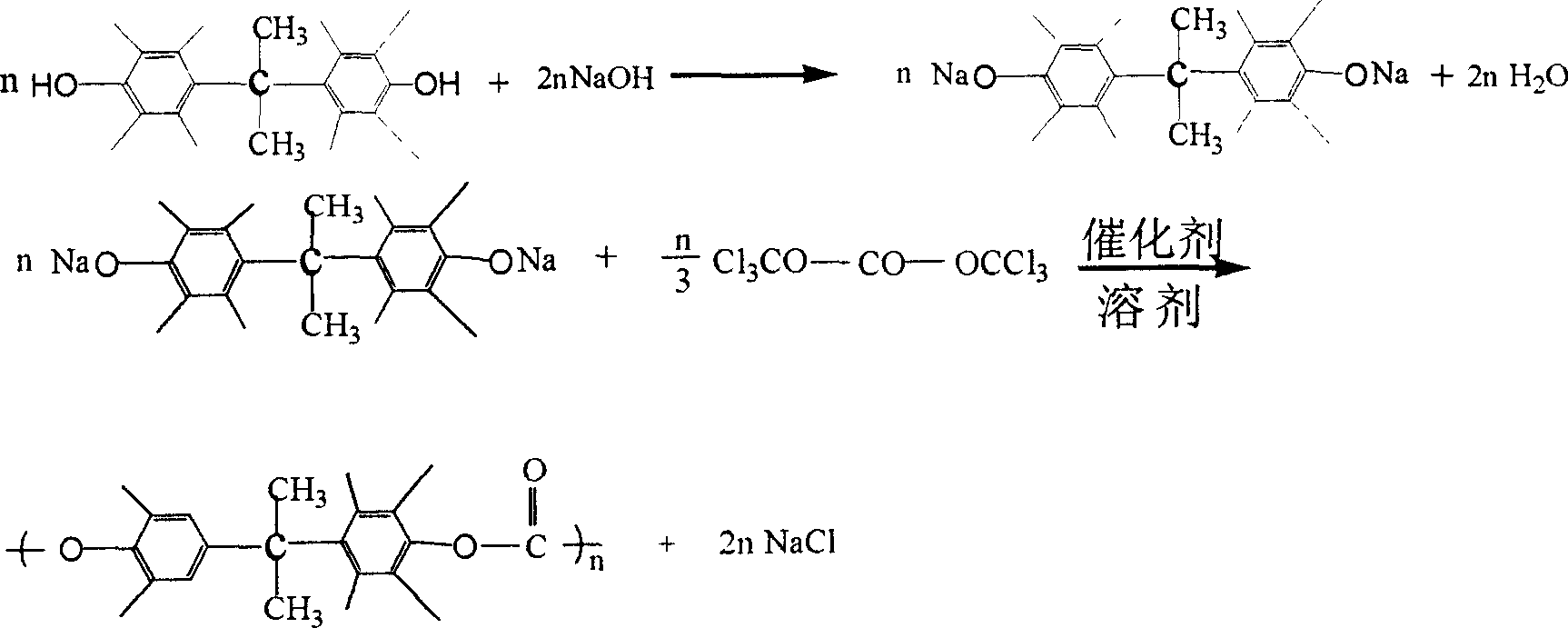

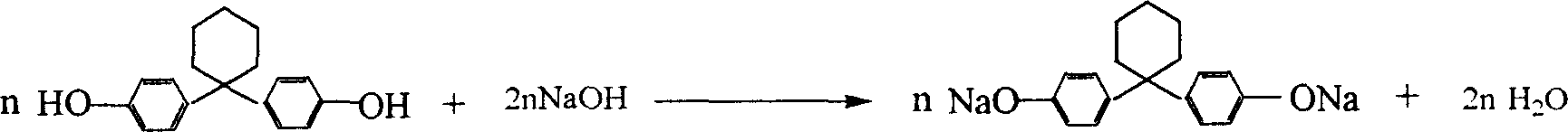

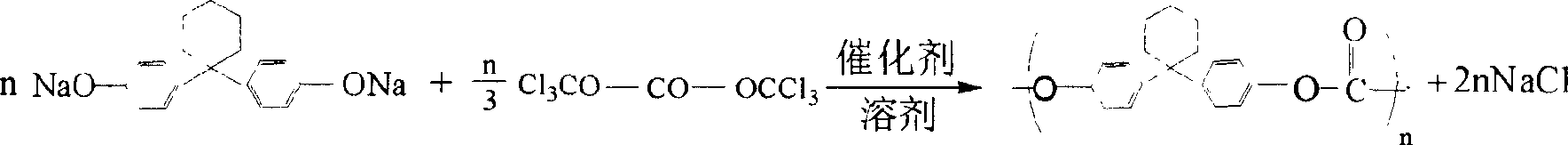

Bisphenol type flame-retardant polycarbonate interface method preparation method

The invention provides a novel method for preparing Bisphenol type flame-retardant polycarbonate characterized by that, tri-phosgene is employed to substitute phosgene for reacting with bis-phenol raw material to obtain flame-proof polycarbonate. The method can realize greatly improved production safety.

Owner:WUHAN CHEM COLLEGE

Method for recovering rhenium from high-sulfur high-arsenic unwieldiness lean rhenium slag

Owner:JINCHUAN GROUP LIMITED

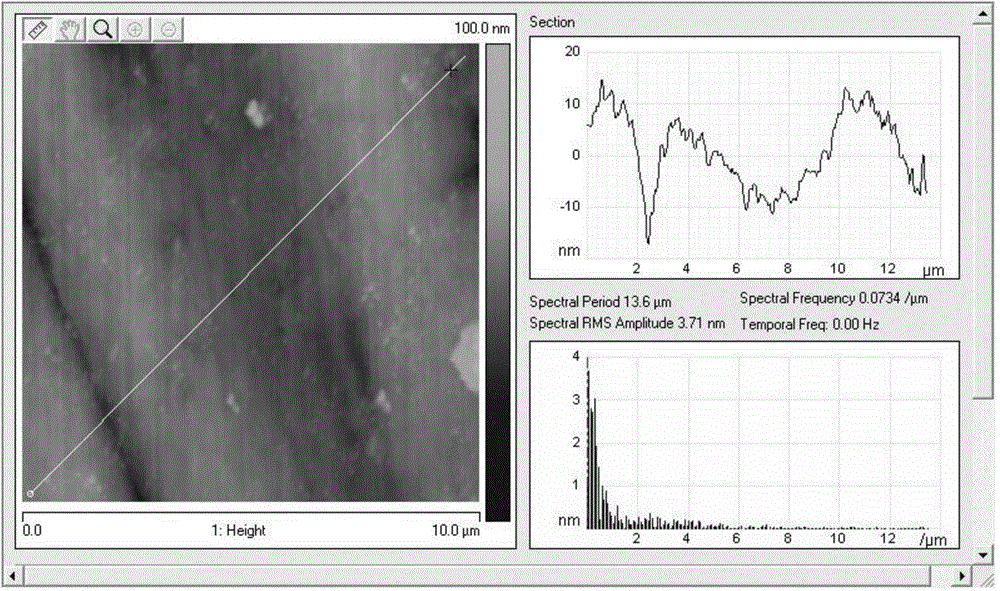

Super-mirror polishing method of metal plate

InactiveCN104400567AEfficient super mirror effectGood flat shapePolishing machinesReduction rateMetal

The invention discloses a super-mirror polishing method of a metal plate. The method comprises the following steps: (1) the metal plate is grinded by a grinding tool, or is coldly rolled by a finishing mill to obtain a straight board shape, wherein the reduction rate of the cold rolling is 3-30%; (2) a water abrasive paper is bonded on a turntable of a metallographic polisher for polishing the metal plate processed in the step (1); and (3) the surface of the metal plate polished in the step (2) is polished by a polisher with a sponge disc under the speed of 1500-2500 r / min until the roughness Ra is smaller than 10 nm; and grinding paste with the particle size of W0.5-W5.0 is coated on the sponge disc. The method has the advantages of short flow, high efficiency, flexible operation and wide application range.

Owner:XIAMEN UNIV OF TECH

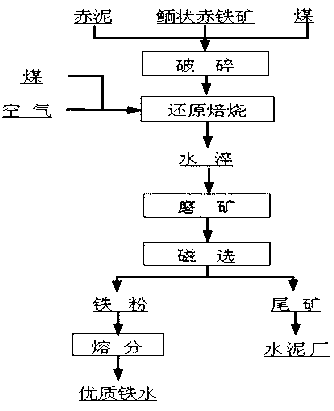

Method for comprehensively treating phosphorus-containing oolitic hematite and red mud

The invention discloses a method for comprehensively treating phosphorus-containing oolitic hematite and red mud, which is characterized by comprising the following steps: after mixing crude ore of the oolitic hematite, the red mud and coal according to a certain proportion, grinding and uniformly mixing; carrying out ore crushing and metallized reduction roasting; after slowly cooling the roasted product to a temperature of 400 to 750 DEG C, carrying out water quenching and shock cooling and carrying out ball milling on the water-quenched roasted product; carrying out magnetic separation on the ball-milled ore pulp to obtain similar sponge iron powder and tailings; and melting the similar sponge iron powder to obtain high-quality molten iron with phosphorus content of less than 0.01%. The method disclosed by the invention has a short flow, is continuous, is energy-saving, has high productivity, has high resource utilization rate and is environmental-friendly; the problems of high stacking construction cost of the red mud, high maintenance cost and the like can be solved; and the product can be used as a high-quality raw material for steelmaking and has high output.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

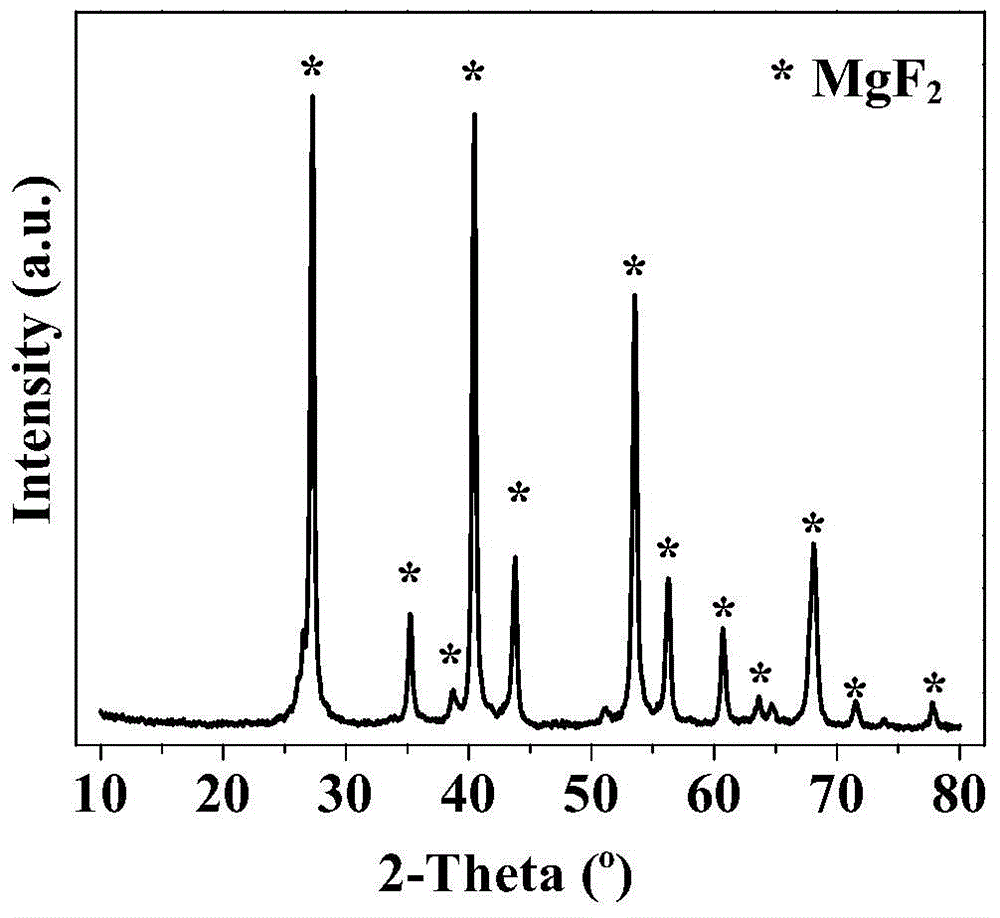

Preparation method of magnesium fluoride with high specific surface area

ActiveCN104071814AThe method flow is shortEasy to controlMagnesium fluoridesPolyvinyl alcoholCarbonization

The invention discloses a preparation method of magnesium fluoride with high specific surface area. The preparation method comprises the steps of: mixing a magnesium source water solution with a fluorine source water solution, wherein the obtained mixed solution contains a carbon source, the carbon source is one of or a mixture of several of saccharose, glucose, furfuryl alcohol, P123, polyvinyl alcohol and phenolic resin and the mole ratio of the carbon source to the magnesium source is 1-10: 1 based on C to Mg; stirring for full reaction and standing for ageing and removing moisture to obtain a carbon source-containing magnesium fluoride precursor; carrying out pre-carbonization on the carbon source-containing magnesium fluoride precursor and then carrying out carbonization in an inert atmosphere to obtain carbon-doped magnesium fluoride; finally carrying out high-temperature decarburization in an oxygen-bearing atmosphere to obtain the magnesium fluoride product. The preparation method is simple, low in production cost, small in environmental pressure, easy to operate and control and low in device corrosion, and has favorable economical, environmental and social benefits.

Owner:ZHEJIANG UNIV OF TECH

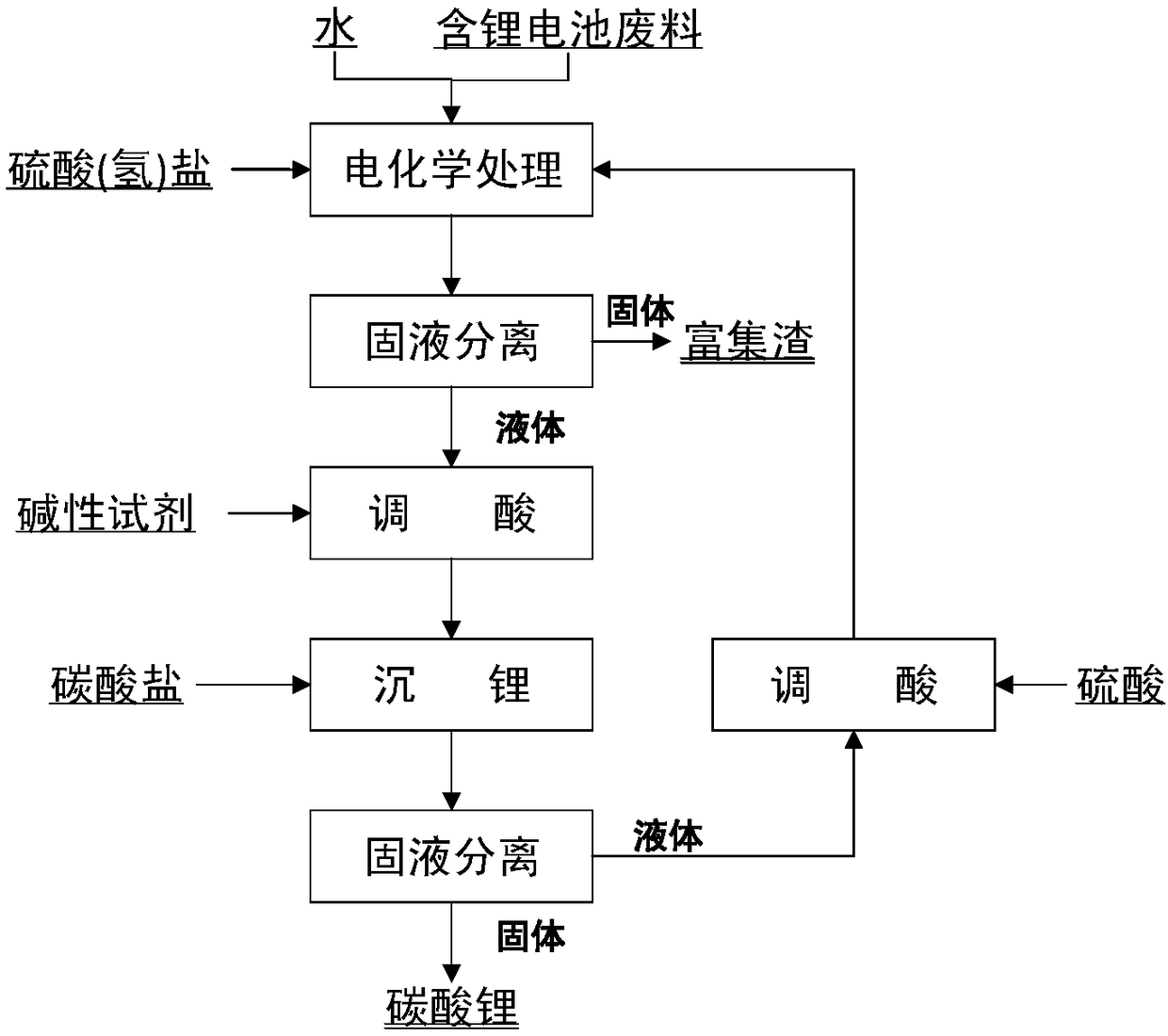

Method for recovering lithium in lithium-containing battery waste materials

ActiveCN108264068ASimplified leachingSimplify removalLithium carbonates/bicarbonatesAdditive ingredientSlurry

The invention provides a method for recovering lithium in lithium-containing battery waste materials. The method comprises the following steps of (1) mixing the lithium-containing battery waste materials with a salt water solution to obtain raw material slurry; performing electrochemical treatment on the raw material slurry; performing solid-liquid separation; obtaining liquid of lithium-containing purified liquid; (2) regulating the pH of the lithium-containing purified liquid in the step (1) to be 7 or higher; adding carbonates for lithium precipitation reaction; performing solid-liquid separation after the reaction; obtaining solid of lithium carbonate. The method provided by the invention has the advantages that the flow process is short; the operation is simple; the reaction process is green and clean; no waste is discharged in the integral flow process; the soaking- precipitation-separation process of a conventional process is realized through one step of the electrochemical processing; the production cost is reduced; the lithium recovery selectivity is as high as 99 percent; the single time recovery rate reaches 95 percent or higher; the obtained product purity reaches the battery grade lithium carbonate requirements; meanwhile, the high-value conversion of other metal ingredients is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

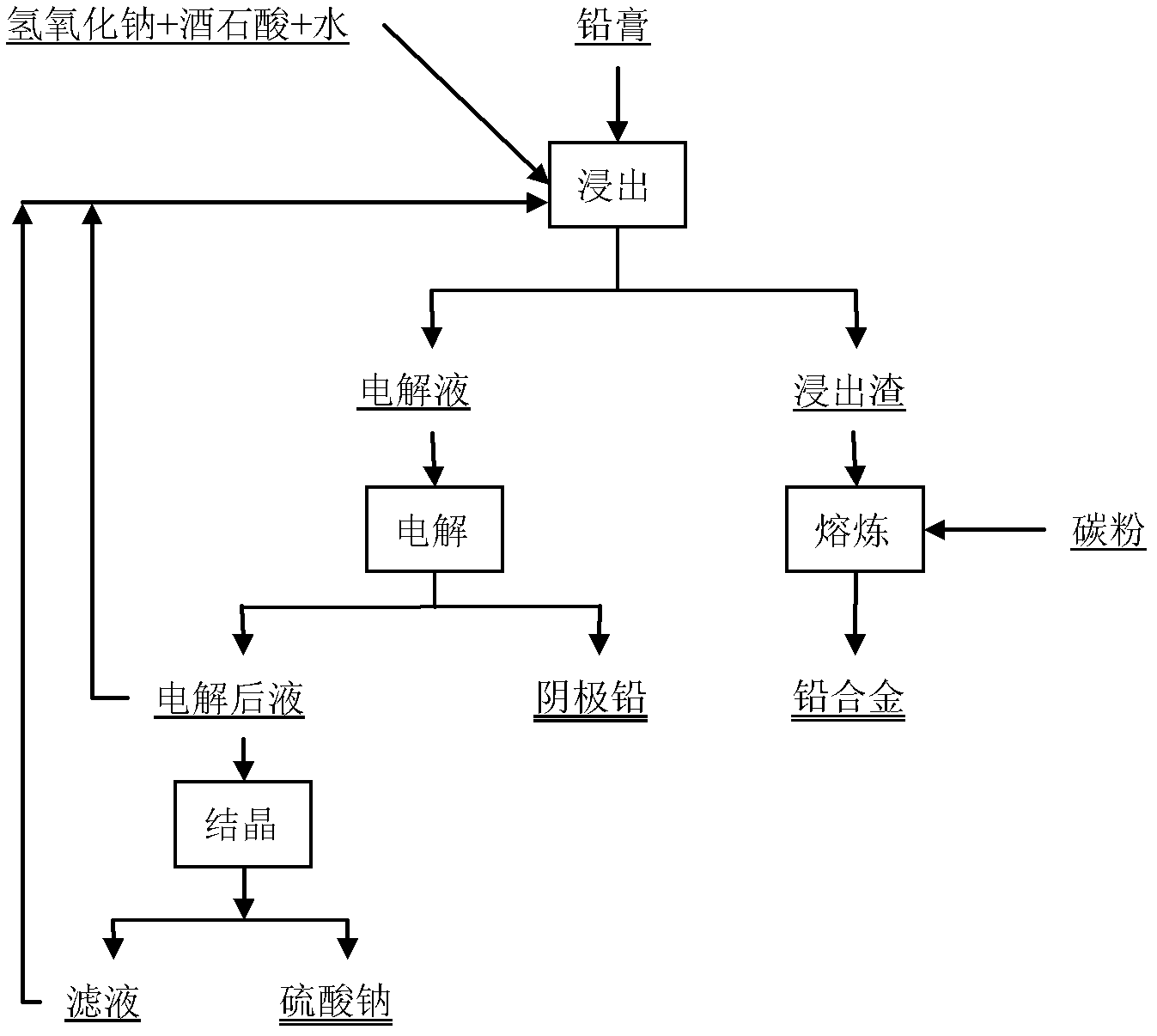

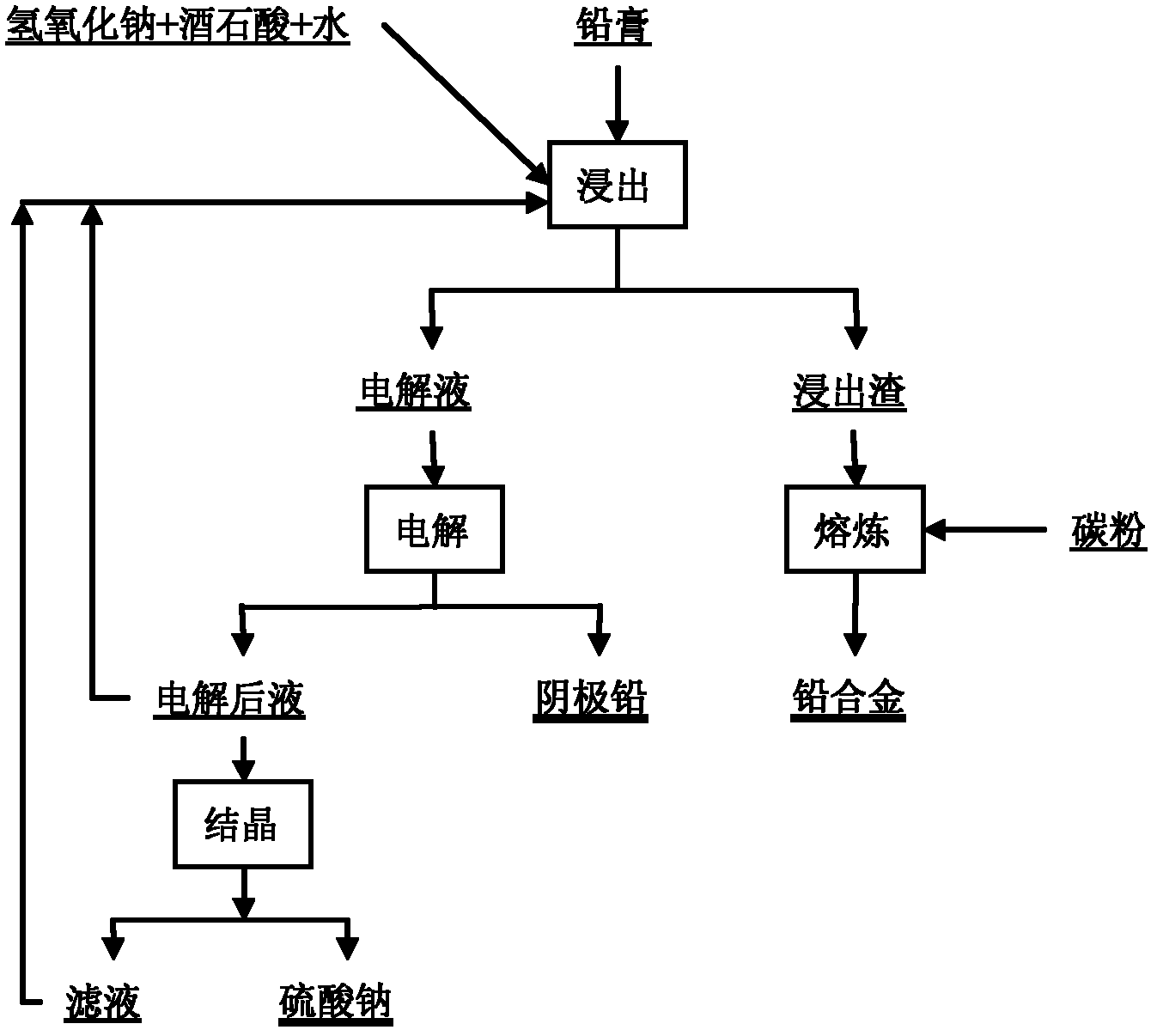

Method for recovering lead in lead plaster of waste lead-acid storage batteries

InactiveCN102677095AThe method flow is shortAdsorbs less electrolytePhotography auxillary processesProcess efficiency improvementLead oxideIngot casting

The invention discloses a method for recovering lead in lead plaster of waste lead-acid storage batteries. The method includes leaching lead oxide and lead sulfate in the lead plaster by heating mixed solution of sodium hydroxide and tartaric acid, directly leaching lead dioxide, and then electrolyzing through heating. The processes of desulfuration and reduction transformation are omitted, and the procedure of the method is short. Purity of cathode lead is higher than 99.5%, and recovery rate of combined lead in the lead plaster is higher than 98.5%. A cathode used is in the shape of a plate and easy to clean and can be used for ingot casting directly due to the fact that the cathode adsorbs little electrolyte.

Owner:HENAN UNIV OF SCI & TECH

Comprehensive recycling method for positive and negative electrodes of scrapped lithium batteries

ActiveCN108933308AShort processModerate energy consumptionWaste accumulators reclaimingBattery recyclingSolid phasesCarbon dioxide

The invention discloses a comprehensive recycling method for positive and negative electrodes of scrapped lithium batteries. The method concretely comprises the following steps: separating aluminum and copper from the batteries through pretreatment, drying the remaining material, adding a phase reconstructing agent, uniformly mixing the remaining material with the phase reconstructing agent, performing low-temperature catalytic calcinations, cooling and crushing the calcined material, performing an impregnating reaction in a neutral salt system, carrying out solid-liquid separation, allowing soluble lithium to enter a liquid phase, removing impurities, carrying out concentrative crystallization, drying and crushing obtained crystals to obtain battery grade lithium carbonate, introducing carbon dioxide to the above obtained crystallization mother liquid, and performing drying and crushing to obtain the battery grade lithium carbonate; and allowing insoluble nickel, cobalt, manganese andcarbon to enter a solid phase, washing the obtained solid phase, adding an ore dressing agent in a carbonate radical-containing environment, carrying out flotation to separate carbon from nickel-cobalt-manganese, performing washing, activation, drying and sorting on the separated carbon to obtain a negative electrode material, and directly washing the separated nickel-cobalt-manganese with pure water to directly become a nickel-cobalt-manganese polynary precursor material raw material. The method has the advantages of short process, moderate energy consumption, high comprehensive yield of valuable elements of the positive and negative electrodes, good product quality, environmental friendliness, low cost, and suitableness for industrialization.

Owner:江西环锂新能源科技有限公司

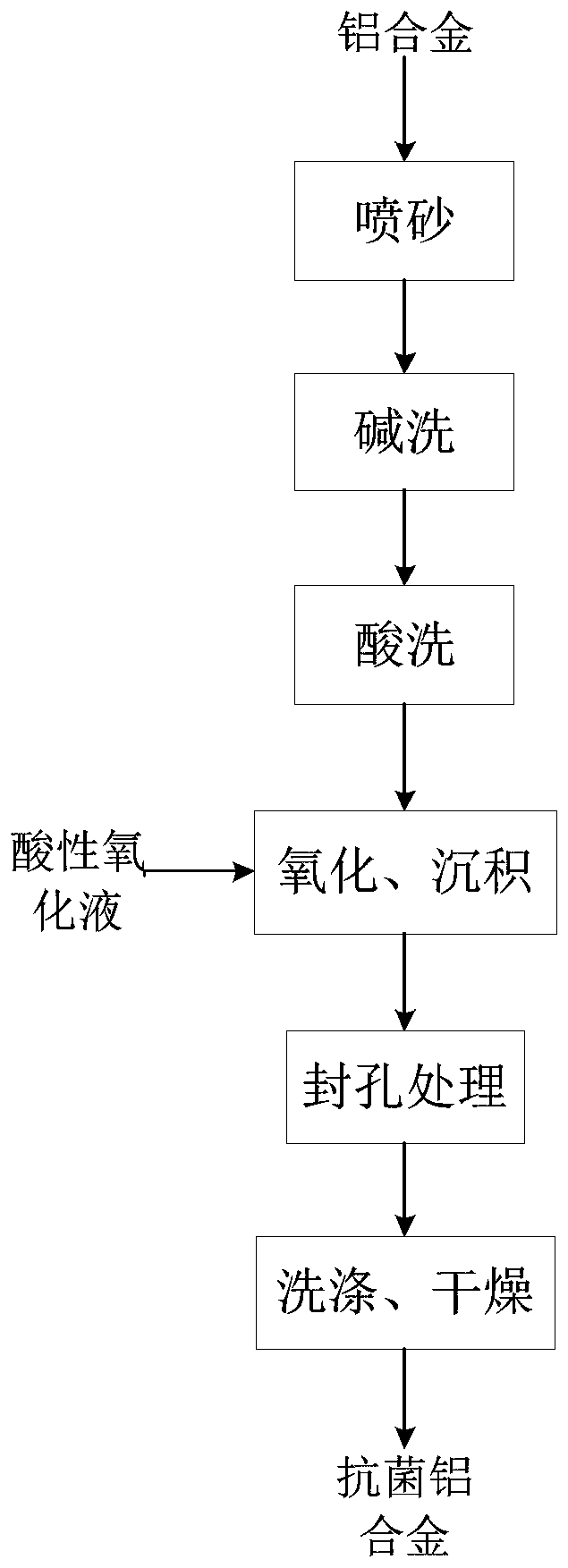

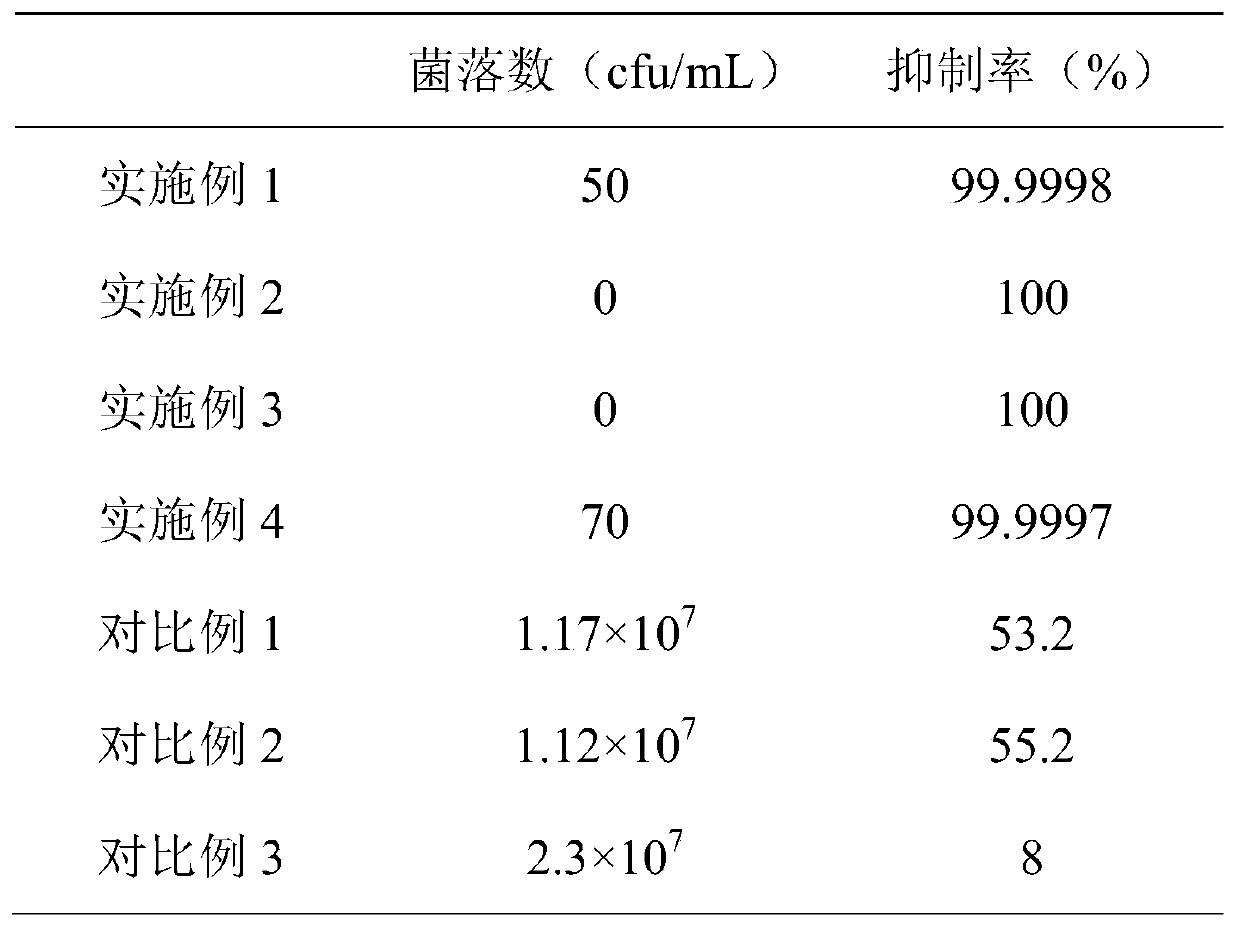

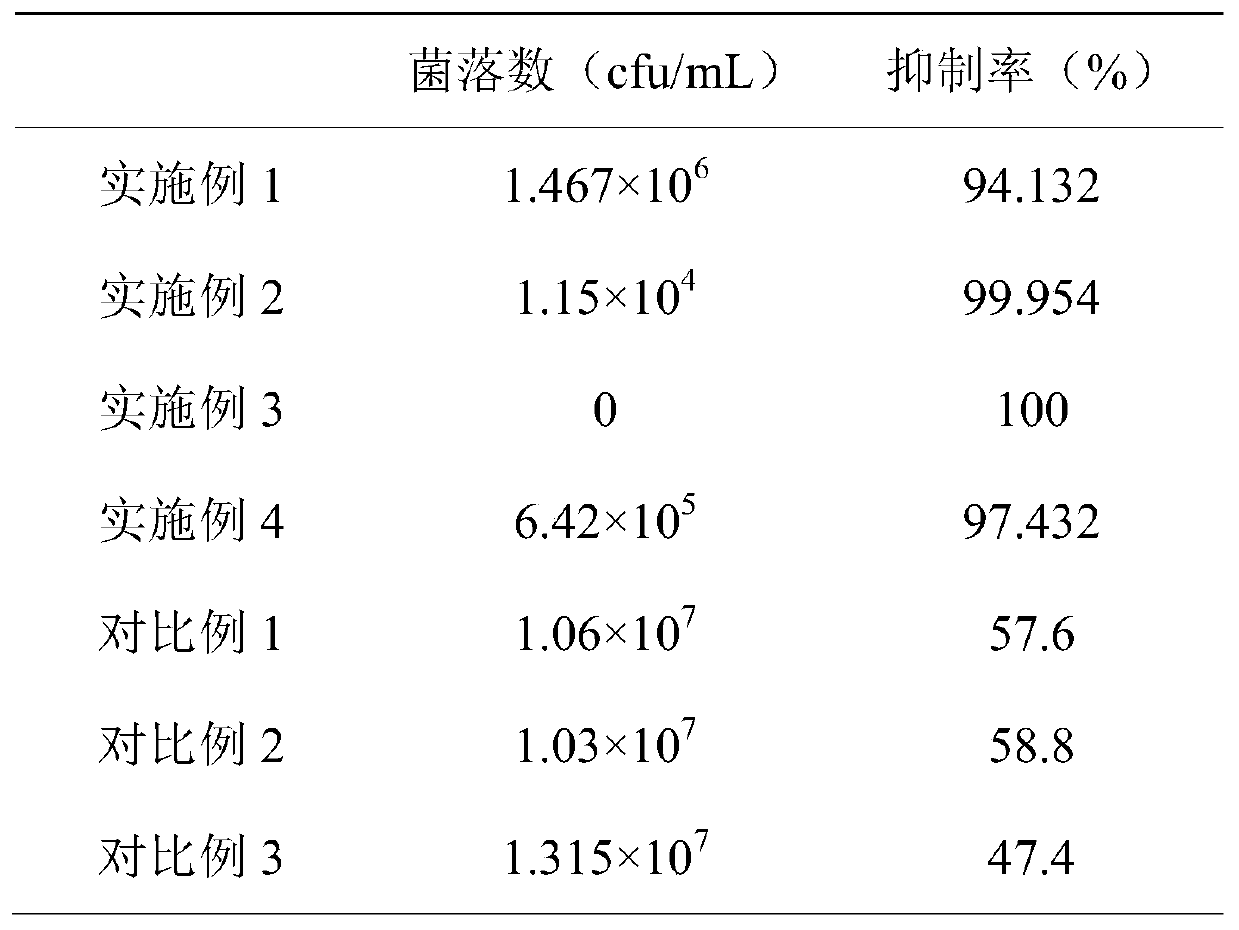

Aluminum alloy surface treatment method

ActiveCN110055572AIncrease productivityThe method flow is shortAnodisationAnodic oxidationCorrosion resistant

The invention provides an aluminum alloy surface treatment method. The aluminum alloy surface treatment method comprises the steps of conducting pretreatment on an aluminum alloy, putting the aluminumalloy into acid oxidation liquid to be subjected to oxidation and deposition under the AC condition, reducing the voltage, and conducting hole sealing treatment in the same solution to obtain the anti-microbial aluminum alloy. According to the aluminum alloy surface treatment method, the aluminum alloy is subjected to anodic oxidation, anti-microbial elements are deposited, hole sealing treatmentis conducted; hole sealing treatment can be conducted in the same solution, and then the anti-microbial and corrosion-resistant aluminum alloy is obtained. The aluminum alloy surface treatment methodis implemented through the one-step method. The process is simplified. The production efficiency of the anti-microbial aluminum alloy is improved. The production cost is reduced.

Owner:同曦集团有限公司

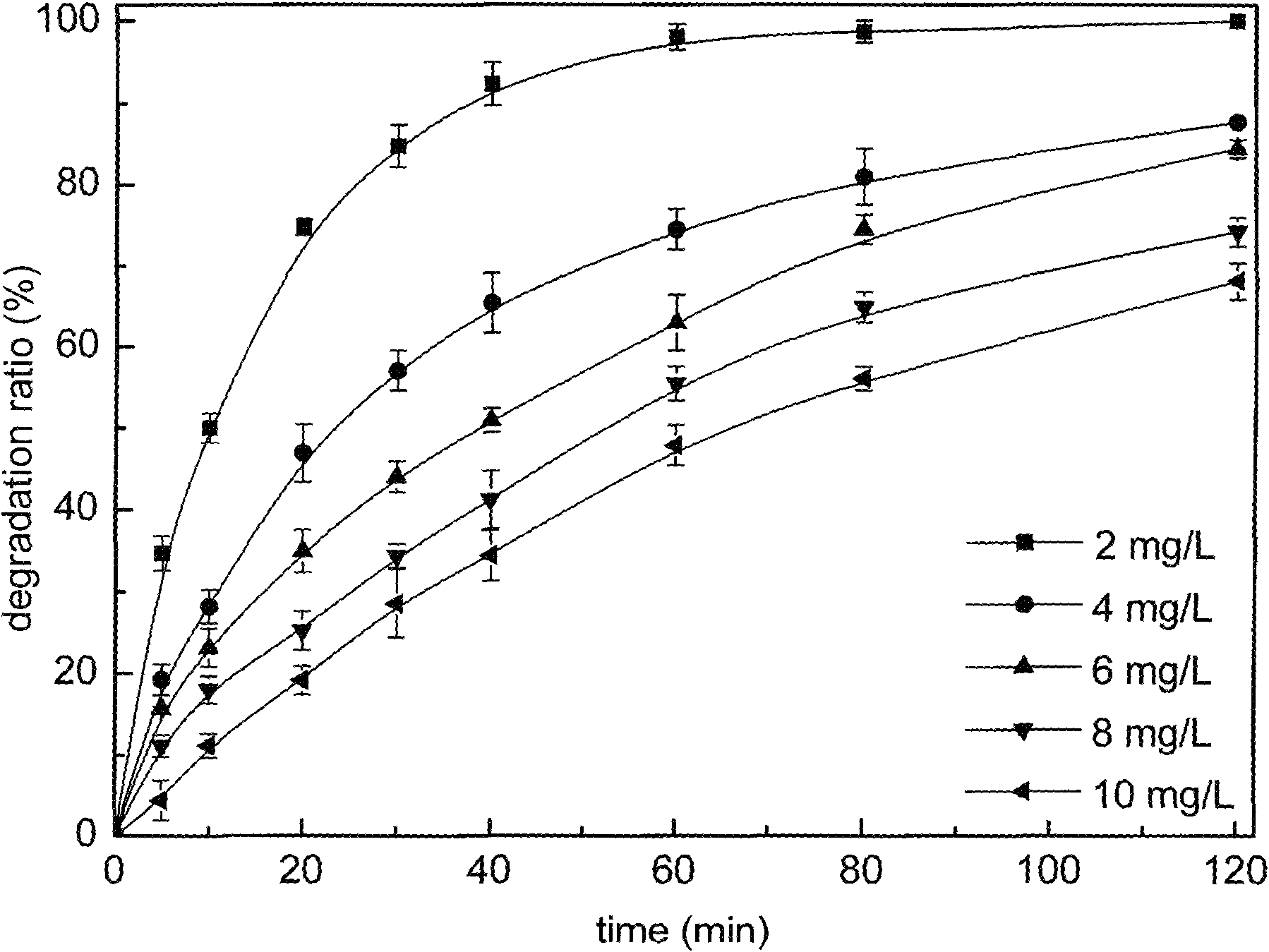

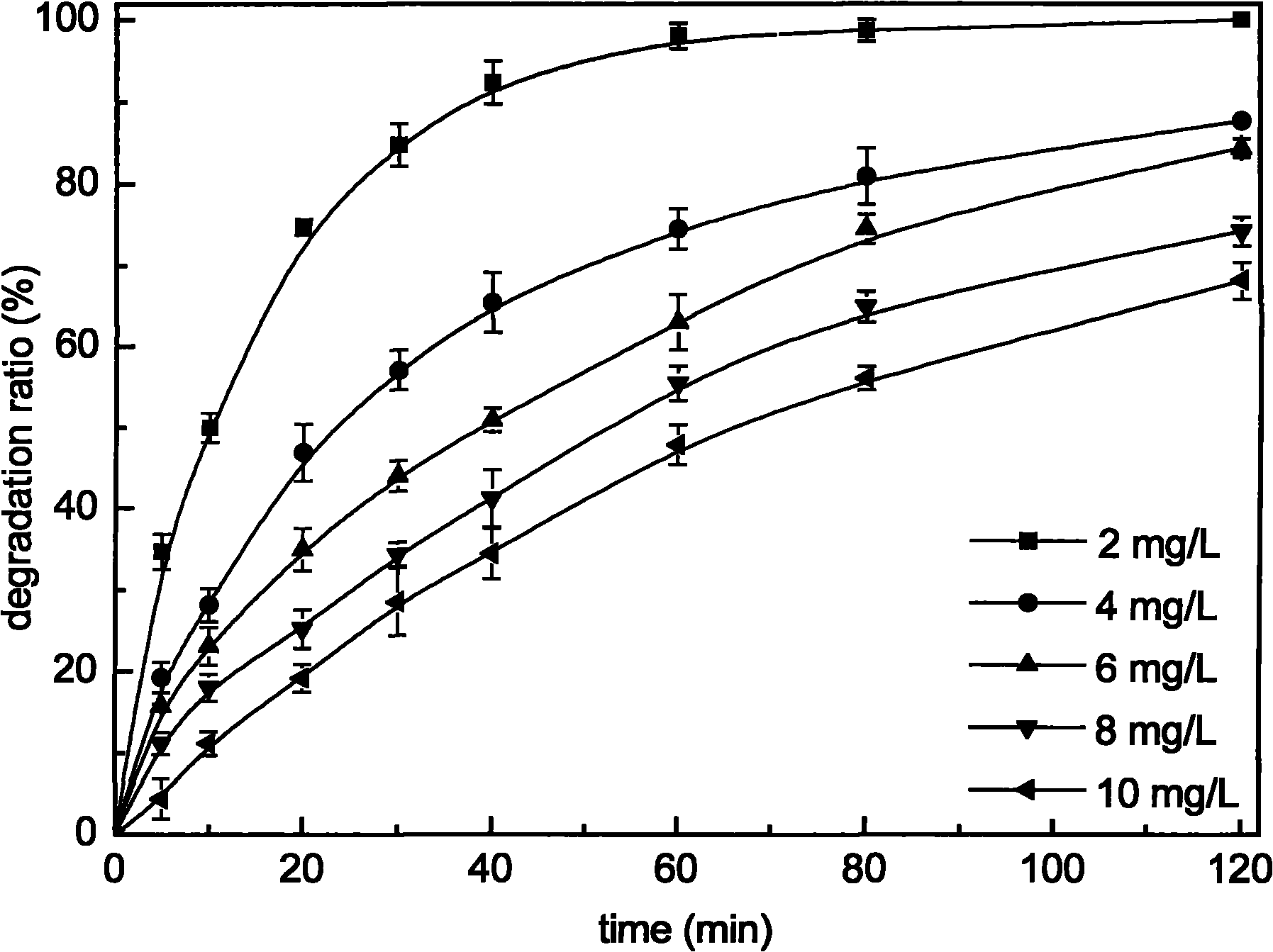

Method for purifying pentachlorophenol in water through photocatalysis

InactiveCN102120665AEfficient use ofEfficient removalWater/sewage treatment by irradiationWater contaminantsPentachlorophenolPurification methods

The invention relates to a method for purifying pentachlorophenol (PCP) in water through photocatalysis, which comprises the following processes of: mixing and stirring a bismuth silicate photocatalyst and pentachlorophenol sewage to be treated, performing ultrasonic dispersion, adsorbing and balancing, irradiating by using a xenon lamp and the like; and pentachlorophenol photocatalytic degradation reaction results prove that the pentachlorophenol in the water can be efficiently purified through the method. The invention can overcome the defects of high energy consumption, complex operation, violent reaction conditions, poor purification capacity and the like in the conventional purification method, provides a method having the advantages of short flow, simple equipment and good efficiency of purifying the pentachlorophenol, and has wide industrial application prospect.

Owner:BEIJING NORMAL UNIVERSITY

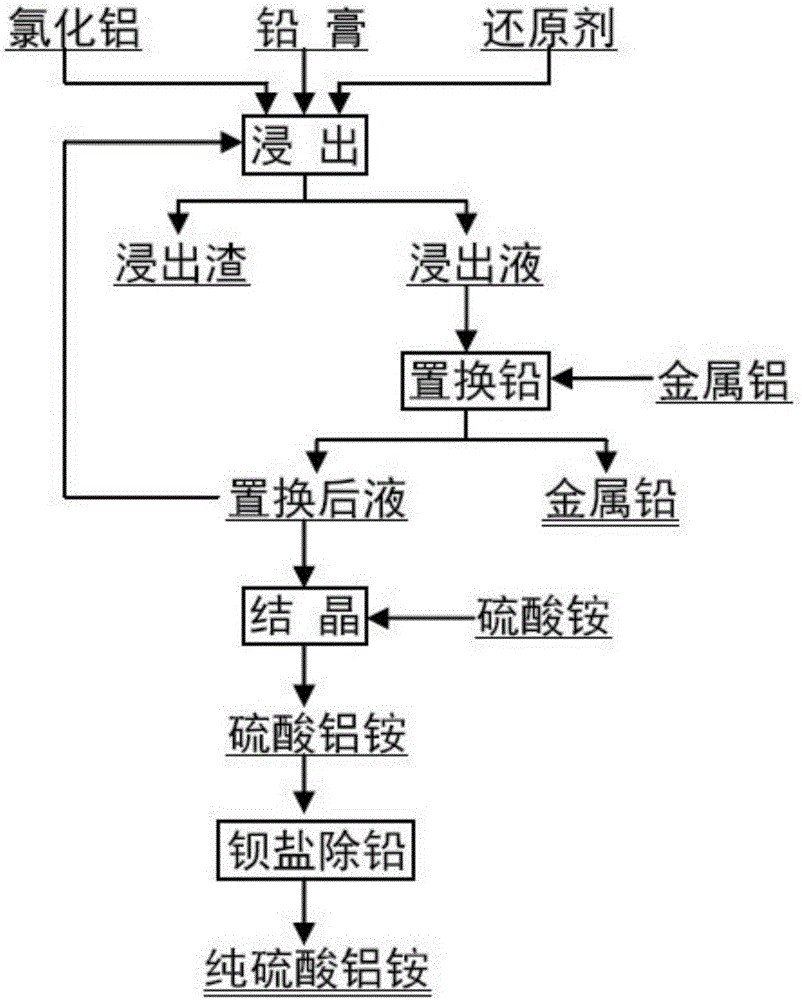

Method of recovering lead from scrap lead-acid storage battery lead plaster

ActiveCN106086414AMeet environmental protection requirementsReduce energy consumptionWaste accumulators reclaimingProcess efficiency improvementAluminium chlorideMetallic aluminum

The invention provides a method of recovering lead from scrap lead-acid storage battery lead plaster, and belongs to the technical field of wet-process metallurgy. The method is characterized in that a reducing agent (FeCl2 or hydrogen peroxide) and lead plaster are added to an aluminum chloride solution, leaching is carried out in an agitating mill to allow lead in the lead plaster to enter the solution, lead in an extract is replaced by metallic aluminum, and after the lead is replaced, the original extract returns and lead slag is leached continuously. The method has the characteristics of short flow, few processes, low energy consumption and cost, and the like, and meets the environmental requirements of cleaning production.

Owner:UNIV OF SCI & TECH BEIJING

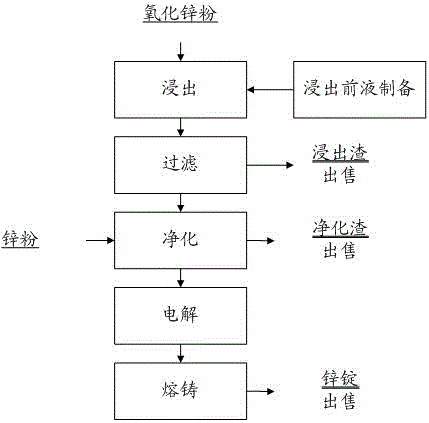

Method for extracting electrodeposited zinc from zinc oxide powder in ammonium chloride solution system

InactiveCN104005051AThe method flow is shortSolve environmental problemsPhotography auxillary processesProcess efficiency improvementWastewaterCircular economy

The invention discloses a method for extracting electrodeposited zinc from a zinc oxide powder in an ammonium chloride solution system. The method comprises the following steps: A, dissolving an ammonium chloride solid in water, at the same time, introducing NH3 and continuously stirring, and allowing the concentration of NH3 of the prepared before-leaching solution to reach 20-70 g / L; B, taking a certain amount of the prepared before-leaching solution, adding the zinc oxide powder according to the liquid-to-solid ratio of 2-10:1, at the same time, introducing NH3 and continuously stirring, and carrying out leaching treatment; C, adding a zinc powder into a filtered liquid after leaching, and carrying out purification treatment to obtain a solution after purification; and D, carrying out electrodeposition treatment of the solution after purification by connecting direct current, wherein an anode adopts graphite and a cathode adopts an aluminum plate. The method is short in flow and has no need of pretreatment of fluorine and chlorine in zinc oxide, the craft process also has no need of a specialized fluorine chlorine removing procedure, process waste water is not produced, and no waste residue is required to be piled up. Therefore, the environmental protection problem is solved, and a development mode of circular economy is also met.

Owner:戴兴征

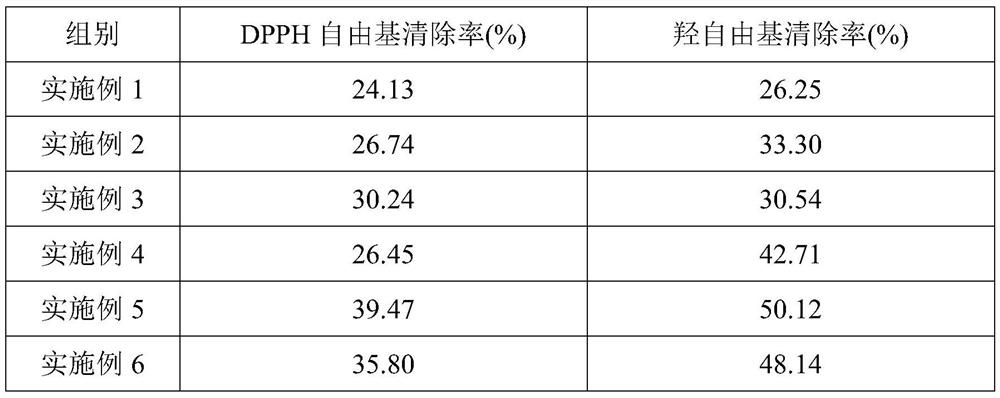

Preparation method of dendrobium officinale extract

InactiveCN112426392AImprove antioxidant capacityGood moisturizing effectCosmetic preparationsToilet preparationsBiotechnologyCellulose

The invention belongs to the technical field of cosmetics, and particularly relates to a preparation method of a dendrobium officinale extract. Through double-bacterium secondary fermentation, the method comprises the following steps: firstly using enzymes generated in the lactic acid bacterium fermentation process for decomposing cellulose and cracking plant cell walls to release active substances, then inoculating with saccharomycetes, taking nutrient elements or macromolecules in plant cells as substrates, and decomposing and synthesizing polyphenol flavone and other functional substances beneficial to skin care. The contents of effective components such as phenols, polysaccharides and amino acids can be remarkably increased, and the obtained dendrobium officinale extract has relativelyhigh antioxidant and moisturizing effects; and the method is short in process, simple to operate, high in yield and suitable for large-scale industrial production.

Owner:泉后(广州)生物科技研究院有限公司

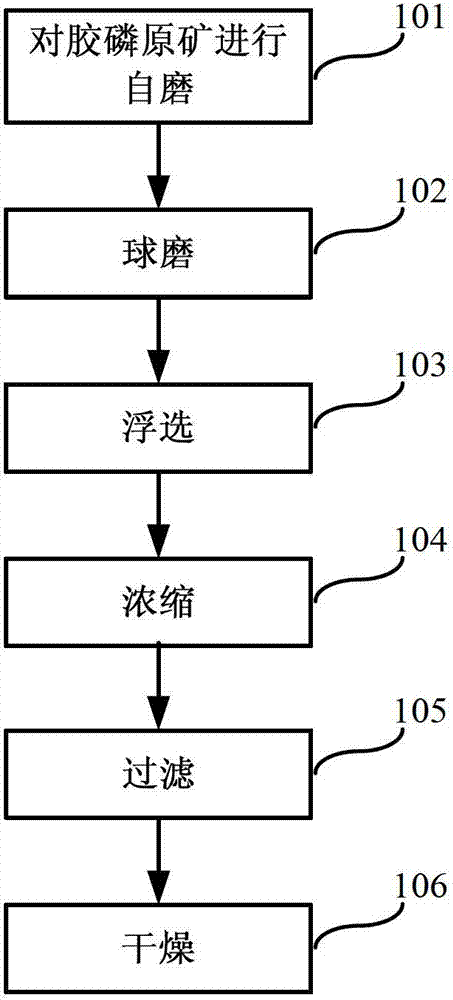

Cellophane beneficiating method

InactiveCN102764699AMineral processing method simplifiedThe method flow is simpleFlotationPhosphoriteCellophane

The invention relates to the field of beneficiation, in particular to a cellophane beneficiating method. The method comprises the following steps of: autogenously grinding raw cellophane; performing ball milling to obtain ore powder; and performing flotation on the ore powder by using a flotation column to obtain concentrate. The raw cellophane is autogenously ground into broken ore with the fineness of 45 to 50 percent, the broken ore is ball-milled into the ore powder with the fineness of 75 to 85 percent, the concentrate of which the MgO content is 0.8 to 0.9 mass percent is obtained by the flotation, the concentrate of which the recovery rate is 91.5 to 92.5 percent is obtained by the flotation through the flotation column, the concentrate obtained by the flotation is concentrated into concentrate pulp of which the water content is less than 40 percent, the concentrate pulp is filtered to obtain filter cakes of which the water content is less than 15 percent, and the obtained filter cakes are dried into concentrate powder of which the water content is less than 5 percent. By the cellophane beneficiating method, the beneficiating flow can be simplified.

Owner:GUIZHOU YANGPU HENGLI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com