PTFE (polytetrafluoroethylene) fiber for denitration and preparation method of PTFE (polytetrafluoroethylene) fiber

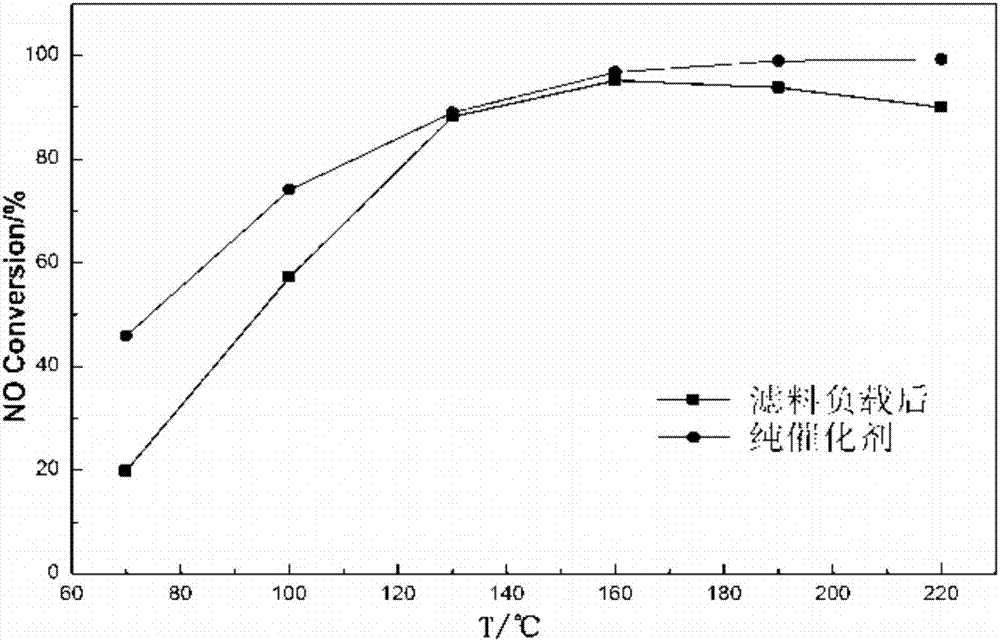

A polytetrafluoroethylene and denitrification technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of not having denitrification function, etc., and achieve the effect of more stable denitrification function, short process and high denitrification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Experimental materials include: polytetrafluoroethylene dispersion resin, aviation kerosene, manganese series low-temperature catalyst powder, montmorillonite.

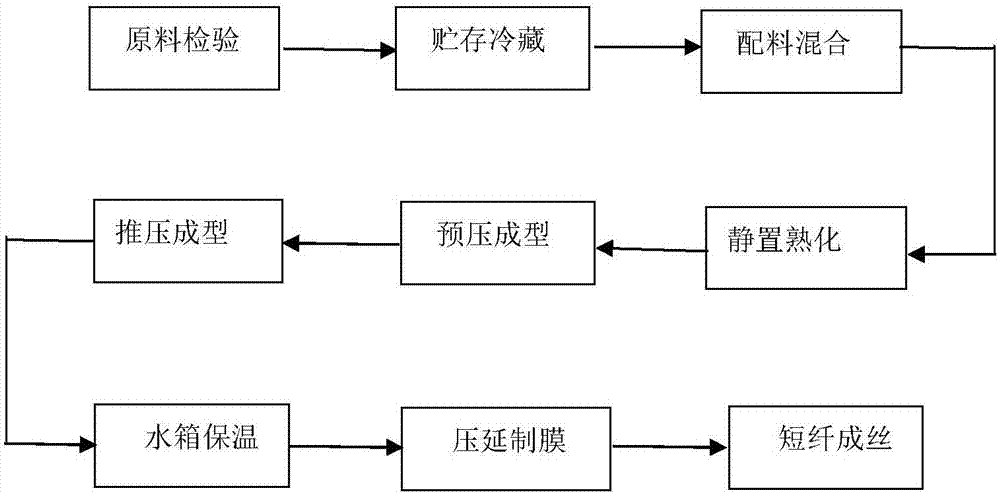

[0024] The specific implementation steps are as follows:

[0025] A1. Raw material inspection: PTFE dispersion resin and manganese-based low-temperature catalyst powder are scanned by scanning electron microscope to observe the raw material morphology, surface state and particle size. Weigh 7.3gMn 2 o 5 , 1.7 g CeO 2 , 0.16gV 2 o 5 , 4.2gWO 3 , 35.2 g TiO 2 Manganese-based low-temperature catalysts are made. Weigh polytetrafluoroethylene dispersed resin: aviation kerosene: manganese series low-temperature catalyst = 12kg: 3kg: 51g for mixing to make raw materials.

[0026] A2. Storage and refrigeration: Put the PTFE dispersion resin and montmorillonite in the same environment at 13°C, and refrigerate for 8 days, so that the materials can be fully refrigerated and dispersed without bonding.

[0027] A3....

Embodiment 2

[0036] Experimental materials include: polytetrafluoroethylene dispersion resin, aviation kerosene, manganese series low-temperature catalyst powder, montmorillonite.

[0037] The specific implementation steps are as follows:

[0038] A1. Raw material inspection: PTFE dispersion resin and manganese-based low-temperature catalyst powder are scanned by scanning electron microscope to observe the raw material morphology, surface state and particle size. Weigh 6.5gMn 2 o 5 , 1gCeO 2 , 0.1gV 2 o 5 , 3.5gWO 3 , 38.9 gTiO 2 Manganese-based low-temperature catalysts are made. Weigh polytetrafluoroethylene dispersion resin: aviation kerosene: manganese series low-temperature catalyst = 11kg: 2.9kg: 50g for mixing to make raw materials.

[0039] A2. Storage and refrigeration: Put the PTFE dispersion resin and montmorillonite in the same environment at 11°C, and refrigerate for 5 days, so that the materials can be fully refrigerated and dispersed without bonding.

[0040] A3. Mi...

Embodiment 3

[0048] Experimental materials include: polytetrafluoroethylene dispersion resin, aviation kerosene, manganese series low-temperature catalyst powder, montmorillonite.

[0049] The specific implementation steps are as follows:

[0050] A1. Raw material inspection: PTFE dispersion resin and manganese-based low-temperature catalyst powder are scanned by scanning electron microscope to observe the raw material morphology, surface state and particle size. Weigh 7.5gMn 2 o 5 , 2gCeO 2 , 0.2gV 2 o 5 , 4.5gWO 3 , 35.8gTiO 2 Manganese-based low-temperature catalysts are made. Weigh polytetrafluoroethylene dispersion resin: aviation kerosene: manganese series low-temperature catalyst = 10kg: 2.7kg: 50g for mixing to make raw materials.

[0051] A2. Storage and refrigeration: Put the PTFE dispersion resin and montmorillonite in the same environment at 12°C, and refrigerate for 10 days, so that the materials can be fully refrigerated and dispersed without bonding.

[0052] A3. Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com