Method for selective extraction of gallium and germanium from oxalic acid solution containing gallium and germanium

A technology of oxalic acid solution and acid solution is applied in the field of extraction of gallium and germanium, which can solve the problems of low cost, inability to separate, and short process, and achieve the effects of low cost, low consumption of chemical reagents, and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Aqueous phase feed solution: oxalic acid leaching solution of zinc replacement slag, which contains 0.274g / L gallium, 0.511g / L germanium, 0.065g / L copper, and 0.55g / L zinc, and the pH value of the feed solution is 0.51;

[0019] Organic phase: the extractant is tertiary amine N235, its volume fraction is 20%, and the diluent in the organic phase is sulfonated kerosene, its volume fraction is 80%.

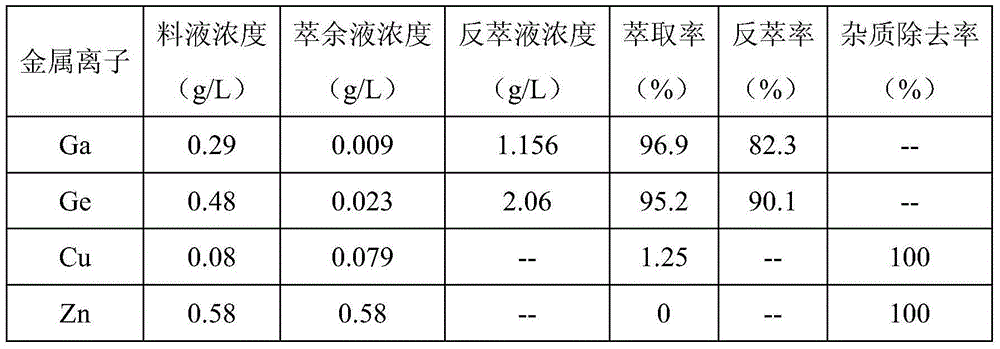

[0020] Extraction and separation: The organic phase and the feed liquid are subjected to single-stage extraction under the condition of a ratio of 1 / 1, the extraction equilibrium time is 10 minutes, and the temperature is 25°C. The experimental results are shown in Table 1.

[0021] Table 1 Tertiary amine N235 is to the extraction rate (%) of metal ion in the oxalic acid leach solution

[0023] It can be seen from Table 1 that the tertiary amine extractant has excellent extraction selectivity for gallium and germanium in the oxalic acid leach so...

Embodiment 2

[0025] Water phase material liquid is with embodiment 1;

[0026] Prepare two organic phases with different compositions numbered 1 and 2 respectively, the diluent in the organic phase is sulfonated kerosene, the No. 1 organic phase is the sulfonated kerosene solution of 20% N235+10% sec-octanol, and the No. 2 organic phase is 20% N235+10% TBP sulfonated kerosene solution.

[0027] Extraction and separation: the above two organic phases are subjected to single-stage extraction at a ratio of 1:1 to the feed liquid, the extraction equilibrium time is 10 minutes, and the temperature is 25°C. The experimental results are shown in Table 2.

[0028] Table 2 The influence of different phase regulators on the extraction rate of each metal ion in the oxalic acid leachate (%)

[0029] Metal ion

[0030] It can be seen from Table 2 that the extraction rate of gallium and germanium in the 20% N235 + 10% 2-octanol + sulfonated kerosene system is above 99%, and the extraction r...

Embodiment 3

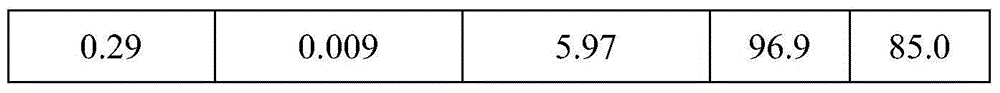

[0032] The aqueous phase feed solution is oxalic acid leaching solution of zinc replacement slag, which contains 0.386g / L gallium, 0.477g / L germanium, 0.12g / L copper, and 0.6g / L zinc, and the pH value of the feed solution is 1.5;

[0033] The organic phase is No. 260 solvent oil solution of 5% N235+10% sec-octanol.

[0034] The organic phase and the aqueous phase feed liquid are subjected to single-stage extraction, the extraction ratio (O / A)=5 / 1, the extraction time is 10 min, and the temperature is 25°C. The experimental results are shown in Table 3.

[0035] Table 35% N235+10% secondary octanol extraction metal ion results in oxalic acid leachate (%)

[0036] Metal ion

[0037] The results show that during the extraction process, the extraction rates of gallium and germanium can reach more than 97%, and copper and zinc are basically not extracted. Reaching above 2500 and 3500 respectively, the separation effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com