Preparation method of positive electrode material lithium iron phosphate for high-compaction lithium ion battery

A technology of lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of a large amount of waste gas treatment costs, poor electrical properties of materials, environmental pollution, etc., to improve grinding efficiency, Excellent electrochemical performance, the effect of improving mass transfer and heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

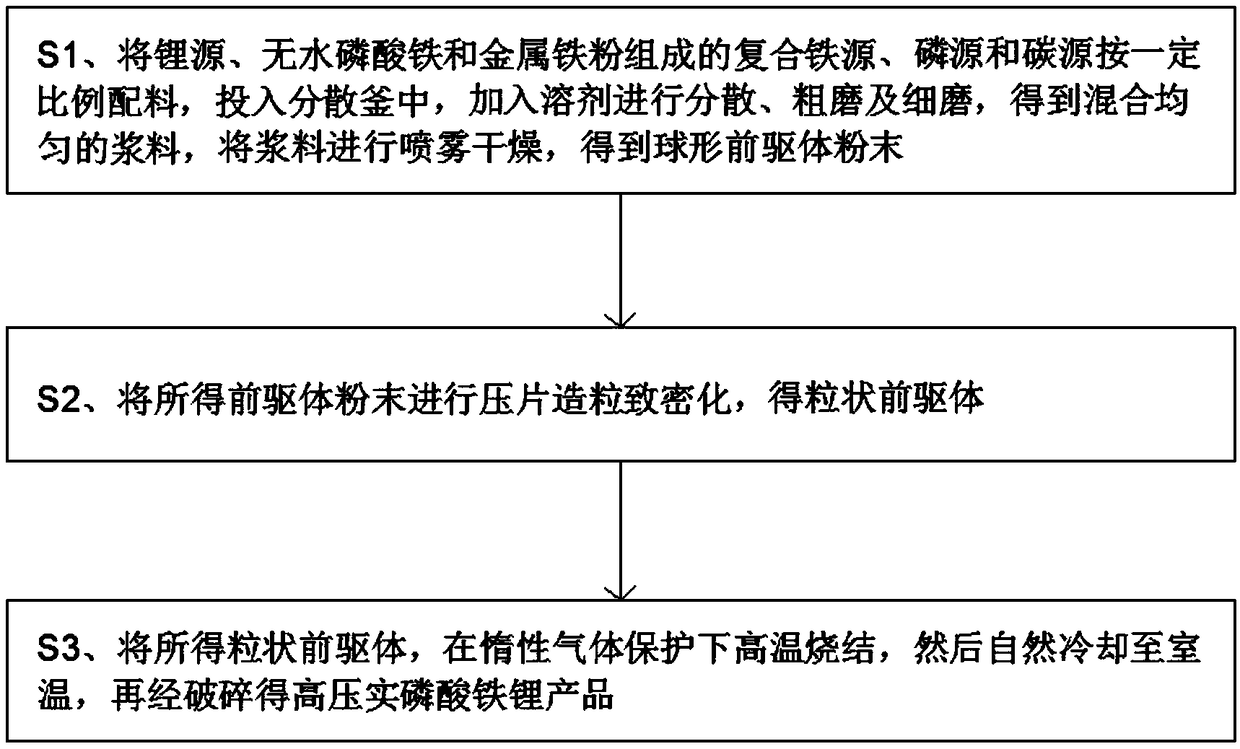

Method used

Image

Examples

Embodiment 1

[0045] Lithium carbonate (Li 2 CO 3 ) 63.36 kg, iron orthophosphate (FePO 4) 250.00 kg, lithium dihydrogen phosphate (LiH 2 PO 4 ) 18.79 kg, D50=2um metal iron powder 10.24 kg, glucose 19.00 kg, and polyethylene glycol 11.00 kg were placed in a dispersion kettle, and then 630 L of deionized water was added for dispersion. The dispersion time of the slurry was 1 hour, and then coarse grinding was carried out. The coarse grinding time is 3 hours, and the particle size D50 of the slurry after coarse grinding is controlled at 1-2um. Finally, fine grinding is carried out, and the fine grinding time is 4 hours. After fine grinding, the particle size D50 of the slurry is controlled at 500nm to obtain a homogeneous mixed slurry.

[0046] Then spray-dry the uniformly mixed slurry obtained, the spray-drying air inlet temperature is controlled at 240°C, and the air outlet temperature is controlled at 90°C to obtain a spherical precursor powder; then the precursor powder is tableted, g...

Embodiment 2

[0049] Lithium carbonate (Li 2 CO 3 ) 50.69 kg of iron orthophosphate (FePO 4 ) 200.00 kg, lithium dihydrogen phosphate (LiH 2 PO 4 ) 57.96 kg, D50=1um metal iron powder (purity ≥ 98.5%) 31.59 kg, glucose 18.5 kg, water-soluble phenolic resin 9.50 kg in a dispersion kettle, then add 550L of deionized water to disperse, and the slurry dispersion time is 2h , then carry out coarse grinding, the coarse grinding time is 1h, the slurry particle size D50 after coarse grinding is controlled at 1-1.5um, and finally fine grinding is carried out, the fine grinding time is 6h, the slurry particle size D50 after fine grinding is controlled at 400nm, and a uniform Quality mixed slurry.

[0050] Then the uniformly mixed slurry obtained is spray-dried, the spray-drying air inlet temperature is controlled at 280°C, and the air outlet temperature is controlled at 100°C to obtain a spherical precursor powder; then the precursor powder is tableted, granulated and densified. The pressure use...

Embodiment 3

[0053] Lithium carbonate (Li 2 CO 3 ) 38.02 kg, iron orthophosphate (FePO 4 ) 150.00 kg, lithium dihydrogen phosphate (LiH 2 PO 4 ) 101.44 kg, D50 = 1.5um metal iron powder (purity ≥ 98.5%) 55.30 kg, sucrose 19.00 kg, polyvinyl alcohol 5.00 kg, PVP 6.00 kg in a dispersion kettle, then add ethanol 520L for dispersion, slurry dispersion time for 2h, and then carry out coarse grinding, the coarse grinding time is 3h, the slurry particle size D50 after coarse grinding is controlled at 1.2~2um, and finally fine grinding is carried out, the fine grinding time is 5h, and the slurry particle size D50 after fine grinding is controlled at 600nm, obtaining Homogenously mix the slurry.

[0054] Then spray-dry the homogeneously mixed slurry. The spray-drying air inlet temperature is controlled at 220°C, and the air outlet temperature is controlled at 70°C to obtain a spherical precursor powder; The pressure used for tablet granulation was 80 MPa to obtain a granular precursor.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com