Method for recovering lead in lead plaster of waste lead-acid storage batteries

A waste lead-acid battery and a recovery method technology, which is applied in the field of recovery of lead in the lead paste of waste lead-acid batteries, can solve the problems of long process and achieve the effects of less adsorption of electrolyte, short process flow and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

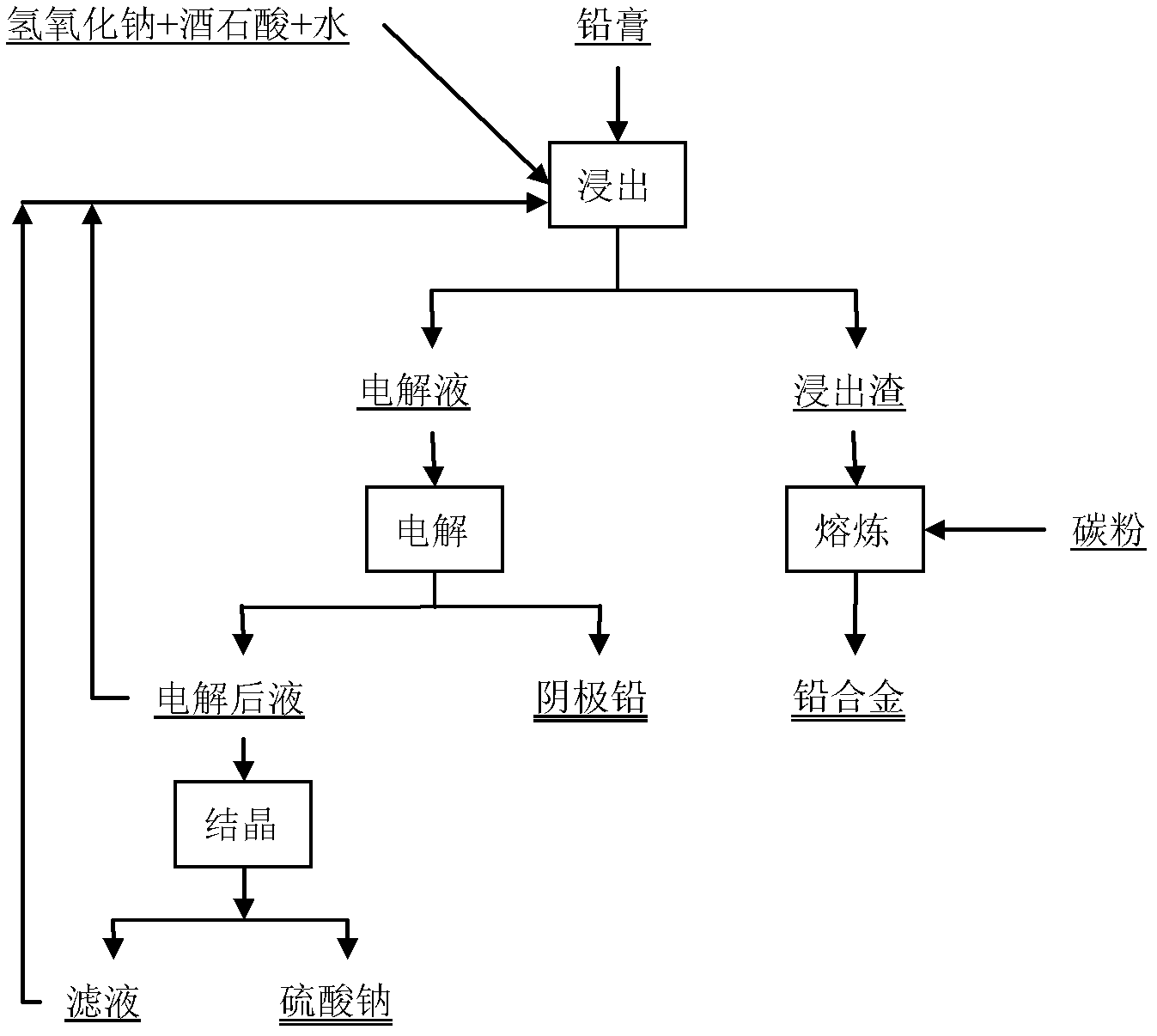

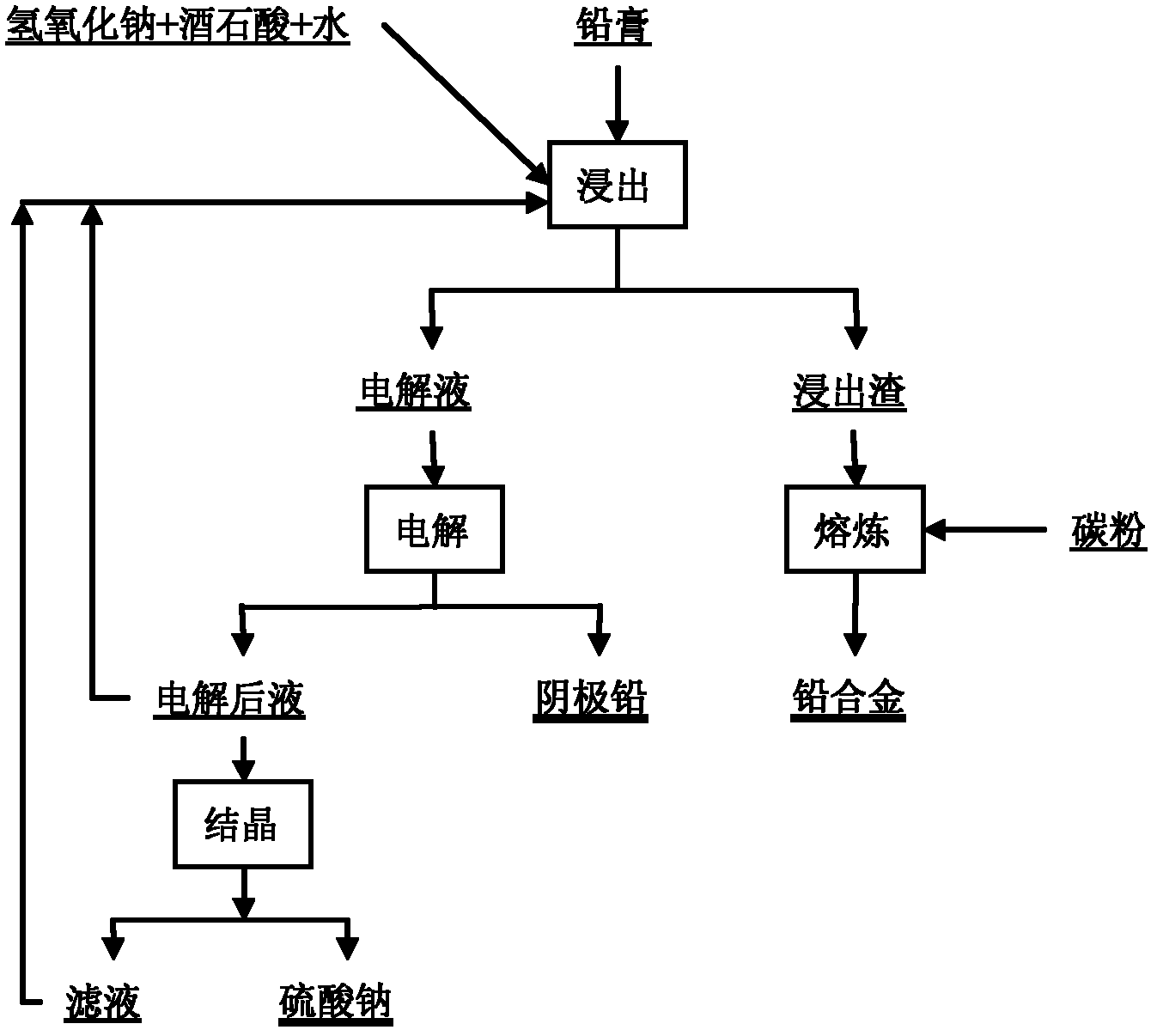

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: present embodiment is to the recovery method of lead in lead plaster, and the steps are as follows:

[0035] (1) After the waste lead-acid battery is crushed, the lead paste part is selected, dried and ground to 100 mesh to obtain the lead paste powder;

[0036] (2) Take by weighing 120g sodium hydroxide, 150g tartaric acid and add in 1.5L water (the weight ratio of water, sodium hydroxide, tartaric acid is 100:8:10), stir and dissolve, obtain leachate;

[0037] (3) Add 180g of lead plaster powder into the leachate, dissolve, react at 50°C with a stirring speed of 500r / min for 3h, filter to obtain an electrolyte, wherein the concentration of tartaric acid is 150g / L, and the concentration of sodium hydroxide is 80g / L, The lead concentration was 78g / L; after the filter residue was dried, 1.1g of carbon powder was added, mixed evenly, and smelted in a muffle furnace at 700°C for 30min to obtain 20.85g of lead alloy, and the recovery rate of lead in the filter...

Embodiment 2

[0041] Embodiment 2: present embodiment is to the recovery method of lead in lead plaster, and the steps are as follows:

[0042] (1) After the waste lead-acid battery is crushed, the lead paste part is selected, dried and ground to 200 mesh to obtain the lead paste powder;

[0043] (2) Take by weighing 240g sodium hydroxide, 150g tartaric acid and add in 1.5L water (the weight ratio of water, sodium hydroxide, tartaric acid is 100:16:10), stir and dissolve, obtain leachate;

[0044] (3) Add 300g of lead plaster powder into the leachate, dissolve, react at 98°C with a stirring speed of 300r / min for 1h, and filter to obtain an electrolyte, wherein the concentration of tartaric acid is 100g / L, and the concentration of sodium hydroxide is 160g / L. The lead concentration was 125g / L; after the filter residue was dried, 2.4g of carbon powder was added, mixed evenly, and smelted in a muffle furnace at 650°C for 30min to obtain 32.93g of lead alloy, and the recovery rate of lead in the...

Embodiment 3

[0048] Embodiment 3: present embodiment is to the recovery method of lead in lead plaster, and the steps are as follows:

[0049] (1) select the lead paste part after crushing the waste lead-acid battery, dry and grind to 300 mesh, and obtain the lead paste powder;

[0050] (2) Take by weighing 180g sodium hydroxide, 210g tartaric acid and add in 1.5L water (the weight ratio of water, sodium hydroxide, tartaric acid is 100:12:14), stir and dissolve, obtain leachate;

[0051] (3) Add 250g of lead plaster powder into the leachate, dissolve, react at 70°C with a stirring speed of 400r / min for 5h, and filter to obtain an electrolyte solution, wherein the concentration of tartaric acid is 140g / L, and the concentration of sodium hydroxide is 120g / L. The lead concentration was 102g / L; after the filter residue was dried, 1.9g of carbon powder was added, mixed evenly, and smelted in a muffle furnace at 700°C for 30min to obtain 27.6g of lead alloy, and the recovery rate of lead in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com