Patents

Literature

34results about How to "Implement selective extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

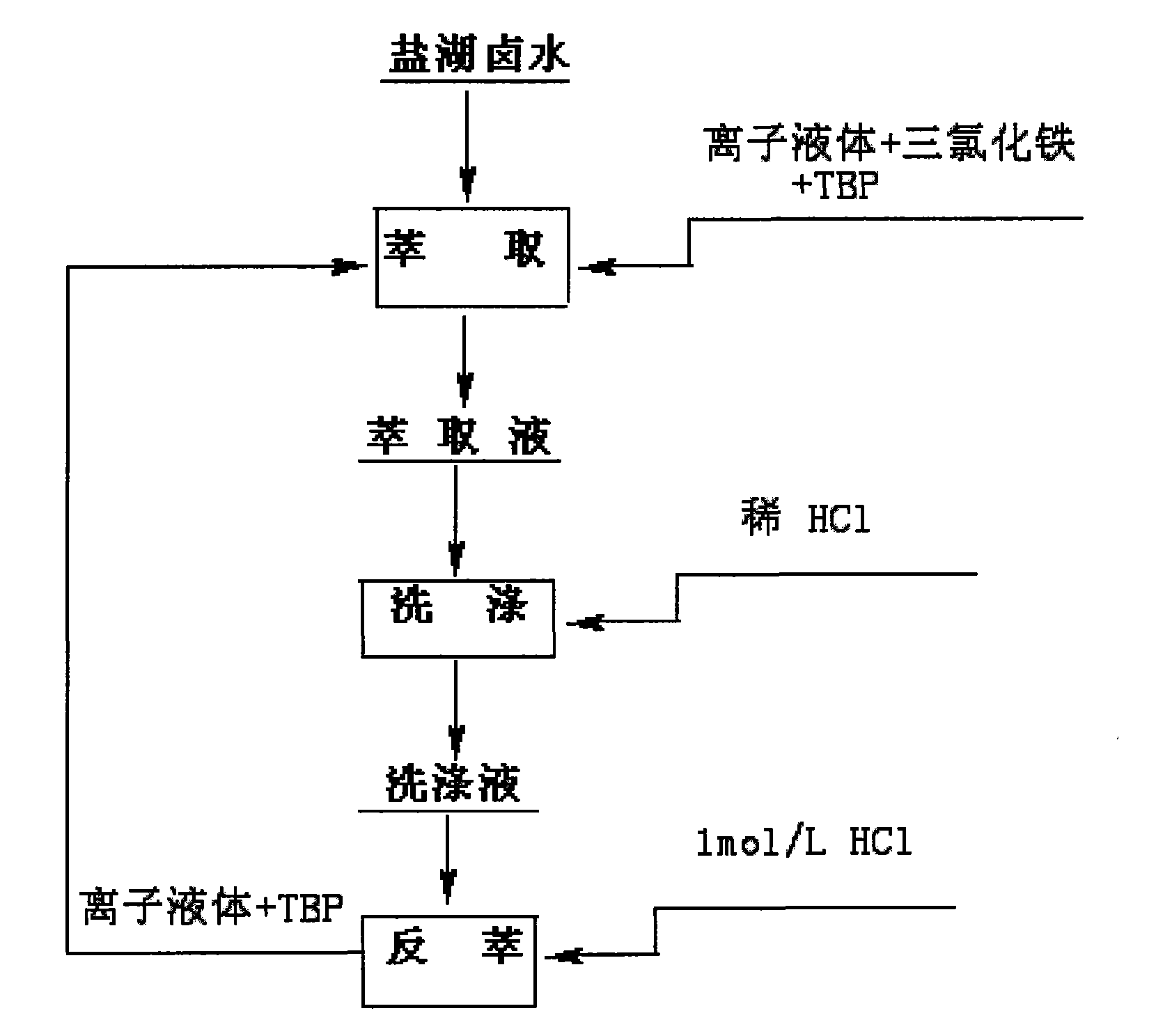

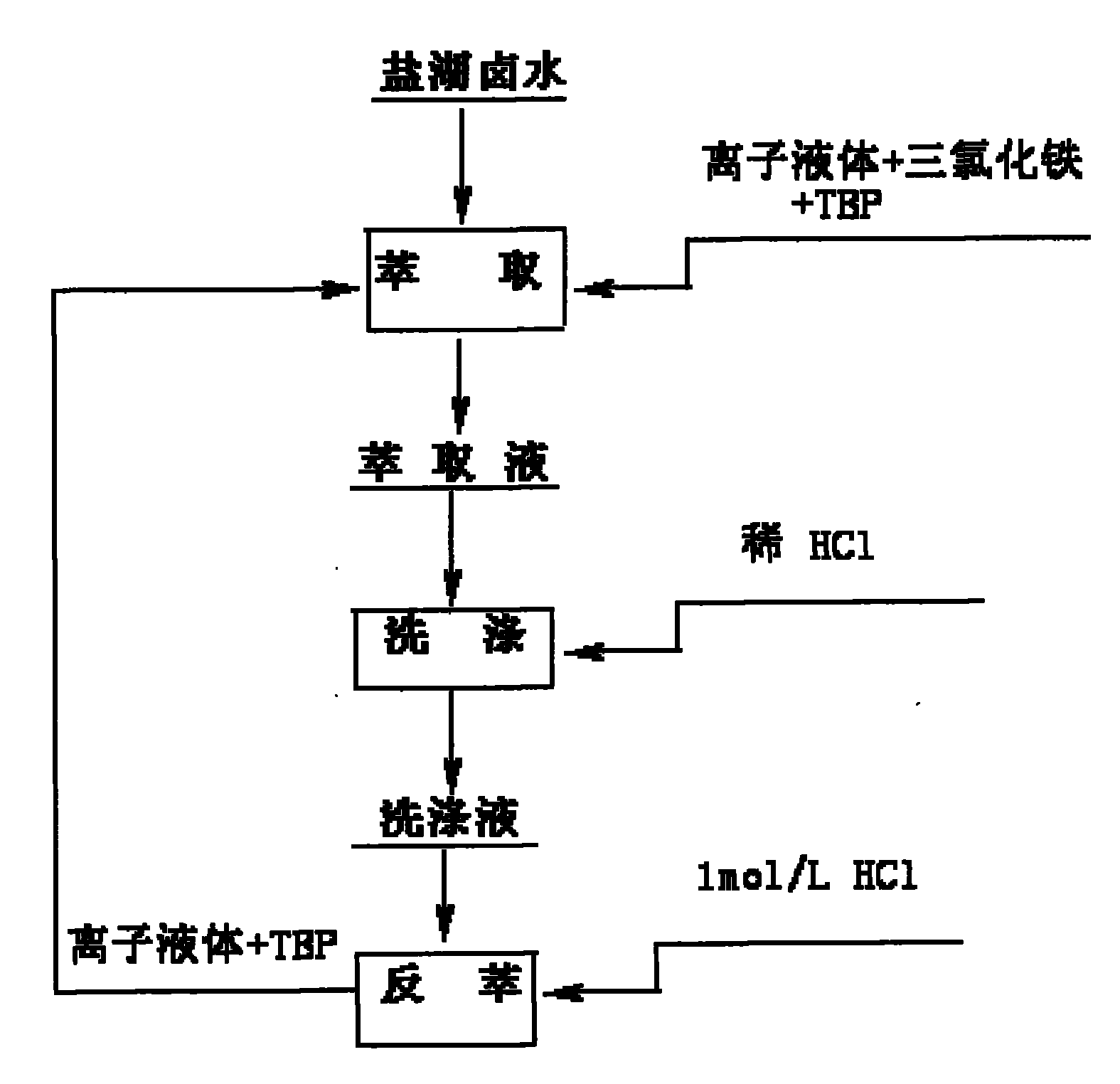

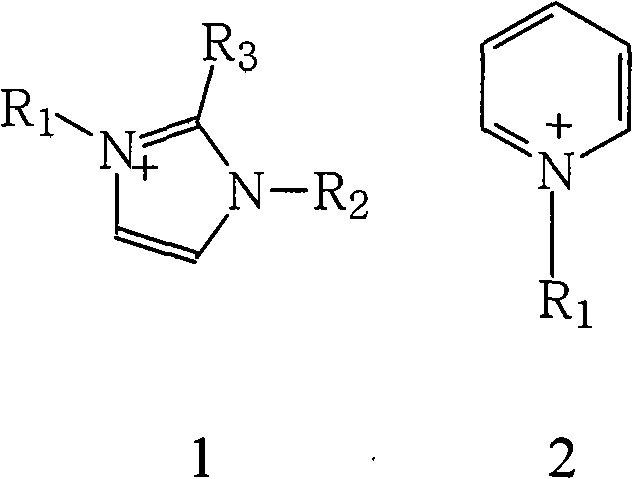

Method for extracting lithium from salt lake brine

InactiveCN101767804AImplement selective extractionHigh extraction rateLithium compoundsHigh concentrationOrganic solvent

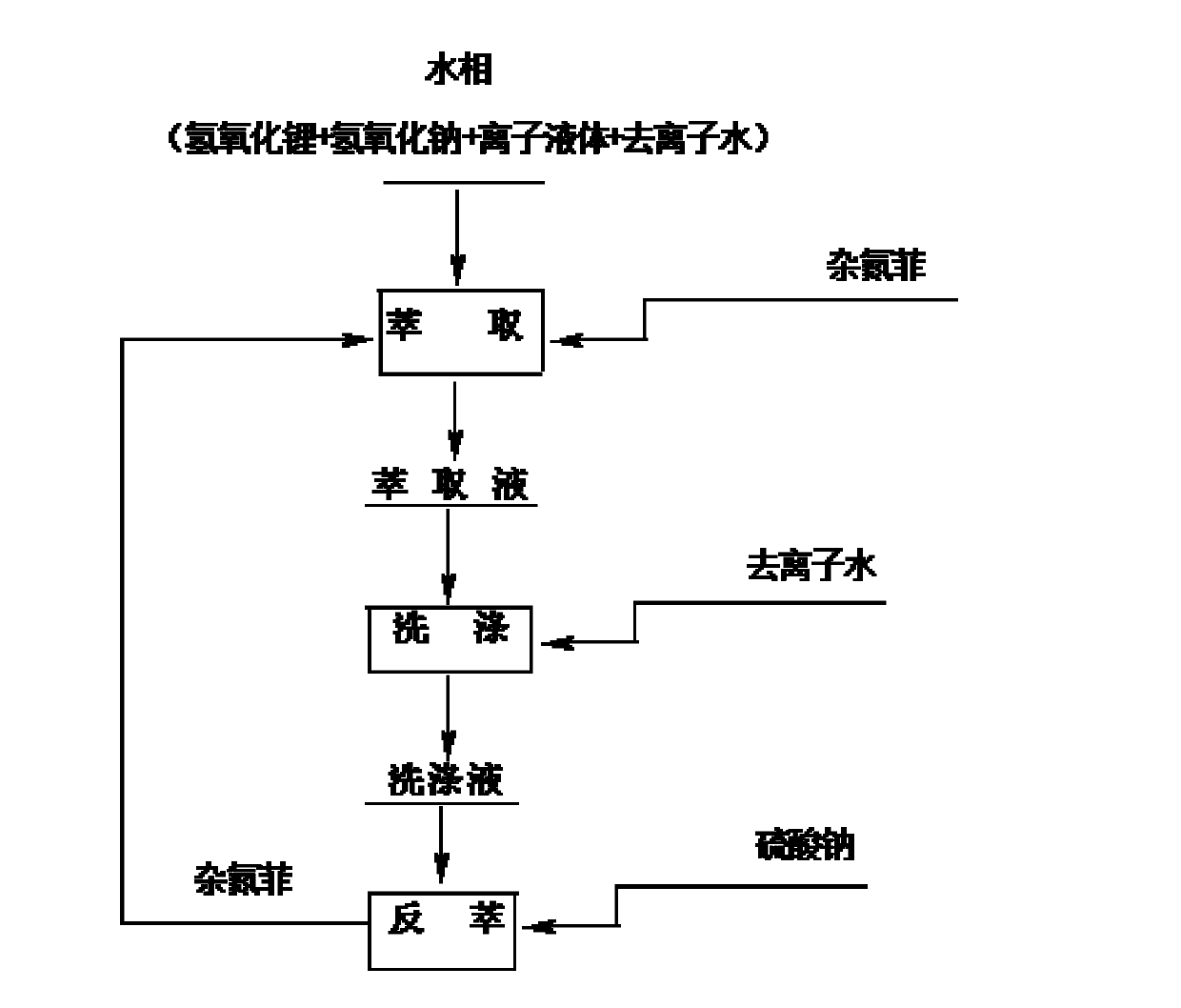

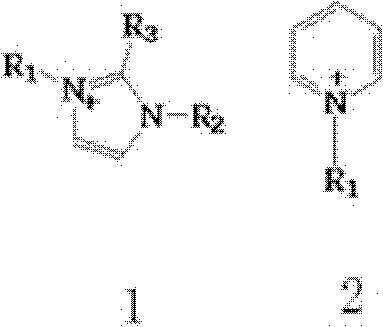

The invention provides a method for extracting lithium from salt lake brine, comprising the following steps: 1) mixing organic phase composed of salt lake brine, extracting agent and extracting medium with synergist, extracting the mixture and collecting the organic phase; 2) mixing the organic phase in step 1 with hydrochloric acid solution and carrying out back-extraction on the mixture, collecting aqueous phase to obtain aqueous solution of Lithium-ion; the step is characterized in that the extracting medium is hydrophobic ionic liquid. Compared with the traditional method for extracting lithium from salt lake brine with solvent gasoline as the medium, the method of the invention employs green and environmental-friendly ionic liquid as the medium; as a result, lithium salt extraction efficiency is improved, back-extraction acidity is lowered, what is more important is that environmental pollution and equipment corrosion due to use of a great deal of volatile organic solvent and high-concentration hydrochloric acid are avoided. In addition, the organic phase of the invention features fine cyclic applicability, thus greatly reducing production cost for extracting lithium from the salt lake brine.

Owner:JIANGNAN UNIV

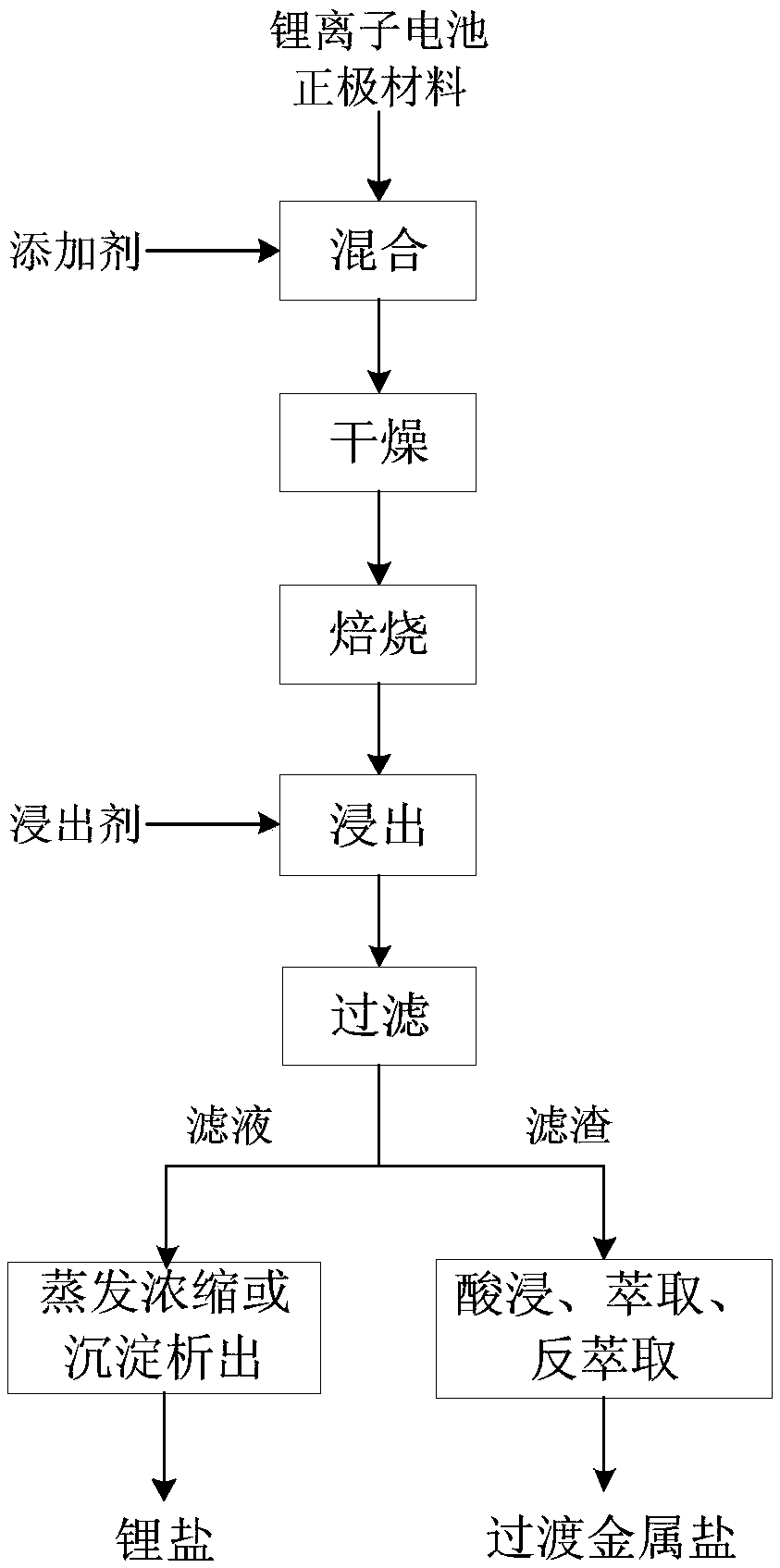

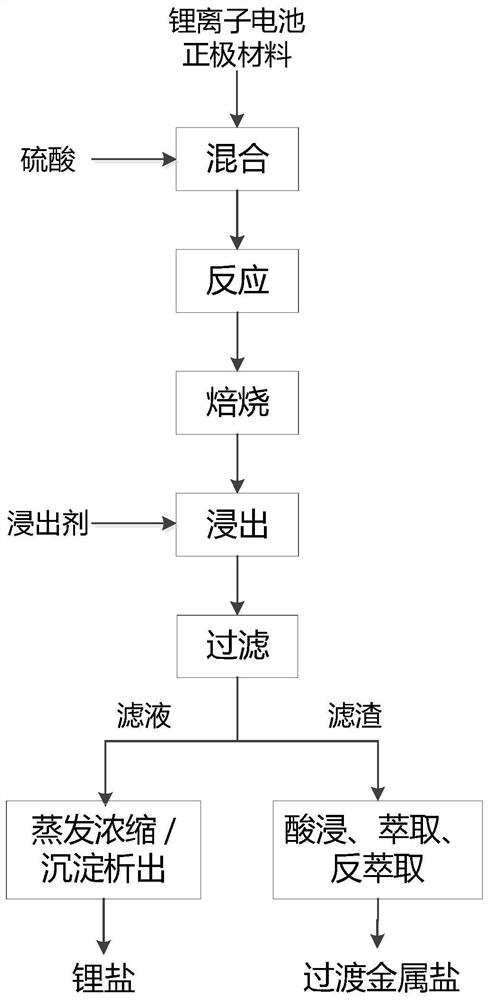

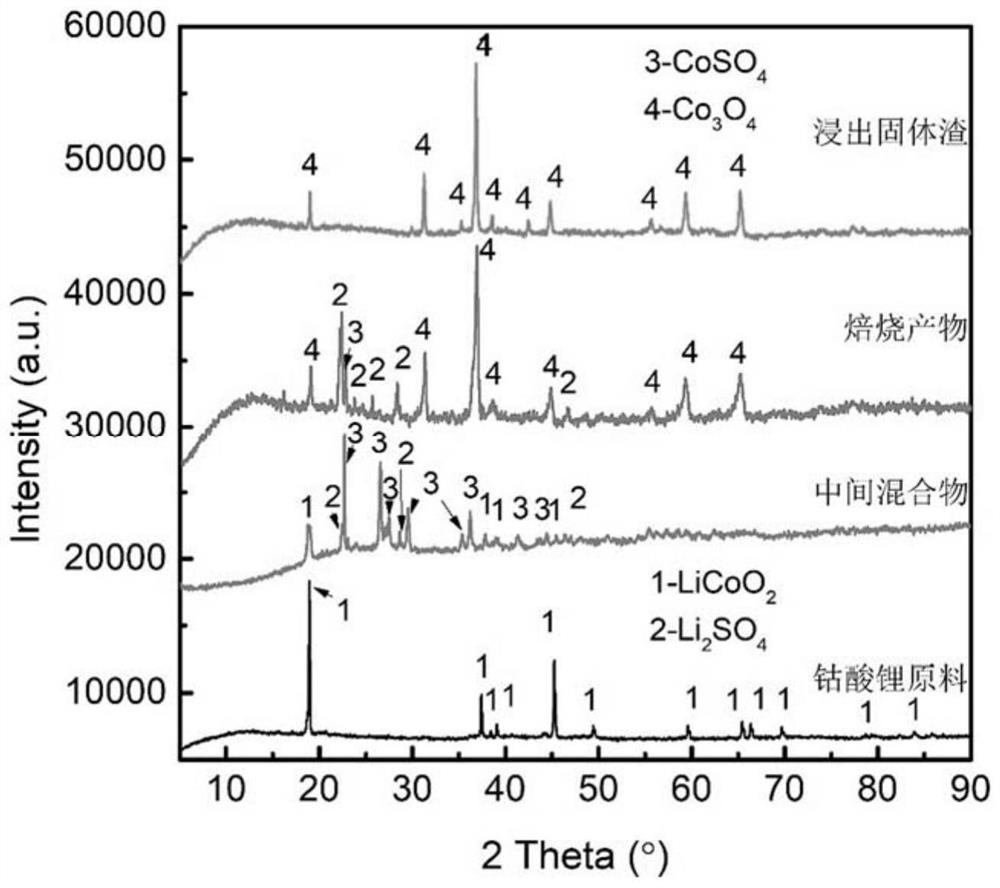

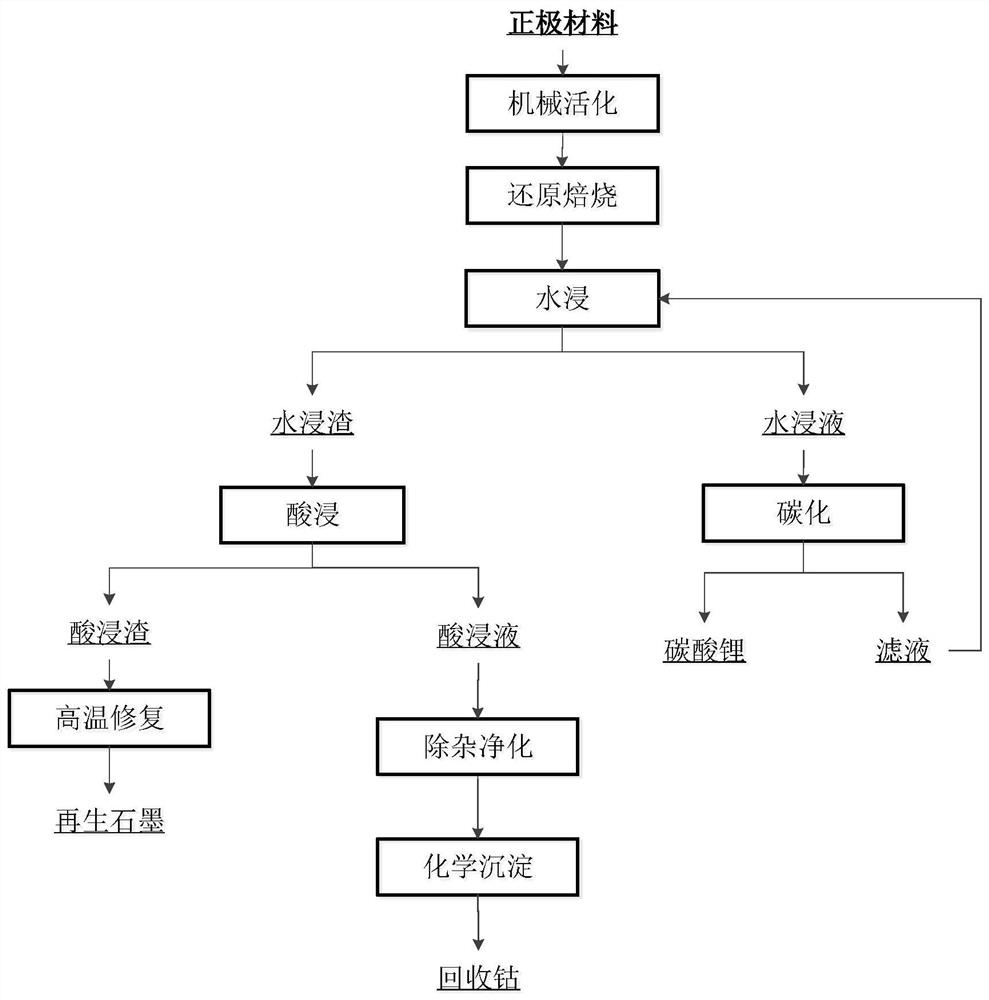

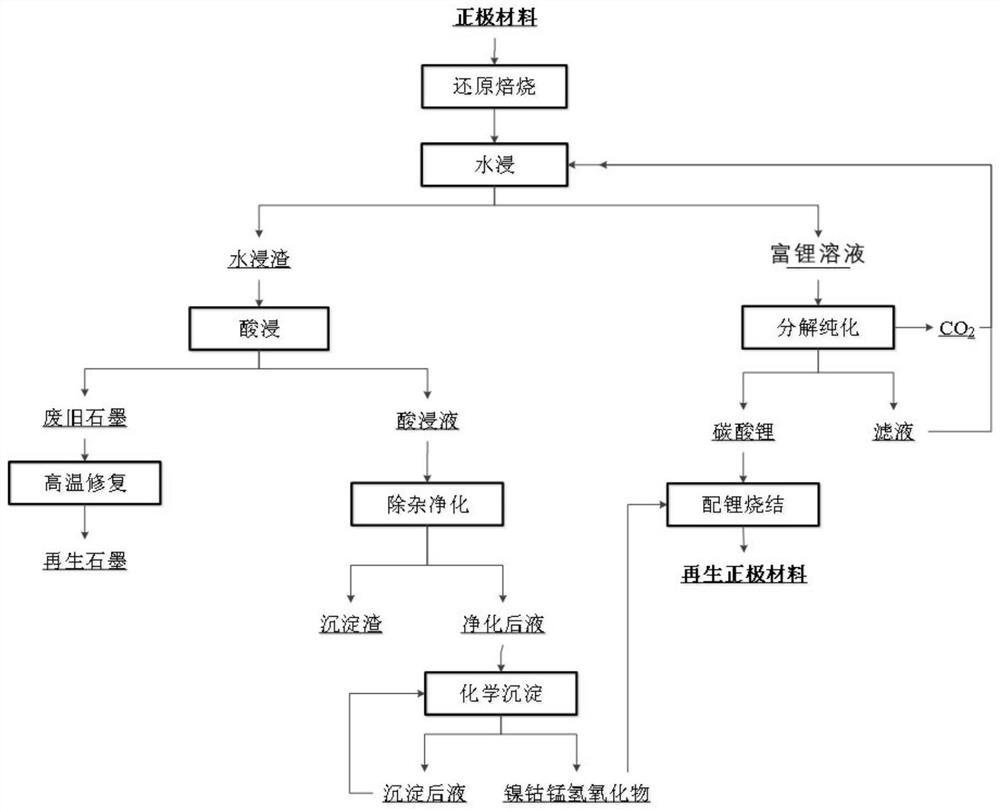

Method for selectively recycling positive electrode materials for lithium ion batteries

ActiveCN108832215AImplement selective extractionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLiquid wasteSlag

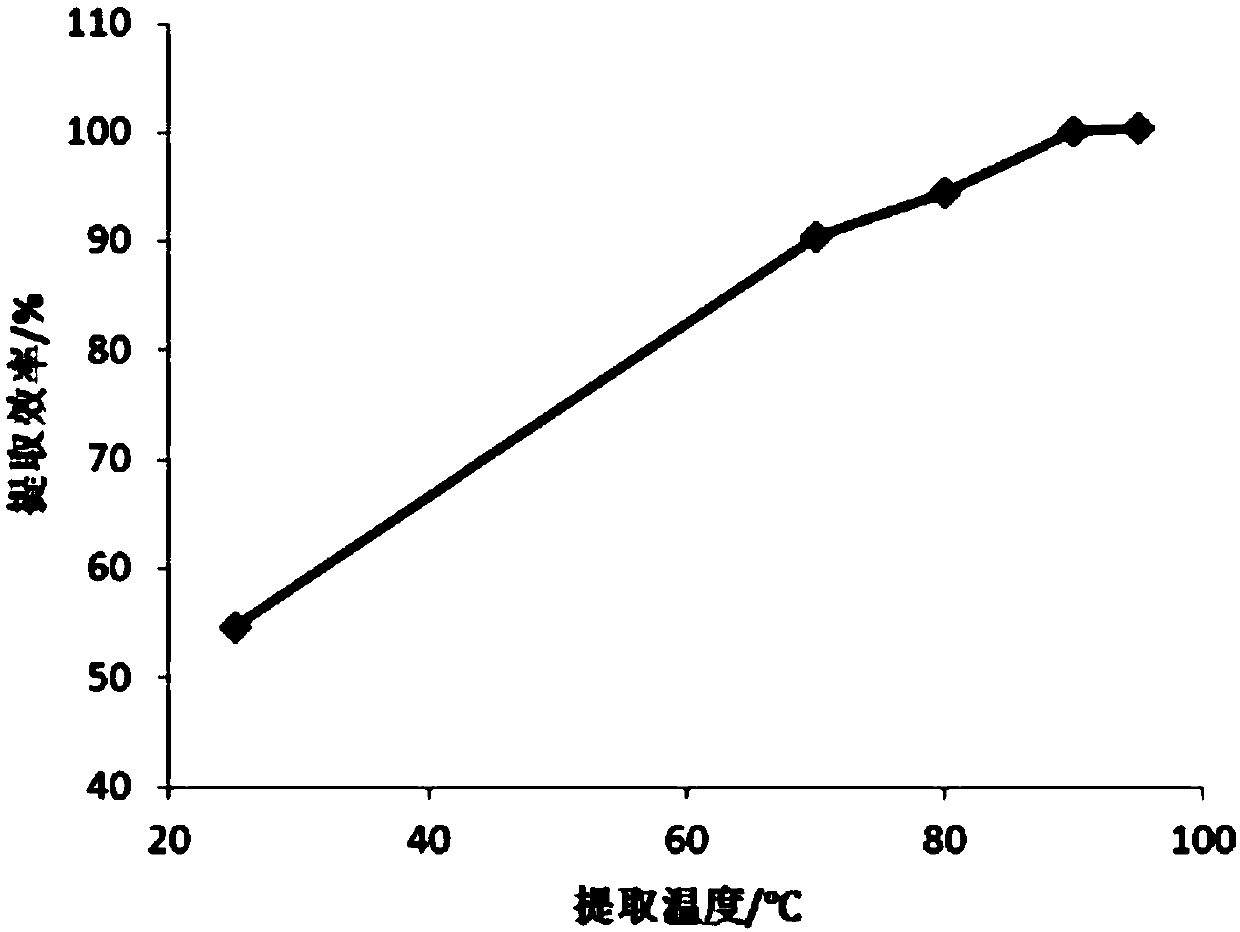

The invention provides a method for selectively recycling positive electrode materials for lithium ion batteries. The method comprises the following steps: carrying out transformation processing aftermixing the recycling positive electrode materials for lithium ion batteries with an additive; leaching an obtained transformation product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and a solid slag; and preparing the obtained lithium-rich solution into a lithium salt and the obtained solid slag into a transition metal salt. According to the method, recycling of valuable metals in the positive electrode materials for lithium ion batteries is realized by using in situ crystal transformation and mild leaching methods, particularly, selectiveextraction for lithium is realized, the recycle rate reaches 95% or above, and the recycle rate of other valuable metals such as nickel, cobalt and manganese reaches 98% or above; the method is shortin flow, other impurity ions are not introduced, the product purity is high, secondary pollution and liquid waste disposal can also be avoided, the recycle cost is saved, and the method is easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

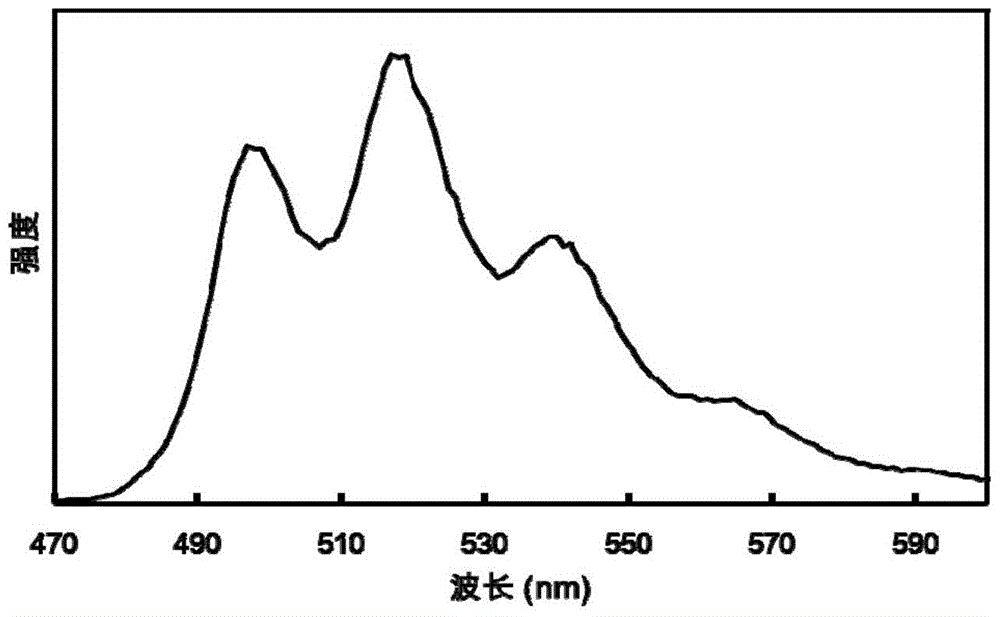

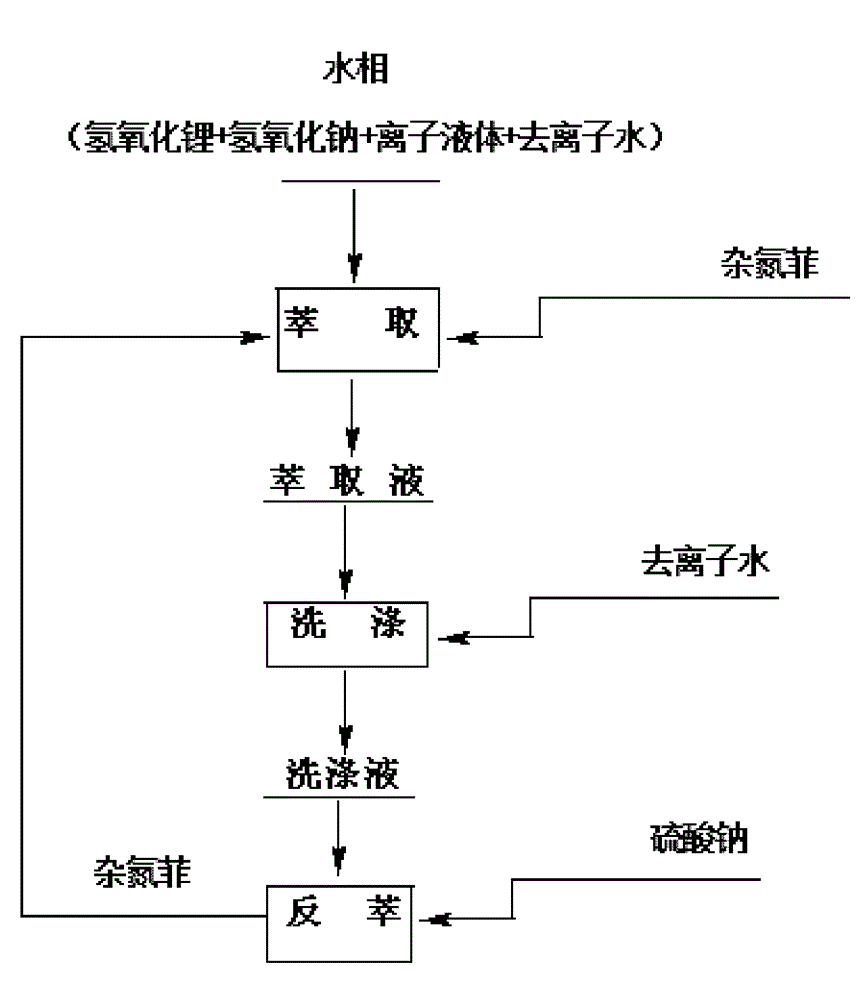

Method for extracting and separating lithium isotope aqueous solution

ActiveCN102430338AHigh extraction rateHigh separation factorIsotope separationLithium hydroxideAqueous solution

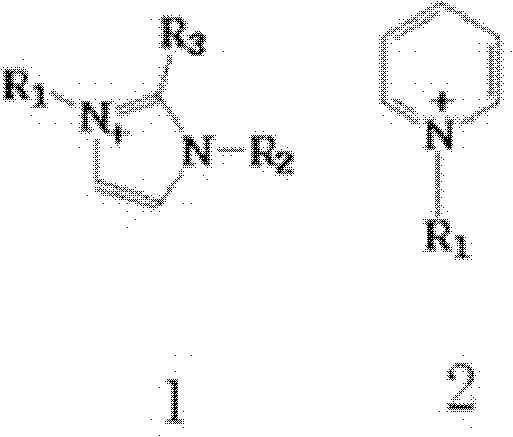

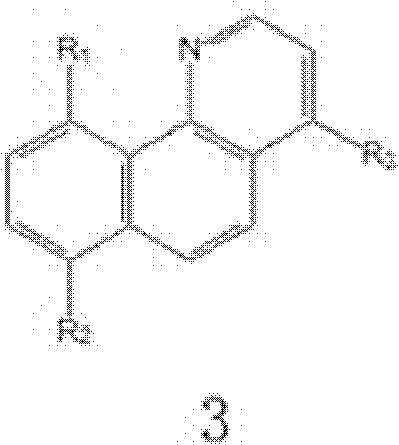

The invention relates to a method for extracting and separating a lithium isotope aqueous solution and belongs to the technical field of solvent extraction. In the method, hydrophobic naphthisoazine and hydrophilic ionic liquid respectively serve as an extracting agent and a synergist; and naphthisoazine, the ionic liquid and lithium ions form a stable ion associated matter under an alkaline condition, lithium ions enter into an organic phase through aqueous phase extraction and an obvious isotope separation effect is generated. The method comprises the following steps of: regulating the alkalinity of a lithium hydroxide solution, respectively adding the extracting agent, the synergist and the hydrophilic ionic liquid serving as an extracting medium, oscillating at normal pressure and normal temperature, standing still for layering, collecting the organic phase, and adding sodium sulfate into the organic phase to carry out lithium salt back extraction so that the lithium ions come back to the aqueous phase, thereby realizing the selective extraction and high-efficiency enrichment of lithium isotopes.

Owner:盐城福万家保温板有限公司

High-efficient method of extracting uranyl ions from water

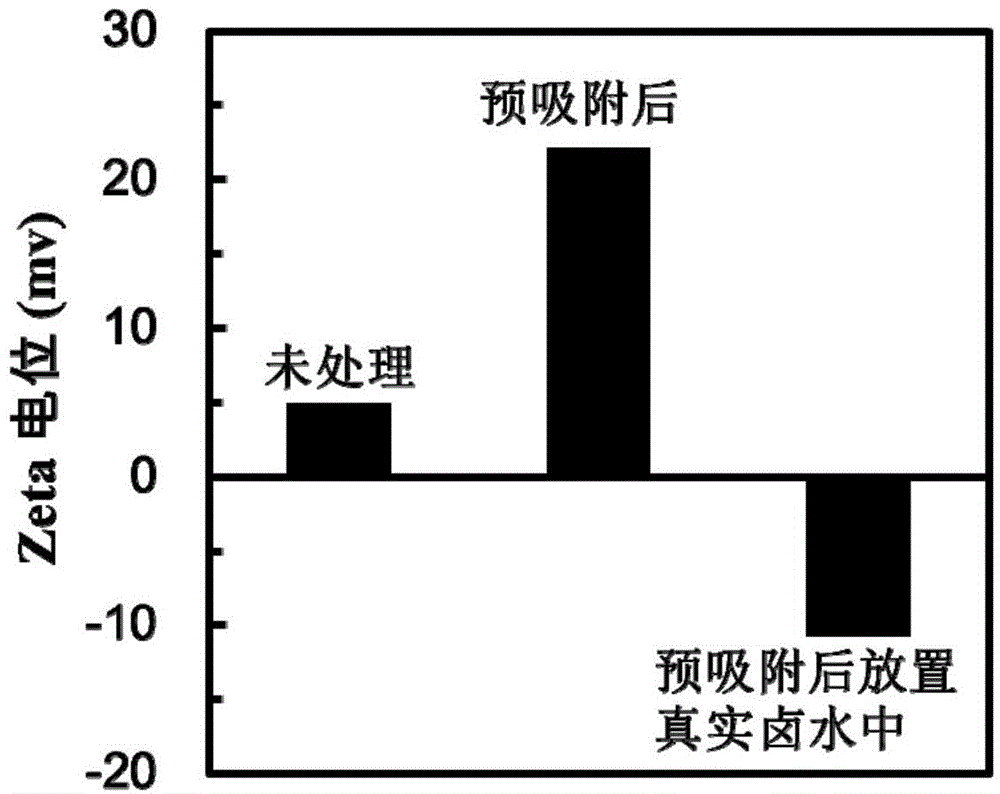

ActiveCN104485148ASimple methodEasy to operateRadioactive decontaminationEnvironmental resistanceWastewater

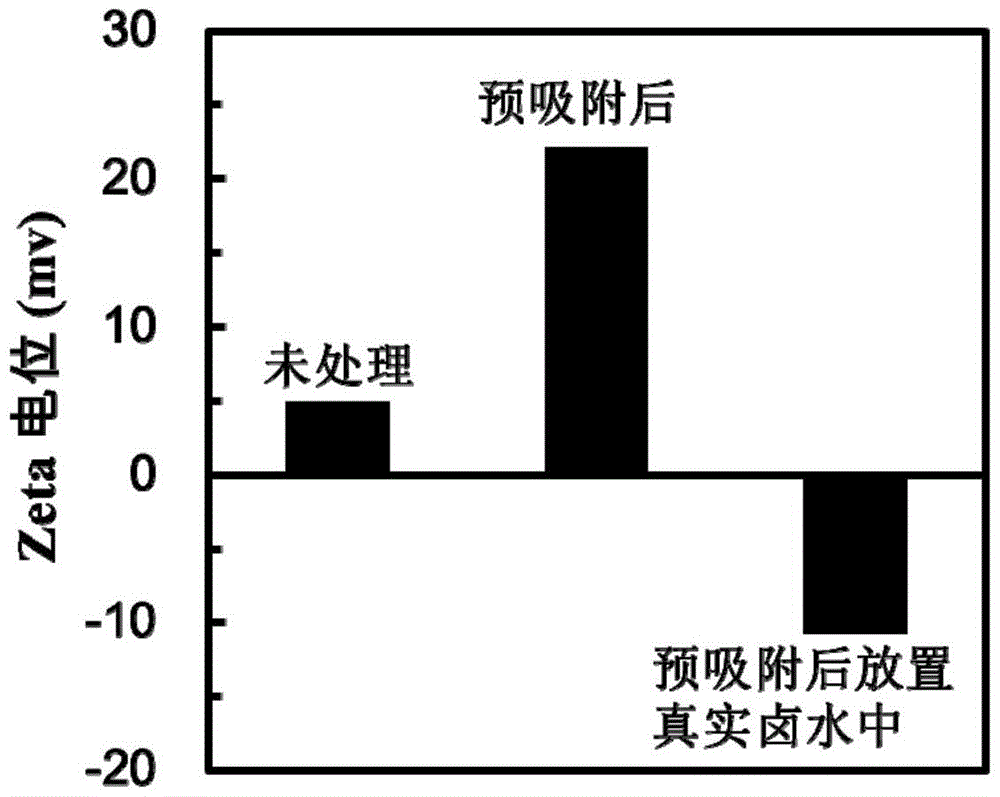

The invention discloses a high-efficient method of extracting uranyl ions from water and belongs to the field of the water treatment technology; the method comprises the steps: absorbing the uranyl ions from the surface of an absorbing material in advance; throwing the absorbing material absorbed with the uranyl ions in advance to waste water containing the uranyl ions, stirring, filtering and finally collecting filter residues. The high-efficient method of extracting the uranyl ions from water has the advantages of simple method, easy operation at normal temperature and no other impurities introduced; the method is green, environmental-friendly, economic and effective; the secondary pollution caused by toxic pollutants is avoided; high-salt and complex ion environments in water can be overcome effectively and the selective extraction of the uranyl ions in water is realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

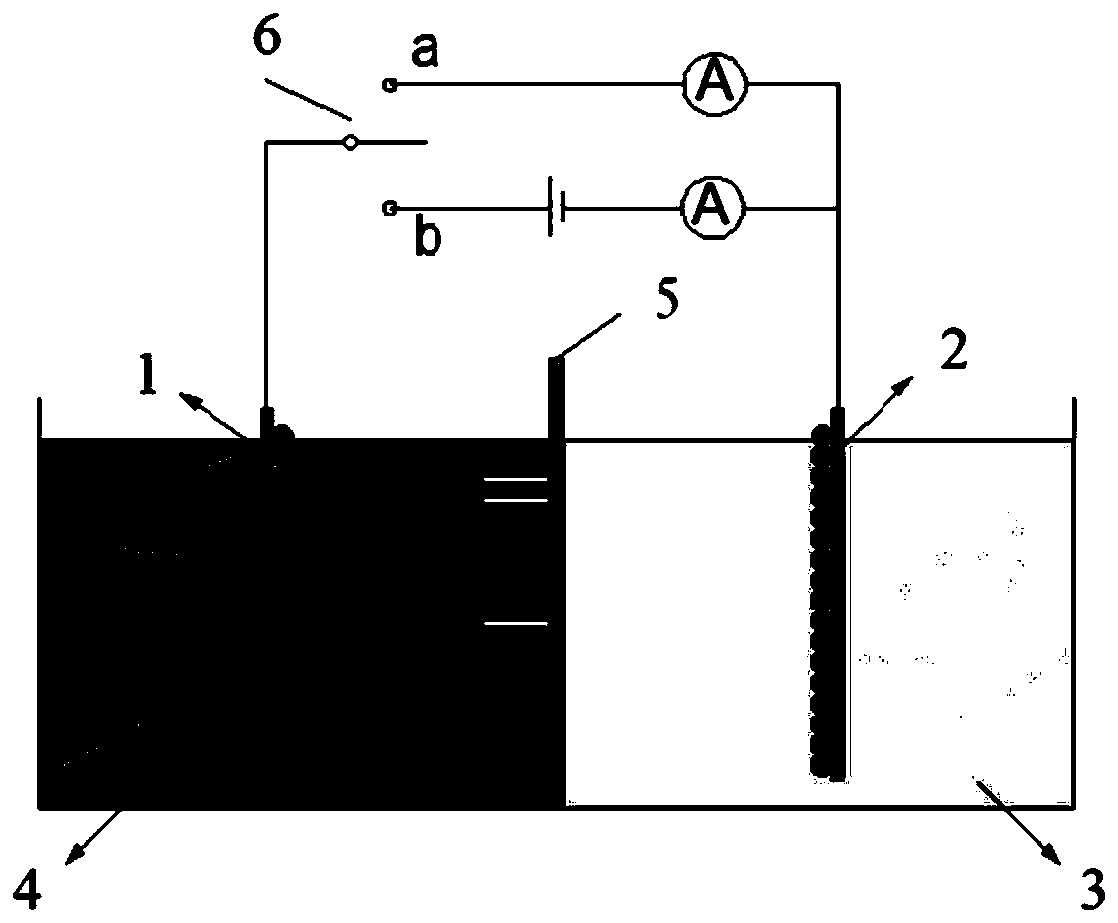

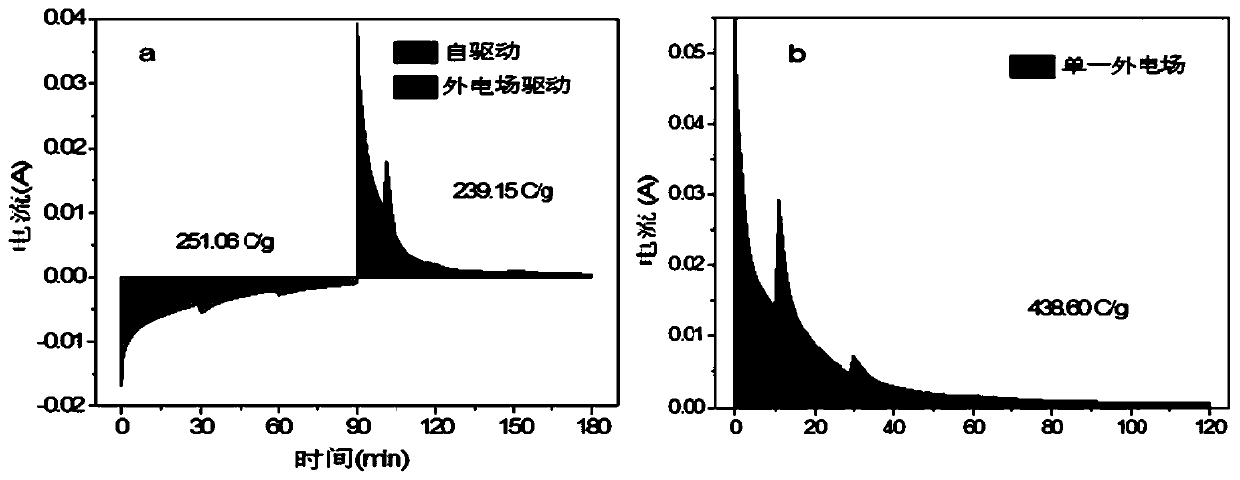

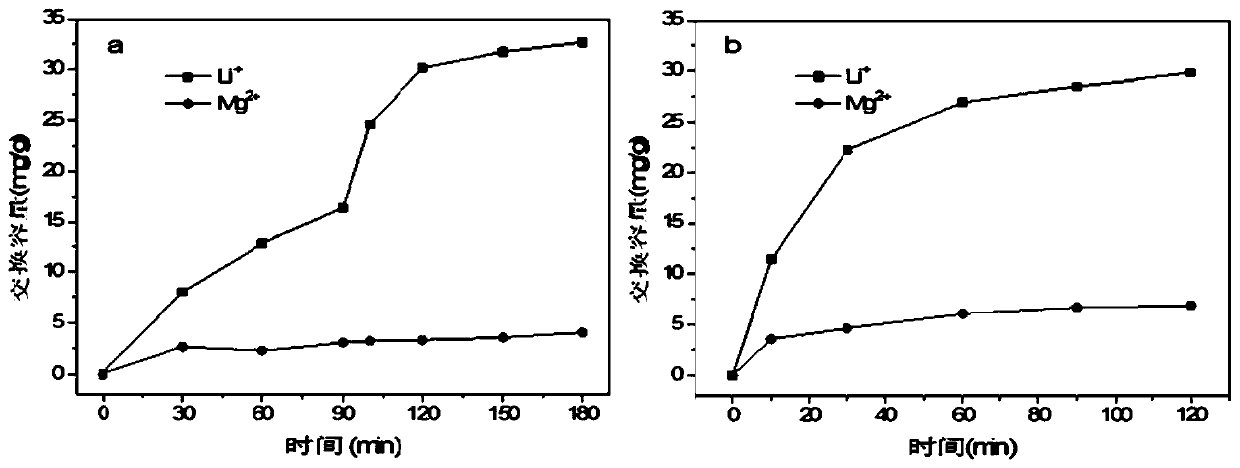

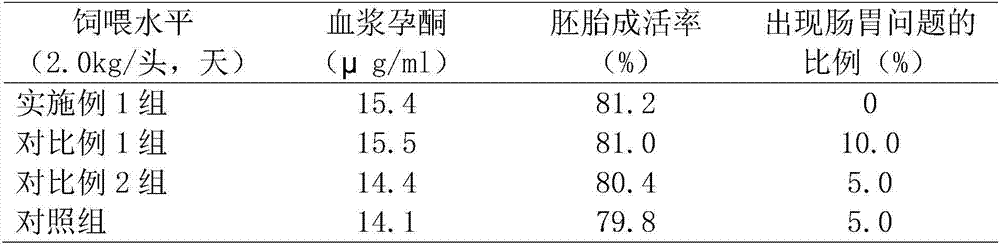

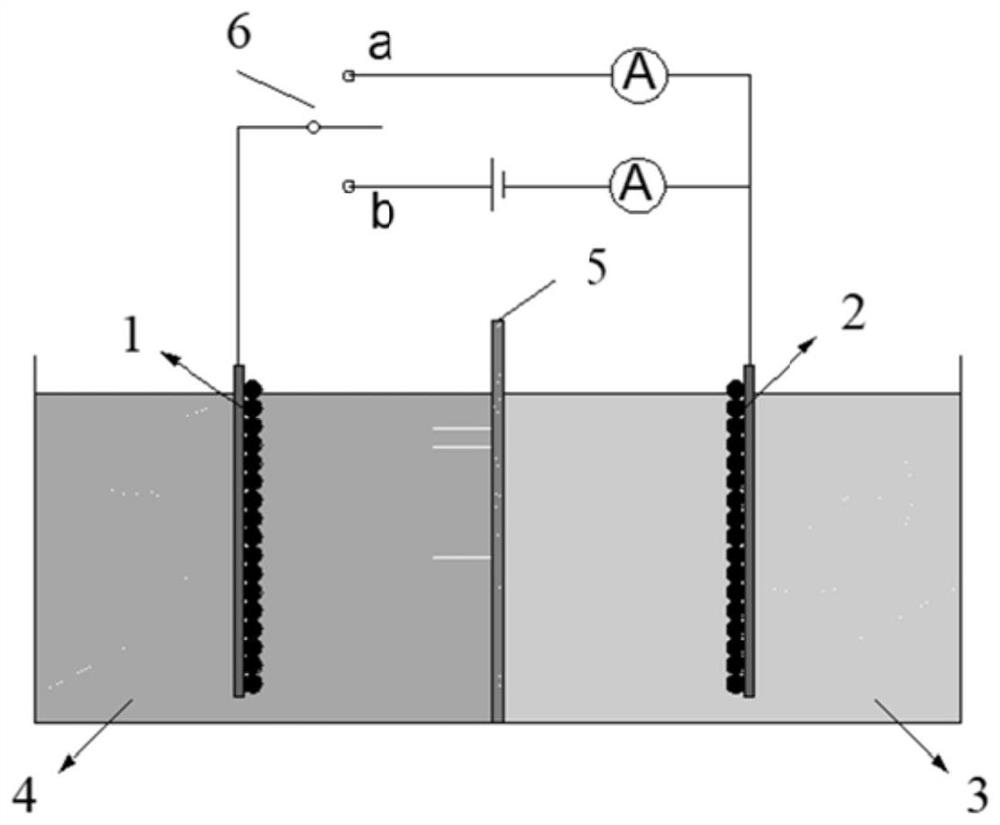

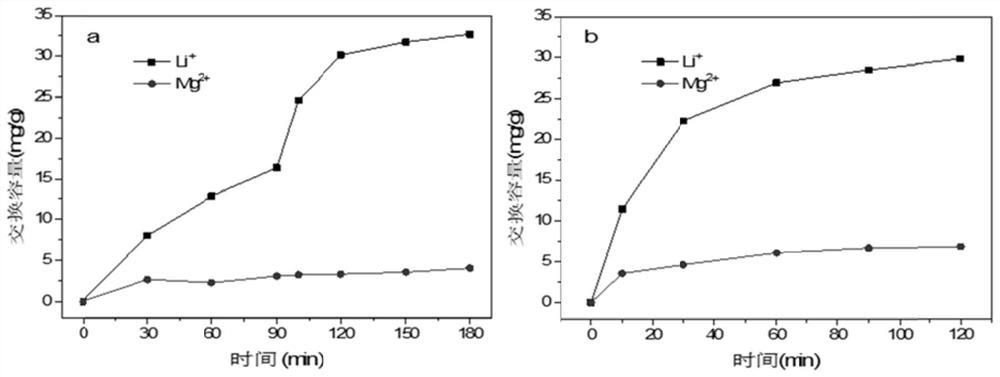

Electrochemical lithium extraction method based on "rocking chair" type structural electrode system

ActiveCN110777390AHigh selectivityIncrease switching capacityElectrolysis componentsChemical physicsEnergy recovery

The invention belongs to the technical field of electrochemical lithium extraction, and in particular relates to an electrochemical lithium extraction method which is based on a "rocking chair" type structural electrode system and can realize high-selectivity and low-energy-consumption extraction of dissolved thin lithium resources. According to the ''self-driven'' electrochemical lithium extraction method based on the ''rocking chair'' type structural electrode system provided by the invention, based on a current electrochemical lithium extraction method based on the ''rocking chair'' type structural electrode system, the ''self-driven'' process is used for the electrochemical lithium extraction method for the first time, the self drive (and even energy recovery) process lithium extraction is performed by using the self potential difference between electrodes in different states in the ''rocking chair'' type structural electrode system, the two electrodes firstly use the self smallerpotential difference for lithium extraction, then an external electric field is applied for further lithium extraction, so that the energy consumption in the lithium extraction process is effectivelyreduced, the synchronous improvement of the electrode-to-lithium exchange capacity and selectivity coefficient is realized, and the method has significant technical advantages.

Owner:HEBEI UNIV OF TECH

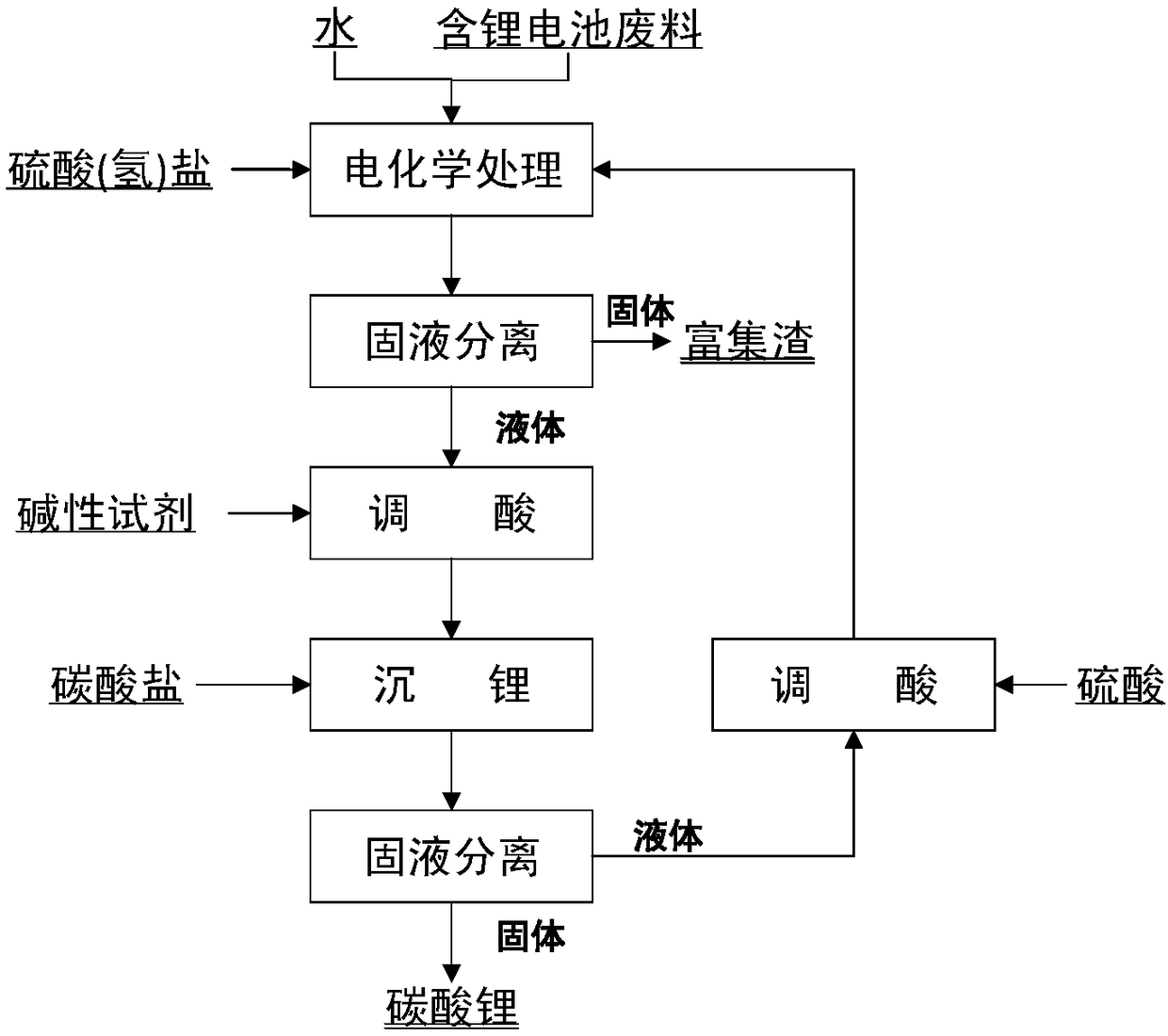

Method for recovering lithium in lithium-containing battery waste materials

ActiveCN108264068ASimplified leachingSimplify removalLithium carbonates/bicarbonatesAdditive ingredientSlurry

The invention provides a method for recovering lithium in lithium-containing battery waste materials. The method comprises the following steps of (1) mixing the lithium-containing battery waste materials with a salt water solution to obtain raw material slurry; performing electrochemical treatment on the raw material slurry; performing solid-liquid separation; obtaining liquid of lithium-containing purified liquid; (2) regulating the pH of the lithium-containing purified liquid in the step (1) to be 7 or higher; adding carbonates for lithium precipitation reaction; performing solid-liquid separation after the reaction; obtaining solid of lithium carbonate. The method provided by the invention has the advantages that the flow process is short; the operation is simple; the reaction process is green and clean; no waste is discharged in the integral flow process; the soaking- precipitation-separation process of a conventional process is realized through one step of the electrochemical processing; the production cost is reduced; the lithium recovery selectivity is as high as 99 percent; the single time recovery rate reaches 95 percent or higher; the obtained product purity reaches the battery grade lithium carbonate requirements; meanwhile, the high-value conversion of other metal ingredients is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for selectively extracting lithium from waste lithium iron phosphate materials

ActiveCN110331288BImplement selective extractionEasy to recycleWaste accumulators reclaimingProcess efficiency improvementLithium iron phosphatePhosphate

The invention discloses a method for selectively extracting lithium from a waste lithium iron phosphate material, which comprises the following steps: immersing the waste lithium iron phosphate material in a sodium hydroxide solution, carrying out alkali leaching to remove aluminum, filtering, and removing aluminum from the filtered The material is dried to obtain lithium iron phosphate powder, and the filtered sodium aluminate filtrate is recovered; the lithium iron phosphate powder is put into a heating furnace, and the selective lithium extraction gas is introduced, and then roasted to obtain iron phosphate and lithium The compound of iron phosphate and lithium is added to the ball mill, wet ball milled, and filtered to obtain iron phosphate solid and lithium-containing solution respectively; the pH value of the lithium-containing solution is adjusted to 9.0‑11.0, and impurities are removed to obtain pure lithium solution; adding sodium carbonate solution to pure lithium solution for reaction, filtering, washing and drying the filtered solid to obtain lithium carbonate. The lithium in the waste lithium iron phosphate material is recovered by the method of the invention, and the recovery rate of the lithium is as high as 95 percent or more.

Owner:HUNAN BRUNP RECYCLING TECH CO LTD +2

A method for selectively extracting lithium from lithium iron phosphate waste

ActiveCN109554545BHigh recovery ratePromoting Recycling DevelopmentWaste accumulators reclaimingProcess efficiency improvementLithium iron phosphateLithium carbonate

The invention discloses a method for selectively extracting lithium from lithium iron phosphate waste materials. The method comprises the following steps that water is added into the lithium iron phosphate waste material for slurry, then acid is added, and the temperature is heated to 40-100 DEG C, the pH value of the system is adjusted to 2-4, the temperature and the pH value range are kept, reacting is carried out for 1-10 hours, and filtering and separating are carried out on the reacted slurry so as to obtain a lithium solution and phosphorus iron slag; and the acid is one of concentratedhydrochloric acid, concentrated sulfuric acid or concentrated nitric acid. According to the method, the lithium in the waste lithium iron phosphate material is recycled, the lithium recovery rate is up to 98% or above, and the purity of the further prepared lithium carbonate reaches 99.0% or above; the method is simple in process, and low in energy consumption; and the selective extraction of thelithium in the waste lithium iron phosphate material is realized, the product value is high, considerable economic benefits are achieved, and the recovery and development of lithium iron phosphate waste batteries are facilitated.

Owner:GUANGDONG BRUNP RECYCLING TECH CO LTD +1

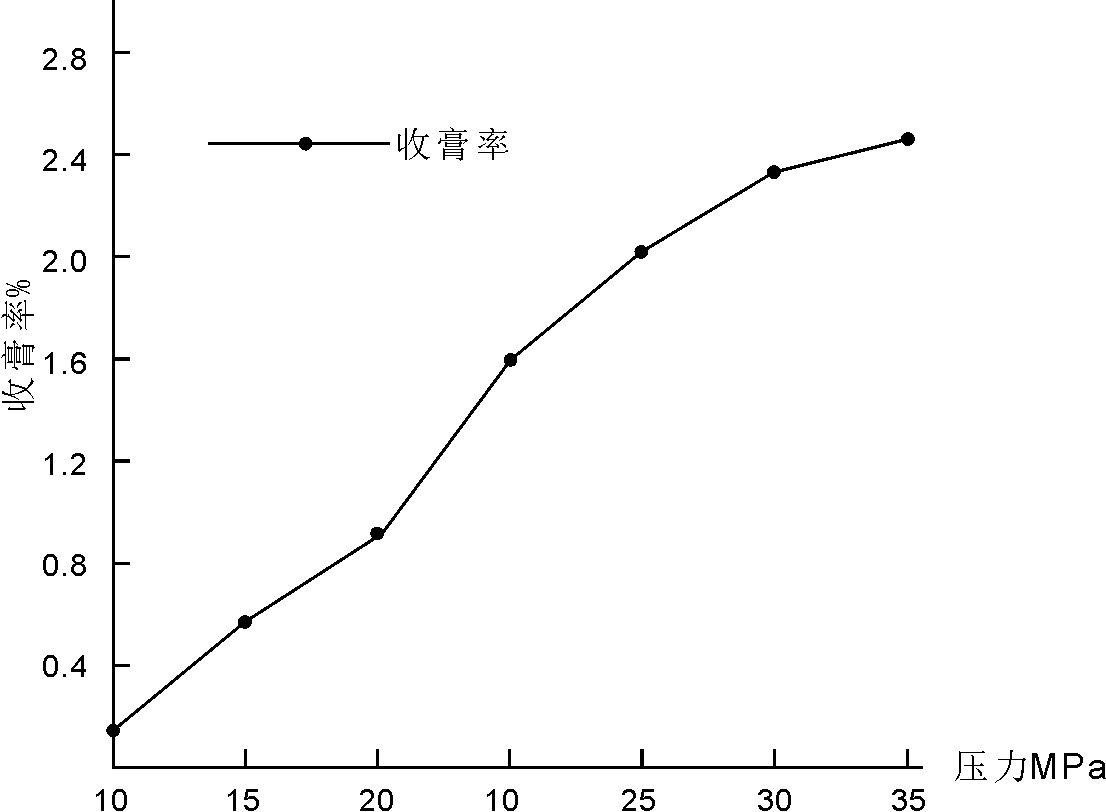

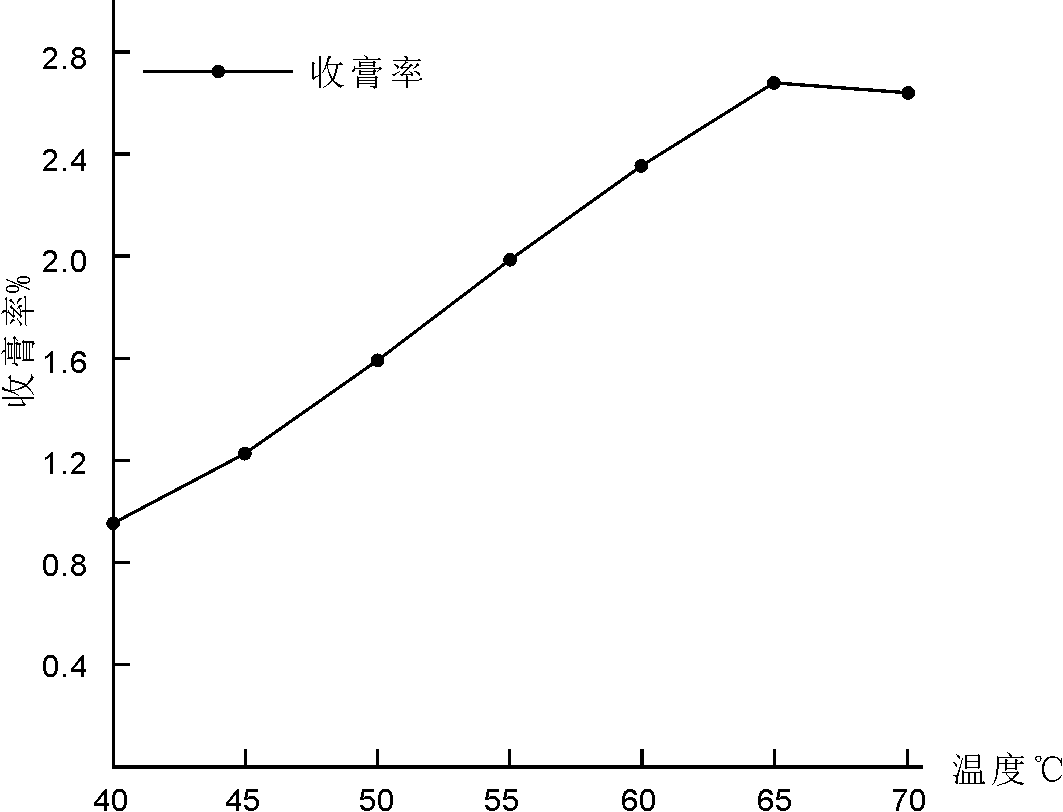

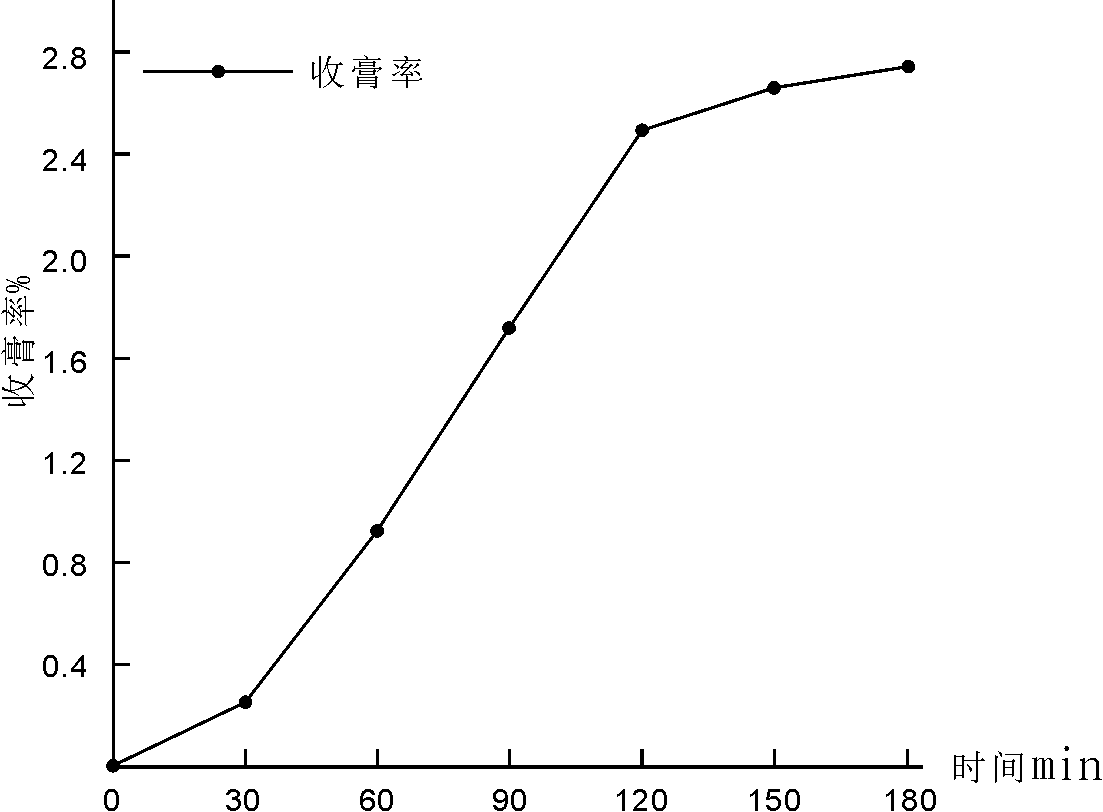

Processing method of donkey-hide gelatin and ginger tea

InactiveCN107712157AImprove solubilityAchieve continuous extractionPre-extraction tea treatmentCavitationPancreas

The invention discloses a processing method of donkey-hide gelatin and ginger tea. The processing method is characterized in that crude trypsin is extracted by processing pig pancreas, so that the activity is better and the benefit for reducing the production cost is achieved; the donkey-hide gelatin is hydrolyzed by the crude trypsin to obtain small-molecular peptides with certain physiological activity, so that the digestion and the absorption by a human body are easier and the effects are exerted more easily; and continuous extraction of effective components of fresh ginger is realized by asubcritical water extraction mode, and the cavitation effect of ultrasonic wave is utilized to generate an enhancing action for extracting subcritical water.

Owner:安徽华健生物科技有限公司

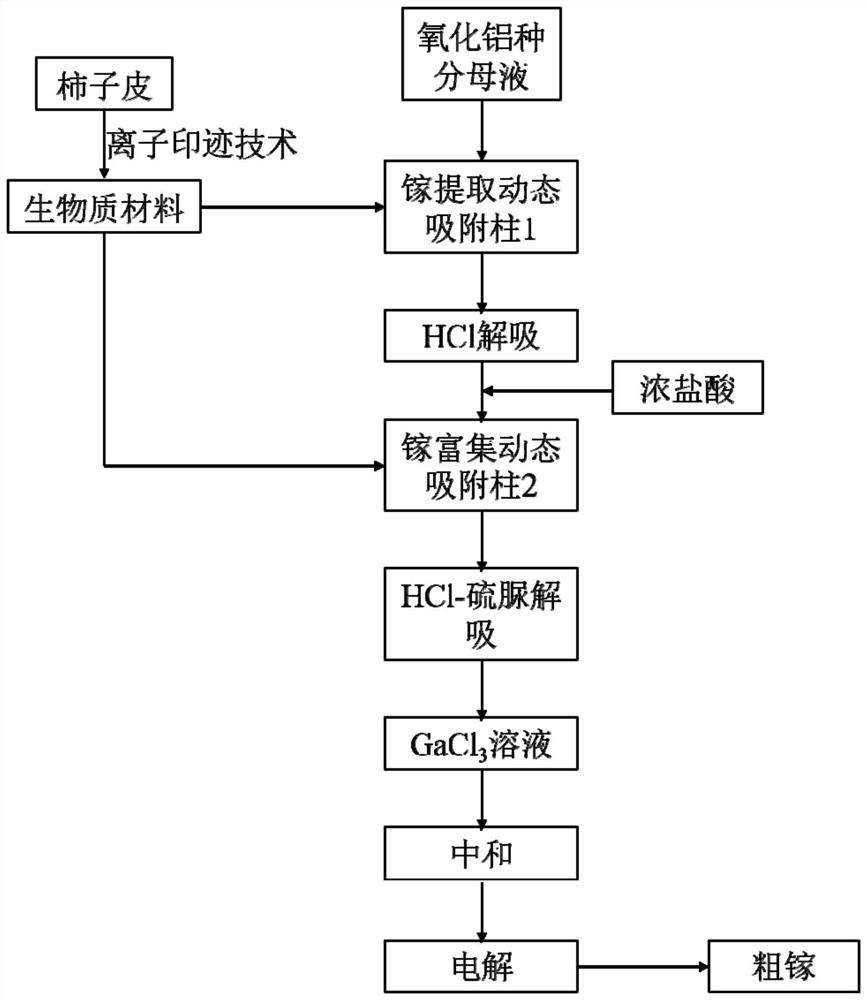

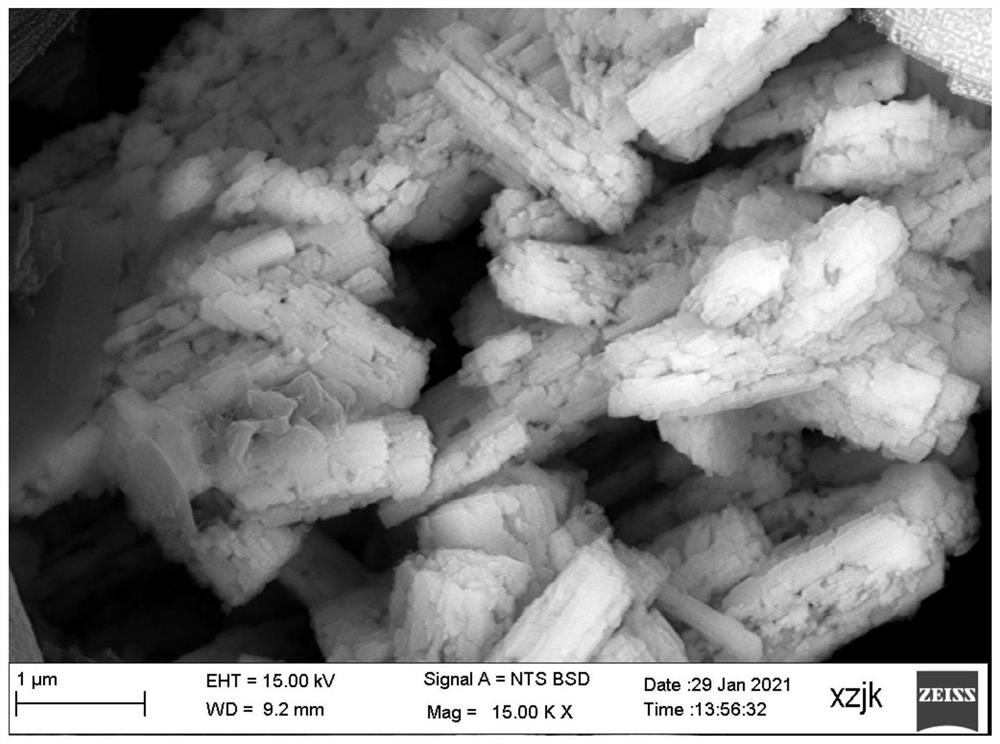

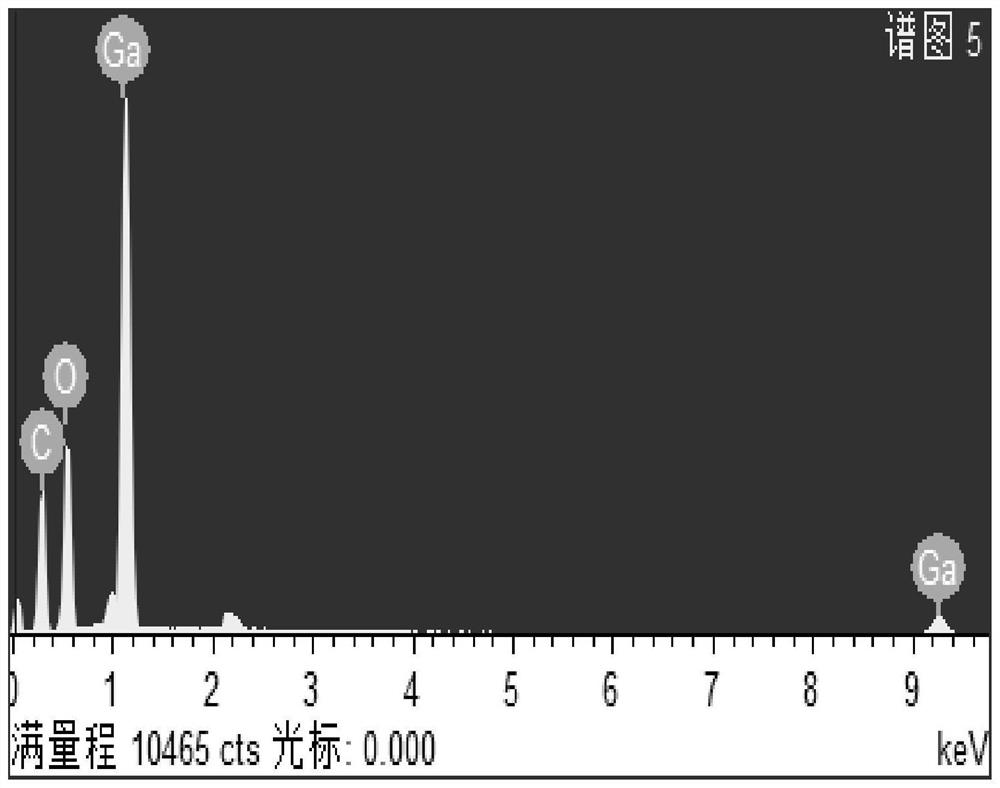

Method for enriching and extracting gallium from alumina seed precipitation mother liquor on basis of biomass material

ActiveCN113249596AEasy to operateLow costPhotography auxillary processesProcess efficiency improvementBiomassEnvironmental chemistry

The invention discloses a method for enriching and extracting gallium from alumina seed precipitation mother liquor on the basis of a biomass material. The method comprises the following steps that the biomass material is taken as an adsorbent, and the biomass material is a persimmon peel-based imprinted composite material obtained by modifying persimmon peel through an ion imprinting technology; and the persimmon peel-based imprinted composite material is loaded into two stages of dynamic adsorption columns, and gallium in the alumina seed precipitation mother liquor is selectively adsorbed and desorbed through a gallium extraction dynamic adsorption column 1 and a gallium enrichment dynamic adsorption column 2 to obtain a gallium-rich electrolytic stock solution. According to the method, the waste biomass persimmon peel serves as a material, the adsorbent is obtained through surface ion imprinting modification, selective extraction of gallium in the alumina seed precipitation mother liquor is achieved through gallium ion specific recognition sites on the surface of the adsorbent, and the method has the advantages of being low in gallium enrichment cost, high in efficiency and the like and has good economic benefits and environmental benefits.

Owner:CHINA UNIV OF MINING & TECH +1

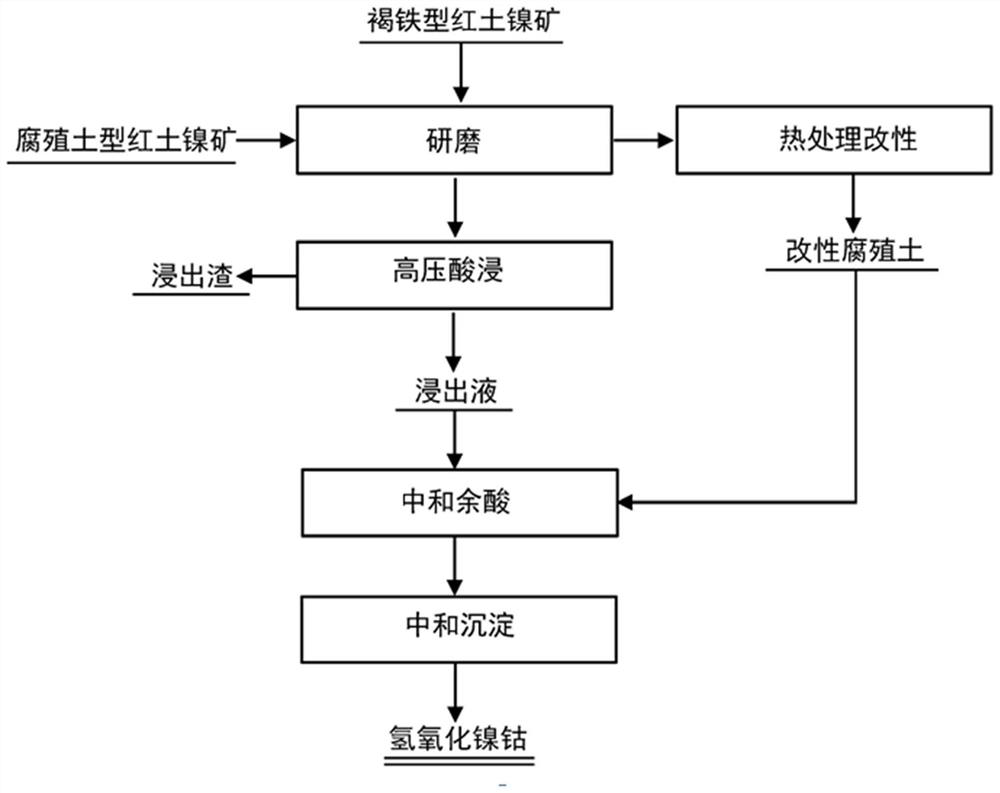

Low-cost and low-acid-consumption laterite-nickel ore leaching method

PendingCN114507780ANeutralization is effectiveNeutralizers are effective in neutralizingNickel compoundsPregnant leach solutionSlag

A low-cost and low-acid-consumption laterite-nickel ore leaching method comprises the following steps that (1) limonite type laterite-nickel ore and a sulfuric acid solution are mixed and subjected to size mixing, then the mixture is transferred into a high-pressure kettle for high-pressure acid leaching, and leaching liquid and leaching residues are obtained; (2) adjusting the pH value of the leaching solution to 3-4 by adopting modified humus soil to obtain iron-aluminum slag and a neutralized solution; the modified humus soil is obtained after humus soil type laterite-nickel ore is subjected to heat treatment; and (3) adjusting the pH value of the neutralized solution to 7.0-8.5 by using alkali, and carrying out solid-liquid separation to obtain the nickel cobalt hydroxide. According to the method, the humus soil type laterite-nickel ore with high magnesium content is subjected to heat treatment modification, the modified humus soil type laterite-nickel ore can serve as a neutralizing agent to neutralize free acid in limonite type laterite-nickel ore leaching liquid, the free acid can be effectively neutralized, and the content of magnesium in the limonite type laterite-nickel ore leaching liquid is increased; and valuable metals such as nickel and cobalt in the humus type laterite-nickel ore can be leached by fully utilizing the residual acid, so that the acid consumption of a unit nickel product is reduced.

Owner:CENT SOUTH UNIV

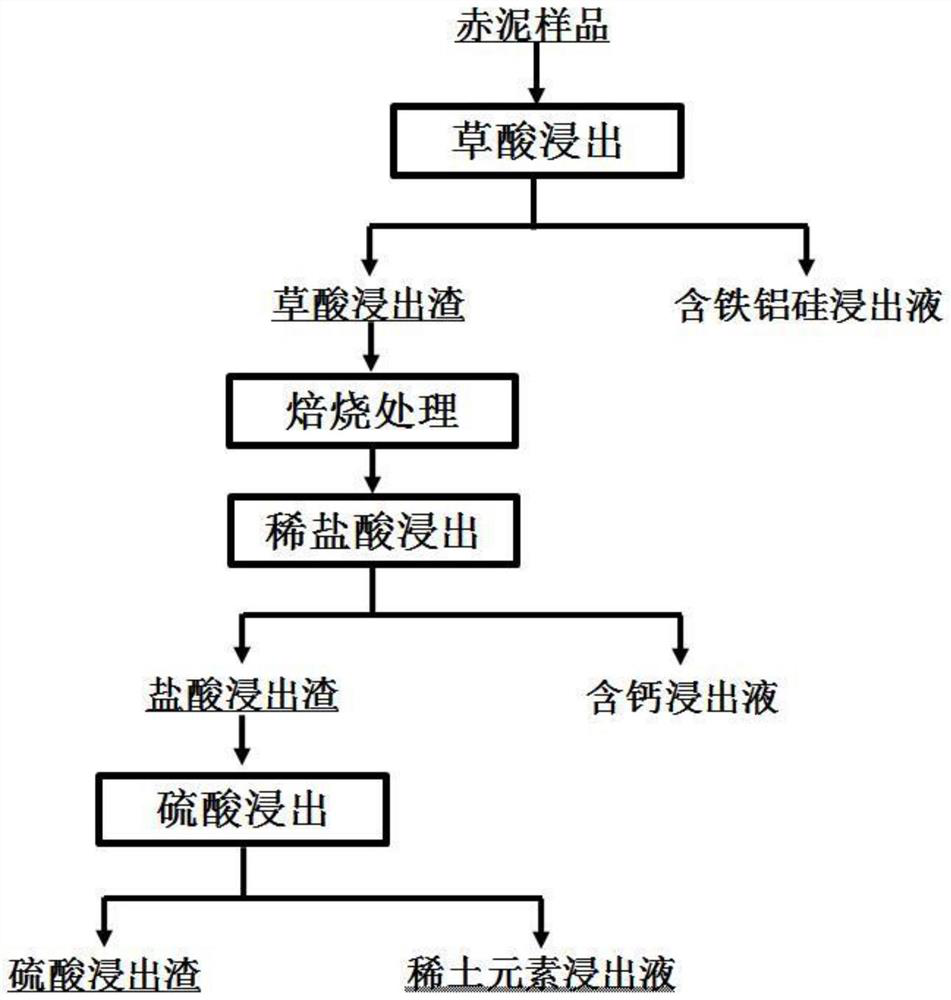

Method for selectively leaching rare earth elements from red mud

ActiveCN114480860AEfficient separationReduce concentrationOrganic compound preparationCarboxylic acid salt preparationOXALIC ACID DIHYDRATERare-earth element

The invention relates to the technical field of rare earth element recovery, in particular to a method for selectively leaching rare earth elements from red mud. Comprising the following steps: leaching the red mud with an oxalic acid solution, and carrying out solid-liquid separation to obtain oxalic acid leaching residues and an oxalic acid leaching solution; roasting the oxalic acid leaching residues, leaching with a diluted hydrochloric acid solution, and carrying out solid-liquid separation to obtain hydrochloric acid leaching residues and a hydrochloric acid leaching solution; and leaching the hydrochloric acid leaching residues by using a sulfuric acid solution, and then carrying out solid-liquid separation to obtain a leaching solution rich in rare earth and sulfuric acid leaching residues. According to the method for extracting the rare earth elements in multiple stages through oxalic acid, diluted hydrochloric acid and sulfuric acid, the technical purposes that iron extraction, calcium removal and selective leaching of the rare earth elements from the red mud are achieved, the leaching rate of the rare earth elements is 80% or above, and the leaching rate of iron, aluminum and silicon elements is 20% or below are achieved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI +1

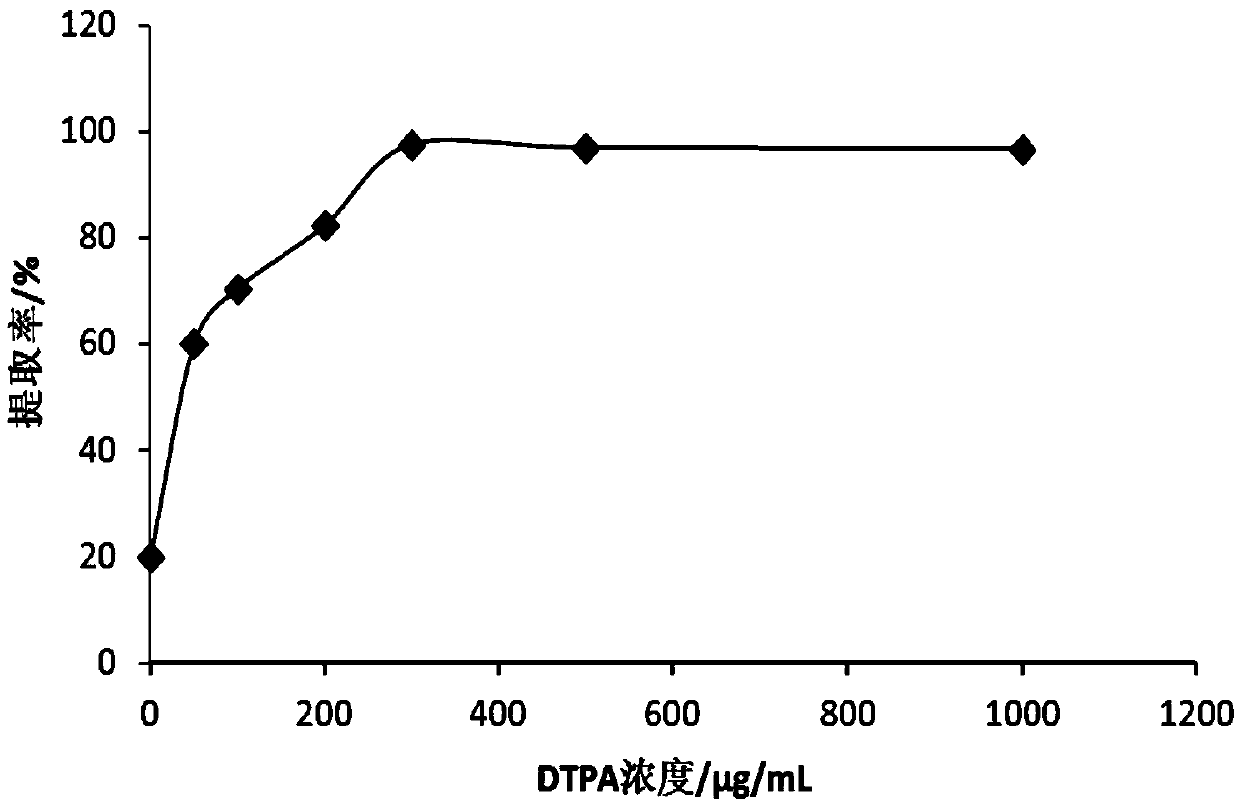

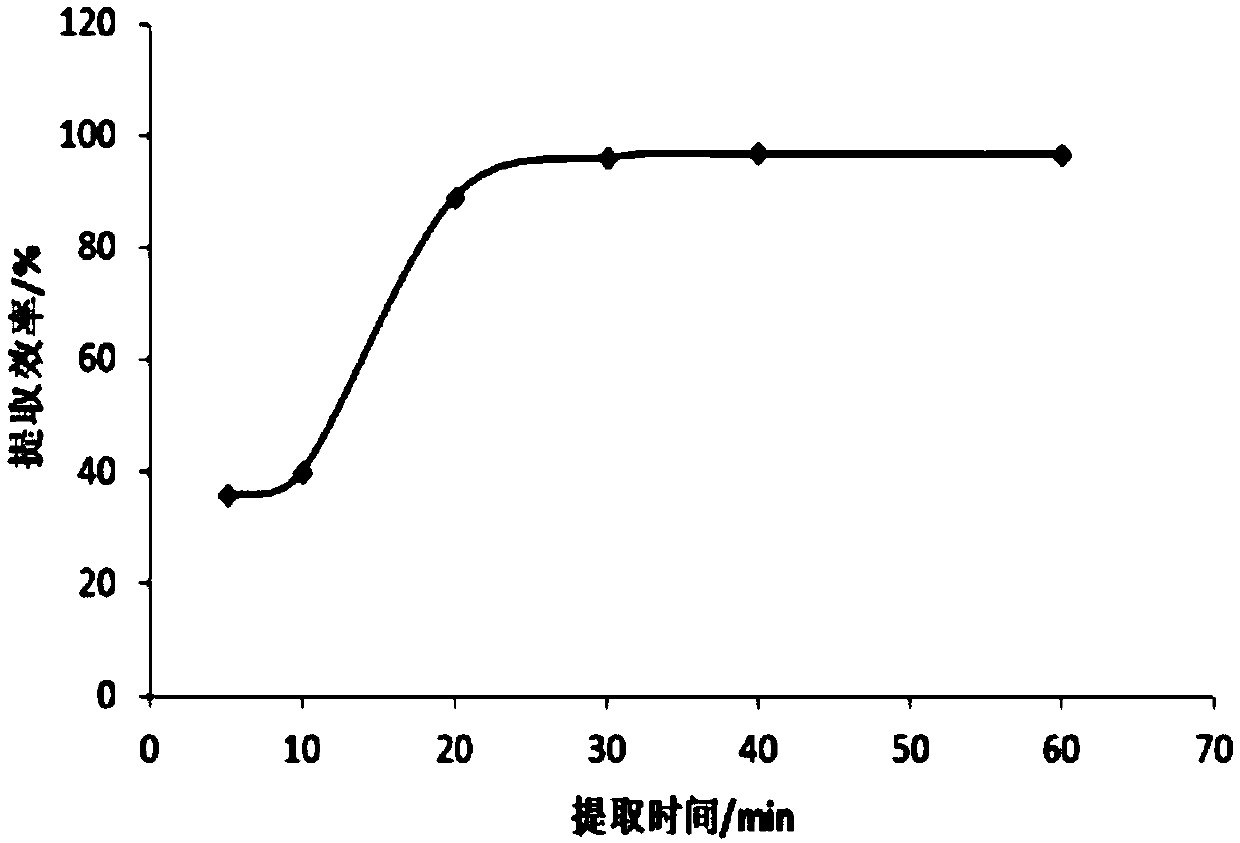

Method and kit for rapidly and selectively detecting added aluminum in food

InactiveCN109632776AImplement selective extractionMeet detectionMaterial analysis by observing effect on chemical indicatorDiethylenetriamineEnvironmental chemistry

The invention discloses a method and a kit for rapidly and selectively detecting added aluminum in a food. According to the method, the added aluminum in a sample is extracted through diethylenetriamine pentaacetic acid (DTPA) complexing, so that selective extraction of the added aluminum in the food is realized; then bismuth ions in a bismuth nitrate solution are used for carrying out competitivecomplexing of DTPA to release aluminum ions; the free aluminum ions, in an ethylenediamine-hydrochloric acid buffer solution, react with chrome azurol S to generate blue-green quaternary micelles inthe presence of TritonX-100 and cetyl trimethyl ammonium bromide; and qualitative comparison with a colorimetric card is carried out. Meanwhile, the concentration of the trivalent aluminum ions in thesample can be estimated according to the known concentration on the colorimetric card, thereby realizing semi-quantification. The kit can meet field rapid detection requirements of food aluminum additives, and is suitable for family detection and field law enforcement detection, particularly flour food detection.

Owner:HUBEI PROVINCIAL INST FOR FOOD SUPERVISION & TEST

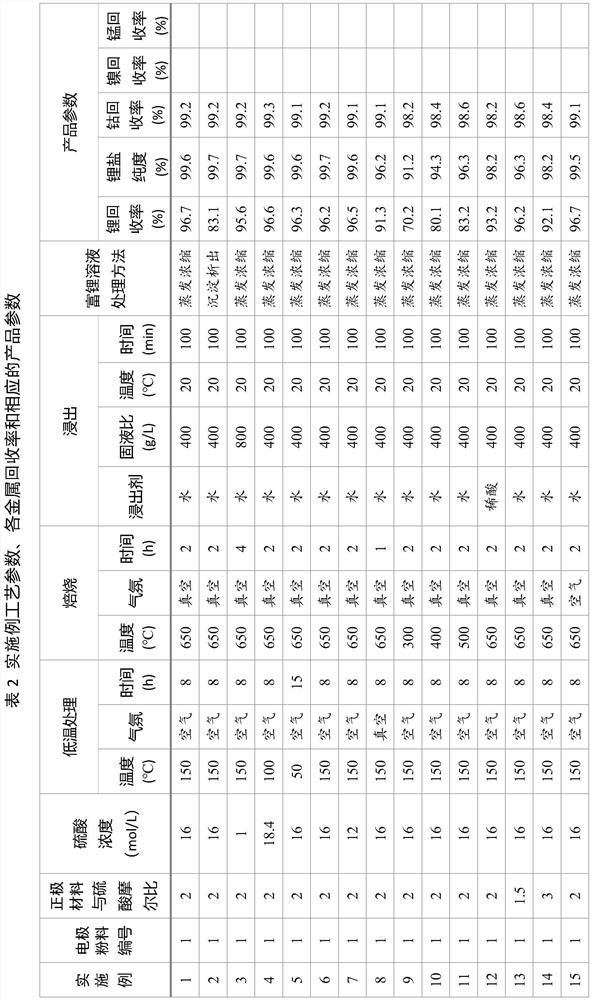

Method for selectively recovering electrode powder of lithium ion battery

InactiveCN111924892AImplement selective extractionEasy to separateWaste accumulators reclaimingCobalt oxides/hydroxidesLithium-ion batteryBattery cell

The invention provides a method for selectively recovering electrode powder of a lithium ion battery. The method comprises the following steps: mixing the electrode powder of the lithium ion battery with sulfuric acid according to a molar ratio of a positive electrode material to sulfuric acid of (1.5-3): 1, and carrying out a heating reaction to obtain an intermediate mixture; roasting the mixture at 300-650 DEG C to obtain a product; and leaching the product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and solid slag.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

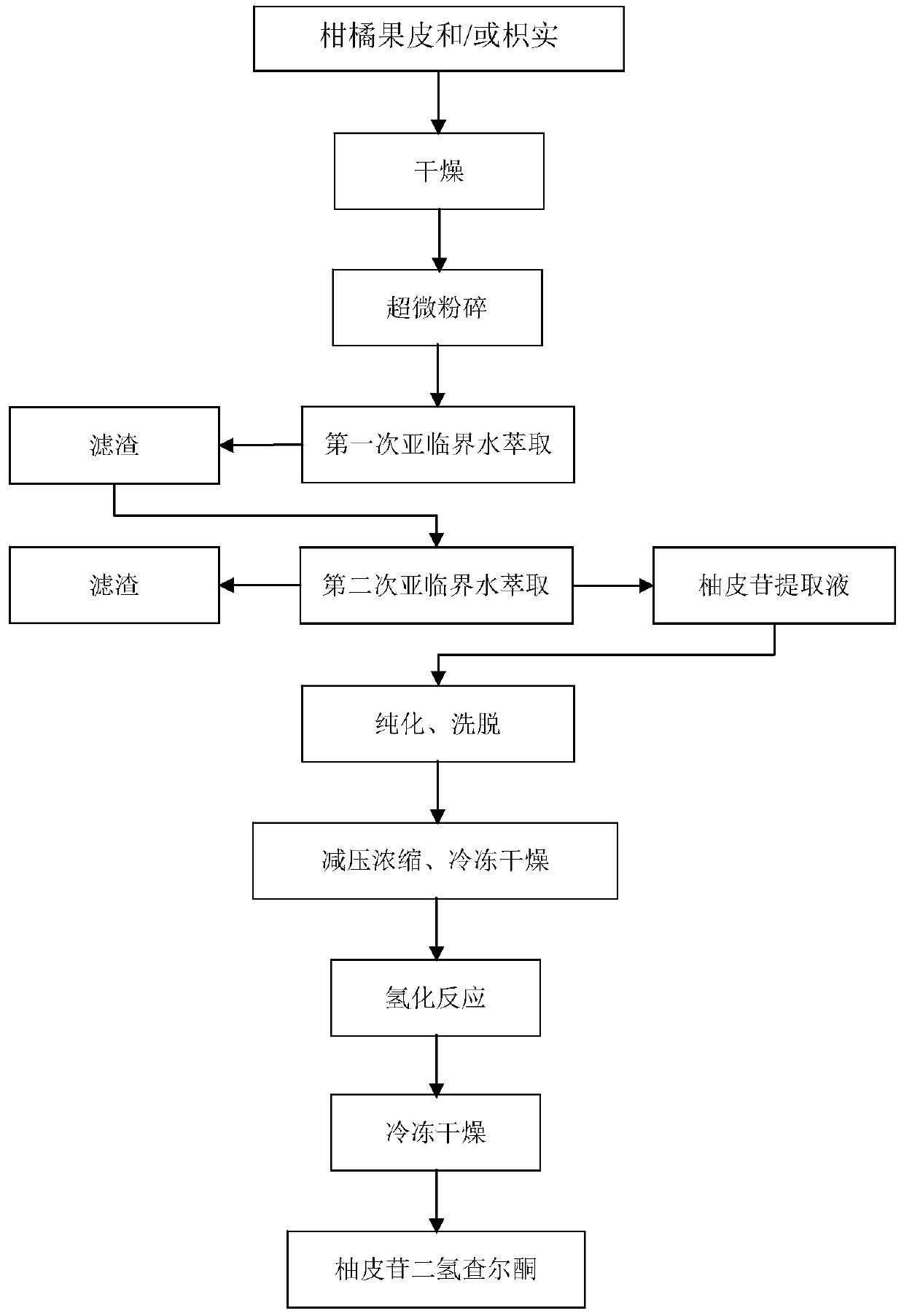

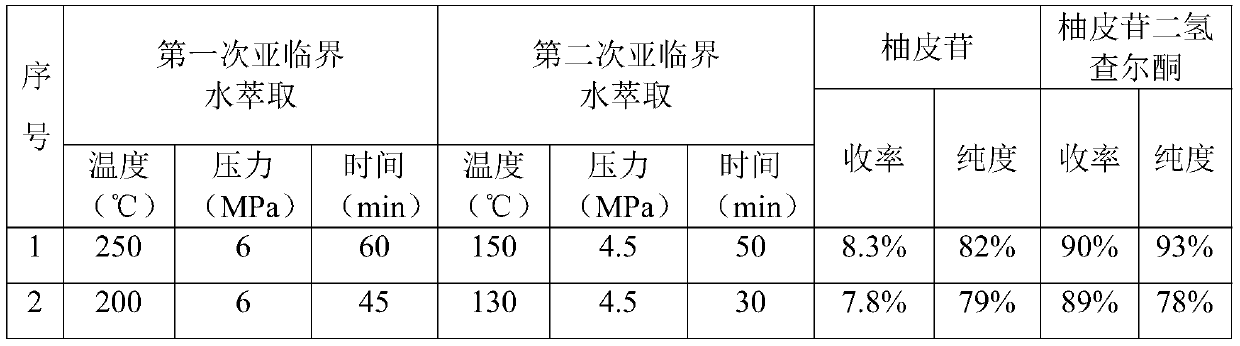

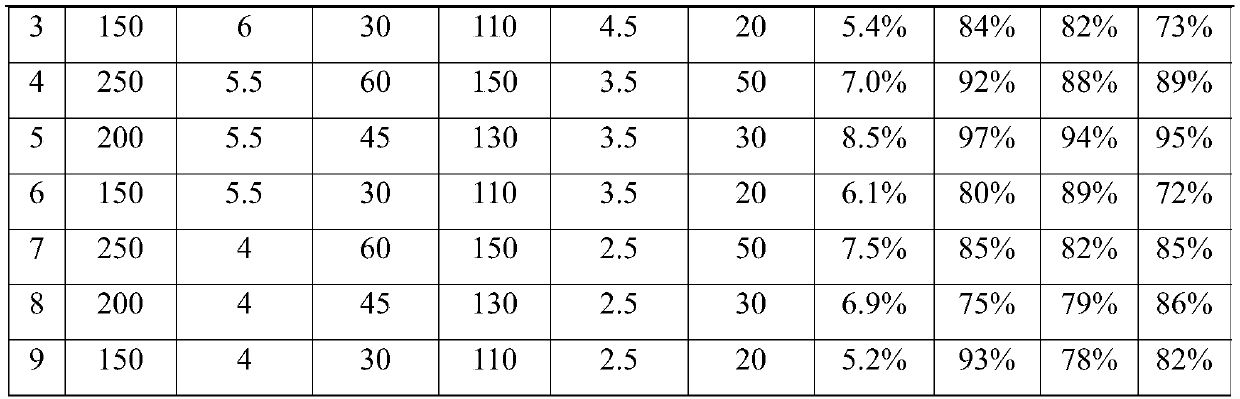

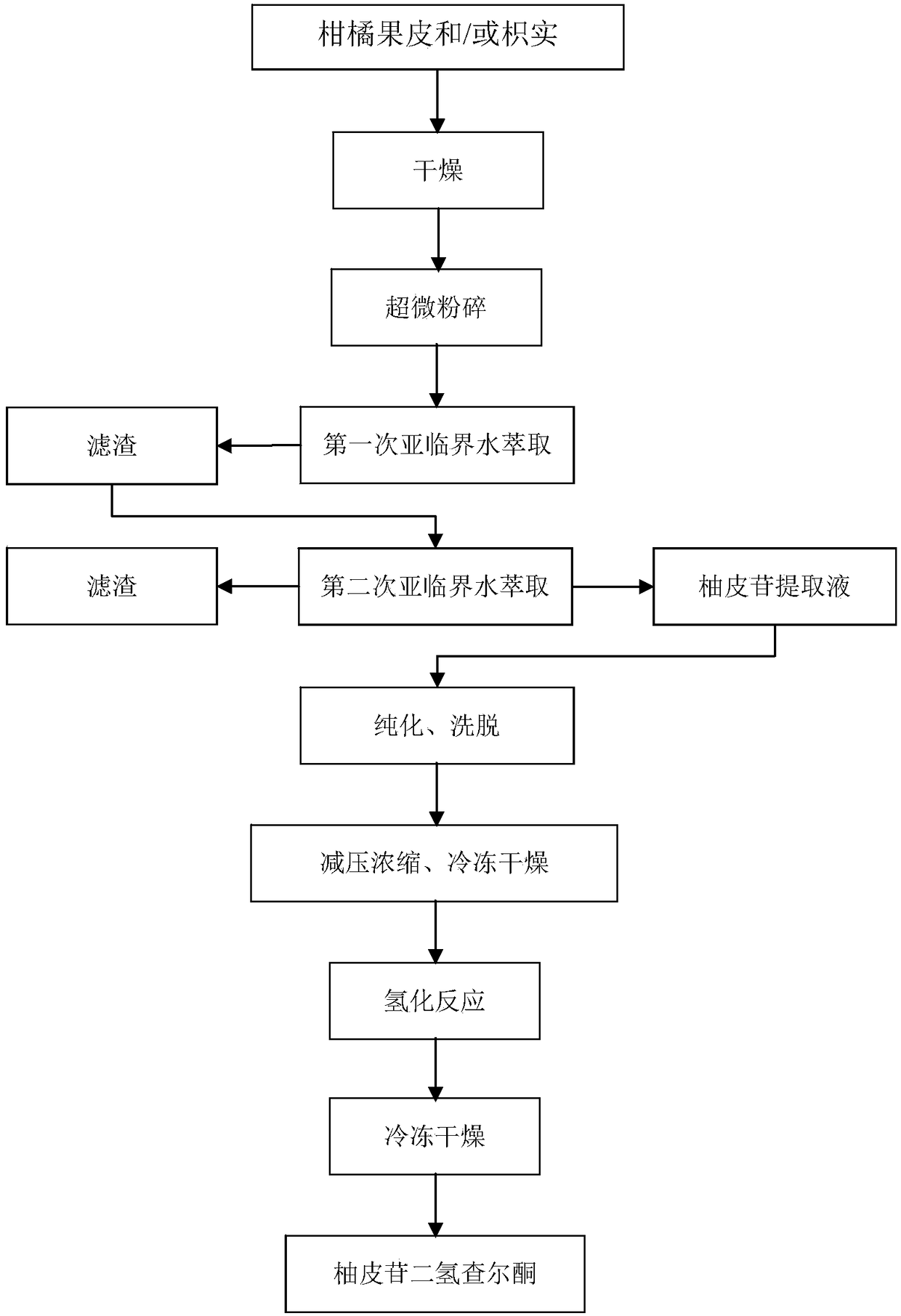

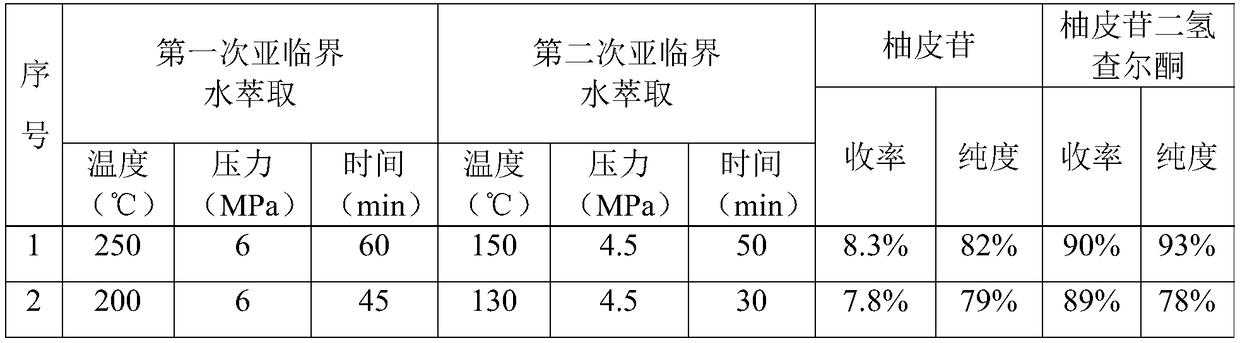

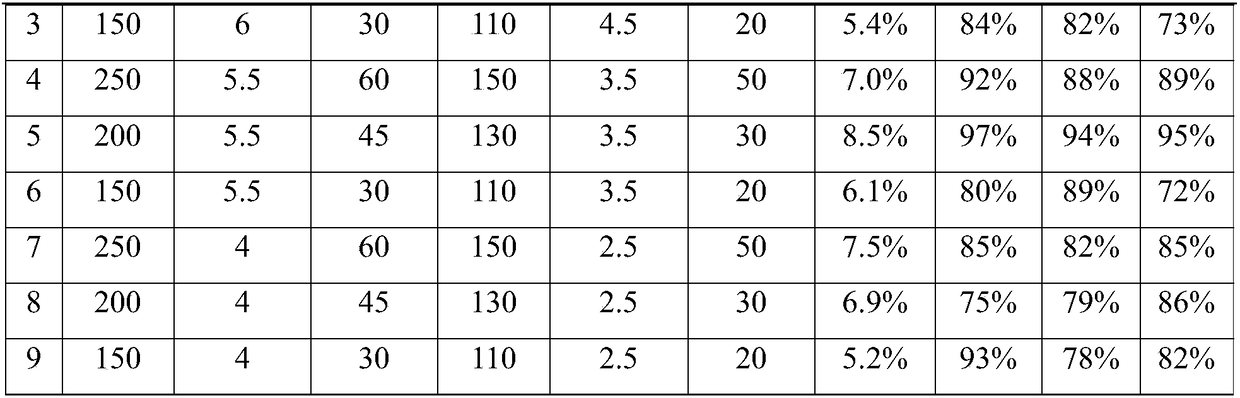

The preparation method of naringin dihydrochalcone

ActiveCN108752400BHigh yieldHigh puritySugar derivativesSugar derivatives preparationNaringinFreeze-drying

The invention discloses a preparation method of naringin dihydrochlcone. The preparation method of the naringin dihydrochlcone comprises the following steps: drying and superfinely grinding a citrus peel and / or fructus aurantii immaturus; conducting subcritical water extraction on a citrus peel powder; purifying and eluting a naringin extracting solution; concentrating a naringin eluant at the reduced pressure, freeze-drying; conducting hydrogenation on the naringin; regulating the pH value of a hydrogenation solution, allowing standing still, filtering, and freeze-drying, thereby obtaining the naringin dihydrochlcone. The preparation method has the advantages of being simple in process, convenient to operate, low in cost, green, and high in yield and purity, the comprehensive utilizationvalue of the citrus and fructus aurantii immaturus is improved, and the preparation method has an excellent application prospect and an excellent economic benefit; in addition, no organic solvent is used in the preparation process, no secondary pollution is caused to the environment, and the preparation method is a promising environmentally friendly preparation method, is suitable for large-scalepreparation, and can be industrially used conveniently.

Owner:HUNAN AGRI PRODS PROCESSING INST

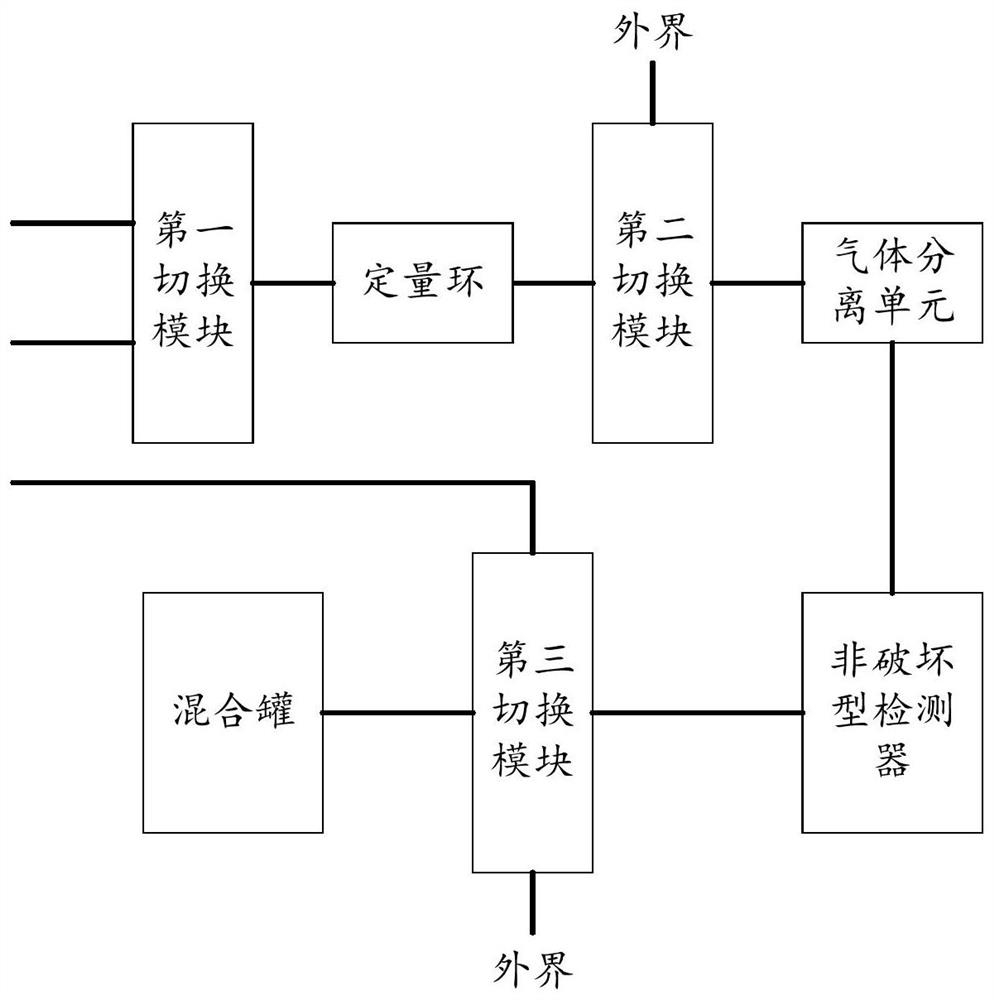

Gas dilution device and method based on selection technology

PendingCN112816601AMeet dilution needsReduce volumeComponent separationControl engineeringGas passing

The invention provides a gas dilution device and method based on a selection technology. The gas dilution device based on the selection technology comprises a mixing tank, a quantitative ring and a gas separation unit, wherein the first switching module is used for enabling the input end of the quantitative ring to selectively communicate with first gas and second gas; the second switching module is used for enabling the output end of the quantitative ring to selectively communicate with the gas separation unit or the outside; the input end of a non-destructive detector is connected with the gas separation unit, and the output end of the non-destructive detector is connected with a third switching module; the third switching module is used for enabling the outlet of the non-destructive detector to be selectively connected with the mixing tank and the outside; third gas enters the mixing tank through a gas pipeline; and a metering module is used for metering the third gas. The gas dilution device meets the requirement of trace gas dilution.

Owner:HANGZHOU PUYU TECH DEV CO LTD

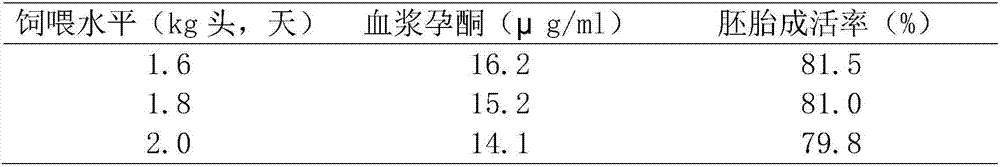

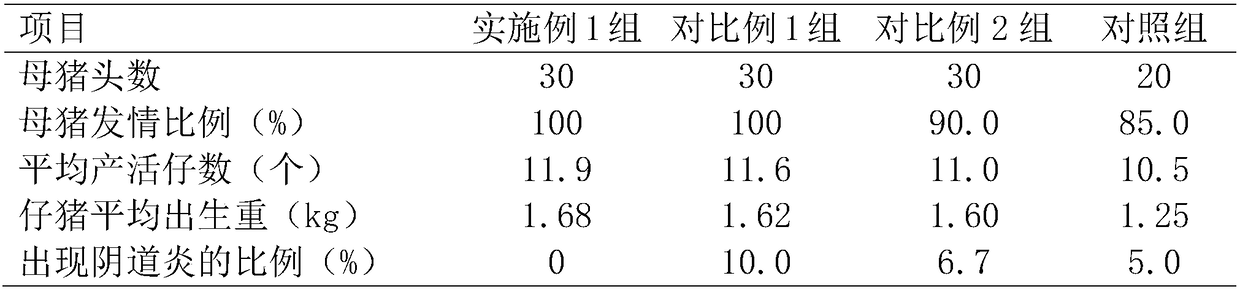

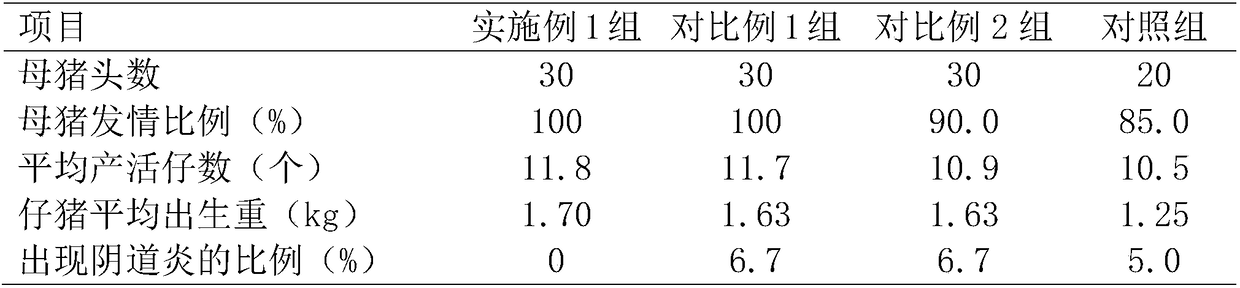

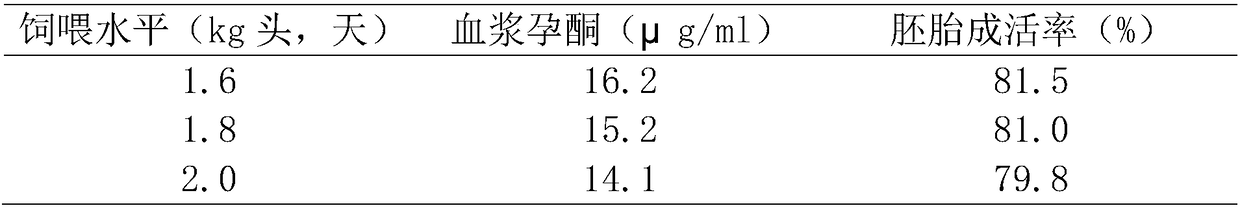

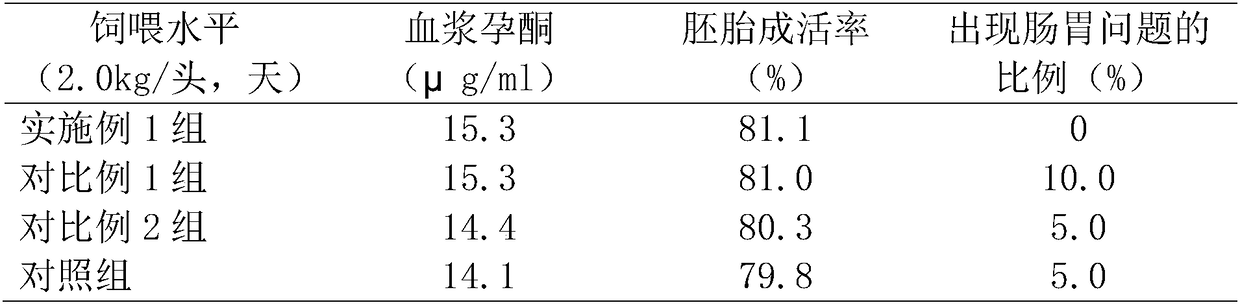

Feed additive for sows at early pregnancy period

InactiveCN107996840AImprove the level ofImprove survival rateFood processingAnimal feeding stuffPregnancyFeed additive

The invention discloses a feed additive for sows at an early pregnancy period. The feed additive is prepared by the preparation method comprising the following steps of (1) treating raw materials: removing fine hair on the surfaces of fresh immature fructus momordicae and falling fructus momordicae, then adding fresh fructus momordicae stems and leaves, of which the weight is one fifth to one fourth of that of the fructus momordicae without the fine hair to obtain materials; (2) performing subcritical water extraction: breaking the materials obtained in step (1), adding deionized water of which the weight is the same as that of the materials, performing subcritical water extraction, wherein the extraction temperature is 120-160 DEG C, the pressure is 5-8MPa, and the extraction time is 10-15min, ending the extraction, performing pressure relief, and collecting extract liquid; and (3) performing concentration: concentrating the extraction liquid obtained in the step (2) to thick paste ofwhich the relative density is 1.10-1.15 at 70 DEG C, so that the feed additive is obtained.

Owner:灵川县亿旺养殖专业合作社

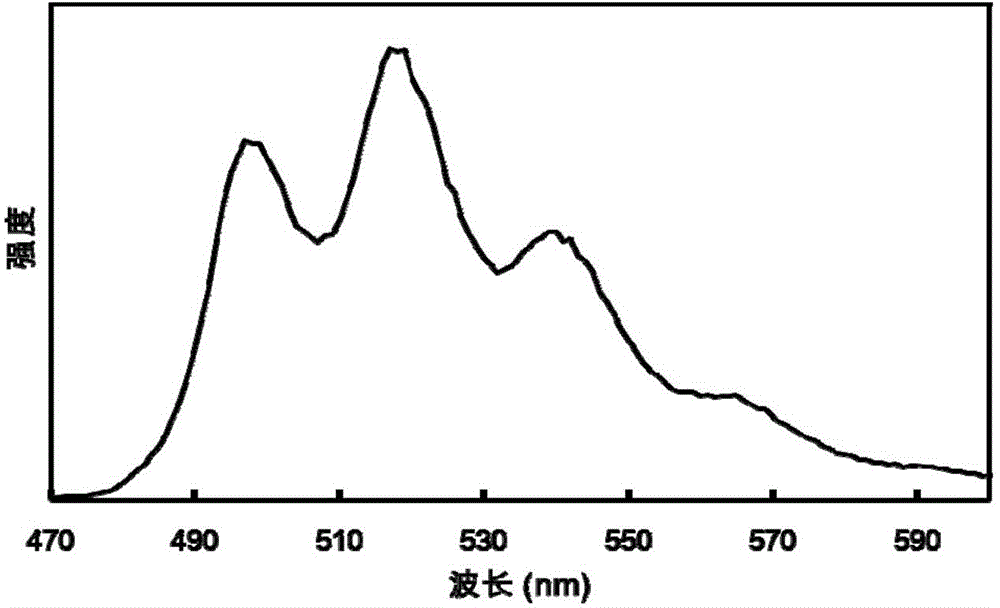

A "self-driven" electrochemical lithium extraction method based on a "rocking chair" electrode system

ActiveCN110777390BImplement selective extractionRealize delithiation/lithium intercalationElectrolysis componentsChemical physicsPotential difference

The invention belongs to the technical field of electrochemical lithium extraction, and specifically relates to an electrochemical lithium extraction method based on a "rocking chair" structure electrode system to realize high selectivity and low energy consumption extraction of dissolved rare lithium resources. The "self-driven" electrochemical lithium extraction method based on the "rocking chair" structure electrode system described in the present invention is based on the existing electrochemical lithium extraction method based on the "rocking chair" structure electrode system. The "drive" process is used in the electrochemical lithium extraction method, using the self-potential difference between electrodes in different states in the "rocking chair" structure electrode system to carry out self-driving (even energy recovery) process to extract lithium, so that the two electrodes first use the smaller potential difference between themselves Lithium extraction is carried out, and then further lithium is extracted by applying an external electric field, which effectively reduces the energy consumption of the lithium extraction process, and realizes the synchronous improvement of the electrode-to-lithium exchange capacity and selectivity coefficient, which has significant technical advantages.

Owner:HEBEI UNIV OF TECH

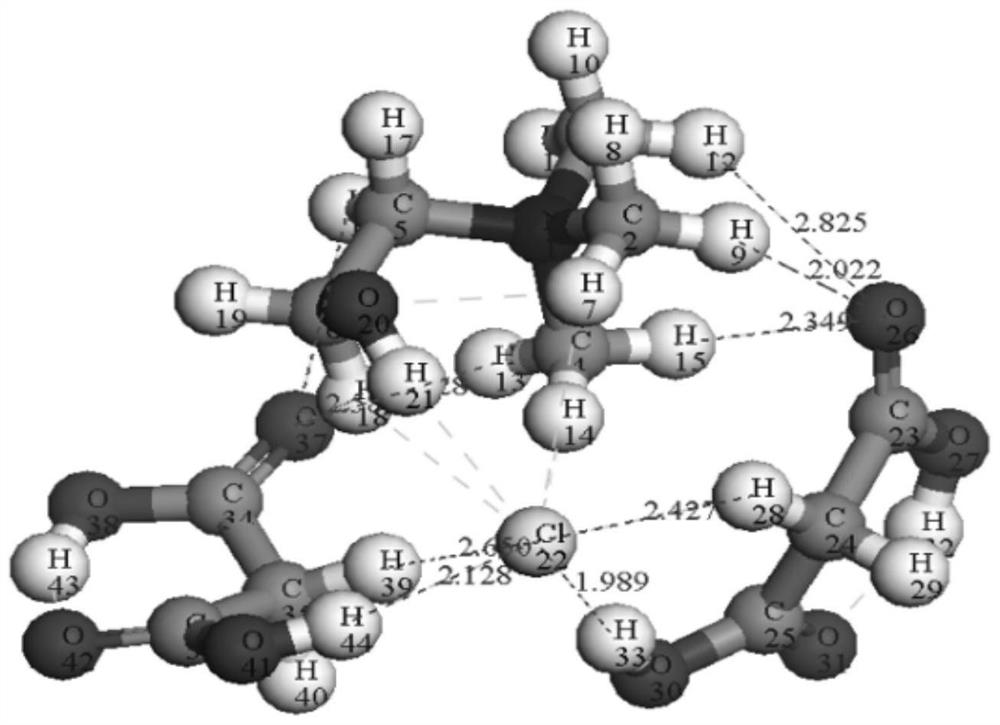

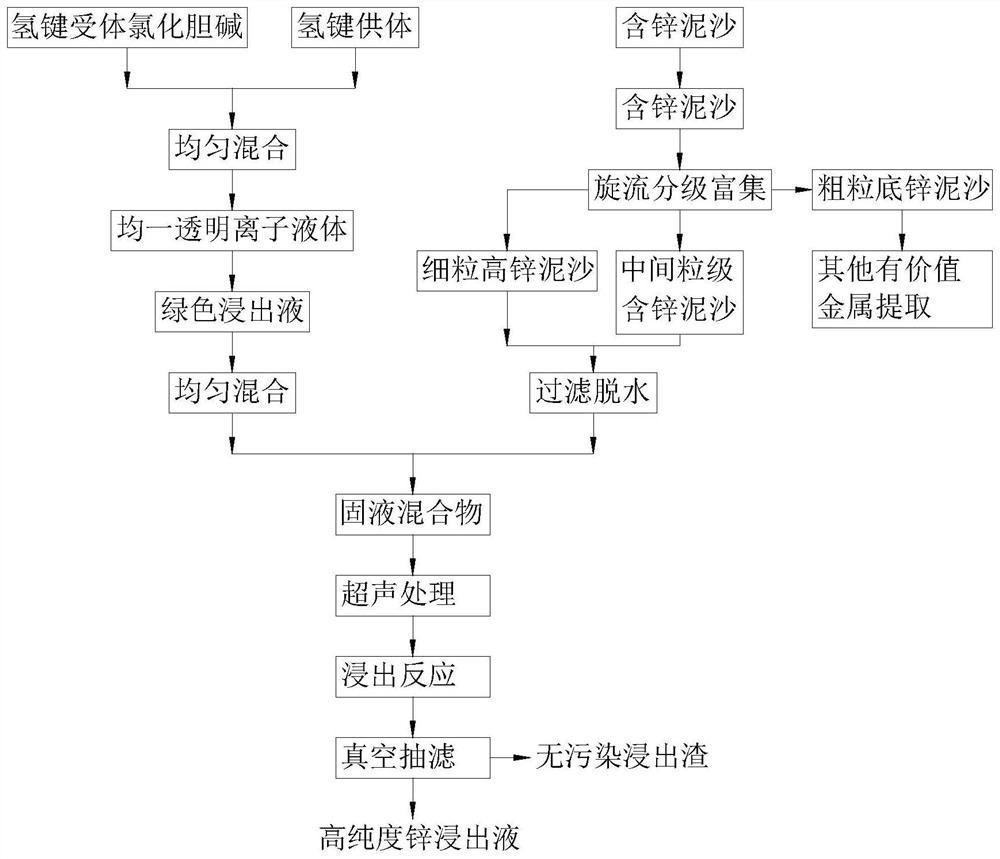

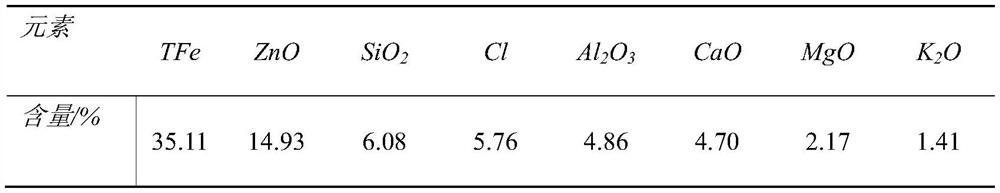

Rotational flow grading-ionic liquid-ultrasonic synergistic selective zinc immersion method

ActiveCN114317984AHigh purityReduce manufacturing costProcess efficiency improvementPregnant leach solutionSludge

The invention discloses a method for selective zinc immersion through cyclone classification-ionic liquid-ultrasonic cooperation, and belongs to the technical field of hydrometallurgy. The method comprises the steps of graded enrichment of zinc-containing dust mud, synthesis of ionic liquid and selective leaching of zinc. According to the method, the special-shaped hydrocyclone is used for pretreating the zinc-containing dust sludge to obtain fine-grain zinc-rich dust sludge, so that efficient leaching of zinc is facilitated, and meanwhile, opening and dispersing of floccules in the zinc-containing dust sludge are facilitated; the ionic liquid and ultrasonic synergistic leaching system has selective dissolving capacity on ZnO, the obtained zinc-containing leaching solution is high in purity, and the problems that components are complex, separation is difficult and the like in a traditional leaching system are solved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Electrochlorination extraction method of gold in gold-containing materials

ActiveCN112144077BImplement selective extractionImplement extractionPhotography auxillary processesElectrolysis componentsElectrochemical responseElectrolytic agent

An electrochlorination extraction method of gold in a gold-containing material, including anodic dissolution and cathodic deposition, which are completed in the same reactor. The gold-containing material is put into the electrochemical reactor containing the sodium chloride concentration of 0.1~3 mol / L electrolyte in the form of flakes, powders or granules, and the control reaction temperature is 25~99 ° C, and the current density is 0.01~3 A / cm 2 , the reaction time is 1-6 h; after the electrolysis is completed, the deposits in the cathode chamber and the cathode plate are collected, washed and dried to obtain gold powder. The invention has the remarkable advantages of high gold extraction efficiency, less chemical reagent consumption, clean process, simple operation, short flow and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of codonopsis pilosula sections

InactiveCN110812380AEasy to keepHigh extraction ratePill deliveryPharmaceutical non-active ingredientsGlycosideMedicinal herbs

The invention discloses a preparation method of codonopsis pilosula sections, which comprises the following steps: cleaning fresh codonopsis pilosula medicinal materials to remove impurities, cleaning, cutting the fresh codonopsis pilosula into sections, cleaning again, drying in a drying oven until the water content is lower than 10%, pulverizing the dried codonopsis pilosula, and drying again until the water content is lower than 5%, and obtaining codonopsis pilosula powder; and then performing supercritical extraction treatment on the codonopsis pilosula powder. A supercritical extraction technology is adopted for extracting the active ingredients of codonopsis pilosula, the extraction rate is remarkably superior to that of a traditional extraction technology, and the supercritical extraction technology has the advantages that extraction and separation can be completed at a time, the extraction efficiency is high, the active ingredients are well reserved, and no solvent is left. According to the supercritical extraction process disclosed by the invention, the components of an entrainer are optimized, so that the extraction rates of saccharides and glycosides are stable, and meanwhile, the extraction of alkaloid can be reduced.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

Aphrodisiacs used for sows at copulation period

InactiveCN108079044AIncrease estrus rateImprove efficiencySexual disorderAnimal husbandryMomordicaFiltration

The invention discloses aphrodisiacs used for sows at a copulation period. The aphrodisiacs is prepared by the following preparation method: 1) raw material treatment: removing villus on the surface of grosvenor momordica fruit for fresh and unripe grosvenor momordica fruit and dropped grosvenor momordica fruit; 2) subcritical water extraction: crushing the raw materials obtained in the last step,adding deionized water which is as heavy as the raw materials, performing subcritical water extraction at an extraction temperature of 120-150 DEG C for 10-15 minutes under a pressure of 5-8 MPa, releasing pressure after extraction is ended, and collecting an extracting solution; and 3) filtration: performing 0.45 mu m filtration on the extracting solution obtained in the last step, and performing sealing and storing, thereby obtaining the aphrodisiacs.

Owner:灵川县亿旺养殖专业合作社

A method for efficiently extracting uranyl ions in water

ActiveCN104485148BSimple methodEasy to operateRadioactive decontaminationEnvironmental resistanceWastewater

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Electrochlorination extraction method for gold in gold-containing materials

ActiveCN112144077AImplement selective extractionImplement extractionPhotography auxillary processesElectrolysis componentsElectrochemical responseElectrolytic agent

The invention discloses an electrochlorination extraction method for gold in gold-containing materials. The electrochlorination extraction method comprises an anode dissolution process and a cathode deposition process which are completed in a same reactor. The electrochlorination extraction method comprises the following steps of putting the gold-containing materials into an electrochemical reactor filled with an electrolyte with sodium chloride concentration of 0.1-3mol / L in a sheet, powder or particle form, and controlling the reaction temperature to be 25-99 DEG C, the current density to be0.01-3A / cm2, and the reaction time to be 1-6 hours; and after electrolysis is completed, collecting sediments of a cathode chamber and a cathode plate, washing and drying the sediments, and obtaininggold powder. The method has the remarkable advantages of being high in gold extraction efficiency, low in chemical reagent consumption, clean in process, simple and convenient in operation, short inflow and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for extracting and separating lithium isotope aqueous solution

ActiveCN102430338BImplement selective extractionEfficient enrichmentIsotope separationAlkalinityLithium hydroxide

The invention relates to a method for extracting and separating a lithium isotope aqueous solution and belongs to the technical field of solvent extraction. In the method, hydrophobic naphthisoazine and hydrophilic ionic liquid respectively serve as an extracting agent and a synergist; and naphthisoazine, the ionic liquid and lithium ions form a stable ion associated matter under an alkaline condition, lithium ions enter into an organic phase through aqueous phase extraction and an obvious isotope separation effect is generated. The method comprises the following steps of: regulating the alkalinity of a lithium hydroxide solution, respectively adding the extracting agent, the synergist and the hydrophilic ionic liquid serving as an extracting medium, oscillating at normal pressure and normal temperature, standing still for layering, collecting the organic phase, and adding sodium sulfate into the organic phase to carry out lithium salt back extraction so that the lithium ions come back to the aqueous phase, thereby realizing the selective extraction and high-efficiency enrichment of lithium isotopes.

Owner:盐城科之园工业发展有限公司

Aphrodisiac for sows in breeding period

InactiveCN108310036AIncrease estrus rateImprove efficiencyPharmaceutical delivery mechanismSexual disorderFiltrationAphrodisiac

The invention discloses an aphrodisiac for sows in a breeding period. The aphrodisiac is obtained by a preparation method comprises the following steps: 1) raw material processing: taking fresh immature and fallen siraitia grosvenorii fruits, removing villi on surfaces of the siraitia grosvenorii fruits, adding 1 / 5-1 / 4 by weight of fresh siraitia grosvenorii stems and leaves; 2) subcritical waterextraction: crushing the raw materials obtained in the step 1, adding equivalent deionized water, extracting subcritical water at 120-150 DEG C under a pressure of 5-8 MPa for 10-15 min, finishing extraction, relieving pressure, and collecting extract; 3) filtration: filtering the extract obtained in the step 2 through 0.45 [mu]m, sealing and storing to obtain the aphrodisiac.

Owner:灵川县亿旺养殖专业合作社

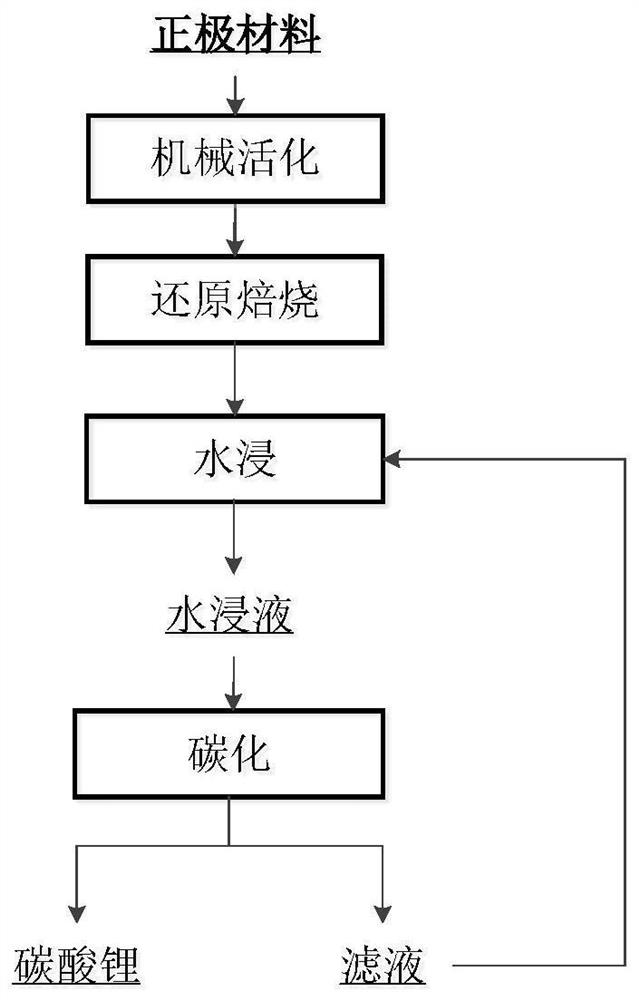

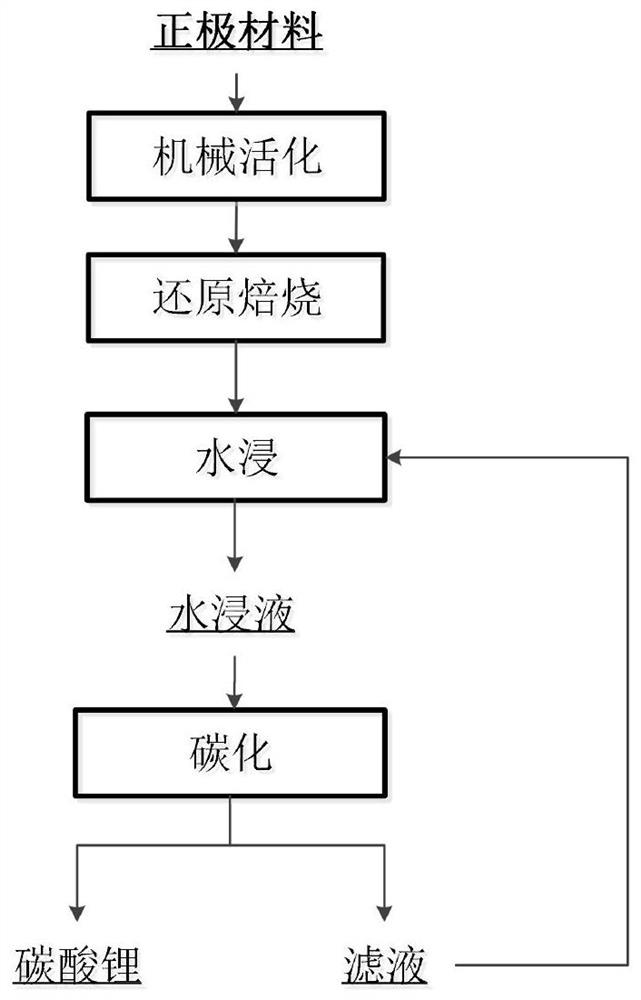

Recycling method of positive electrode material of waste lithium cobalt oxide battery

PendingCN112981110AImprove conversion and recoveryReduce energy consumptionWaste accumulators reclaimingProcess efficiency improvementWater immersionElectrode material

The invention provides a method for recycling a positive electrode material of a waste lithium cobalt oxide battery. The method comprises the following steps of adding a salt assistant and a reducing agent into the positive electrode material of the lithium cobalt oxide battery, roasting the obtained mixture in a reducing atmosphere, carrying out water leaching treatment on the roasted product, and carrying out solid-liquid separation to obtain a lithium-rich solution. According to the method, lithium in the positive electrode material of the lithium cobalt oxide battery can be efficiently transformed into water-soluble lithium salt at a relatively low temperature, effective separation of lithium from other components can be realized through water immersion treatment, and the method simplifies the production process, reduces the energy consumption and has potential industrial application value.

Owner:中节能工程技术研究院有限公司

Preparation method of naringin dihydrochlcone

ActiveCN108752400AHigh yieldHigh puritySugar derivativesSugar derivatives preparationNaringinOrganic solvent

The invention discloses a preparation method of naringin dihydrochlcone. The preparation method of the naringin dihydrochlcone comprises the following steps: drying and superfinely grinding a citrus peel and / or fructus aurantii immaturus; conducting subcritical water extraction on a citrus peel powder; purifying and eluting a naringin extracting solution; concentrating a naringin eluant at the reduced pressure, freeze-drying; conducting hydrogenation on the naringin; regulating the pH value of a hydrogenation solution, allowing standing still, filtering, and freeze-drying, thereby obtaining the naringin dihydrochlcone. The preparation method has the advantages of being simple in process, convenient to operate, low in cost, green, and high in yield and purity, the comprehensive utilizationvalue of the citrus and fructus aurantii immaturus is improved, and the preparation method has an excellent application prospect and an excellent economic benefit; in addition, no organic solvent is used in the preparation process, no secondary pollution is caused to the environment, and the preparation method is a promising environmentally friendly preparation method, is suitable for large-scalepreparation, and can be industrially used conveniently.

Owner:HUNAN AGRI PRODS PROCESSING INST

Feed additive for sows at early pregnancy period

InactiveCN108450658AImprove survival rateUnlimited feedingAnimal feeding stuffPregnancyFeed additive

The invention discloses a feed additive for sows at an early pregnancy period. The feed additive is prepared by a preparation method comprising the following steps of (1) treating raw materials: removing fine hair on the surfaces of fresh immature fructus momordicae and falling fructus momordicae; (2) performing subcritical water extraction: smashing the raw materials obtained in the step (1), adding deionized water of which the weight is the same as that of the raw materials, performing subcritical water extraction, wherein the extraction temperature is 120-160 DEG C, the pressure is 5-8MPa,and the extraction time is 10-15min, when extraction is completed, performing pressure relief, and collecting extract liquid; and (3) performing concentration: concentrating the extract liquid obtained in the step (2) to thick paste of which the relative density is 1.10-1.15 at 70 DEG C, so that the feed additive is obtained.

Owner:灵川县亿旺养殖专业合作社

Recycling method for positive electrode material of waste lithium cobalt oxide battery

InactiveCN113106247AImprove conversion rateHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryElectrode material

The invention provides a recycling method for a positive electrode material of a waste lithium cobalt oxide battery. The method comprises the steps of adding a salt assistant and a reducing agent into the positive electrode material of the lithium cobalt oxide battery, and roasting the obtained mixture in a reducing atmosphere; and carrying out water leaching treatment on the roasted product, and carrying out solid-liquid separation to obtain a lithium-rich solution. According to the method, lithium in the positive electrode material of the lithium cobalt oxide battery can be efficiently transformed into water-soluble lithium salt at a low temperature, and effective separation of lithium and other components can be realized through water leaching treatment; and the method simplifies the production process, reduces the energy consumption and has potential industrial application value.

Owner:北京佰利格瑞资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com