Low-cost and low-acid-consumption laterite-nickel ore leaching method

A kind of laterite nickel ore, low-cost technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry and other directions, can solve the problems of harsh operating conditions, consumption of large neutralizers, restricting the development of the industry, etc. The effect of short time and acid consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

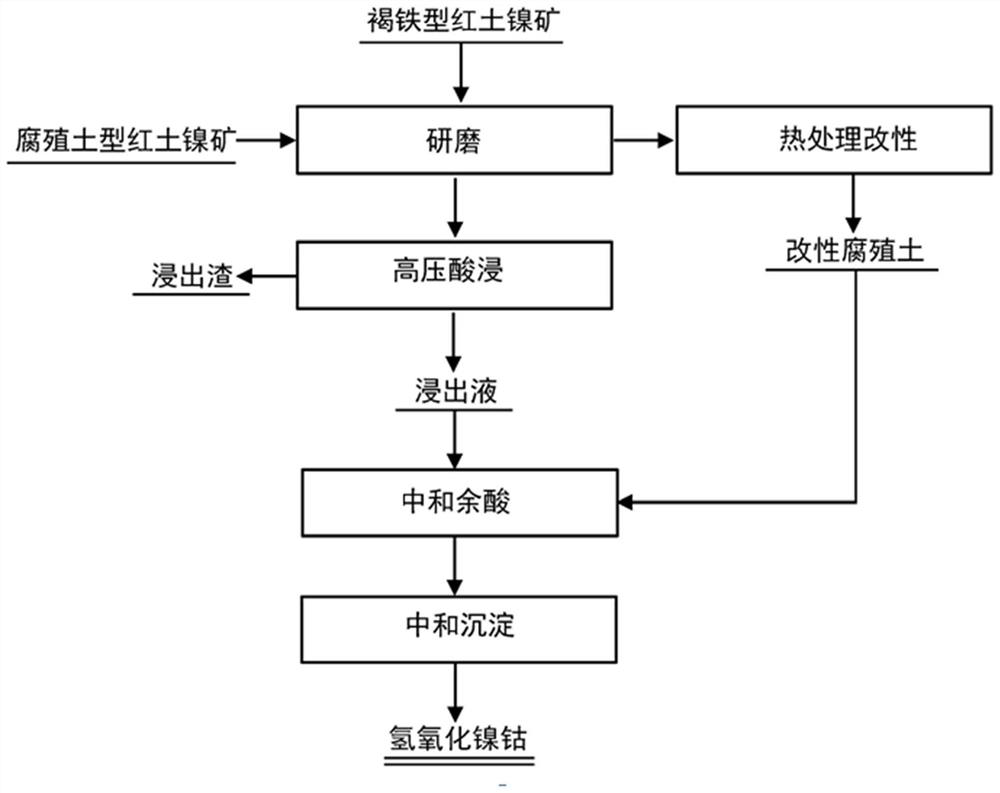

[0031] A kind of leaching method of the laterite nickel ore of low cost, low acid consumption of the present invention, technological process is as figure 1 shown, including the following steps:

[0032] (1) Grinding: the limonite-type laterite-nickel ore and the humic-type laterite-nickel ore are respectively crushed and ground to -0.15mm;

[0033] (2) High-pressure acid leaching: mix the limonite-type lateritic nickel ore, sulfuric acid solution, and water after step (1) to make a slurry. The addition amount is 350Kg / t dry ore; then it is placed in a titanium autoclave for high-pressure acid leaching, the leaching temperature is 250°C, and the leaching time is 60 minutes to obtain leaching liquid and leaching residue. During this process, Ni, Co, Mn, Sc The leaching rates of , Fe, Mg, Al and Cr are 96.91%, 95.36%, 92.87%, 93.19%, 2.07%, 77.72%, 20.79% and 7.69% respectively;

[0034] (3) Modification of humic soil-type laterite nickel ore: put the humic soil-type laterite ...

Embodiment 2

[0045] A kind of leaching method of the laterite nickel ore of low cost, low acid consumption of the present invention, technological process is as figure 1 shown, including the following steps:

[0046] (1) Grinding: the limonite-type laterite-nickel ore and the humic-type laterite-nickel ore are respectively crushed and ground to -0.15mm;

[0047] (2) High-pressure acid leaching: Mix the limonite-type lateritic nickel ore, sulfuric acid solution, and water after step (1) to make slurry. The liquid-solid ratio in the slurry mixing process is 3:1. The addition amount is 350Kg / t dry ore, and then placed in a titanium autoclave for high-pressure acid leaching, the leaching temperature is 250°C, and the leaching time is 60 minutes to obtain leaching liquid and leaching residue. During this process, Ni, Co, Mn, Sc The leaching rates of , Fe, Mg, Al and Cr are 95.45%, 93.97%, 92.16%, 91.60%, 3.51%, 79.30%, 19.67% and 8.16% respectively;

[0048] (3) Modification of humic soil-typ...

Embodiment 3

[0052] A kind of leaching method of the laterite nickel ore of low cost, low acid consumption of the present invention, technological process is as figure 1 shown, including the following steps:

[0053] (1) Grinding: the limonite-type laterite-nickel ore and the humic-type laterite-nickel ore are respectively crushed and ground to -0.15mm;

[0054] (2) High-pressure acid leaching: Mix the limonite-type lateritic nickel ore, sulfuric acid solution, and water after step (1) to make slurry. The liquid-solid ratio in the slurry mixing process is 10:1. The addition amount is 350Kg / t dry ore, and then placed in a titanium autoclave for high-pressure acid leaching, the leaching temperature is 250°C, and the leaching time is 60 minutes to obtain leaching liquid and leaching residue. During this process, Ni, Co, Mn, Sc The leaching rates of , Fe, Mg, Al and Cr are 97.34%, 96.18%, 94.08%, 94.46%, 1.79%, 80.16%, 19.43% and 7.25% respectively;

[0055] (3) Modification of humic soil-ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com