A "self-driven" electrochemical lithium extraction method based on a "rocking chair" electrode system

A self-driven, electrochemical technology, applied in the field of electrochemical lithium extraction, can solve the problem of high energy consumption, reduce energy consumption, reduce energy waste, and achieve the effect of lithium selectivity coefficient and exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

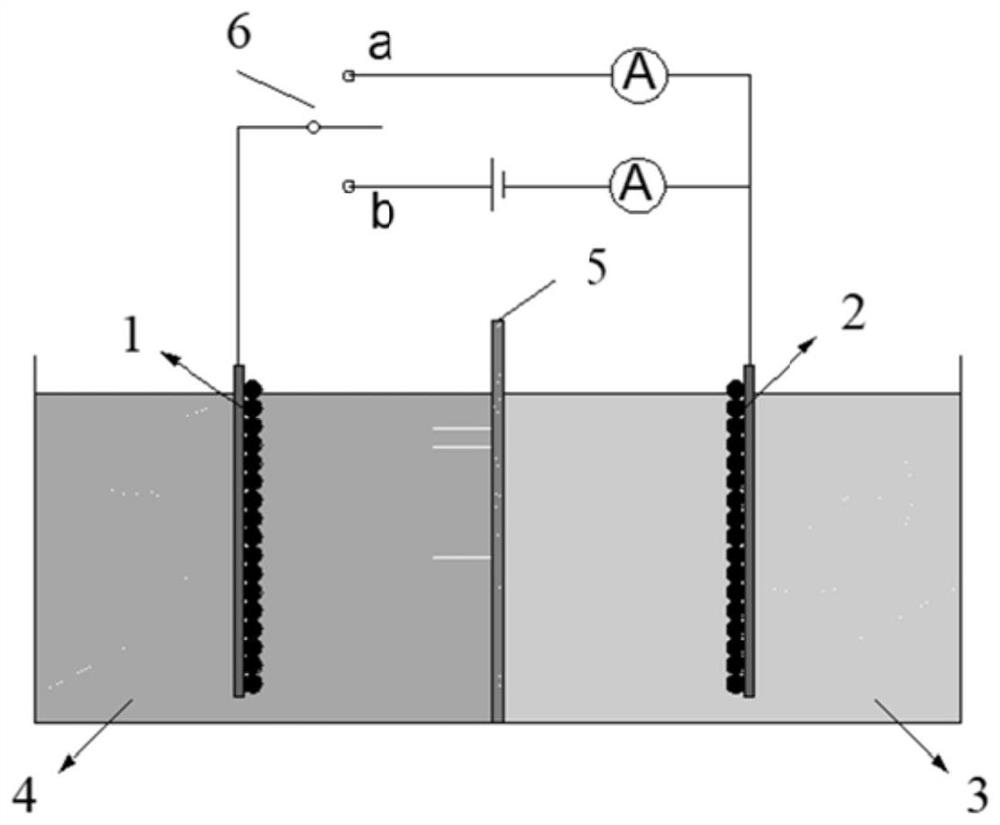

[0037] A "self-driven" electrochemical lithium extraction method based on a "rocking chair" structure electrode system according to the present invention comprises the following steps:

[0038] (1) Construction of "rocking chair" structure electrode system

[0039] Self-made LiMn by high temperature solid phase method 2 o 4 Powder, with the obtained LiMn 2 o 4 Mix with carbon black and LA132 binder at a mass ratio of 8:1:1, add 50% ethanol solvent to stir thoroughly, and disperse ultrasonically for 3 minutes to obtain a uniformly dispersed slurry, and evenly coat the obtained slurry on 3.5* On a 5cm carbon fiber cloth, the coating thickness is about 5-6mg / cm 2 , and dried at 70°C for 12 hours to obtain a lithium-rich electrode;

[0040] The resulting lithium-rich LiMn 2 o 4 The electrode is connected to the positive electrode, and the AgCl electrode is connected to the negative electrode, and placed in a 0.05mol / L KCl solution for a constant voltage 1.2V reaction. When ...

Embodiment 2

[0054] A "self-driven" electrochemical lithium extraction method based on a "rocking chair" structure electrode system according to the present invention comprises the following steps:

[0055] (1) Construction of "rocking chair" structure electrode system

[0056] Self-made LiMn by high temperature solid phase method 2 o 4 Powder, with the obtained LiMn 2 o 4 Mix with carbon black and LA132 binder at a mass ratio of 8:1:1, add 50% ethanol solvent to stir thoroughly, and disperse ultrasonically for 3 minutes to obtain a uniformly dispersed slurry, and coat the resulting slurry on a surface of 3.5*5cm On the carbon fiber cloth, the coating thickness is about 5-6mg / cm 2 , dried at 70°C for 12 hours to obtain a lithium-rich electrode;

[0057] The resulting lithium-rich LiMn 2 o 4 The electrode is connected to the positive electrode, and the AgCl electrode is connected to the negative electrode, and placed in a 0.05mol / L KCl solution for constant voltage 0.8V reaction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com