Recycling method for positive electrode material of waste lithium cobalt oxide battery

A battery cathode and recycling method technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of evaporative crystallization, complex process, unreasonable reaction engineering, etc., to improve the conversion rate and recovery rate , the overall cost reduction, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

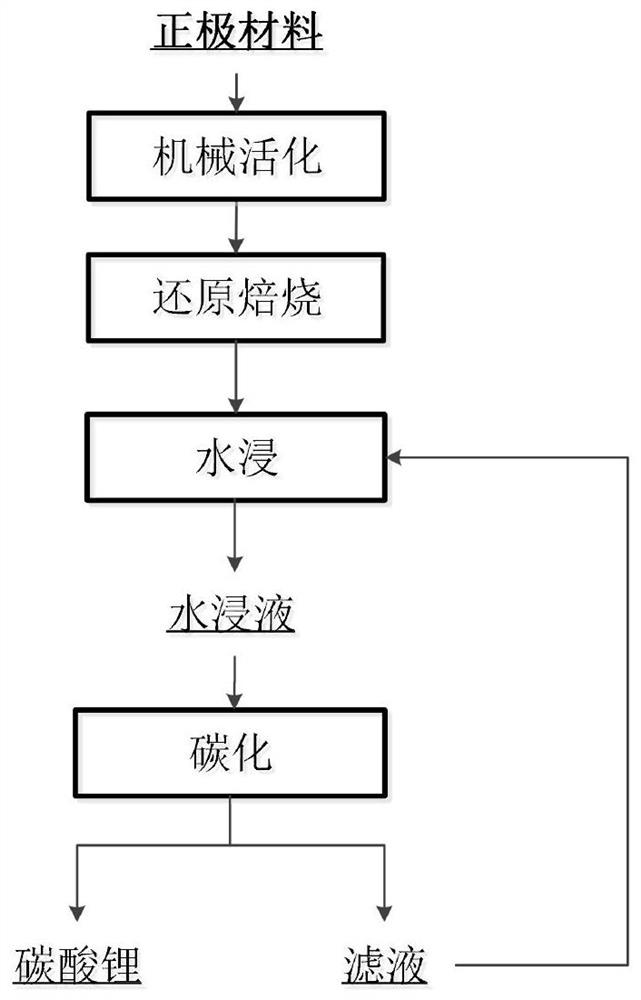

[0037] Take 100g of the positive and negative electrode mixture of lithium cobalt oxide battery (the negative electrode material accounts for 35%), add 42g of ammonium chloride, mechanically activate for 20min, reduce and roast at 500°C, control the CO atmosphere, and react for 3h;

[0038] Add 800ml of water to the roasted product, soak lithium at room temperature for 1.5h, the leaching rate of lithium is 98.46%, and other metals are not dissolved, filter to obtain a lithium-rich solution, the recovery rate of lithium is 96.2%;

[0039] Inject CO into the Li-rich solution 2 , CO 2 The feed rate was 1.5 L / min, reacted at 60°C for 2 hours, and filtered to obtain lithium carbonate with a purity of 99.32% and a lithium precipitation rate of 95.8%.

Embodiment 2

[0041] Take 100g of the positive and negative electrode mixture of lithium cobaltate battery (the negative electrode material accounts for 38%), add 20g of ammonium sulfate, mechanically activate for 10min, reduce and roast at 580°C, control the CO atmosphere, and react for 1.5h;

[0042] Add 600ml of water to the roasted product, soak lithium at room temperature for 2 hours, the leaching rate of lithium is 98.76%, and other metals are not dissolved, filter to obtain a lithium-rich solution, the recovery rate of lithium is 97.8%;

[0043] Inject CO into the Li-rich solution 2 , CO 2 The feed rate was 1 L / min, reacted at 40°C for 2 hours, and filtered to obtain lithium carbonate with a purity of 99.65% and a lithium precipitation rate of 96.4%.

Embodiment 3

[0045]Take 100g of the positive and negative electrode mixture of lithium cobalt oxide battery (the negative electrode material accounts for 45%), add 30g of sodium phosphate, mechanically activate for 15min, reduce and roast at 600°C, control the CO atmosphere, and react for 1h;

[0046] Add 1000ml of water to the roasted product, soak lithium at room temperature for 2 hours, the leaching rate of lithium is 98.34%, and other metals are not dissolved, filter to obtain a lithium-rich solution, the recovery rate of lithium is 95.8%;

[0047] Inject CO into the Li-rich solution 2 , CO 2 The feed rate was 1.5 L / min, reacted at 50°C for 1.5 h, and filtered to obtain lithium carbonate with a purity of 99.27% and a lithium precipitation rate of 95.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com