Preparation method of codonopsis pilosula sections

A technology of Codonopsis pilosula and wet material, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. The effect of reducing, stable extraction rate and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] One embodiment of the present invention discloses a preparation method of Codonopsis Radix, comprising the following steps:

[0037] (1) Clean the fresh Codonopsis pilosula to remove impurities, then clean it, then cut the fresh Codonopsis pilosula into segments, wash it again and put it in an oven to dry until the water content is lower than 10%, then crush the dried Codonopsis pilosula again Dry until the moisture content is lower than 5%; obtain Codonopsis powder;

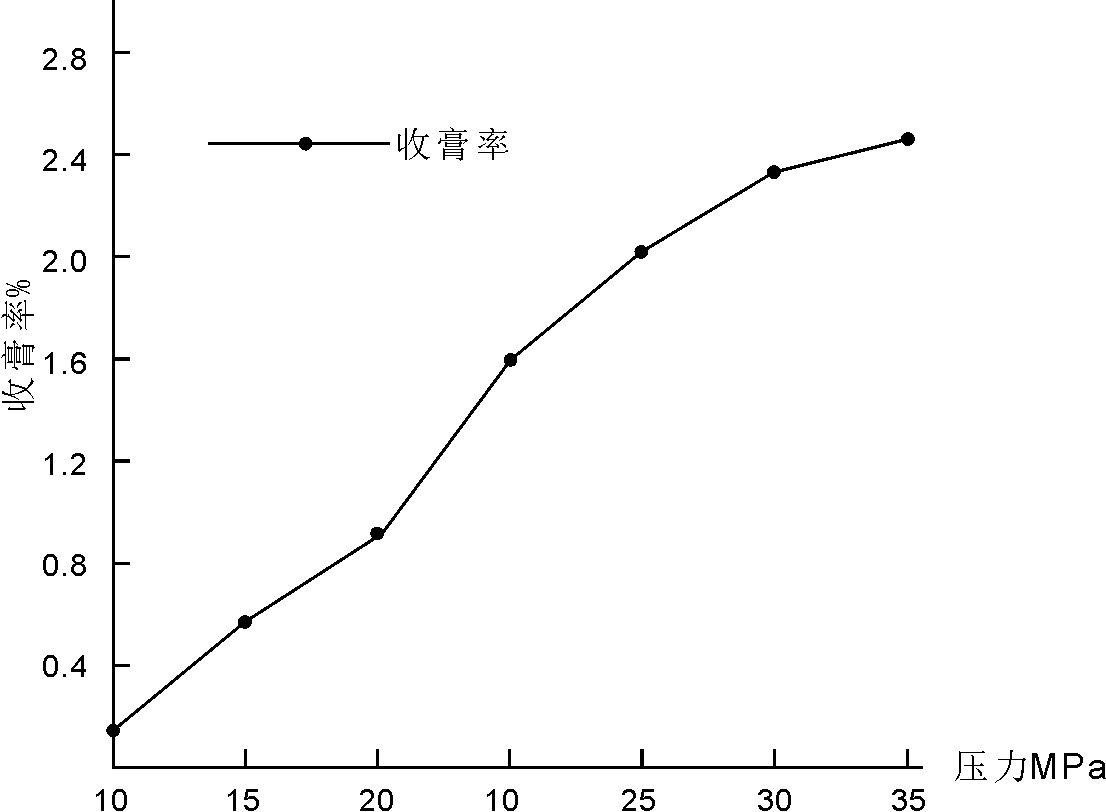

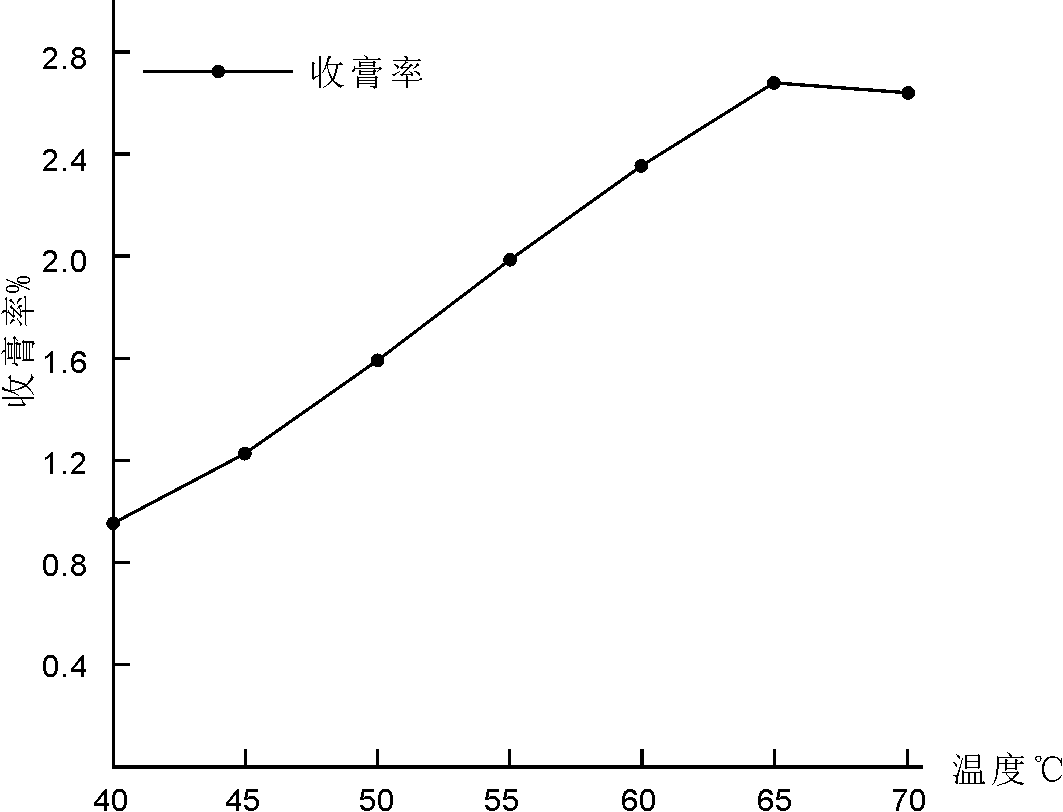

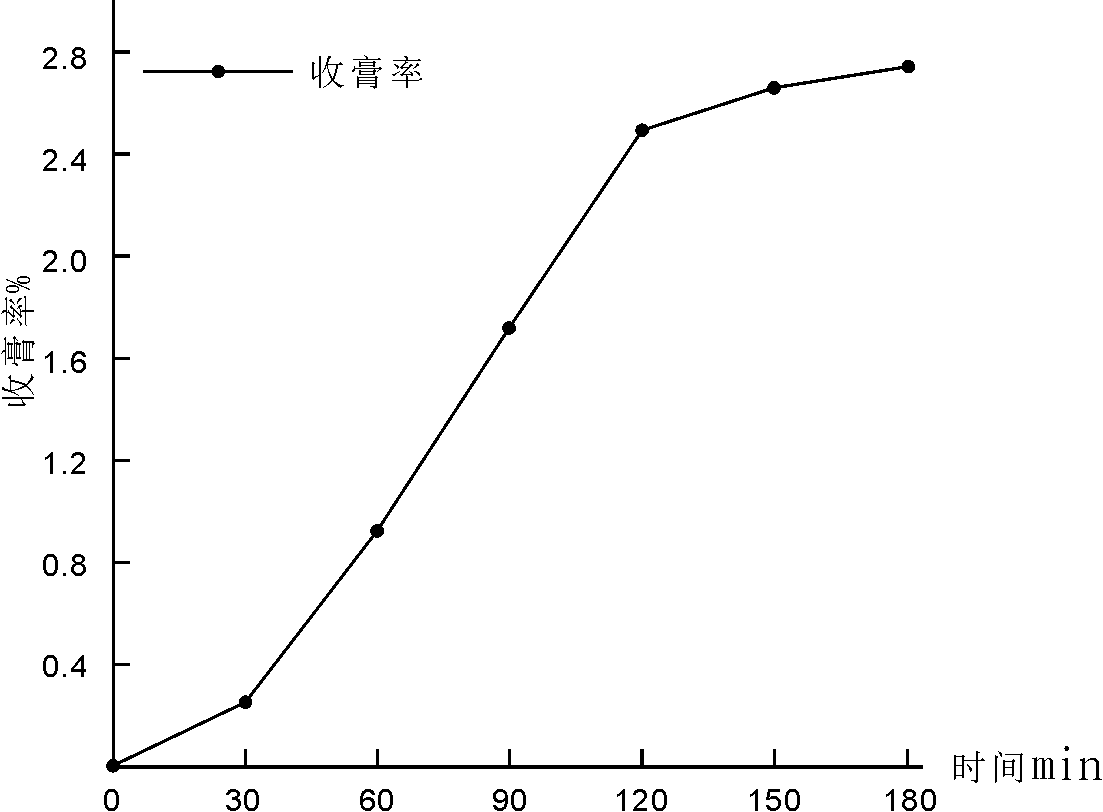

[0038] (2) Carry out supercritical extraction of Codonopsis Codonopsis powder with carbon dioxide, the extraction pressure of supercritical extraction is 25Mpa~35Mpa, the extraction temperature is 60°C~70°C, the flow rate of carbon dioxide is 1.5L / min~3L / min, and the extraction time is 2h~ 3h; entrainer flow rate is 0.5ml / min~1.5ml / min, entrainer is ethanol 60%~70% by weight, n-octyltrimethoxysilane 10%~20%, the balance is acetone; extraction is completed After obtaining Codonopsis pilosula extract;

[...

Embodiment 1

[0055] Embodiment 1: Preparation of Codonopsis Codonopsis Extract

[0056] (1), fresh Codonopsis pilosula is washed and cut off, and after cleaning again, it is placed in an oven and dried until the water content is 8%, then the dried Codonopsis pilosula is crushed and dried again until the water content is lower than 5%; then sieved, and 100-mesh powder is taken, Get Codonopsis powder;

[0057] (2), Codonopsis Codonopsis powder is subjected to carbon dioxide supercritical extraction, and the extraction pressure of supercritical extraction is 28Mpa, and extraction temperature is 68 ℃, and carbon dioxide flow rate is 2.2L / min, and extraction time is 2h; Entrainer flow rate is 1ml / min, entrains The agent is 65% by weight of ethanol, 15% of n-octyltrimethoxysilane, and the balance is 20% of acetone; that is, 65g of ethanol, 15g of n-octyltrimethoxysilane and 20g of acetone are prepared as entraining agents, and the extraction is completed After obtaining the Codonopsis pilosula ...

Embodiment 2

[0058] Embodiment 2: the preparation of Codonopsis pilosula segment dry product

[0059] The Codonopsis pilosula extract is vacuum-dried at 75° C. and ground into a dry powder, and auxiliary materials and water are added to the dry powder to prepare a wet material. Add 30g of auxiliary materials per 100g of dry powder in the wet material. Specifically, the auxiliary materials include 20 g of maltodextrin, 5 g of microcrystalline cellulose and 5 g of magnesium stearate. Dry powder and auxiliary materials are added with water to form a semi-dry mixture, and wet materials are added with water until they can be kneaded and formed, which is convenient for pressing into segments.

[0060] Then the wet material is extruded into strips, then cut to form 5 cm wet material of Codonopsis section, and then the wet material of Codonopsis section is vacuum-dried at a drying temperature of 55° C. until the moisture content is 4%, to obtain a dry product of Codonopsis section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com