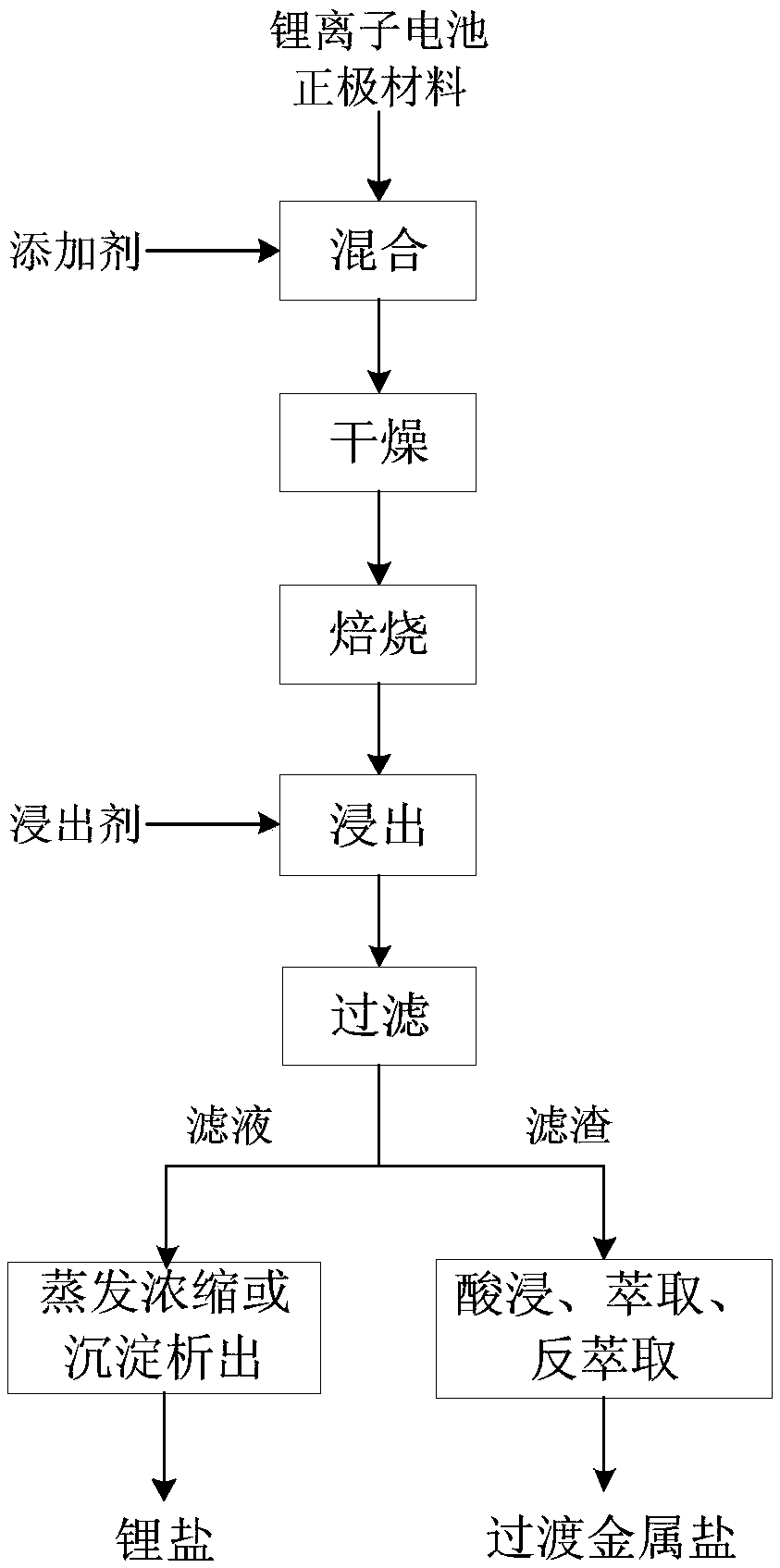

Method for selectively recycling positive electrode materials for lithium ion batteries

A technology for lithium-ion batteries and cathode materials, which is applied in the field of selective recovery of cathode materials for lithium-ion batteries, and can solve problems such as low recovery rate, limited industrial application value, and cumbersome recycling procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a method for selectively recovering the positive electrode material of a lithium ion battery. The lithium ion battery is a waste lithium cobalt oxide battery, and the metal element composition of the positive electrode material is shown in Table 1.

[0066] Table 1 Composition of metal elements in cathode materials of waste lithium cobaltate batteries

[0067] Metal

Li

Al

Ni

co

mn

Content, wt%

6.81

0.52

0.03

59.23

0.01

[0068] The method comprises the steps of:

[0069] (1) After mixing the positive electrode material of lithium cobalt oxide battery with sulfuric acid at a molar ratio of 2:1, dry it at 150°C for 8 hours, and then bake it at 800°C for 2 hours. Carried out under vacuum conditions;

[0070] (2) leaching the roasted product obtained in step (1) with water, the solid-to-liquid ratio of the roasted product and water is 400g L -1 , leached at 20°C for 400 minutes, filtered and ...

Embodiment 2

[0074] This embodiment provides a method for selectively reclaiming the positive electrode material of a lithium-ion battery, and the lithium-ion battery is a waste nickel-cobalt lithium manganate battery (LiNi 0.5 co 0.2 mn 0.3 o 2 ), the metal element composition of its cathode material is shown in Table 2.

[0075] Table 2 Composition of metal elements in the positive electrode material of waste nickel-cobalt lithium manganese oxide battery

[0076] Metal

Li

Al

Ni

co

mn

Content, wt%

6.69

0.20

28.64

12.10

16.45

[0077] The method comprises the steps of:

[0078] (1) After mixing the positive electrode material of nickel-cobalt lithium manganese oxide battery, sulfuric acid and sodium sulfate in a molar ratio of 2:2:1, dry at 100°C for 12h, and then bake in air atmosphere at 500°C for 6h;

[0079] (2) leaching the roasted product obtained in step (1) with water, the solid-to-liquid ratio of the roasted product and w...

Embodiment 3

[0083] This embodiment provides a method for selectively reclaiming the positive electrode material of a lithium-ion battery, and the lithium-ion battery is a waste nickel-cobalt lithium manganate battery (LiNi 0.3 co 0.3 mn 0.3 o 2 ), the metal element composition of its cathode material is shown in Table 3.

[0084] Table 3 Composition of metal elements in the positive electrode material of waste nickel-cobalt lithium manganese oxide battery

[0085] Metal

Li

Al

Ni

co

mn

Content, wt%

6.71

0.19

20.64

20.10

18.45

[0086] The method comprises the steps of:

[0087] (1) After mixing the positive electrode material of nickel-cobalt lithium manganese oxide battery with sulfuric acid at a molar ratio of 5:1, dry it at 300°C for 0.2h, and then bake it at 1500°C for 0.5h in an argon atmosphere;

[0088] (2) leaching the roasted product obtained in step (1) with water, the solid-to-liquid ratio of the roasted product and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com