Rotational flow grading-ionic liquid-ultrasonic synergistic selective zinc immersion method

A technology of ionic liquid and cyclone classification, which is applied in the field of hydrometallurgy, can solve the problems of secondary pollution reaction conditions, poor leaching selectivity, and high cost of leaching agents, and achieve low reaction temperature, low liquid-solid ratio, and high leaching efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

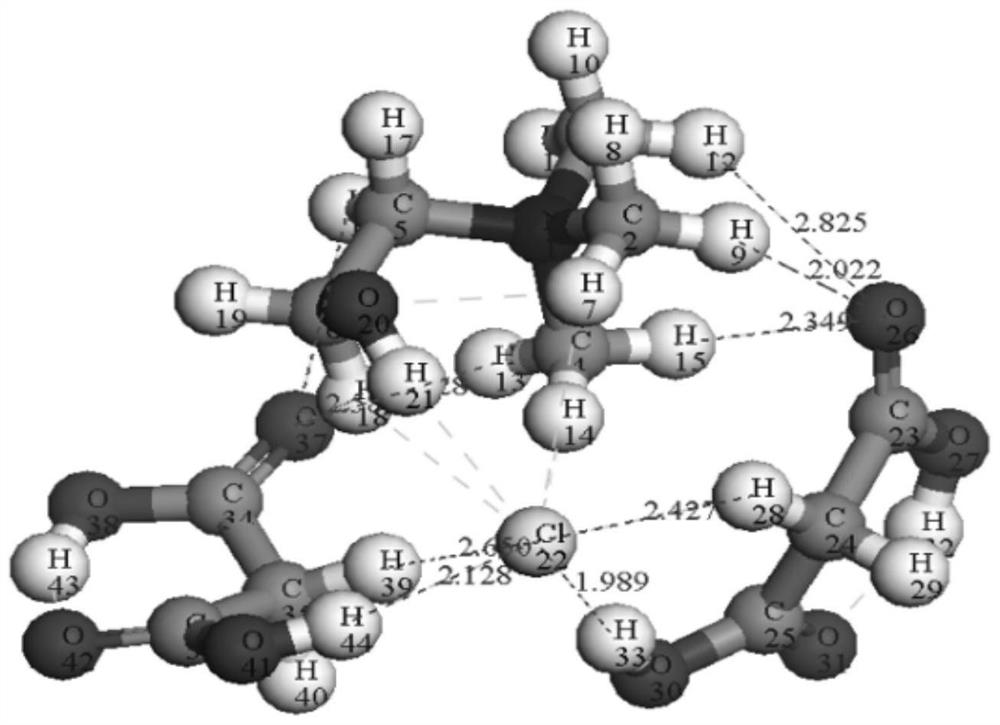

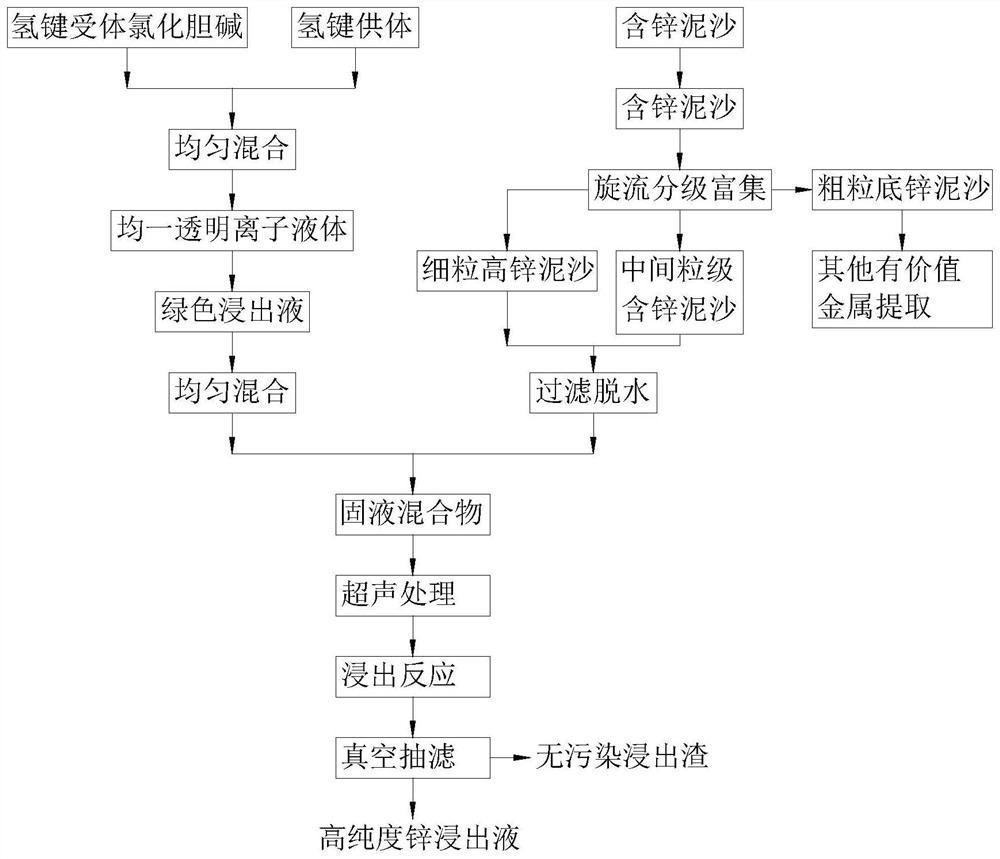

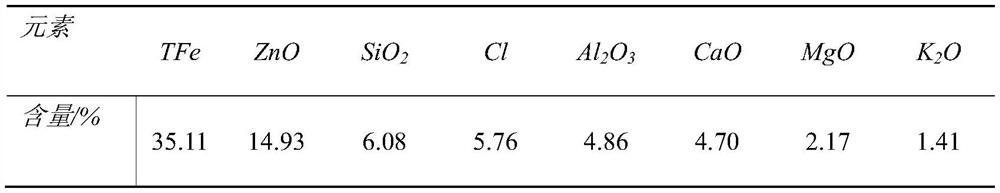

[0042] In this embodiment, choline chloride and malonic acid are synthesized to prepare ionic liquid for leaching and extracting zinc in zinc-containing dust. The specific steps are as follows:

[0043] Classification and enrichment of zinc-containing dust and sludge: use special-shaped hydrocyclones to classify and enrich zinc-containing dust and sludge, the classification particle size is 0.018mm, and -300 mesh accounts for 95% of the classified products. Fine-grained and intermediate-grained products are used for leaching and zinc extraction after filtration and dehydration.

[0044] Ionic liquid synthesis: dry a certain amount of choline chloride and malonic acid, put them into a vacuum drying oven, set the temperature of the drying oven at 353K, the relative vacuum at –0.05Mpa, and the drying time for 12h. The dried choline chloride and malonic acid were weighed and added into a 1L beaker at a molar ratio of 1:2 and mixed thoroughly. The beaker was placed in a 353K vacuum...

Embodiment 2

[0047] In this embodiment, choline chloride and urea are used to synthesize and prepare an ionic liquid for leaching and extracting zinc from zinc-containing dust. The specific steps are as follows:

[0048] (1) Classification and enrichment of zinc-containing dust and sludge: use special-shaped hydrocyclones to classify and enrich zinc-containing dust and sludge, the classification particle size is 0.018mm, and -300 mesh in the classified products accounts for 97% . Fine-grained and intermediate-grained products are used for leaching and zinc extraction after filtration and dehydration.

[0049] (2) Synthesis of ionic liquid: dry a certain amount of choline chloride and urea, put them into a vacuum drying oven, set the temperature of the drying oven at 353K, the relative vacuum degree at –0.05Mpa, and the drying time for 12h. The dried choline chloride and urea were weighed and added to a 1L beaker at a molar ratio of 1:2 and mixed thoroughly. The beaker was placed in a 333K...

Embodiment 3

[0052] In this embodiment, choline chloride and malonic acid are synthesized to prepare ionic liquid for leaching and extracting zinc in zinc-containing dust. The specific steps are as follows:

[0053] (1) Classification and enrichment of zinc-containing dust and sludge: Use special-shaped hydrocyclones to classify and enrich zinc-containing dust and sludge. The classification particle size is 0.018mm. Among the classified products, -300 mesh accounts for 96% of the fine-grained and intermediate-sized products. . Fine-grained and intermediate-grained products are used for leaching and zinc extraction after filtration and dehydration.

[0054] (2) Synthesis of ionic liquid: dry a certain amount of choline chloride and malonic acid, put them into a vacuum drying oven, set the temperature of the drying oven to 353K, the relative vacuum to –0.05Mpa, and the drying time to be 12h . The dried choline chloride and malonic acid were weighed and added into a 1L beaker at a molar rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com