Patents

Literature

32results about How to "Reduce the liquid-solid ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for pretreating cellulosic biomass

InactiveCN103790056ASimple processing methodIncrease contact areaEnergy inputFermentationMechanical crushingLignocellulosic biomass

The invention relates to relates to a method for pretreating cellulosic biomass, which comprises the following steps: before or after the cellulosic biomass is mechanically crushed, or when the cellulosic biomass is mechanically crushed, the cellulosic biomass is contacted with a chemical drug capable of degrading the cellulosic biomass, and the heat generated due to mechanical crushing is used for increasing the temperature of a mixture of the cellulosic biomass and the chemical drug.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838AImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixture is stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

Method for preparing high pure ammonium paramolybdate

InactiveCN1480404AReduce the liquid-solid ratioReduce carryoverCrystallization separationMolybdeum compoundsSal ammoniacEthylenediamine

A process for preparing high-purity ammonium paramolybdate from ammonium polymolybdate as raw material includes adding purified water and ammonia water, heating while stirring, stirring under a certain steam pressure for evaporation crystallizing while boiling the solution, concentrating, solid-liquid separation, and baking. Its advantages are high purity and high crystallizing rate (94.5-96%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Production method for alumina

InactiveCN1876569AReduce the liquid-solid ratioGood for recyclingAlkali metal oxidesFiltration separationL&D processSeed crystal

The invention provides the preparing method of aluminum oxide, comprising preparing ore pulp, digest, diluting ore pulp, separating and washing red mud, disassembling seed crystal, separating and washing aluminum hydroxide, calcining aluminum hydroxide, evaporating mother liquid and causticizing soda solution. The invention adopts pressing filter to replace hydro-separator at the course of separating and washing red mud. The method is in favor of the reclamation of Na2O and Al2O3, and the invention has the advantages of saving cost, short process flow and little apparatus.

Owner:娄进

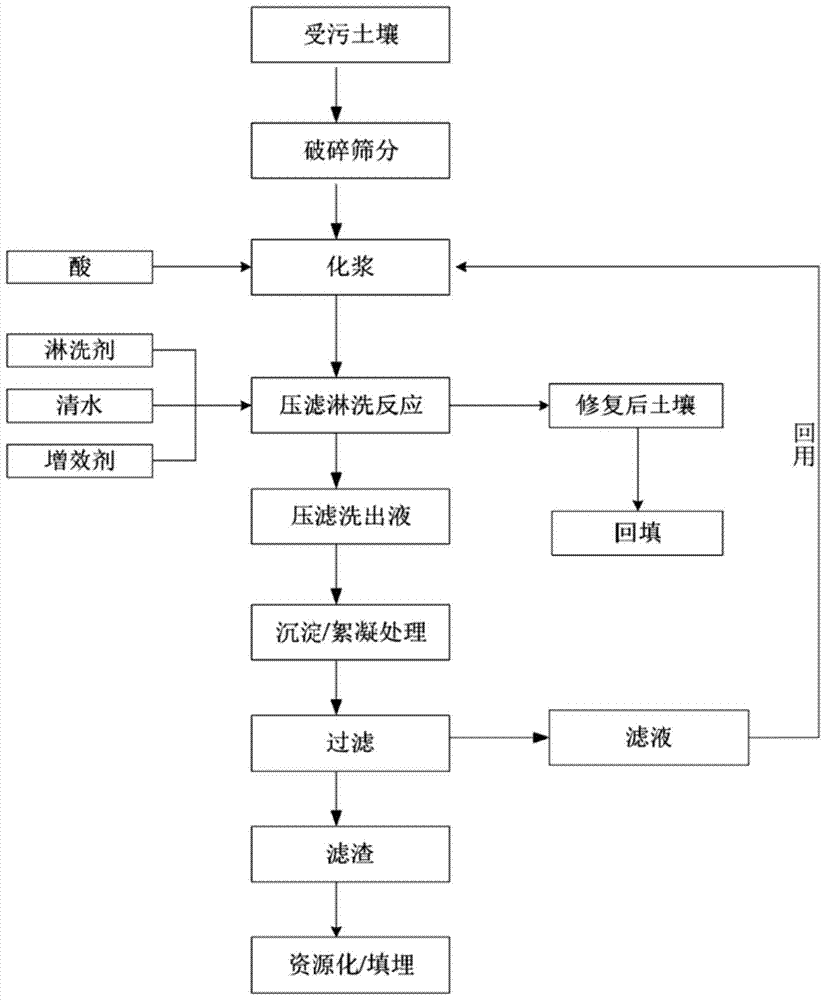

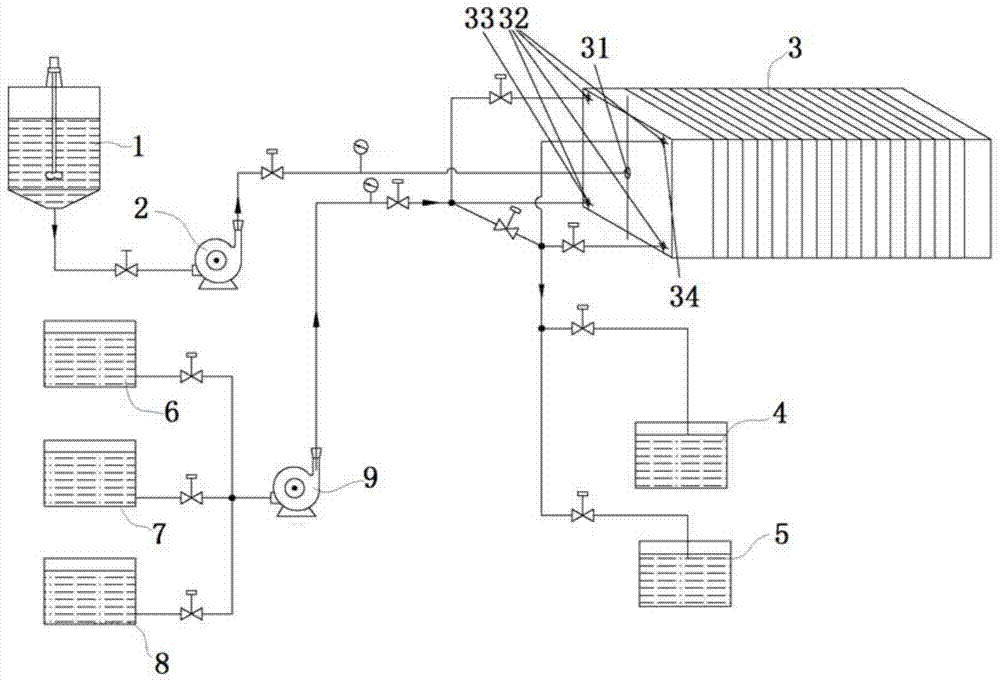

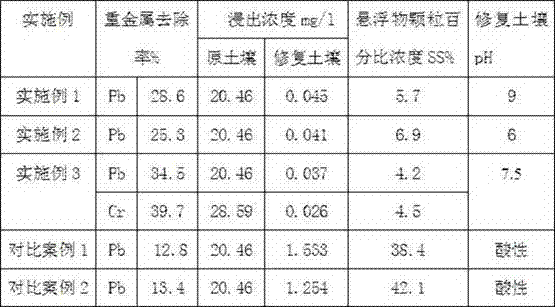

Method and system for efficient filter pressing and drip washing of contaminated soil and control method

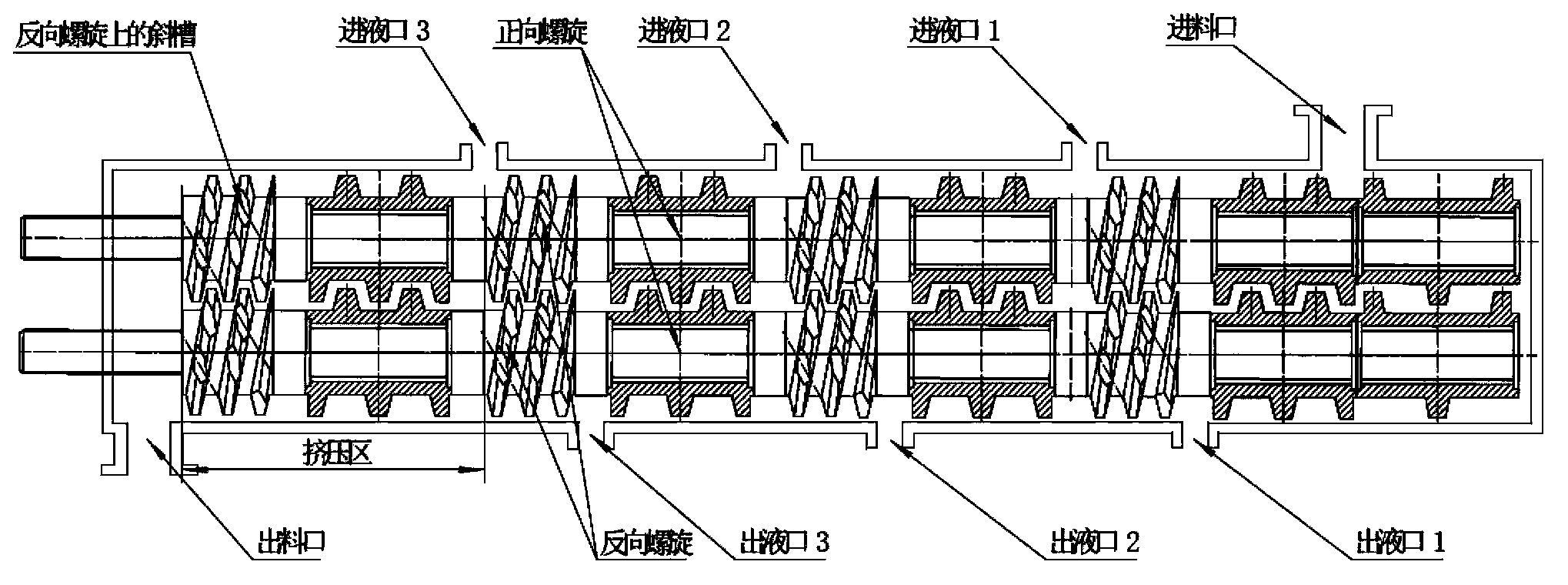

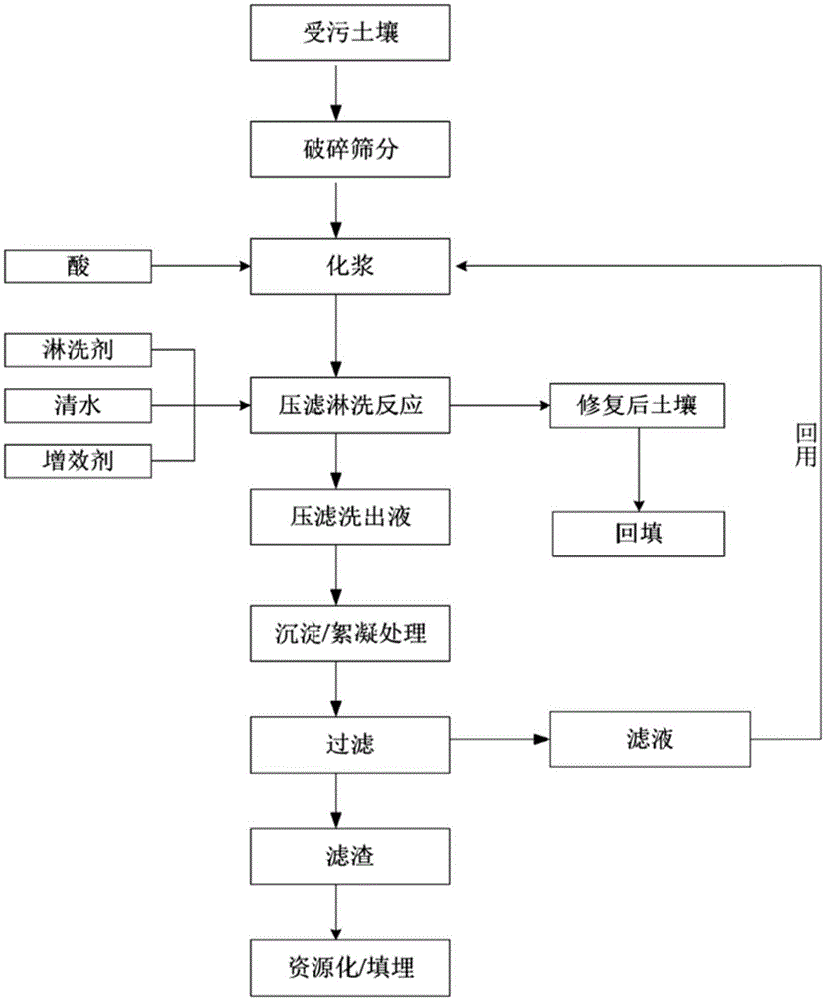

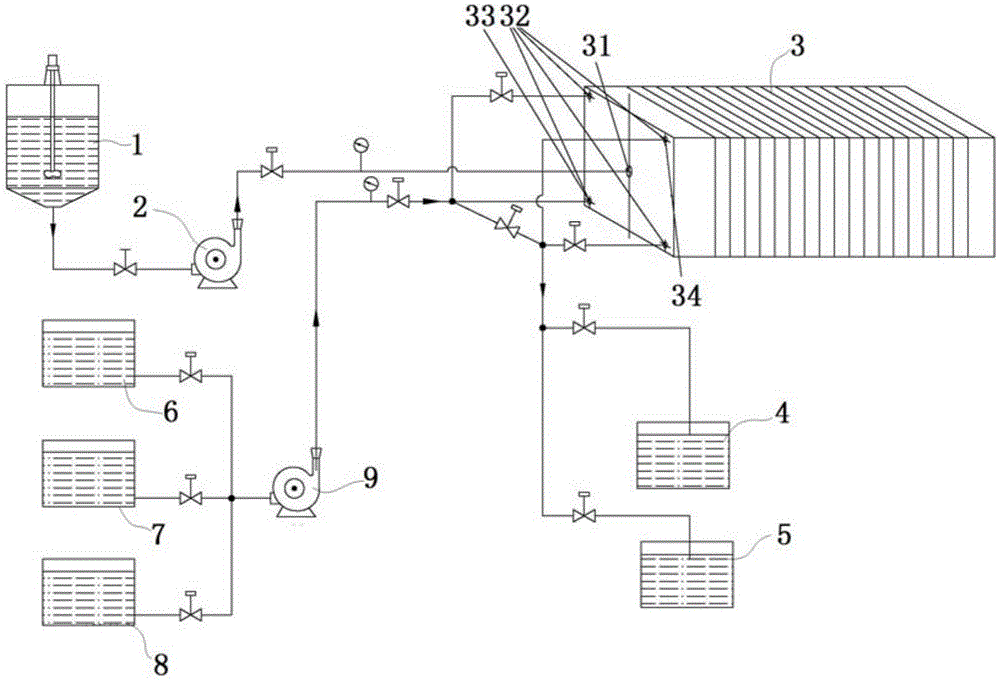

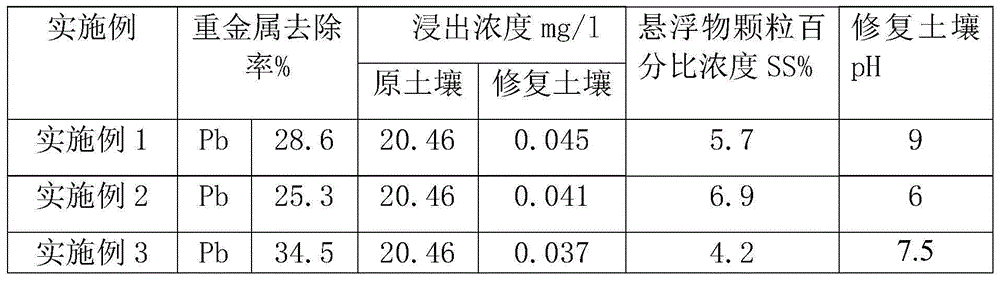

InactiveCN105032921AReduce the amount requiredReduce the liquid-solid ratioContaminated soil reclamationVulcanizationPollution soil

The invention discloses a method and system for efficient filter pressing and drip washing of contaminated soil and a control method. The method for repairing heavy metal contaminated soil comprises the following steps that firstly, the pulp smelting and acidification reaction is carried out; secondly, a sizing agent obtained after the sufficient reaction is filtered to obtain a soil filter cake and filter liquor; thirdly, pre-drip washing is carried out, heavy metal left in capillary holes in the filter cake is replaced and washed out; fourthly, after pre-drip washing is carried out, an eluting agent is injected in a washing reaction type membrane press filter step by step to carry out the multi-stage drip washing reaction; fifthly, after the drip washing reaction is carried out, dissociative heavy metal left in the soil filter cake can be stabilized, tiny heavy metal particles formed in the stabilization process are moved out of the soil, the input pressure ranges from 0.22 MPa to 0.35 MPa, and the vulcanization drip washing amount accounts for 50-80% of the total water content of the soil; and sixthly, the soil is stabilized. The problem that in the drip washing process in the prior art, leacheate is left in the soil, and consequently the soil leaching toxicity heavy metal index exceeds the standard is solved.

Owner:HUNAN MUKUN ENVIRONMENTAL PROTECTION

Method for recycling phosphorus from sludge ash

The invention discloses a method for recycling phosphorus from sludge ash. According to the method, sludge incineration ash is taken as a raw material and undergoes first extraction with a sulfuric acid solution, then the obtained extraction liquid is mixed with a concentrated sulfuric acid solution according to a volume ratio of 28.8:1.2 to 28.4:1.6, so that a new extracting agent is prepared andused to extract the remaining sludge ash; and if necessary, the sludge ash can be divided into multiple parts for multiple extraction, and an extracting agent used in a next extraction is formed by mixing an extraction liquid obtained after a previous extraction with a concentrated sulfuric acid solution. In the method of the present invention, the extraction liquid is used as an extracting agent, so that discharge of waste liquid is greatly reduced, and after cyclic extraction, the extraction rate of phosphorus in the sludge ash can exceed 96%, and the concentration of phosphorus in a finalextraction liquid exceeds 21-23 g / L, thereby effectively solving the technical problems of low phosphorus extraction rate, large consumption of chemicals and large amount of waste liquid in the priorart.

Owner:SICHUAN UNIV

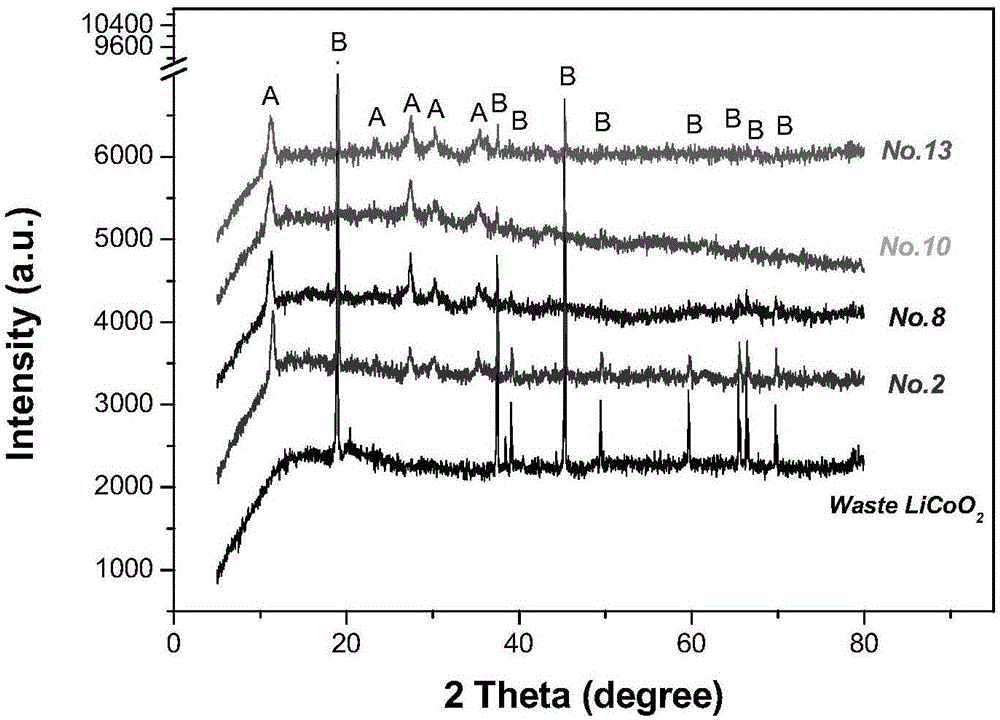

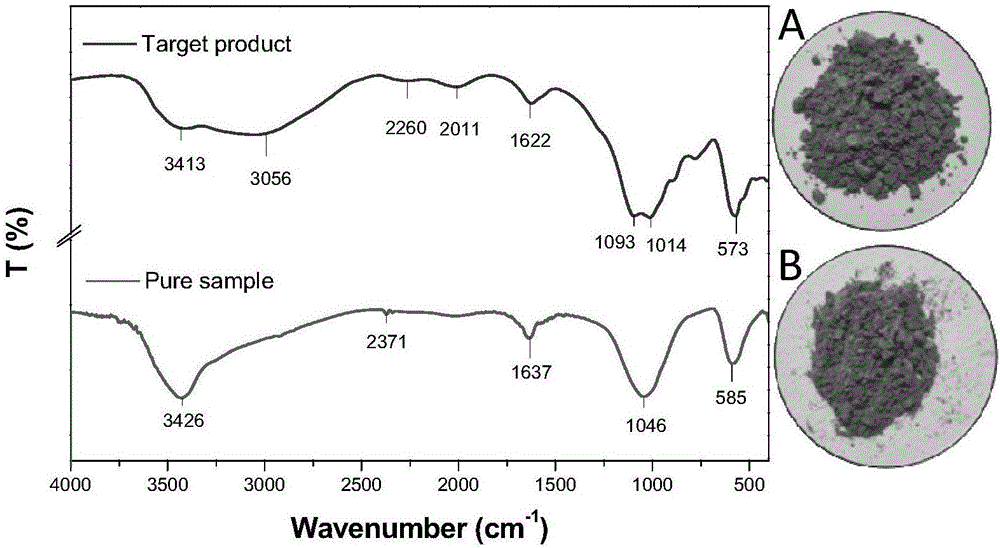

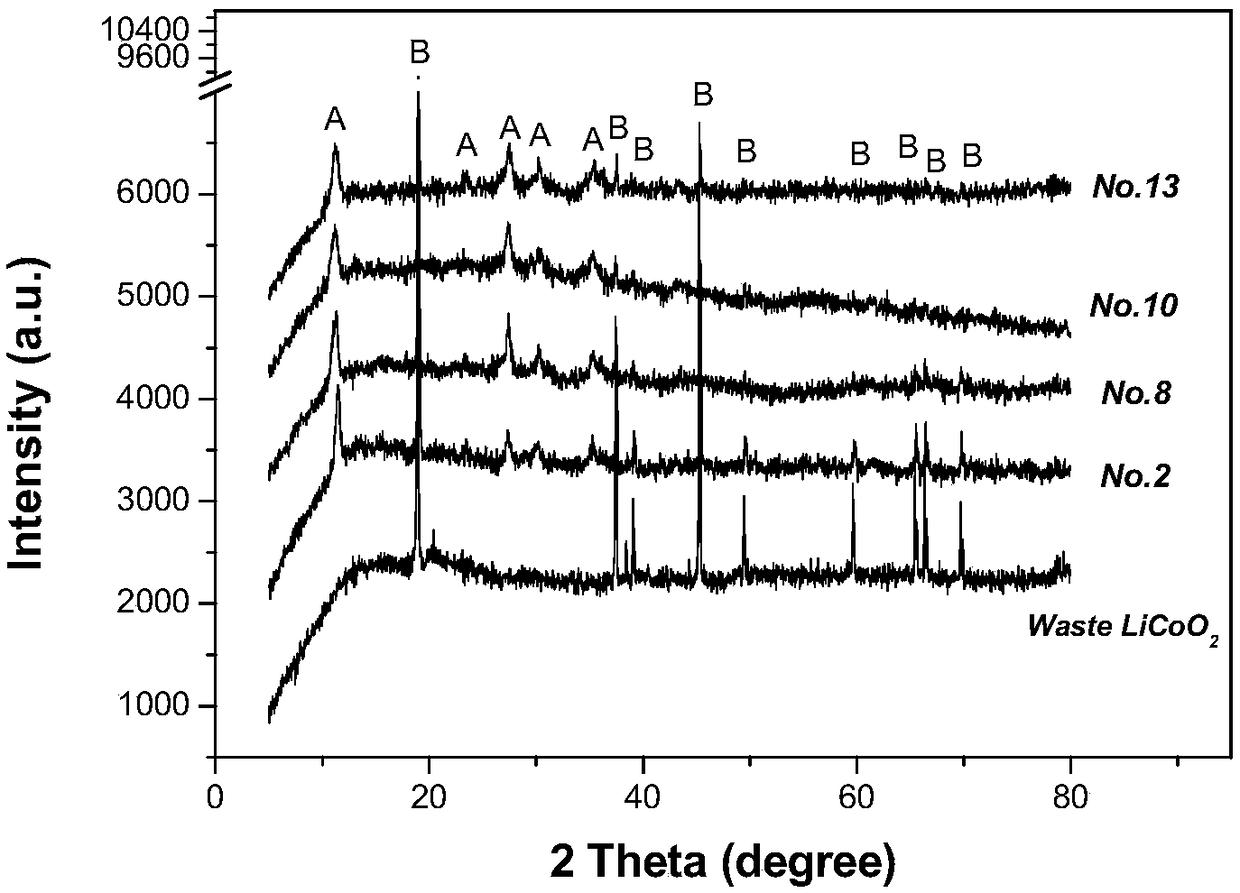

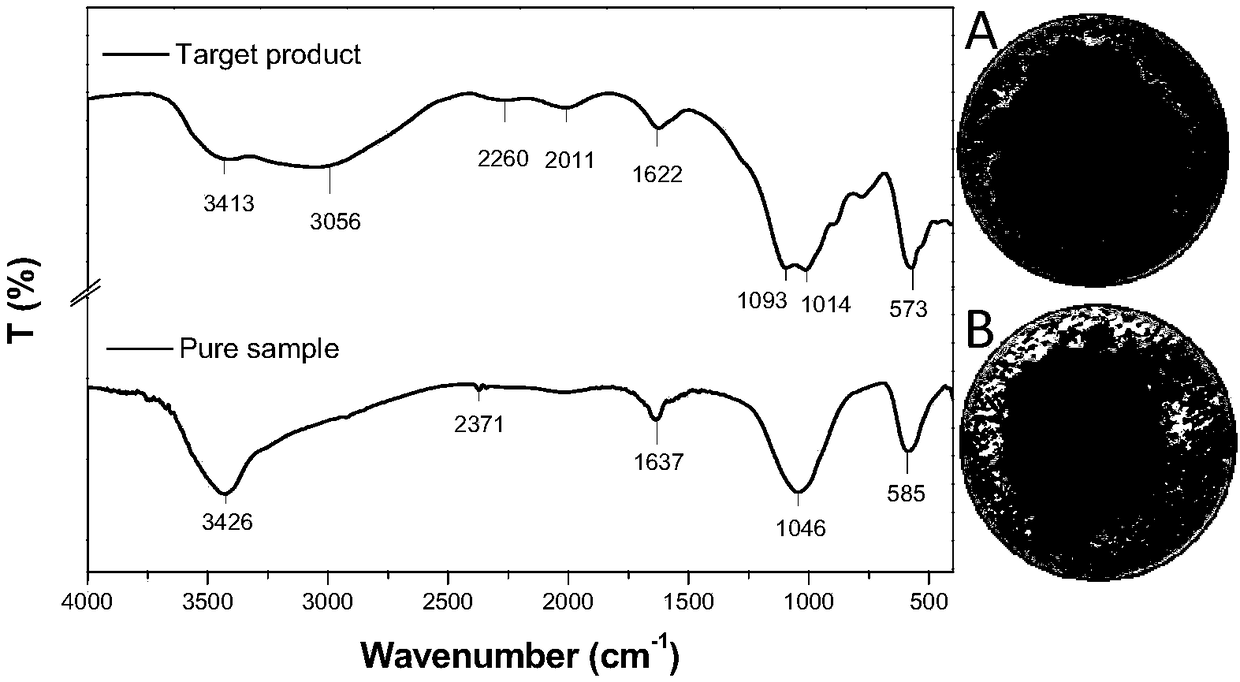

Method for separating Co (cobalt) and Li (lithium) from LiCoO2 (lithium cobalt oxide) of waste lithium batteries to prepare cobaltous phosphate

ActiveCN106395784AEasy to separateEfficient recyclingSolid waste disposalTransportation and packagingPregnant leach solutionPhosphate

The invention discloses a method for separating Co (cobalt) and Li (lithium) from LiCoO2 (lithium cobalt oxide) of waste lithium batteries to prepare cobaltous phosphate. The method comprises the following steps: (1) disassembling and peeling the waste lithium batteries to obtain anode and cathode active substances; (2) calcining and grinding the anode and cathode active substances to obtain LiCoO2-containing powder materials; (3) performing leaching on the LiCoO2-containing powder materials by mixed leaching liquid of H3PO4 and H2O2; neutralizing the obtained leaching liquid; performing solid-liquid separation to obtain cobaltous phosphate sediment and a lithium-containing solution. The method has the advantages that the LiCoO2 of typical waste lithium batteries is used as a raw material; the Co and the Li are effectively separated by a roasting and leaching method; the cobalt with high additional values is recovered for preparing the cobaltous phosphate (cobalt violet); the resource recycling and utilization of the LiCoO2 of the waste lithium batteries are realized.

Owner:CENT SOUTH UNIV

Preparation method of trimeric cyanamide cyanurate flame retardant

InactiveCN102731423AReduce the liquid-solid ratioDelayed reaction timeOrganic chemistryWater useChemical industry

The invention discloses a preparation method of a trimeric cyanamide cyanurate flame retardant and belongs to the technical field of chemical industry. The method comprises the following steps of: (1) adding 100-120 parts by weight of water used as a solvent into a reaction container, successively adding 4-6 parts by weight of a catalyst and 10-15 parts by weight of melamine, uniformly stirring and heating to 65-75 DEG C, adding 10-15 parts by weight of cyanuric acid, stirring and heating to 95 DEG C, beginning insulation, adjusting pH value of the system to 9-10, continuously stirring and reacting for 45-65 min; and (2) centrifuging the obtained reaction product by the use of a centrifuge, recovering a filtrate, drying the solid product at 100-120 DEG C, and crushing to 1.0-4.0 microns so as to obtain the trimeric cyanamide cyanurate flame retardant.

Owner:张士钊

Method for extracting rose essential oil by molecular sieve extracting agent

The invention belongs to the technical field of flower essential oil extraction, and in particular relates to a method for extracting rose essential oil by a molecular sieve extracting agent. By utilization of the selective adsorption effect of the molecular sieve, the soakage capability of the extracting agent on the rose as well as the emulsification and solubilizing effects on the essential oil in the rose are improved, and the dispersing amount of the essential oil in the rose in the extracting agent is increased. Fresh incompletely bloomed roseleaves, of which the receptacles are cut, are subjected to pretreatment, extraction, filtration under reduced pressure, steam distillation and oil-water separation, the obtained product does not contain pigment, is pure and bright and has fragrant and strong odor, the yield is 0.020 to 0.025 percent, and the extraction rate of the essential oil is 11 percent higher than that of the essential oil in the traditional industrial extraction method. The molecular sieve extracting agent with the selective adsorption effect instead of an organic solvent is used for extracting the rose essential oil for once in a water solution, so the problem of environmental pollution is solved, the problems that the traditional extraction process has high energy consumption and low oil yield are solved, and the method has the advantages of recyclability of the molecular sieve extracting agent, operation safety, low production cost and the like.

Owner:河南教育学院

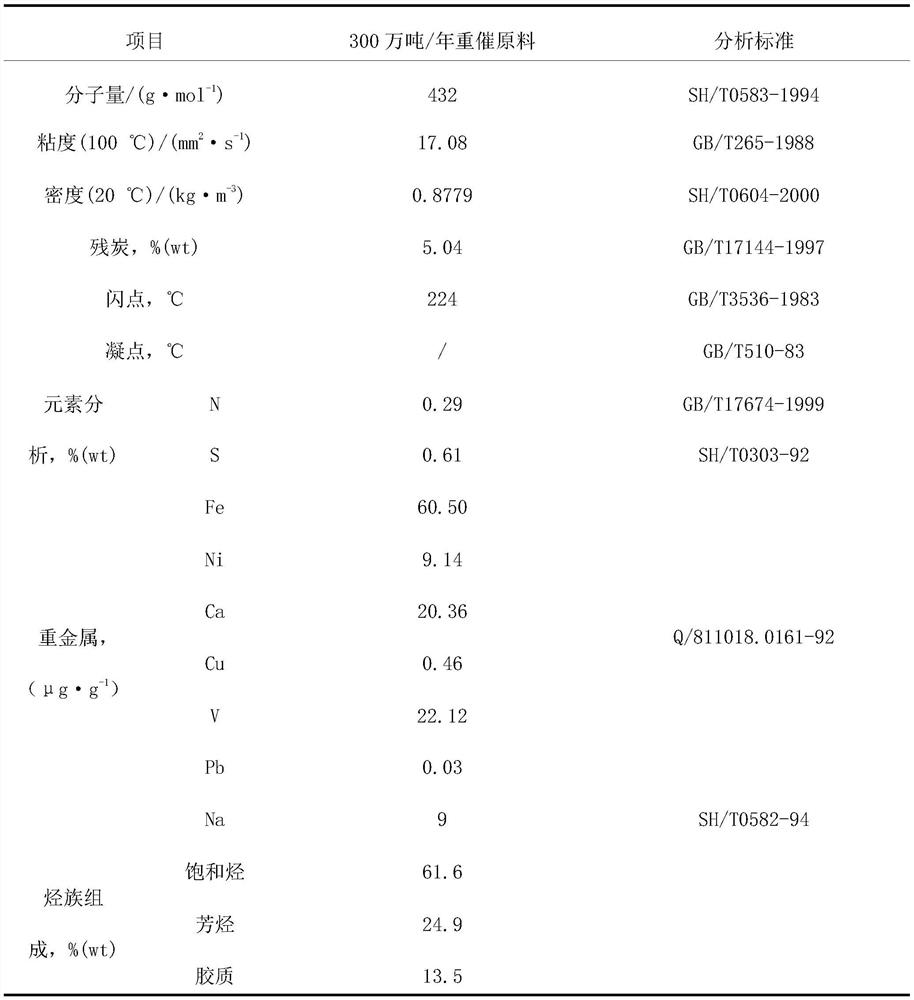

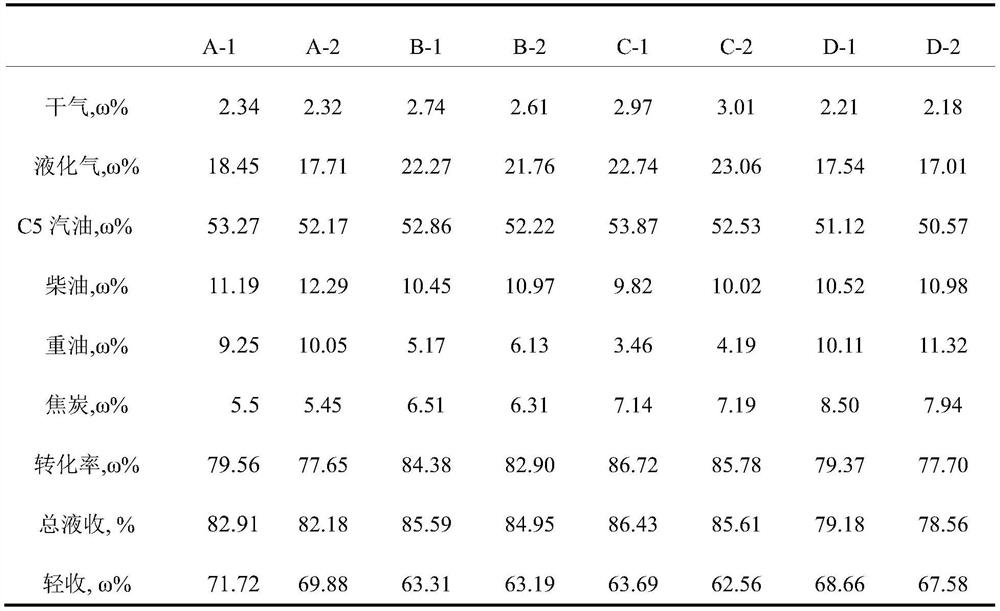

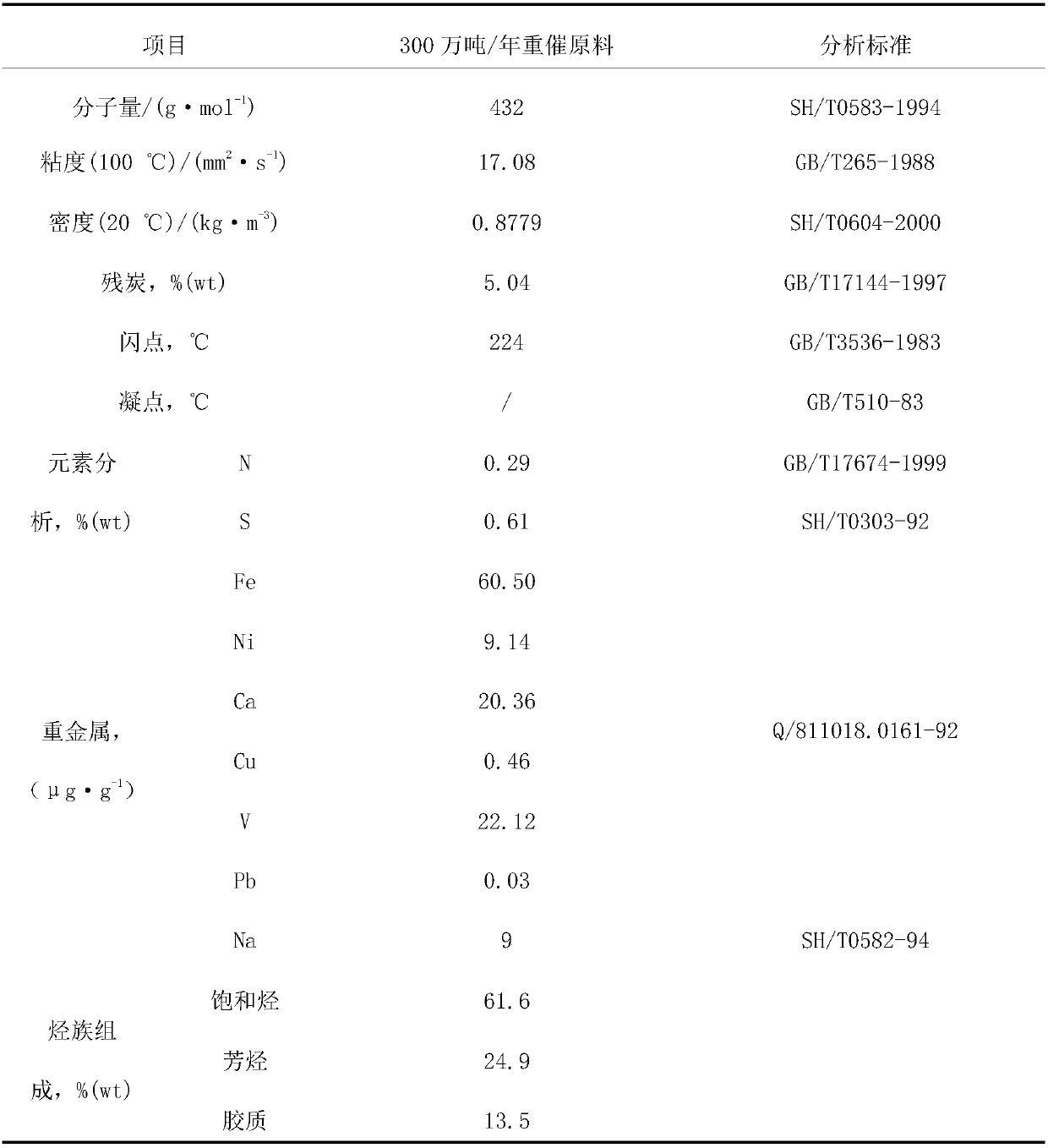

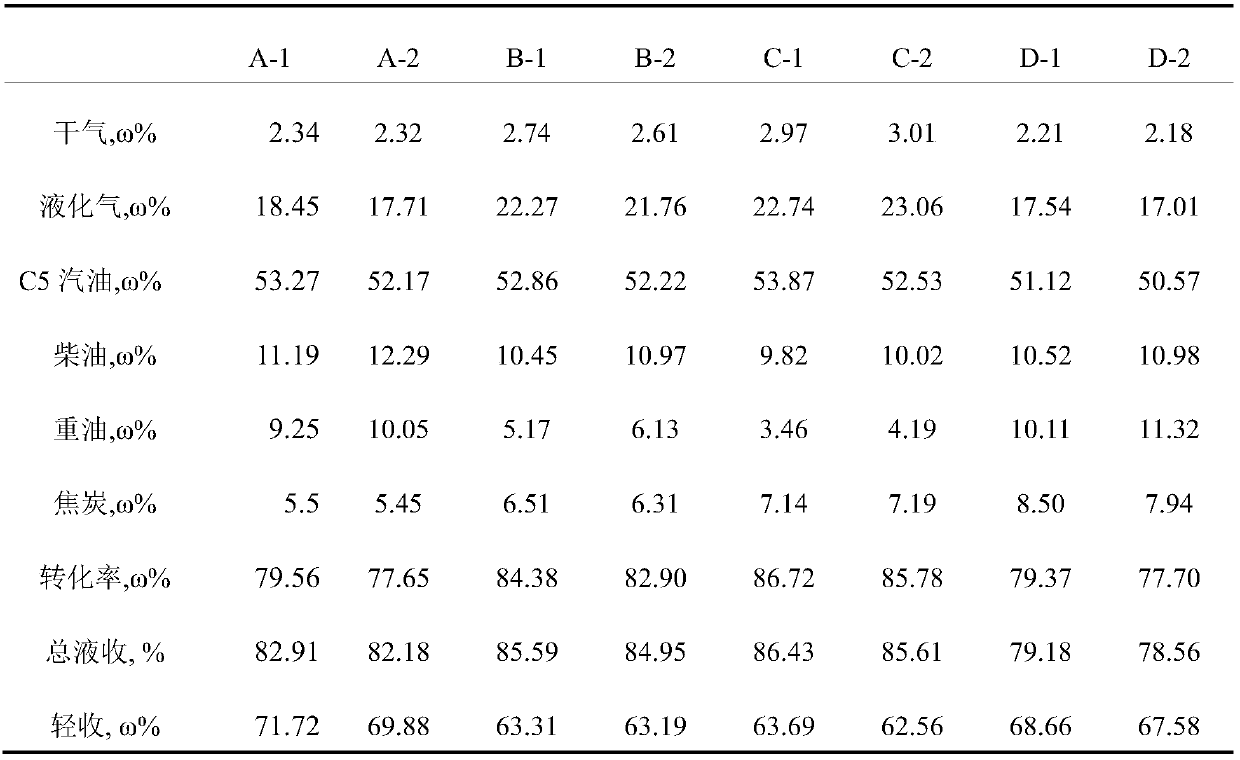

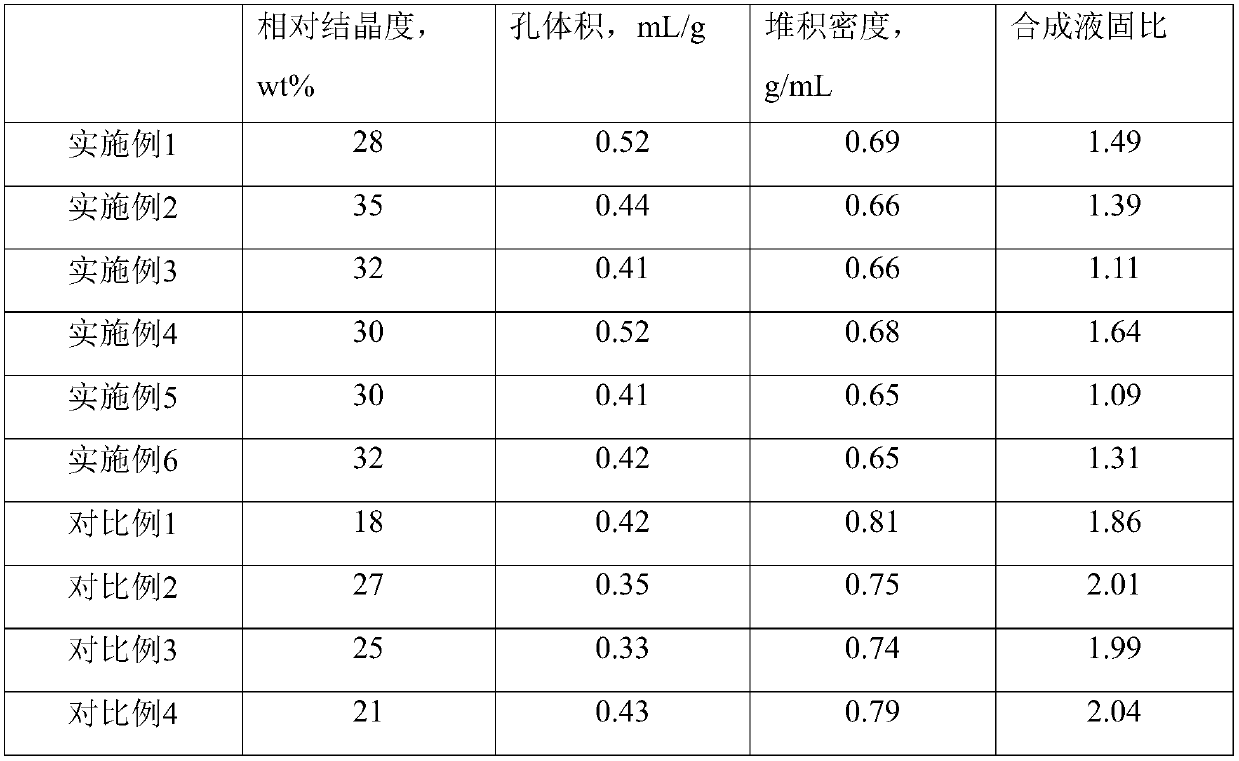

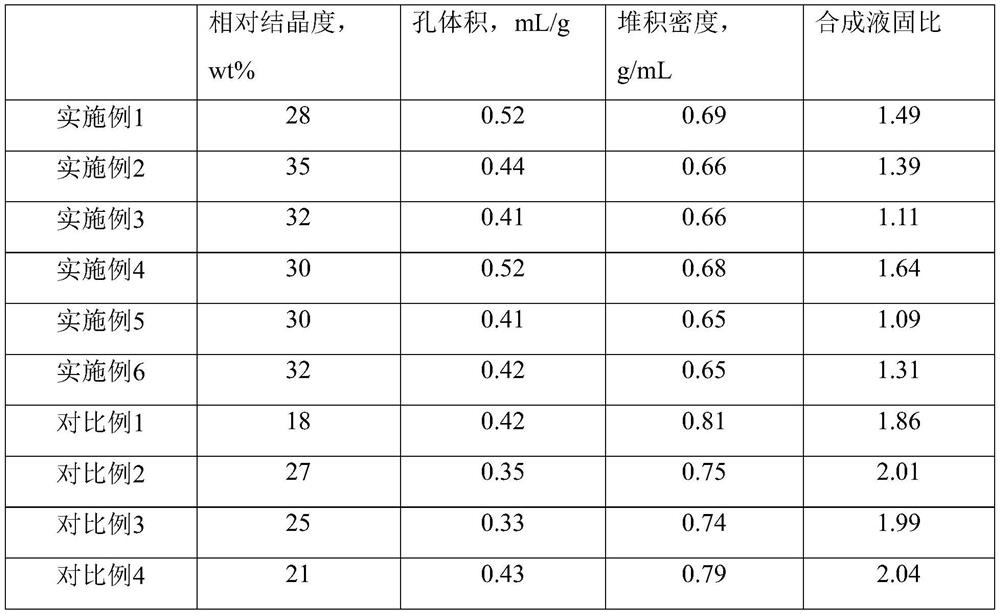

A kind of preparation method of in-situ crystallization catalytic cracking catalyst

ActiveCN110523429BIntensity is not affectedLarge pore volumeCatalytic crackingMolecular sieve catalystsPtru catalystMicrosphere

The invention provides a preparation method of an in-situ crystallization catalytic cracking catalyst, specifically, by adjusting the in-situ crystallization process, the roasted soil balls and the sodium hydroxide solution used for crystallization are firstly mixed, and then directly added Directing agent for crystallization, without adding any external silicon source, directly obtains high crystallinity, large pore volume, and low bulk ratio in-situ crystallization products. This method avoids the conventional addition of special materials to kaolin microspheres Functional component, method to improve pore structure and increase crystallinity. Moreover, the method reduces the production cost of the in-situ crystallization product, which is embodied in the low raw material cost and no need to add an external silicon source; the liquid-solid ratio decreases during the synthesis process, and the single-pot yield increases. After the in-situ crystallization product is modified with rare earth, the conversion rate of heavy oil can be improved, and the yield of target product can be increased.

Owner:PETROCHINA CO LTD

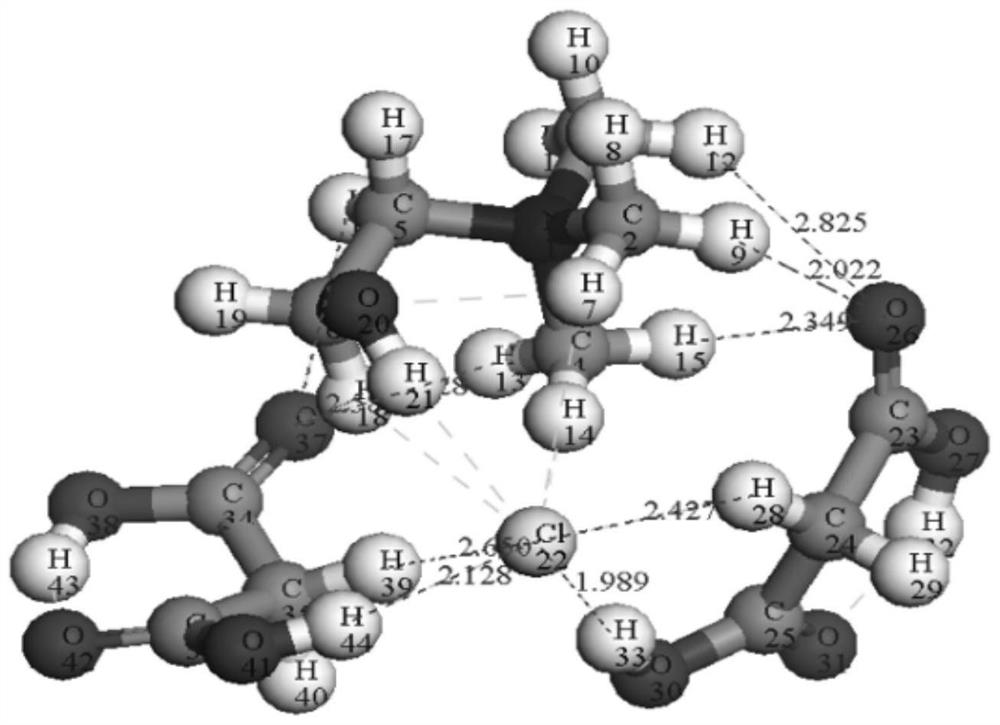

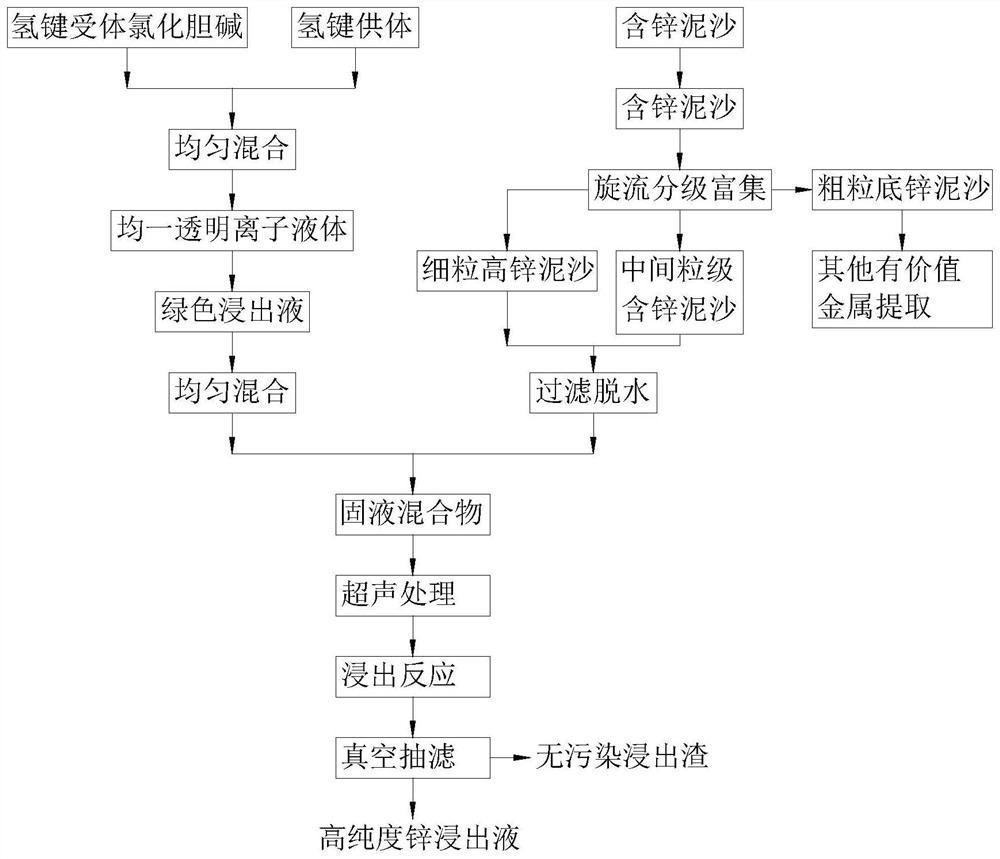

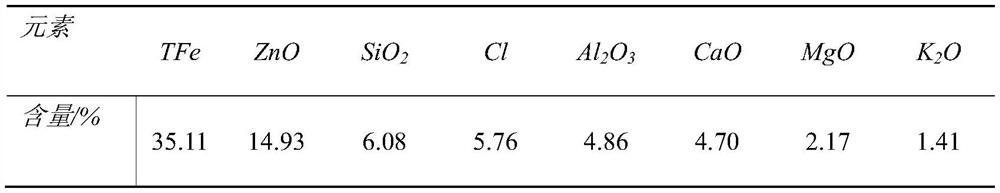

Rotational flow grading-ionic liquid-ultrasonic synergistic selective zinc immersion method

ActiveCN114317984AHigh purityReduce manufacturing costProcess efficiency improvementPregnant leach solutionSludge

The invention discloses a method for selective zinc immersion through cyclone classification-ionic liquid-ultrasonic cooperation, and belongs to the technical field of hydrometallurgy. The method comprises the steps of graded enrichment of zinc-containing dust mud, synthesis of ionic liquid and selective leaching of zinc. According to the method, the special-shaped hydrocyclone is used for pretreating the zinc-containing dust sludge to obtain fine-grain zinc-rich dust sludge, so that efficient leaching of zinc is facilitated, and meanwhile, opening and dispersing of floccules in the zinc-containing dust sludge are facilitated; the ionic liquid and ultrasonic synergistic leaching system has selective dissolving capacity on ZnO, the obtained zinc-containing leaching solution is high in purity, and the problems that components are complex, separation is difficult and the like in a traditional leaching system are solved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of in-situ crystallization catalytic cracking catalyst

ActiveCN110523429AReduce manufacturing costAvoid joiningCatalytic crackingMolecular sieve catalystsIn situ crystallizationMicrosphere

The invention provides a preparation method of an in-situ crystallization catalytic cracking catalyst. Specifically, an in-situ crystallization process is adjusted, that is, the method comprises the steps of firstly mixing roasted soil balls and a sodium hydroxide solution for crystallization, and directly adding a guiding agent for crystallization without adding any external silicon sources to directly obtain an in-situ crystallization product with high crystallinity, a large pore volume and a low bulk density, and the method provided by the invention avoids a conventional method of adding special functional components into kaolin microspheres to improve a pore structure and improve crystallinity; the method provided by the invention reduces the production costs of the in-situ crystallization product, specifically, the raw material costs are low, and additional silicon sources are not required to be added; in the synthetic process, the liquid-solid ratio is reduced, and the single-kettle yield is increased; and after the in-situ crystallization product is modified by rare earth, the conversion rate of heavy oil can be increased, and the yield of a target product is increased.

Owner:PETROCHINA CO LTD

Myrciaria cauliflora leaf-based handmade soap and preparation method thereof

ActiveCN108485845ARich aromaImprove bactericidal effectAntibacterial agentsSoap detergents with perfumesChemistrySemiaquilegia adoxoides

The invention discloses a myrciaria cauliflora leaf-based handmade soap and a preparation method thereof. The preparation method comprises the following steps: mixing a transparent soap base and rosehydrolat, heating in a water batch for dissolving, then adding four types of base oils, namely sweet almond oil, wheat germ oil, jojoba oil and olive oil respectively, as moisturizing agents, and thenadding a myrciaria cauliflora leaf extract concentrate and a semiaquilegia adoxoides extract concentrate, dripping in citronella essential oil and mint essential oil, uniformly stirring, moulding, standing, ventilating and drying to obtain the myrciaria cauliflora leaf-based handmade soap. The handmade soap prepared by the preparation method provided by the invention, is light brown, semitransparent, natural, safe, mild, smooth and rich in aroma, contains myrciaria cauliflora leaf fragrance, rose fragrance, citronella fragrance and mint fragrance, is a multifunctional handmade soap with antioxidant, antibacterial, itching-relieving, mosquito-repellent effects and the like.

Owner:FUJIAN ACADEMY OF AGRI SCI SUBTROPICAL AGRI RES INST

Method for promoting uranium ore leaching by applying magnetic field

InactiveCN113025816AIncrease the amount of dissolved oxygenImprove solubilityPregnant leach solutionPhysical chemistry

The invention discloses a method for promoting uranium ore leaching by applying a magnetic field. The method comprises the steps that (1) a leaching solution is magnetized through a pipeline, a magnetic field generator is arranged outside the pipeline, and the leaching solution is any one of an acid leaching solution, an alkaline leaching solution or a neutral leaching solution; and (2) the magnetized leaching solution is introduced into a liquid injection drill hole to be injected into an underground uranium ore layer, and then solute is lifted to the earth surface through a liquid extraction hole away from the liquid injection drill hole by a preset distance. According to the scheme, more dissolved oxygen can be provided for the oxidation leaching process of uranium, and therefore the oxidation leaching process is enhanced, blockage of calcium sulfate crystals to a leaching solution seepage channel can be reduced, and the migration capacity of the solute is improved.

Owner:CENT SOUTH UNIV

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838BImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixtureis stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

A method for preparing cobalt phosphate by separating cobalt lithium from waste lithium battery lithium cobaltate

ActiveCN106395784BEasy to separateEfficient recyclingSolid waste disposalTransportation and packagingPregnant leach solutionPhosphate

Owner:CENT SOUTH UNIV

A method, system and control method for high-efficiency pressure filtration and leaching of polluted soil

InactiveCN105032921BReduce the amount requiredReduce the liquid-solid ratioContaminated soil reclamationSoil scienceSulfidation

The invention discloses a method, system and control method for high-efficiency pressure filtration and leaching polluted soil. The method for repairing heavy metal-contaminated soil comprises the following steps: S1, pulping, acidifying reaction; S2, filtering the above-mentioned fully reacted slurry to obtain soil filter cake and filtrate; S3, pre-washing, so that the filter cake The remaining heavy metals in the capillary pores are replaced and washed out; S4, after the pre-washing, inject the eluent step by step into the washing reaction type diaphragm filter press to perform a multi-stage leaching reaction; S5, after the rinsing reaction, the Stabilize the free heavy metals remaining in the soil filter cake, and at the same time make the tiny heavy metal particles formed during the stabilization process migrate out of the soil, the input pressure is 0.22‑0.35 MPa, and the amount of sulfide leaching water is 50‑80 of the total water content in the soil %; S6, stabilized soil. The invention solves the problem in the prior art that the leaching solution remains in the soil during the leaching process and the index of toxic heavy metals leached from the soil exceeds the standard.

Owner:HUNAN MUKUN ENVIRONMENTAL PROTECTION

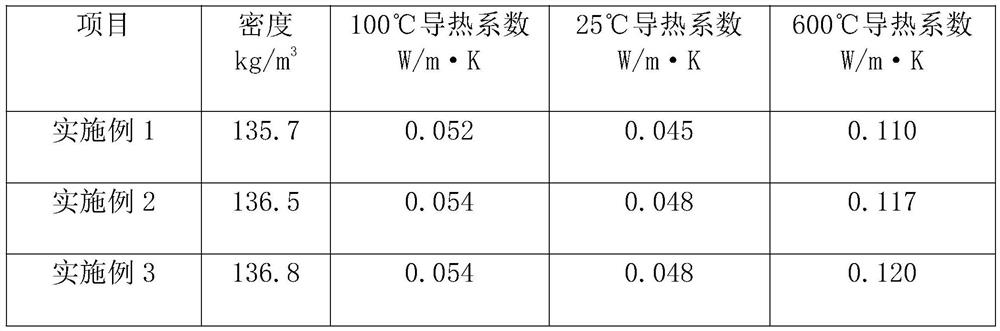

Preparation method of thermal-insulation fireproof material

The invention provides a preparation method of a thermal-insulation fireproof material, belongs to the field of thermal-insulation fireproof materials, and solves the problems of high cost and the like in the existing production of xonotlite, the preparation method of the thermal-insulation fireproof material comprises the following steps: step S01, mixing fly ash, quick lime and water, putting the mixture into a reaction kettle, and carrying out a reaction, reacting to obtain a reacted material; and S02, adding reinforcing fibers into the reacted material, mixing and stirring, filtering water, and drying to obtain xonotlite. The fireproof thermal-insulation board has excellent fireproof thermal-insulation performance.

Owner:内蒙古中建亚太建材科技有限公司

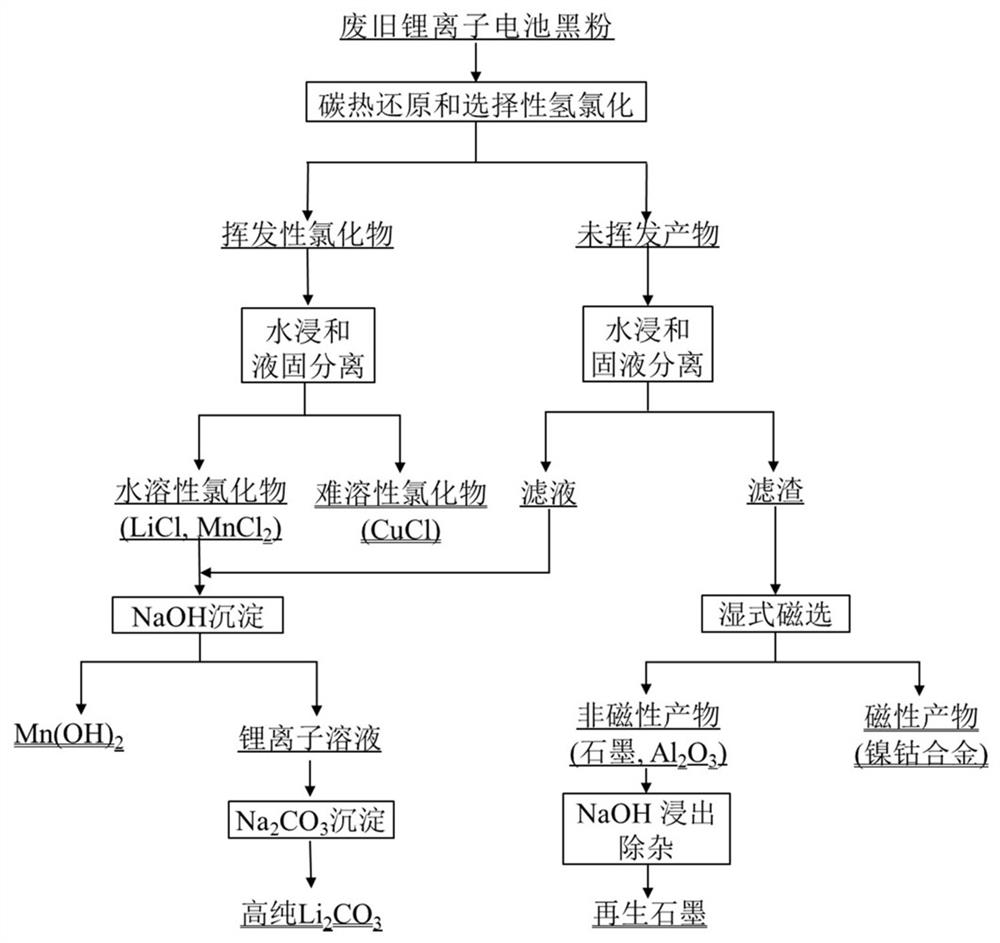

A method for comprehensive recovery of valuable metals in waste lithium-ion battery black powder

ActiveCN114381605BRealize impurity removalReduce lossesWaste accumulators reclaimingBattery recyclingPregnant leach solutionEnvironmental engineering

Owner:CENT SOUTH UNIV

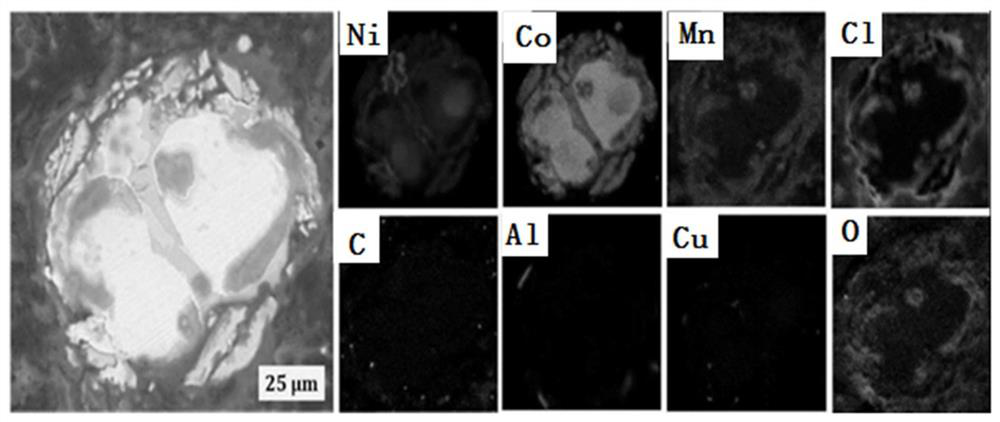

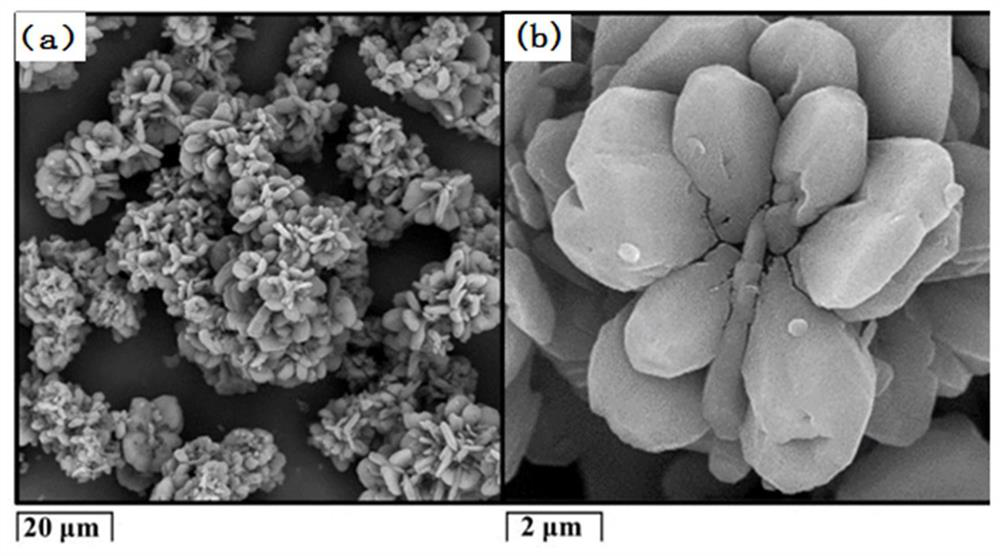

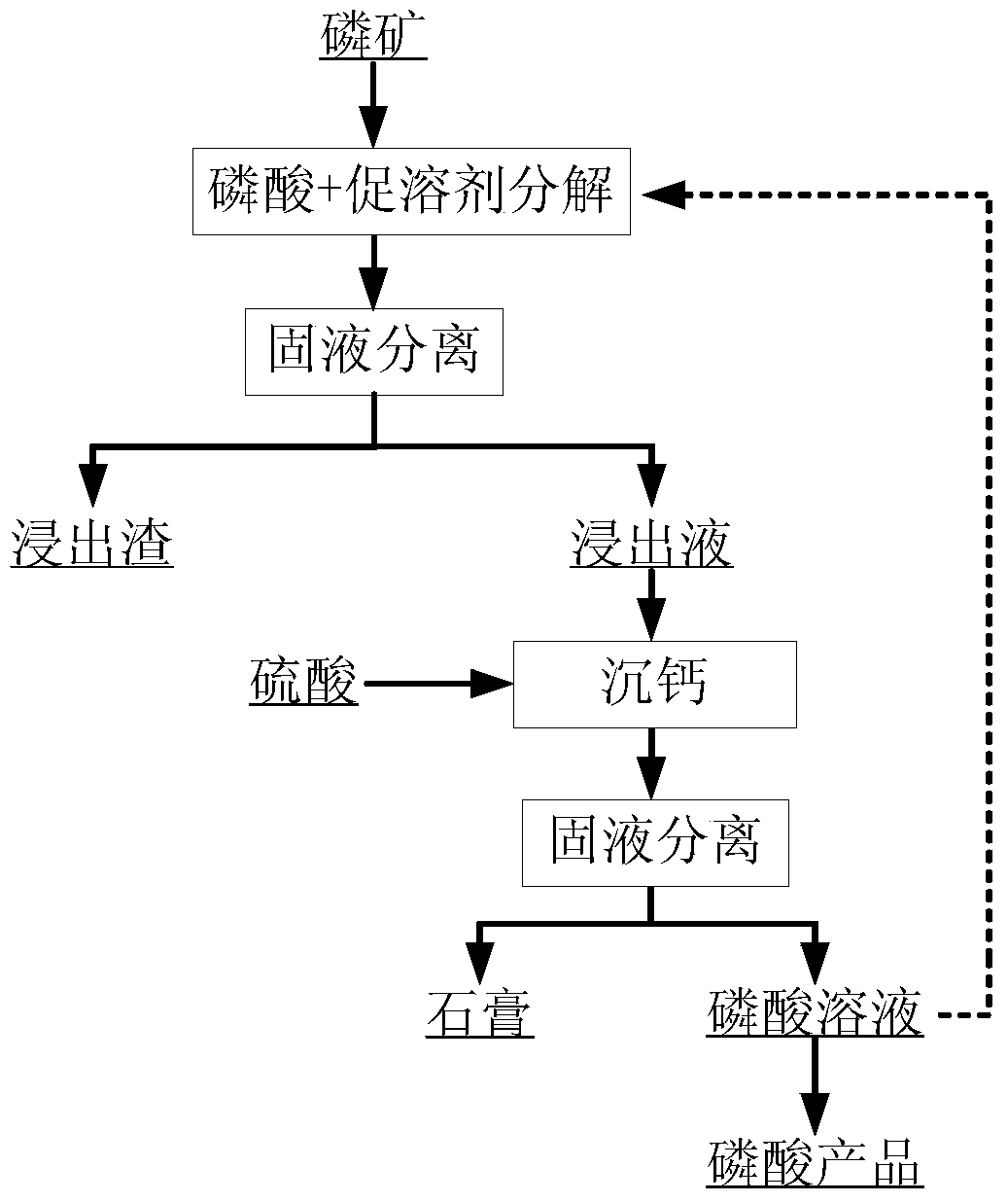

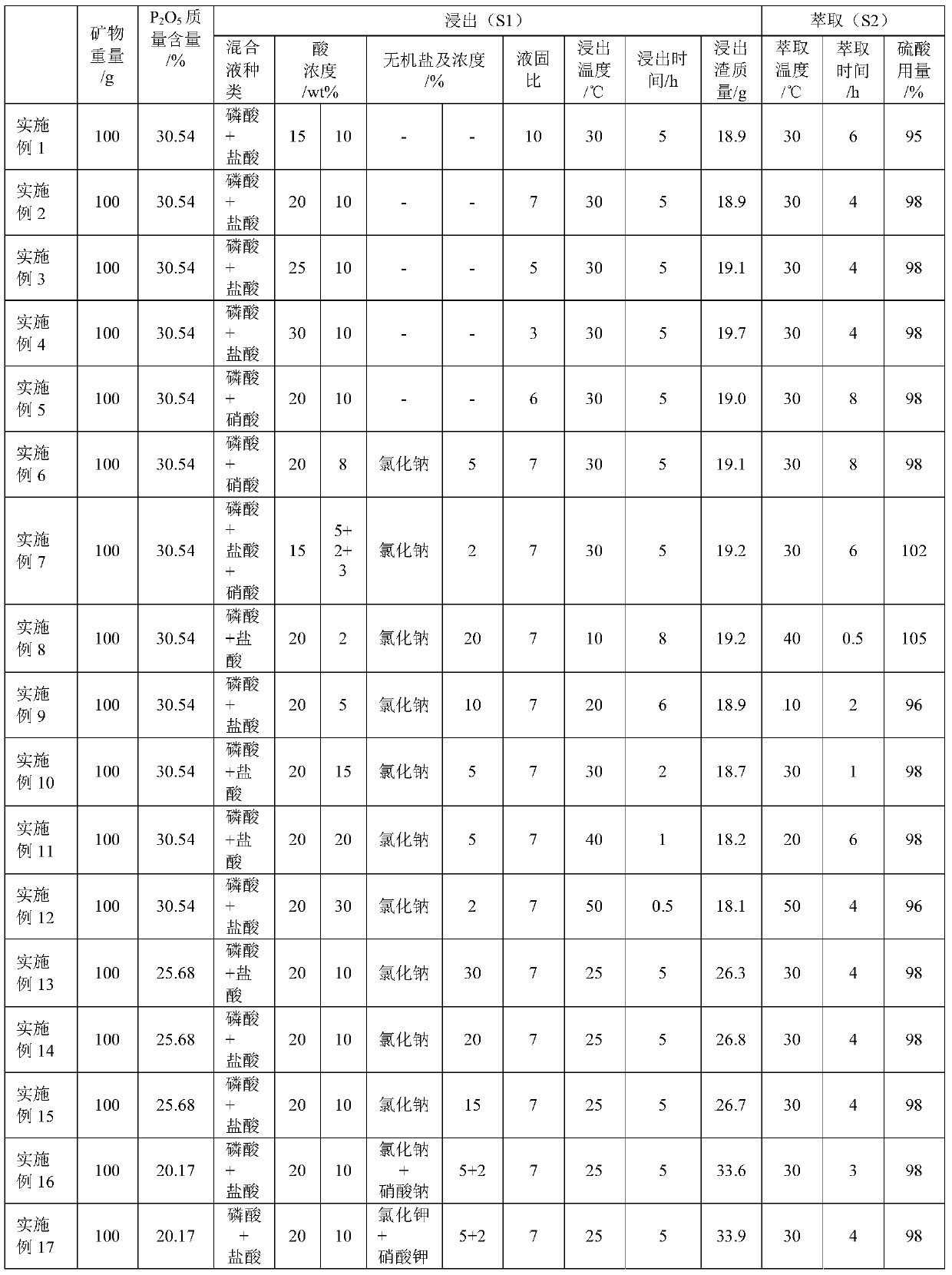

Decomposition method of phosphate rock

ActiveCN107522183BHigh recovery rateReduce dosagePhosphoric acidPregnant leach solutionDecomposition

The invention provides a phosphorite decomposition method which comprises the following steps: S1, leaching out phosphorite by using a mixed solution of phosphoric acid and a solutizer so as to obtain a lixivium and leaching residues; and S2, extracting the lixivium by using sulfuric acid, thereby obtaining ardealite and a phosphoric acid solution. As the phosphorite is decomposed by using the mixed solution of the phosphoric acid and the solutizer, not only are the decomposition ate of phosphorite and the recycling rate of phosphorus increased, but also the amount of the mixed solution for leaching out the phosphorite is reduced, that is, the phosphorus recycling rate is increased on premise that a liquid-solid ratio is reduced. Correspondingly, the amount of the mixed solution is reduced, the liquid-solid ratio of gypsum to extraction residue pulp after the extraction step is reduced, furthermore the treatment amount of the pulp is reduced, and the production efficiency is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

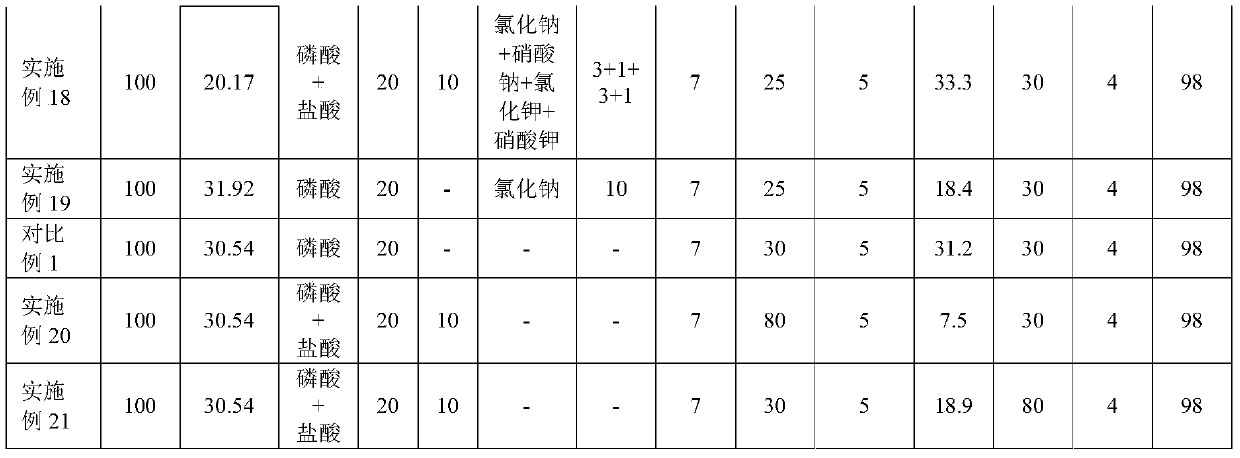

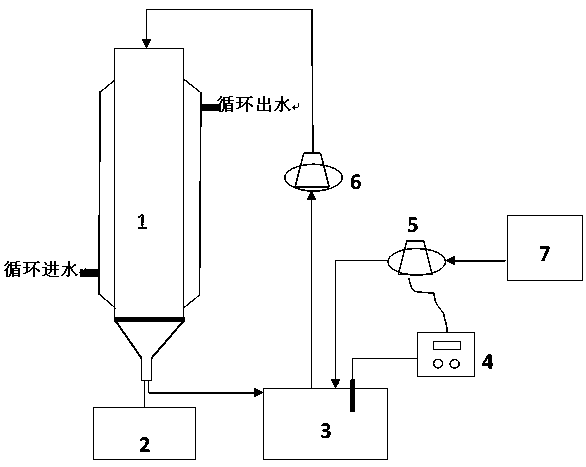

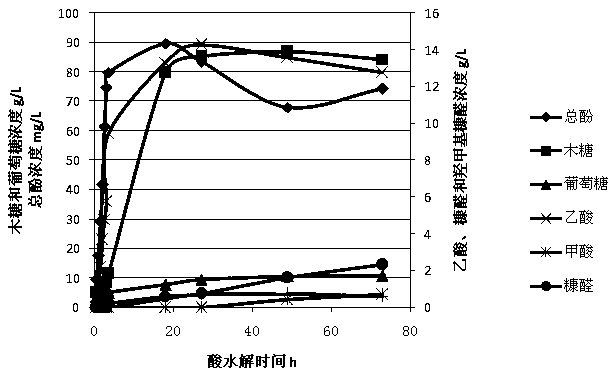

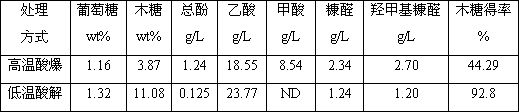

A kind of method for preparing hydrolyzed sugar from lignocellulose raw material

ActiveCN104611391BAvoid negative effectsIncrease fermentation concentrationFermentationHydrolysateXylose

The invention relates to a method for preparing hydrolysis sugar from a lignocellulose raw material. The method comprises the following contents: (1) a column reactor is filled with a lignocellulose granular raw material, the top of the reactor is provided with a hydraulic piston structure capable of compacting the raw material; (2) a dilute acid eluent is heated to 60-99 DEG C and then added into the reactor through the top of the reactor to carry out elution so as to remove part of inhibitors; (3) a dilute acid hydrolysate is heated to 60-99 DEG C and then is added into the reactor through the top of the reactor by a circulating pump to carry out circulated hydrolysis so as to obtain a concentrated hydrolysis sugar liquor; and (4) pH value of the concentrated hydrolysis sugar liquor is adjusted to 4.5-5.5, and cellulose is added into the hydrolysis sugar liquor to carry out circulated enzymolysis so as to obtain a concentrated sugar liquor containing xylose and glucose. The prepared concentrated sugar liquor contains few inhibitors and has high sugar concentration. Negative effects of inhibitors generated during the dilute acid hydrolysis process on cellulase hydrolysis and enzymatically decomposed glucose fermentation for ethanol production are solved, and the hydrolysis sugar concentration process is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of in-situ crystallization type catalytic cracking catalyst

ActiveCN110523427AIntensity is not affectedLarge pore volumeCatalytic crackingMolecular sieve catalystsIn situ crystallizationMicrosphere

The invention provides a preparation method of an in-situ crystallization type catalytic cracking catalyst. The preparation method specially comprises the steps that by adjusting an in-situ crystallization technology, that is, roasted soil balls and a sodium hydroxide solution used for crystallization are mixed firstly, then a guiding agent is directly added for crystallization, any additional silicon source does not need to be added, and thus an in-situ crystallization product with the high crystallization degree, large pore volume and low heap ratio is obtained. Through the preparation method, a conventional method for adding special functional components into kaolin microspheres to improve a pore structure and increase the crystallization degree is avoided; the production cost of the in-situ crystallization product is lowered, as for specific embodiment, the raw material cost is low, and the additional silicon source does not need to be added; and in the synthesis process, the liquid-solid ratio is lowered, and the single-kettle yield is increased.

Owner:PETROCHINA CO LTD

Method for preparing high pure ammonium paramolybdate

InactiveCN1191202CReduce the liquid-solid ratioReduce carryoverCrystallization separationMolybdeum compoundsCooking & bakingEthylenediamine

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

A kind of Garbo fruit leaf handmade soap and preparation method thereof

ActiveCN108485845BImprove antioxidant capacityEfficient extractionAntibacterial agentsSoap detergents with perfumesJojoba oilSemiaquilegia

The invention discloses a myrciaria cauliflora leaf-based handmade soap and a preparation method thereof. The preparation method comprises the following steps: mixing a transparent soap base and rosehydrolat, heating in a water batch for dissolving, then adding four types of base oils, namely sweet almond oil, wheat germ oil, jojoba oil and olive oil respectively, as moisturizing agents, and thenadding a myrciaria cauliflora leaf extract concentrate and a semiaquilegia adoxoides extract concentrate, dripping in citronella essential oil and mint essential oil, uniformly stirring, moulding, standing, ventilating and drying to obtain the myrciaria cauliflora leaf-based handmade soap. The handmade soap prepared by the preparation method provided by the invention, is light brown, semitransparent, natural, safe, mild, smooth and rich in aroma, contains myrciaria cauliflora leaf fragrance, rose fragrance, citronella fragrance and mint fragrance, is a multifunctional handmade soap with antioxidant, antibacterial, itching-relieving, mosquito-repellent effects and the like.

Owner:FUJIAN ACADEMY OF AGRI SCI SUBTROPICAL AGRI RES INST

Vegetable fiber-based polyether polyol and preparation method thereof

The invention discloses a preparation method of vegetable fiber-based polyether polyol. The preparation method comprises the following steps of: (1) stirring and mixing polyethylene glycol and low-molecular polyatomic alcohol according to the mass ratio of (1:1)-(20:1) and obtaining a liquefied reagent; (2) weighing 10 parts by mass of vegetable fiber material which is dried and crushed into 10-200 meshes, and after stirring and mixing with 10-50 parts by mass of liquefied reagent at room temperature, standing for 5 minutes to 12 hours; (3) under stirring, preheating 5-20 parts by mass of liquefied reagent to be 140-180 DEG C, adding the mixture obtained in the step (2), controlling the temperature, adding 0.2-4 parts by mass of inorganic oxyacid simultaneously and gradually, and ensuring simultaneous completion of adding of the mixture and the acid; maintaining the temperature and the stirring state before adding the material, continuously reacting for 20-120 minutes and stopping heating; and (4) adjusting the pH value to be 6-8; and then discharging. In the preparation method, the yield of liquefied products is improved, the liquid-solid ratio is reduced and the cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

A method for circularly extracting phosphorus from sludge ash

The invention discloses a method for circularly extracting phosphorus from sludge ash. In the method, sludge incineration ash is used as a raw material, and sulfuric acid solution is used for extraction once, and then the extract and concentrated sulfuric acid solution are mixed according to the ratio of 28.8:1.2 to 28.4: The volume ratio of 1.6 is mixed and prepared into a new extractant to extract the remaining sludge ash; according to the needs, the sludge ash can be divided into multiple parts for multiple extractions, and the extractant used in the latter extraction is changed from the previous one. After the extraction is completed, the extract is mixed with concentrated sulfuric acid solution. In the present invention, the extract is used as an extractant, which can greatly reduce the discharge of waste liquid, and after cyclic extraction, the extraction rate of phosphorus in sludge ash can exceed 96%, and the concentration of phosphorus in the final extract exceeds 21-23g / L, can effectively solve the technical problems of low phosphorus extraction rate, large consumption of chemicals and large amount of waste liquid in the prior art.

Owner:SICHUAN UNIV

Method for liquefying plant biomass and waste polyester mixed supercritical fluid

ActiveCN101693844BImprove utilization efficiencyRealize pollution-free utilizationLiquid hydrocarbon mixture productionPolyesterBüchner funnel

Owner:莱鼎电子材料科技有限公司

A kind of preparation method of in-situ crystallization type catalytic cracking catalyst

ActiveCN110523427BIntensity is not affectedLarge pore volumeCatalytic crackingMolecular sieve catalystsPtru catalystMicrosphere

The invention provides a method for preparing an in-situ crystallization type catalytic cracking catalyst, specifically, by adjusting the in-situ crystallization process, the roasted soil balls and the sodium hydroxide solution used for crystallization are firstly mixed, and then directly Adding a directing agent for crystallization, without adding any external silicon source, directly obtains a method of in-situ crystallization products with high crystallinity, large pore volume, and low bulk ratio. This method avoids the conventional addition of silicon to kaolin microspheres. Special functional component, method to improve pore structure and increase crystallinity. Moreover, the method reduces the production cost of the in-situ crystallization product, which is embodied in the low raw material cost and no need to add an external silicon source; the liquid-solid ratio decreases during the synthesis process, and the single-pot yield increases.

Owner:PETROCHINA CO LTD

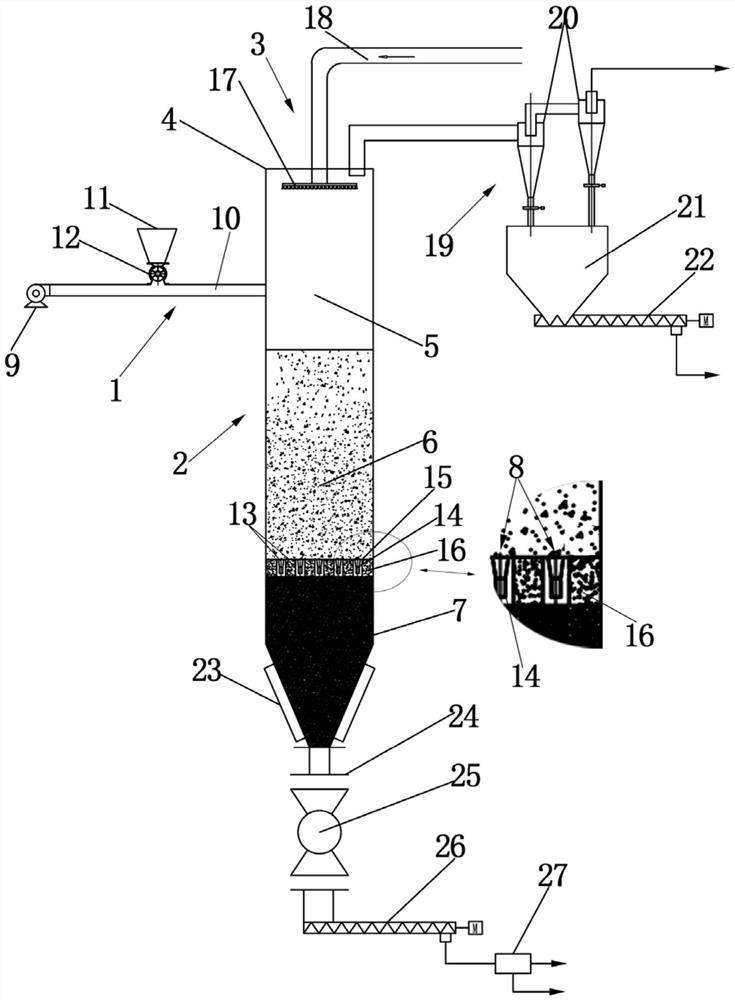

Waste incineration fly ash ultrasonic washing device

PendingCN113909258AShorten cleaning timeImprove solubilityTransportation and packagingSolid waste disposalEnvironmental engineeringFly ash

A waste incineration fly ash ultrasonic washing device is disclosed, a fly ash ultrasonic washing unit comprises a fly ash ultrasonic washing container, and the fly ash ultrasonic washing container is provided with a fly ash pneumatic conveying and entering area, a fly ash washing and dissolving area and a fly ash settling area; and the fly ash washing and dissolving area is located on the lower portion of the fly ash pneumatic conveying and entering area and provided with an ultrasonic assembly. The fly ash settling area is positioned at the lower portion of the fly ash washing and dissolving area; a fly ash conveying unit is connected with the fly ash pneumatic conveying and entering area, and the fly ash conveying unit conveys fly ash to the fly ash pneumatic conveying and entering area; and a spraying unit is connected with the fly ash pneumatic conveying and entering area and is used for spraying the fly ash of the fly ash conveying unit. According to the waste incineration fly ash ultrasonic washing device, the dissolution rate of chlorine salt in the fly ash and the dissolution and flocculation of heavy metal ions can be improved to the greatest extent, the cost is low, and the benefit is high; the liquid-solid ratio is relatively low, water resources are saved, the dehydration performance of the washed fly ash is improved, and the water content of the dehydrated washed fly ash is reduced; and continuous washing and discharging can be realized.

Owner:JIANGSU CHINA NUCLEAR IND HUAWEI ENGDESIGN & RES

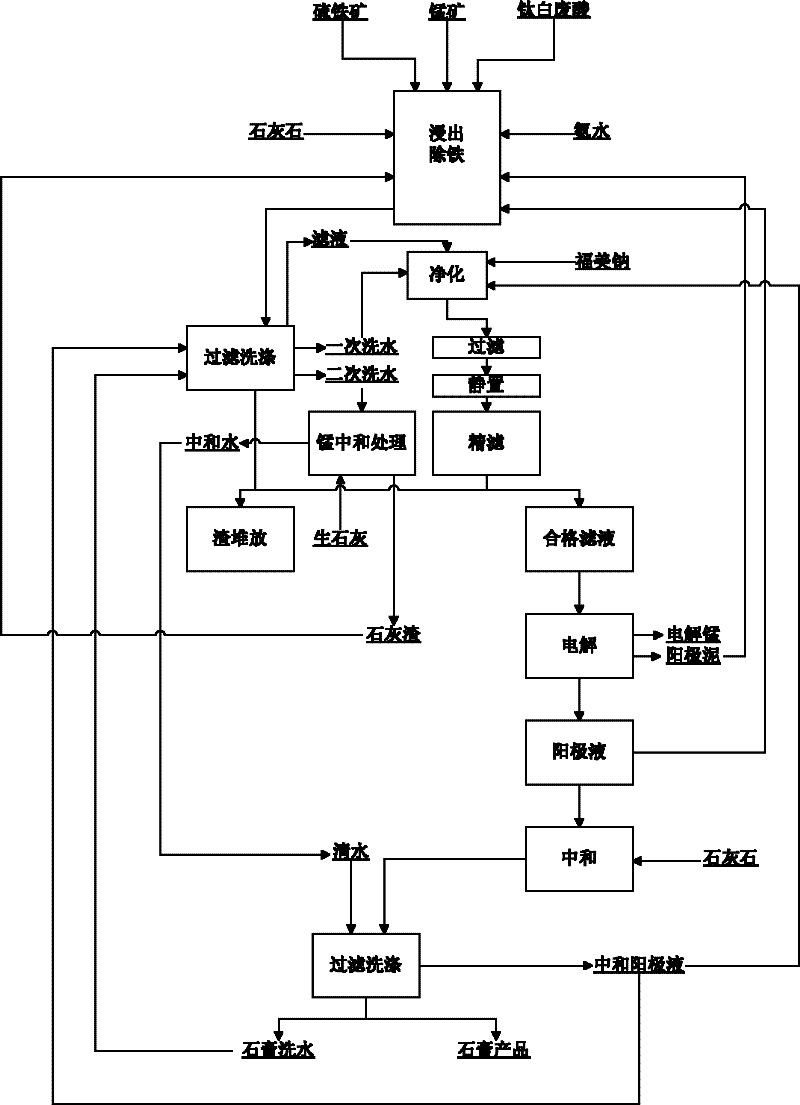

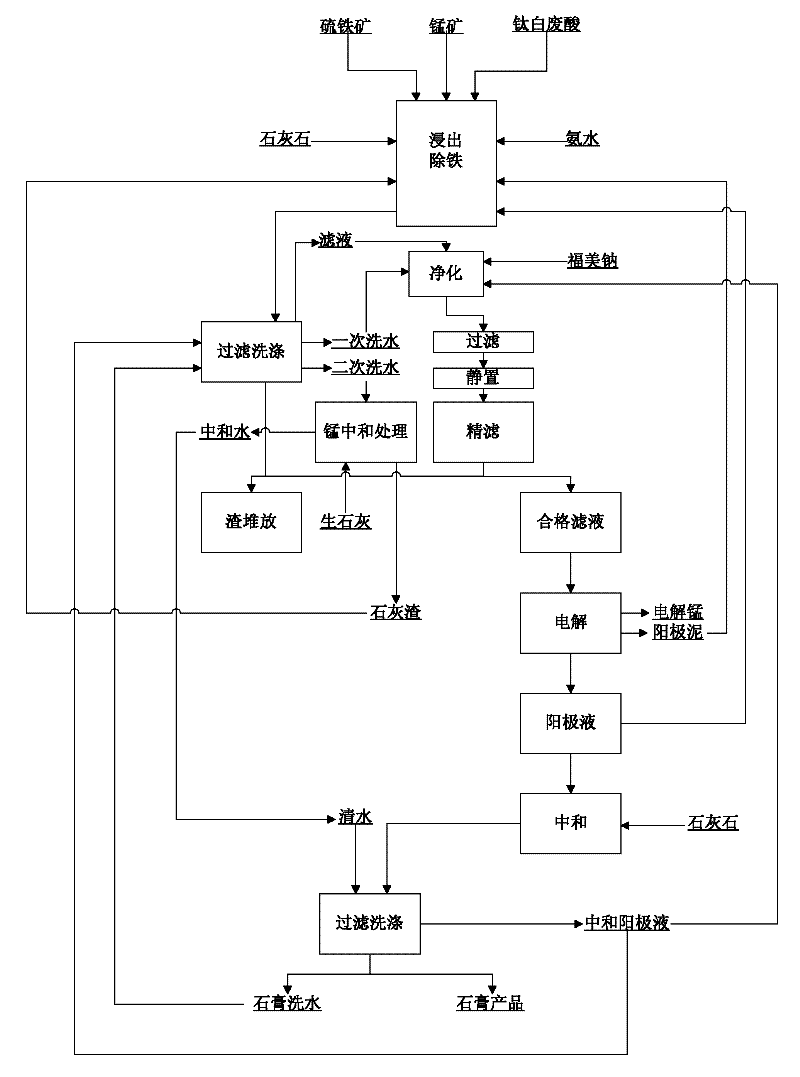

Method utilizing titanium white waste acid to prepare electrolytic manganese metal

ActiveCN101787546BReduce consumptionReduce the liquid-solid ratioPhotography auxillary processesProcess efficiency improvementElectrolysisManganese

The invention relates to a method utilizing titanium white waste acid to prepare electrolytic manganese metal, belonging to the field of metallurgical chemistry. The technical problem that the invention aims at solving is to provide the method with lower production cost for utilizing the titanium white waste acid to prepare the electrolytic manganese metal. The steps of the method are as follows:a. leaching: manganese ore containing manganese dioxide, pyrite ore and the titanium white waste acid are reacted in a reaction container after being heated to the temperature of 90 to 100 DEG C, water in proper quantity is added to make up for the evaporated quantity of water in the reaction process, CaCO3 is added when the pH value of solution is within 1.5 to 2 so as to neutralize the pH valueof the solution to 4.8 to 5.2, and then ammonia water is added to adjust the pH value to 6.2 to 6.4; b. filtering: a reaction product of step a is filtered to obtain filtering solution and filtering residues; c. purifying and removing of heavy metal: sulfide salt is added to the filtering solution obtained in step b so as to remove the heavy metal, and the filtering solution is simply filtered and then filtered in a fine manner after being stewed for 24 to 48 hours so as to obtain the filtering solution that meets the electrolytic requirement; d. electrolyzing: the manganese metal and waste electrolytic solution namely anode solution containing sulfuric acid are obtained.

Owner:PANZHIHUA LIYU MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com