Method utilizing titanium white waste acid to prepare electrolytic manganese metal

A technology for electrolysis of metal manganese and titanium dioxide waste acid, applied in the field of metallurgical chemistry, can solve the problems of high process cost, high liquid-solid ratio, increased energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

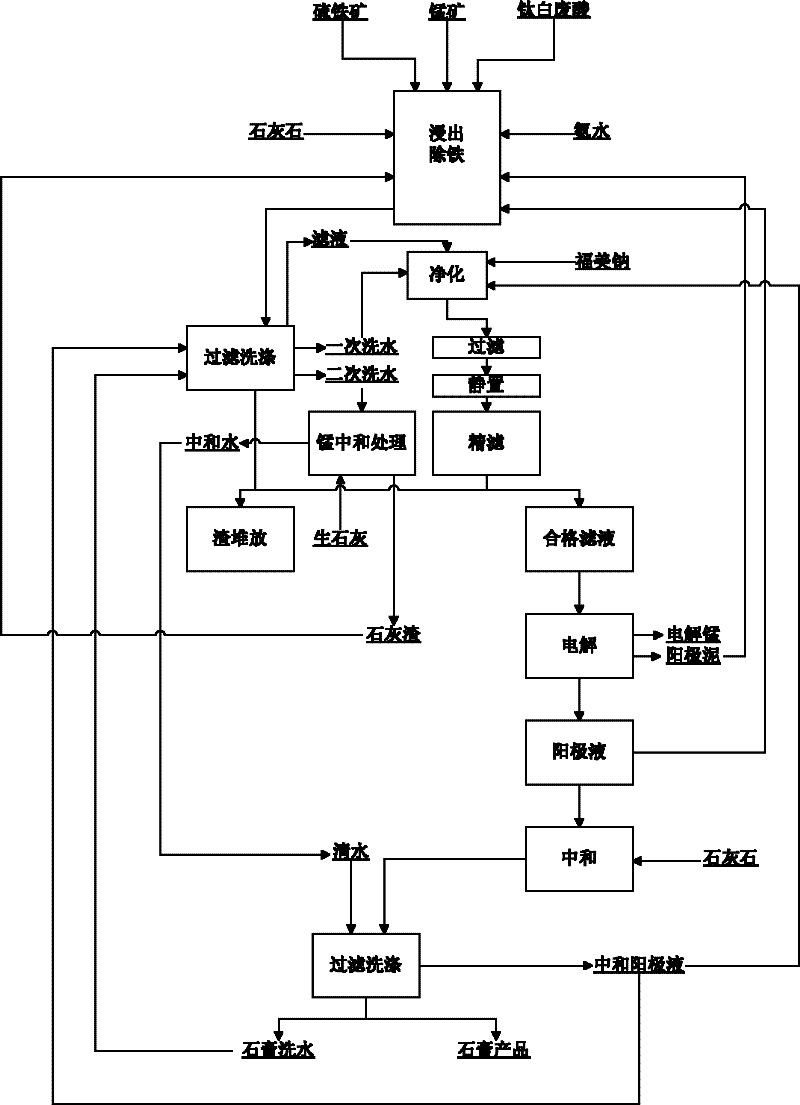

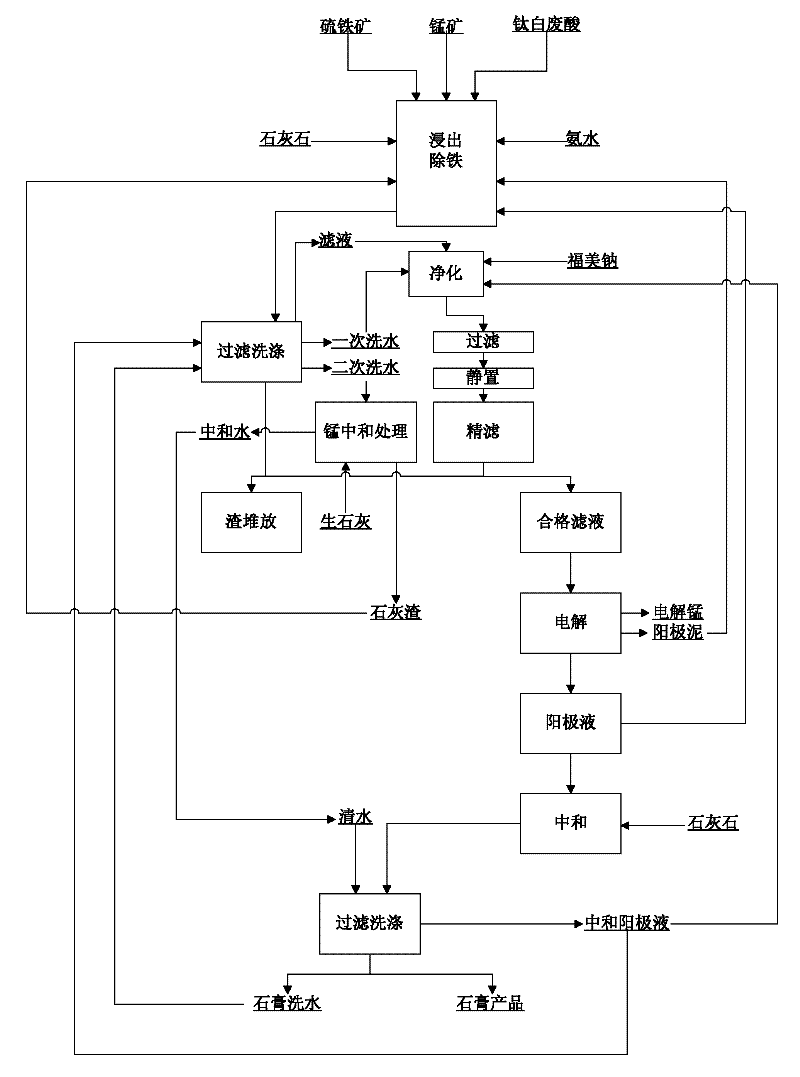

Image

Examples

Embodiment Construction

[0037] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

[0038] Embodiment adopts the inventive method to prepare electrolytic metal manganese

[0039] 1. Put 11kg pyrolusite (containing manganese 39.03%), 3kg pyrite (containing sulfur 41%), 30L titanium white waste acid (containing sulfuric acid 20%, iron 30g / L) into the chemical combination tank for reaction, the reaction process Add 30L of anolyte to make up for the evaporated water and maintain the liquid-solid ratio balance. When the reaction pH value reaches 1.5-2, add 4kg of limestone powder (containing 31% calcium) to neutralize the pH value to 5.0, and then add 400mL of dilute ammonia water ( containing ammonia 8%) to adjust the pH value to 6.2-6.4. The leaching heating adopts steam direct heating method, and the leaching temperature is 95°C (the manganese leaching rate is 95.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com