Method for pretreating cellulosic biomass

A technology of cellulose and biomass, applied in the chemical field, can solve the problems of large water consumption, high energy consumption of steam explosion treatment, and easy production of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

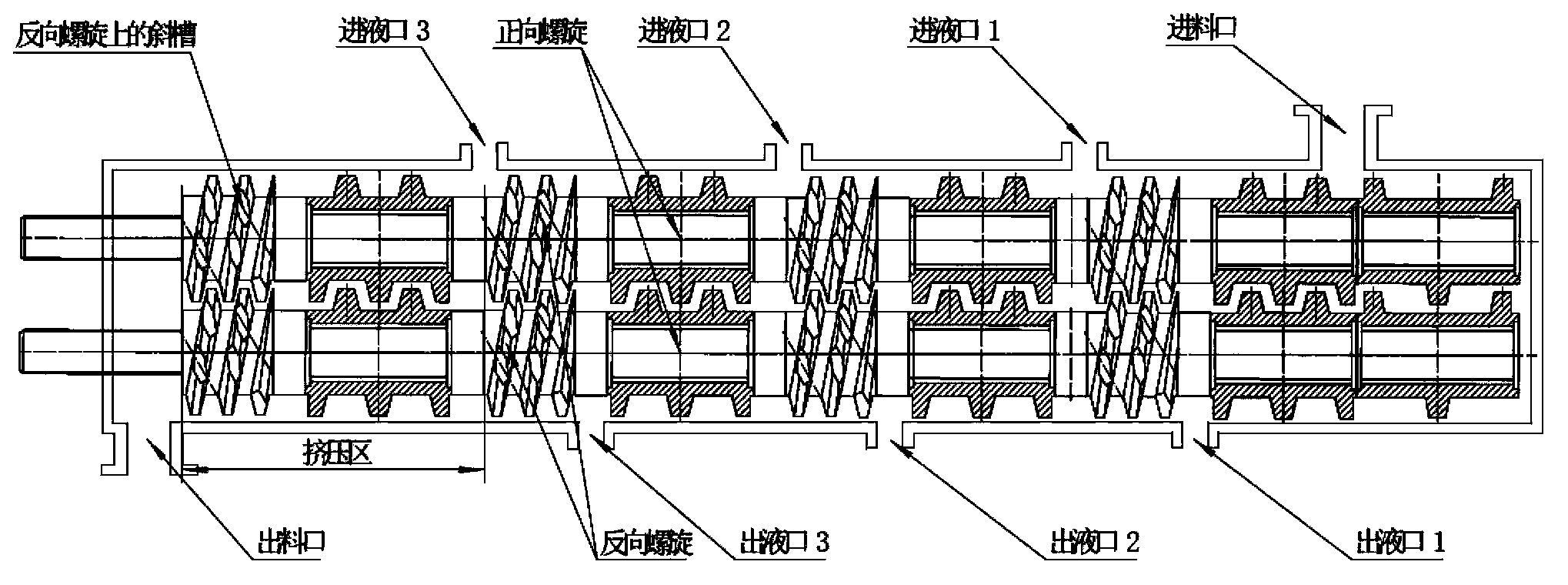

Embodiment 1

[0076] The air-dried corn stalks were cut to 3-5 cm with a guillotine, and loaded into a twin-screw extruder (Hebei Tianzheng Screening and Pulping Equipment Co., Ltd., TEP80) through the feed port. Water is added through the feed port for washing, and the water content in the extruded material can be adjusted through the liquid outlet. In this embodiment, the water content is controlled so that the material concentration is about 50% (ie, the mass of water included is equivalent to 1 times the mass of the dry material). Add a sodium hydroxide solution with a concentration of 6% through the liquid inlet 3, and adjust the final concentration and consumption of the sodium hydroxide solution appropriately through the liquid outlet and the liquid inlet. In this embodiment, the amount of sodium hydroxide solution is controlled so that the material concentration is further reduced to about 33% (that is, the quality of the used sodium hydroxide solution is equivalent to 1 times the q...

Embodiment 2

[0082] The air-dried corn stalks were preliminarily crushed to 1-3 cm with a pulverizer, and loaded into a twin-screw extruder (Hebei Tianzheng Screening and Pulping Equipment Co., Ltd., TEP80) through the feed port. Water is added through the feed port for washing, and the water content in the extruded material can be adjusted through the liquid outlet. In this embodiment, the water content is controlled so that the material concentration is about 45%. Add a 10% sodium hydroxide solution through the liquid inlet 3, and adjust the final concentration and dosage of the sodium hydroxide solution appropriately through the liquid outlet and the liquid inlet. In this embodiment, the amount of sodium hydroxide solution is controlled so that the material concentration is further reduced to about 35% (that is, the quality of the used sodium hydroxide solution is equivalent to 0.6 times the quality of the dry material).

[0083] The rotational speed of the spindle of the twin-screw ex...

Embodiment 3

[0088] The air-dried corn stalks were preliminarily crushed to 1-3 cm with a pulverizer, and loaded into a twin-screw extruder (Hebei Tianzheng Screening and Pulping Equipment Co., Ltd., TEP80) through the feed port. Water is added through the feed port for washing, and the water content in the extruded material can be adjusted through the liquid outlet. In this embodiment, the water content is controlled so that the material concentration is about 50%. Add a sulfuric acid solution with a concentration of 1% through the liquid inlet 2, and adjust the final concentration and dosage of the sulfuric acid solution appropriately through the liquid outlet and the liquid inlet. In this embodiment, the amount of sulfuric acid solution is controlled so that the concentration of the material is further reduced to about 35% (that is, the mass of the sulfuric acid solution used is equivalent to 0.8 times the mass of the dry material).

[0089] The rotational speed of the spindle of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com