A method for preparing cobalt phosphate by separating cobalt lithium from waste lithium battery lithium cobaltate

A technology for waste lithium batteries and lithium cobalt oxide, applied in chemical instruments and methods, solid waste removal, phosphorus compounds, etc., can solve the problems of secondary pollution, complicated recycling process, low recycling efficiency, etc., and achieve separation and recycling High efficiency, solve the effect of complex recycling process and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

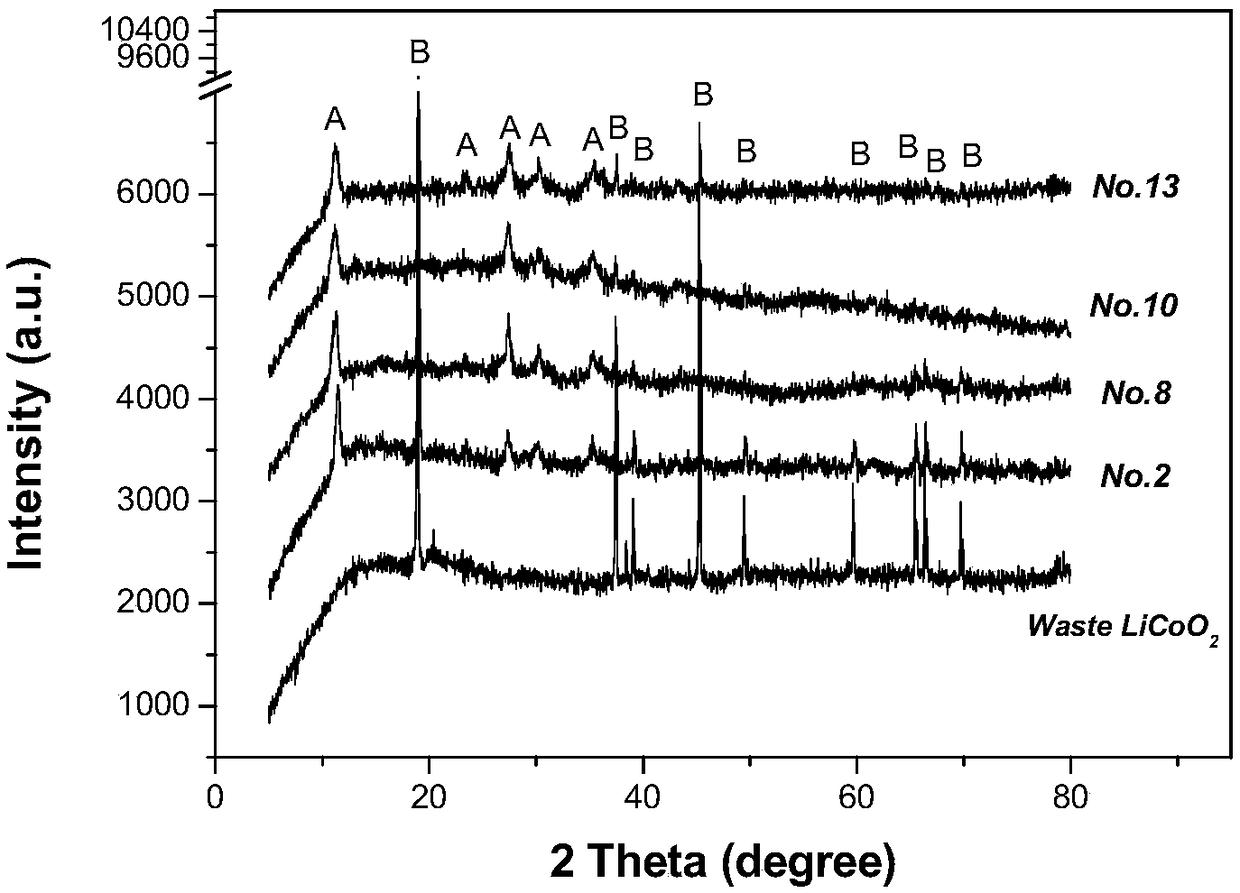

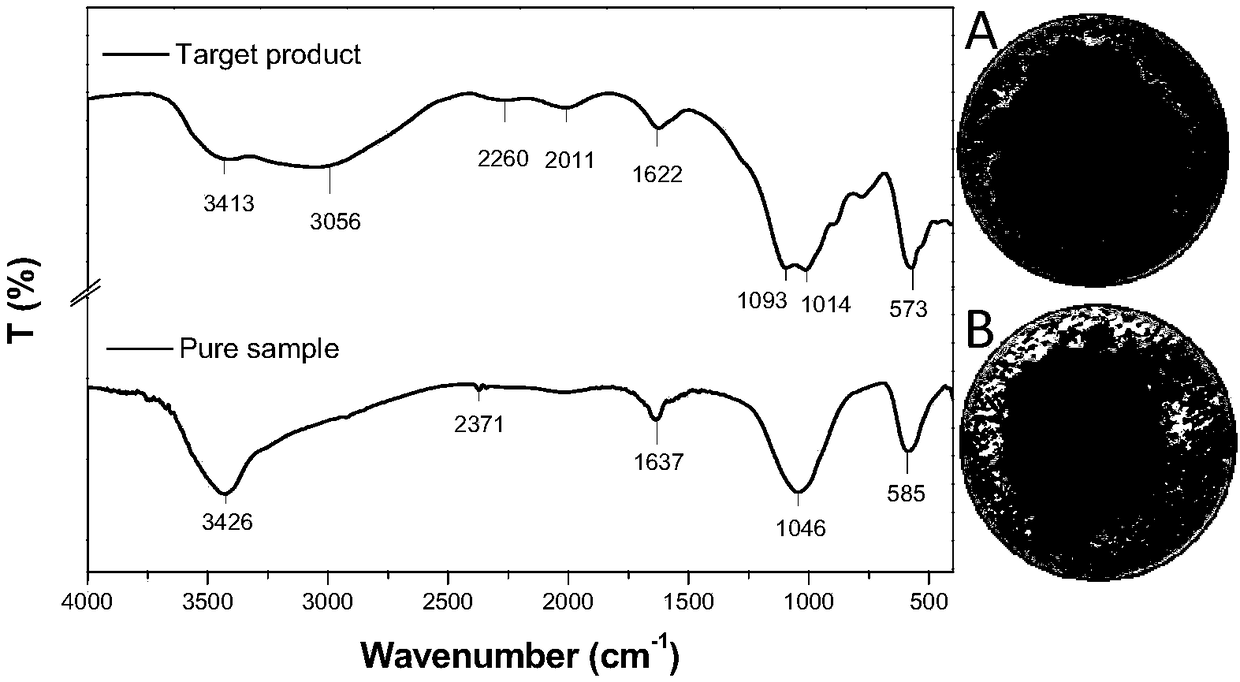

[0027] (1) Take about 5kg of typical waste lithium batteries (the positive electrode active material is LiCoO 2 ) for disassembly and pretreatment, and the metal case, separator, current collector pole piece (Al foil and Cu foil), positive and negative active material powder mixture and other components can be obtained respectively. Then the obtained 2.17kg positive and negative electrode active material powder (the main component is LiCoO 2 and C) calcined in a muffle furnace at 700 °C for 2 h, fully ground in a ball mill and passed through a 200-mesh sieve to obtain 1.38 kg of fine-grained waste LiCoO 2 powder.

[0028] (2) Then each time accurately weigh the LiCoO of the fine particles obtained above 2 About 5 grams of powder were placed in a 250mL three-necked flask; corresponding orthogonal experiments were designed (L16(4 5 ), a total of 16 experiments: No.1~No.16), under the experimental conditions of controlling the reaction temperature at 40~80℃, the stirring rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com