Preparation method of in-situ crystallization type catalytic cracking catalyst

A catalytic cracking and in-situ crystallization technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as a large increase in white powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

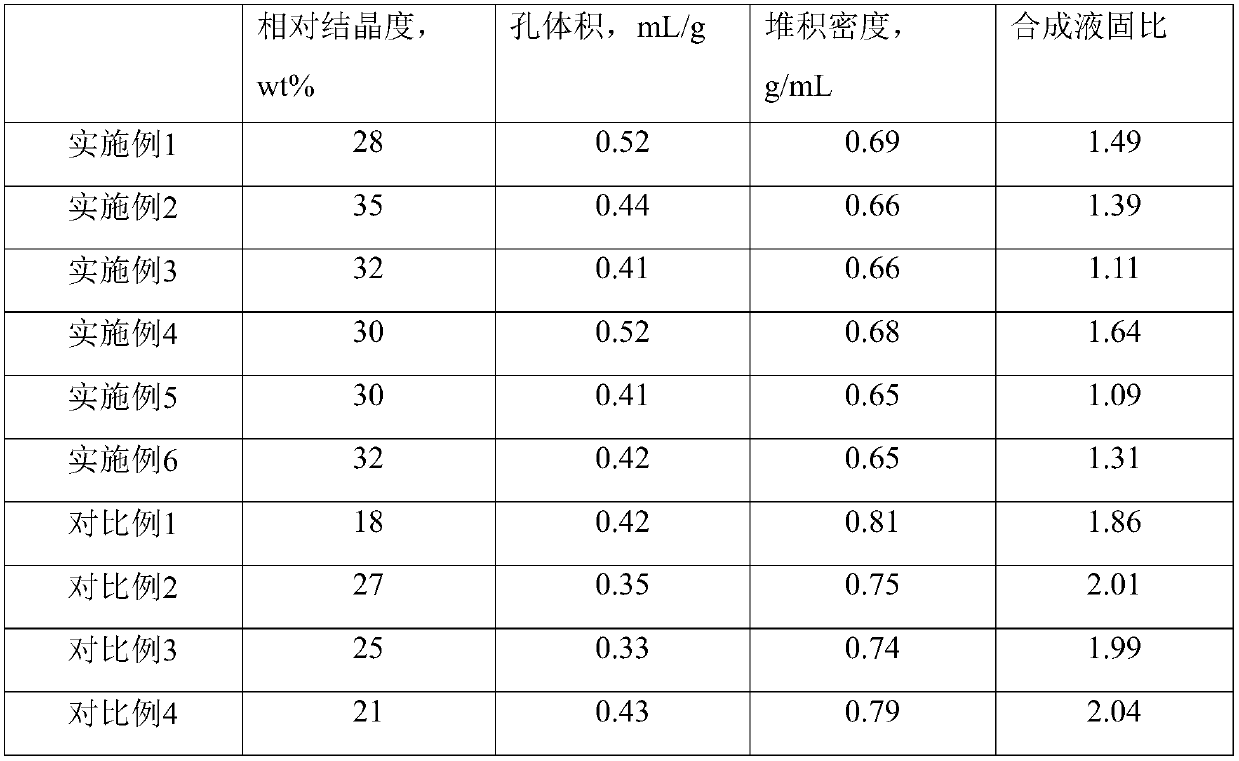

Examples

Embodiment 1

[0038] 10 kg of kaolin and water are prepared into a slurry with a solid content of 35%, and 500 g of sodium silicate is added as a dispersant, and spray molding is performed. The resulting sprayed soil ball was calcined at 940°C for 2h. After roasting, 1kg of the calcined soil ball was stirred with a 10% sodium hydroxide solution with a mass concentration of 1050mL and heated to 85°C for 120min, then 200g of directing agent was added, heated to 93°C, static crystallization for 25h, filtered, washed, and dried.

Embodiment 2

[0040] 10 kg of kaolin and water are prepared into a slurry with a solid content of 27%, and 1000 g of aluminum sol is added as a dispersant, and sprayed. The sprayed soil balls are calcined at 920°C for 6 hours to obtain high soil balls, and at 600°C for 6 hours to obtain partial soil balls. After roasting 800g of high soil ball and 200g of partial soil ball and 950mL with a mass concentration of 18% sodium hydroxide solution, stir, and heat up to 70℃ for 180min, then add 220g of directing agent, heat up to 96℃, stir and crystallize for 24h, Filter, wash and dry.

Embodiment 3

[0042] 10 kg of kaolin and water are prepared into a slurry with a solid content of 40%, and 500 g of aluminum sol is added as a dispersant, and sprayed. The sprayed soil balls are calcined at 1030°C for 1.5 hours to obtain high soil balls, and at 850°C for 1.5 hours to obtain partial soil balls. The calcined high soil balls 650g and 350g partial soil balls are stirred with 750mL of a 20% sodium hydroxide solution with a mass concentration and heated to 100°C for 45min, then 180g of directing agent is added, heated to 85°C, stirred and crystallized for 36h. Filter, wash and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com