Patents

Literature

177 results about "In situ crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst of catalyzing, cracking for reducing sulfur content in gasoline and preparation process thereof

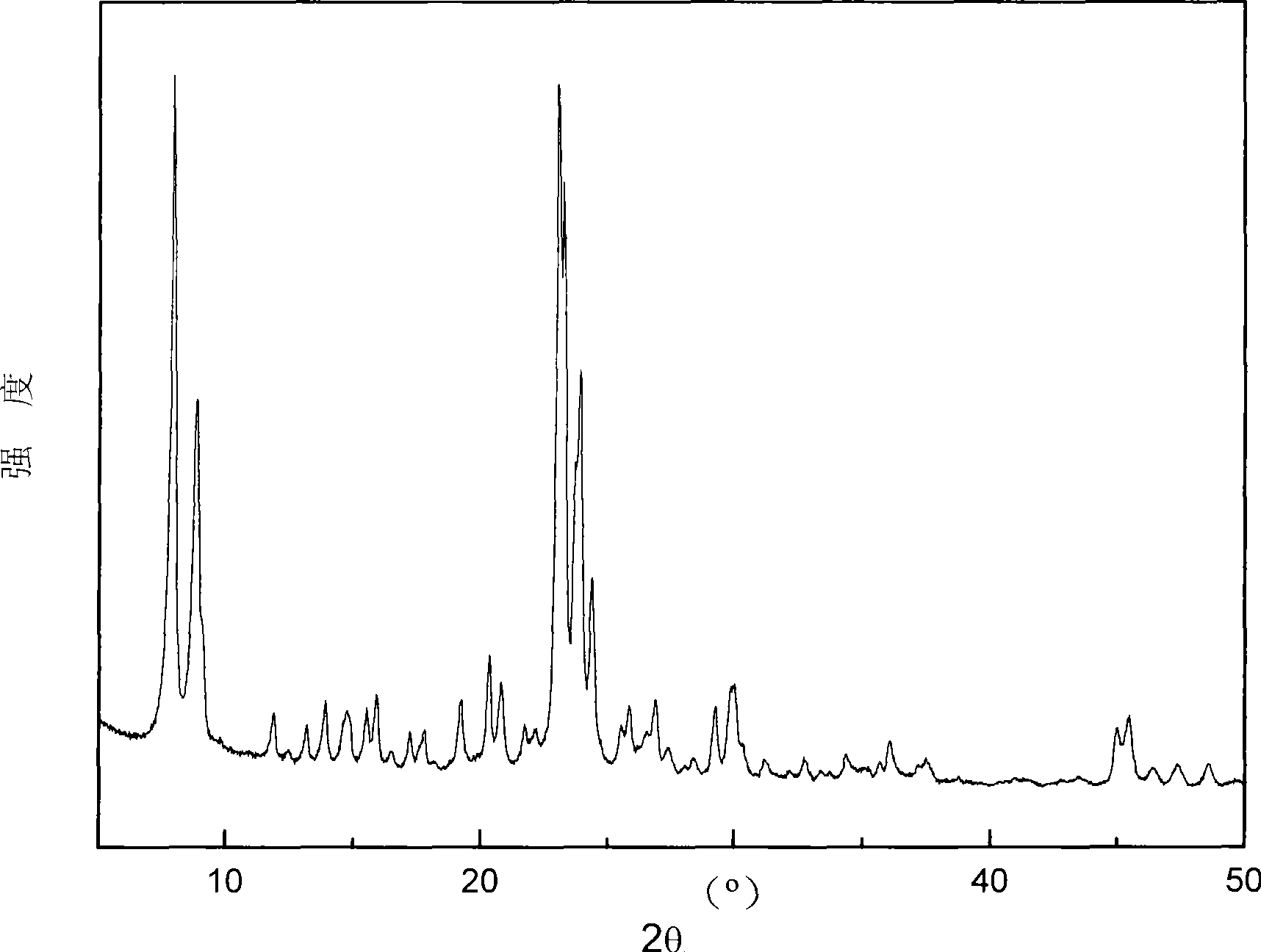

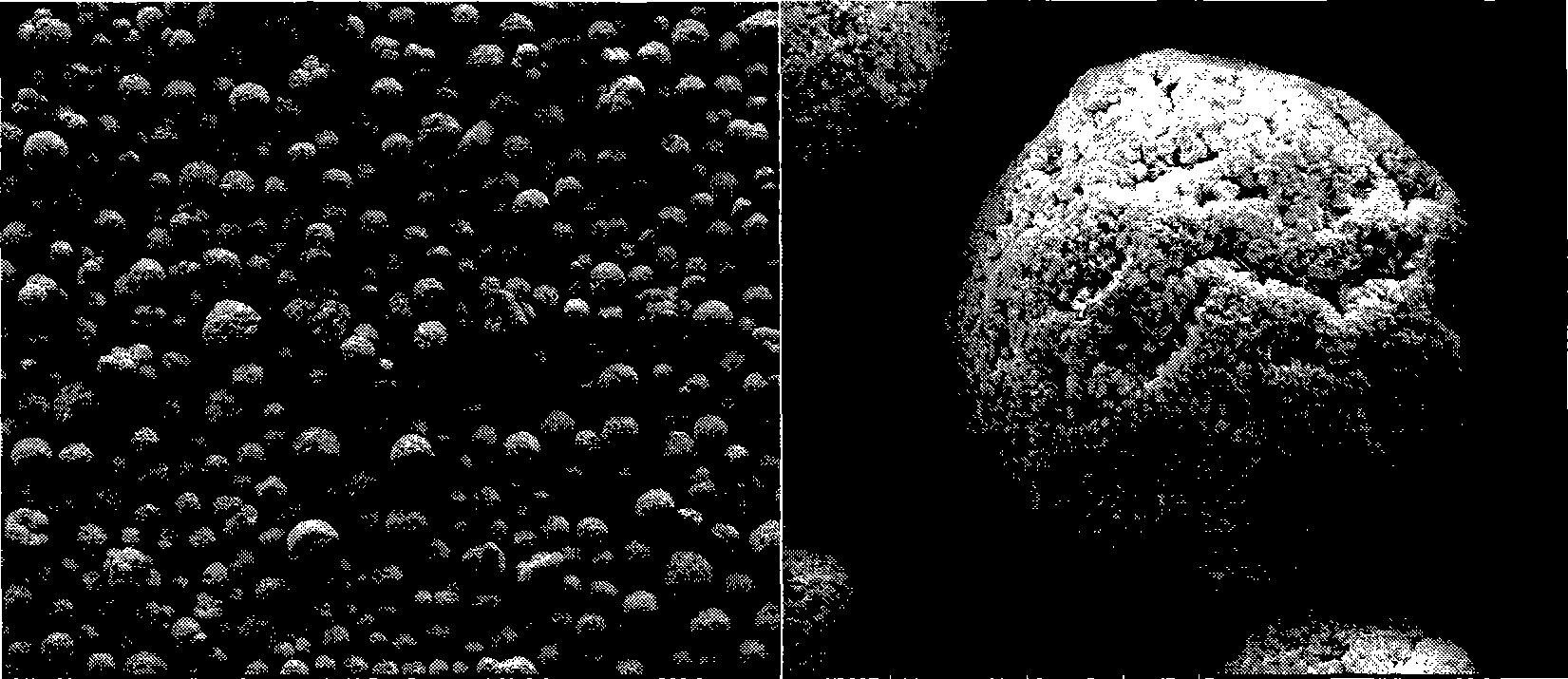

InactiveCN1597850AGood dispersionGood hydrothermal stabilityCatalytic crackingMolecular sieveIn situ crystallization

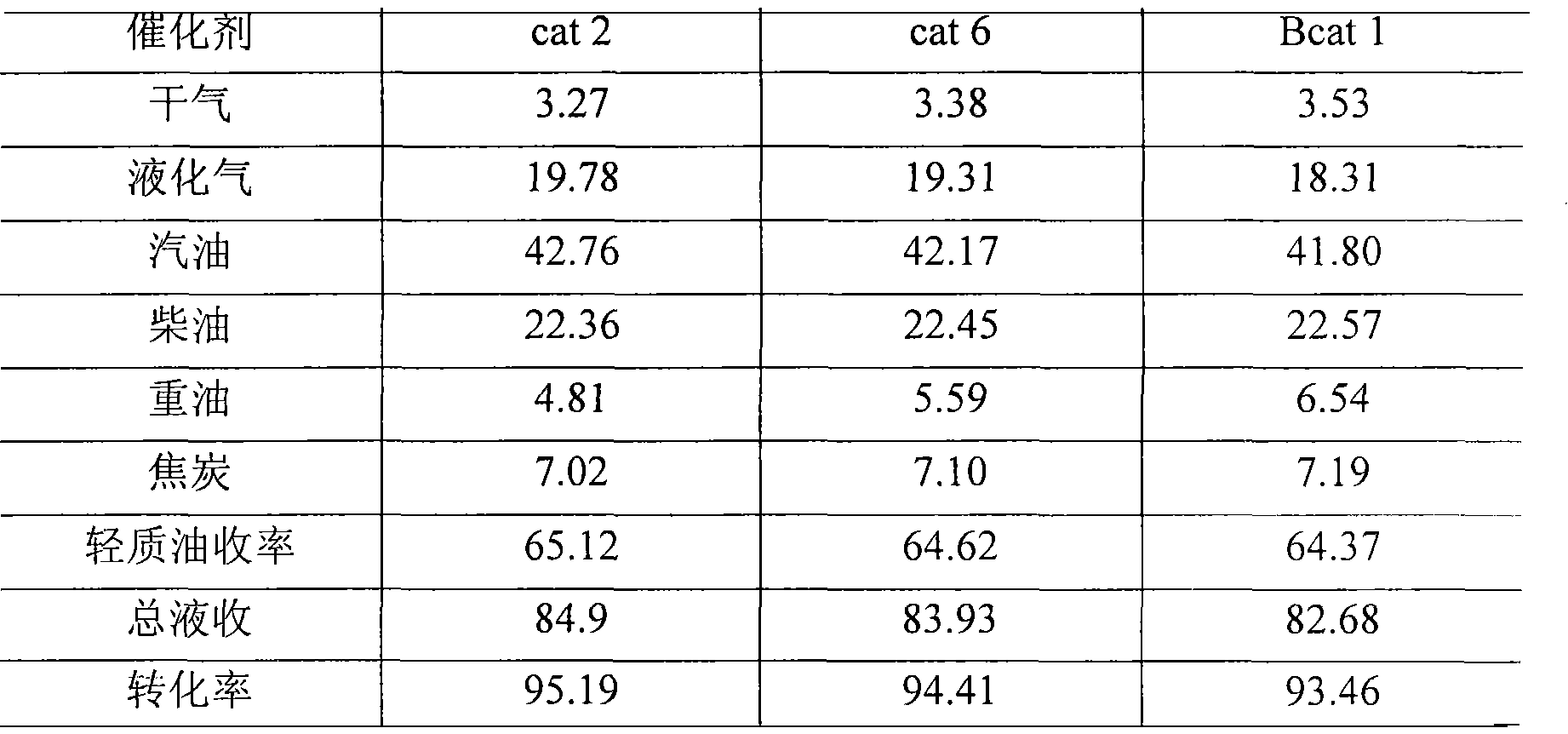

The invention is a catalytic cracking catalyst to reduce sulfur content of gasoline and its preparing method, synthesis gama-type molecular sieve by kaoline in-situ crystallization and making exchange sodium reduction or / and rare-earth ion exchange processing to prepare it, and its characteristic: the weight percent of sodium oxide contained in it is less than 0.75%, the ratio of zeolite to silica-alumina is above 4.5, and it adds one or several of the sourish metal elements: Cu, Zn, Fe, Al, Ni, Zr, Sn, Ga, Ti and V in weight percent of 0.1-10%. It has good zeolite dispersivity and excellent hydrothermal stability, good catalytic cracking property, and excellent function of reducing sulfur content of gasoline. It can be used by mixing with routine FCC catalyst and also be singly applied in the catalytic cracking process course.

Owner:PETROCHINA CO LTD

Microporous Aluminophosphate Molecular Sieve Membranes for Highly Selective Separations

InactiveUS20090114089A1High selectivityGood chemical and thermal stabilityPhosphatesPretreated surfacesChemical stabilityPolymer

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

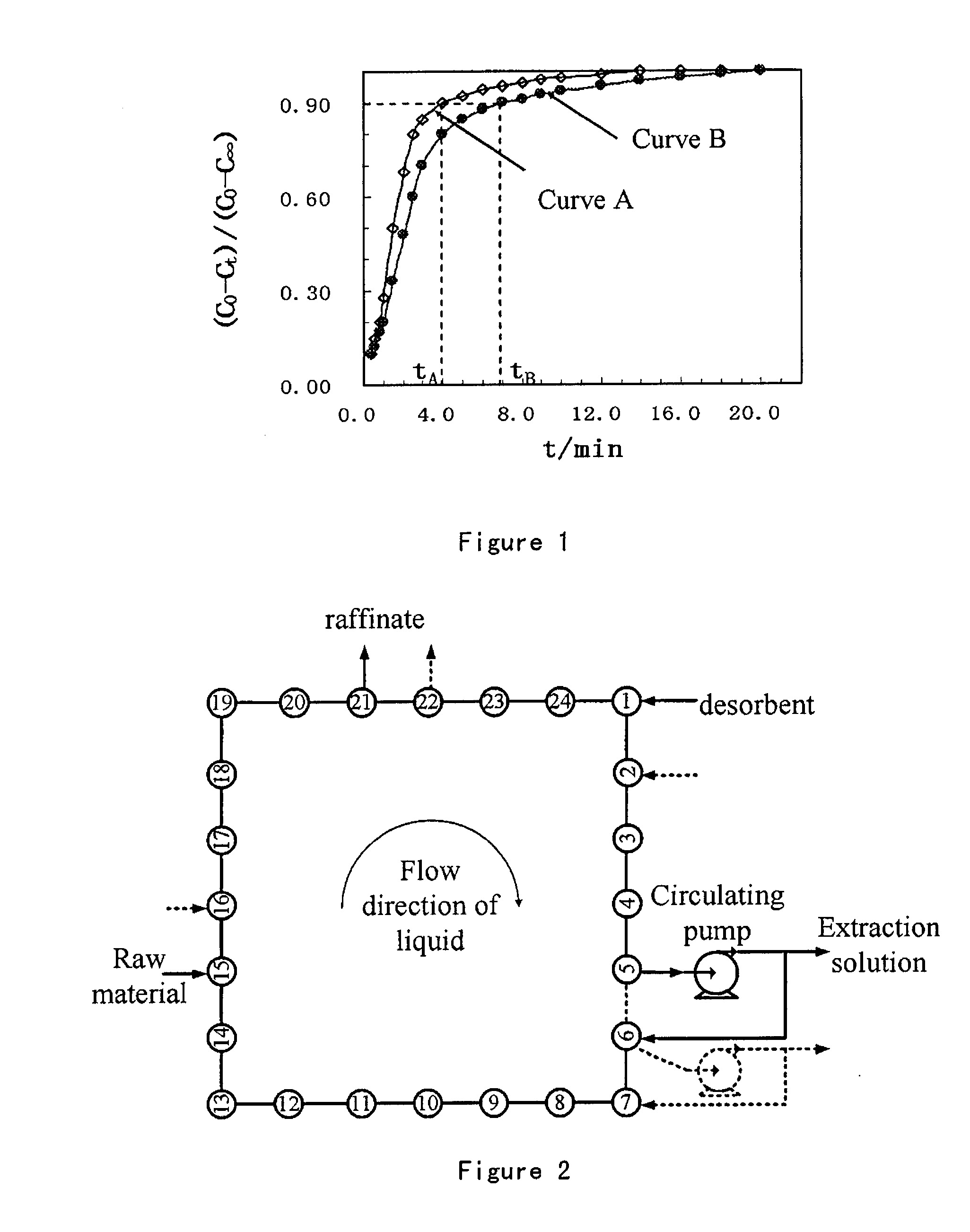

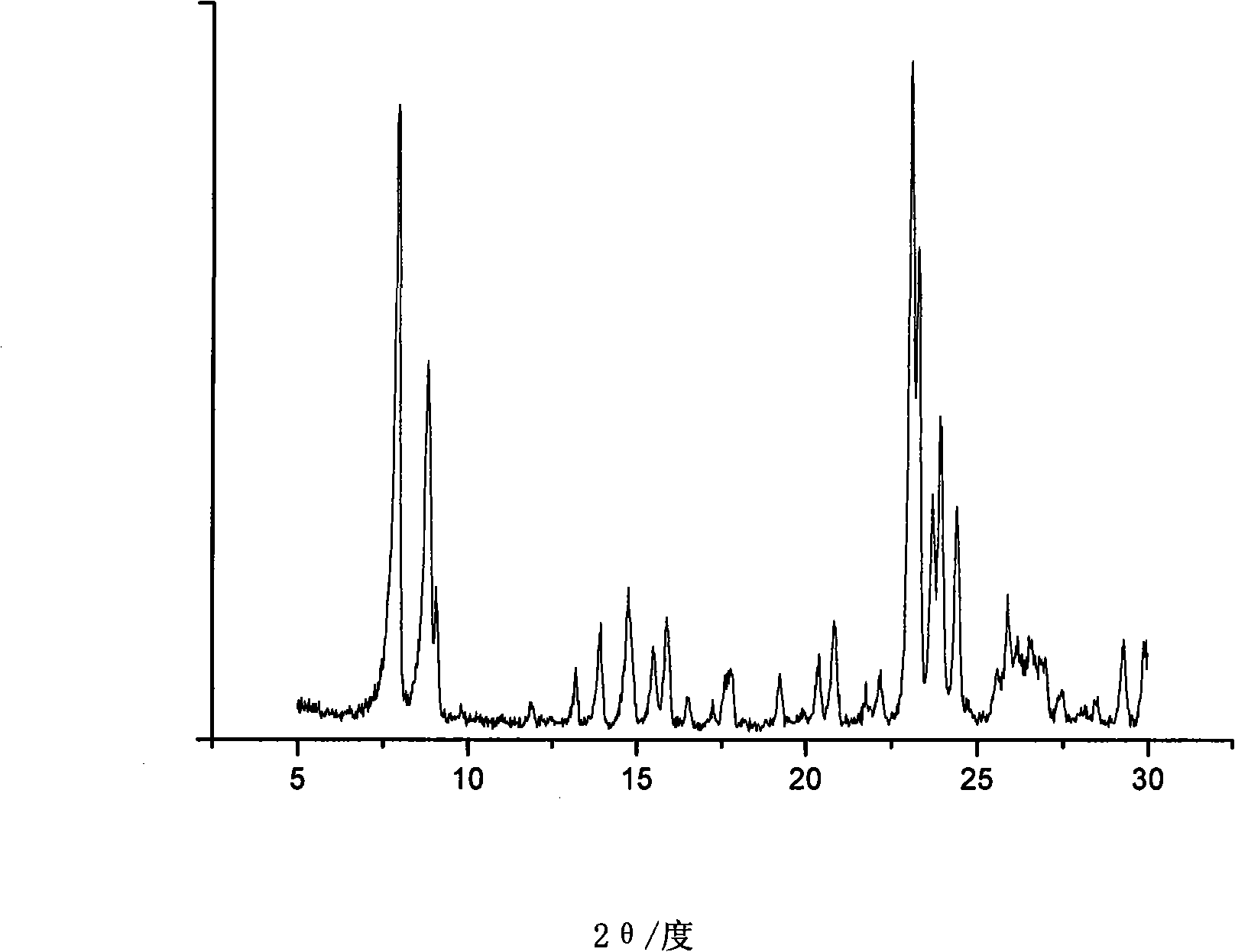

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

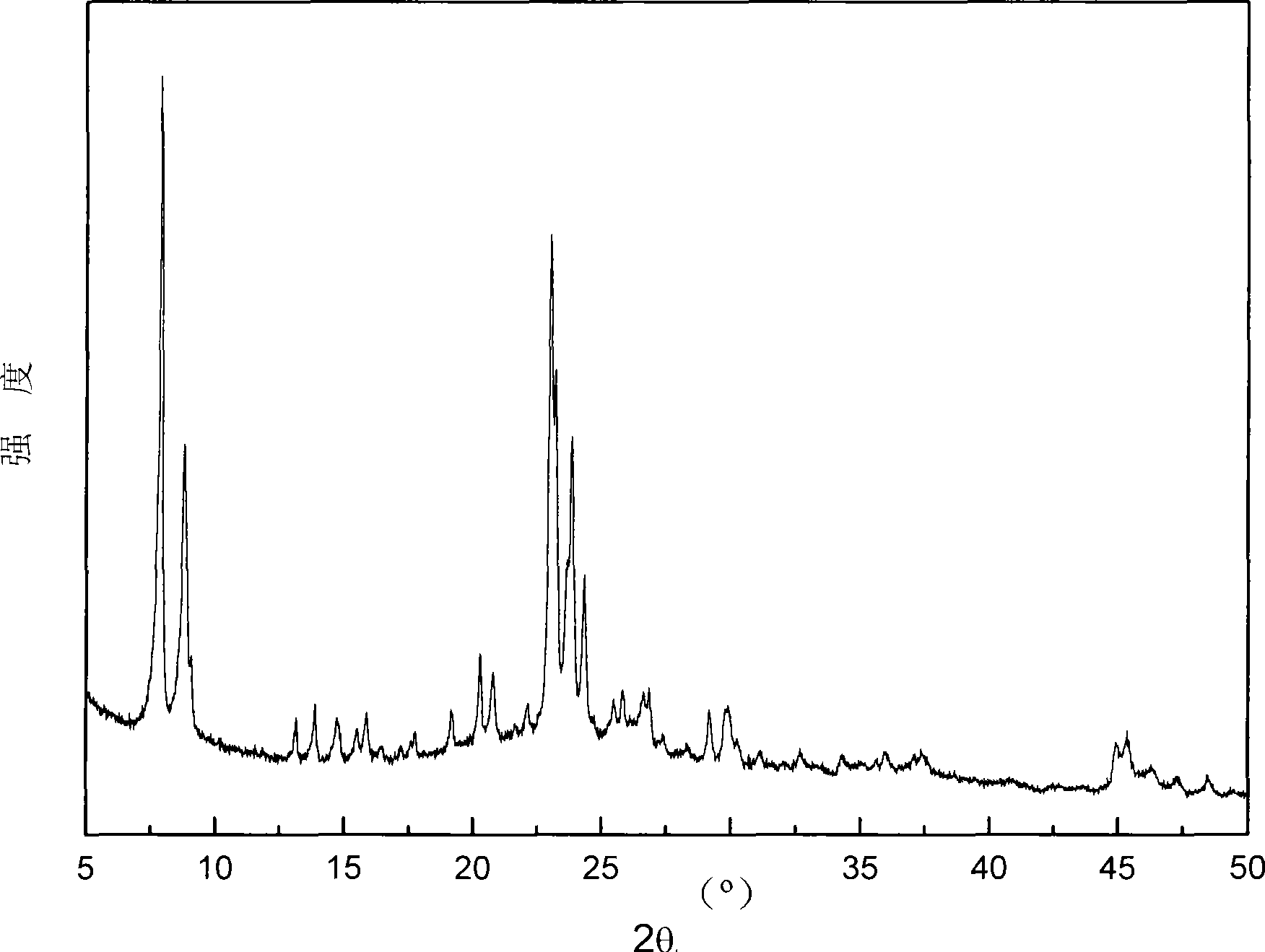

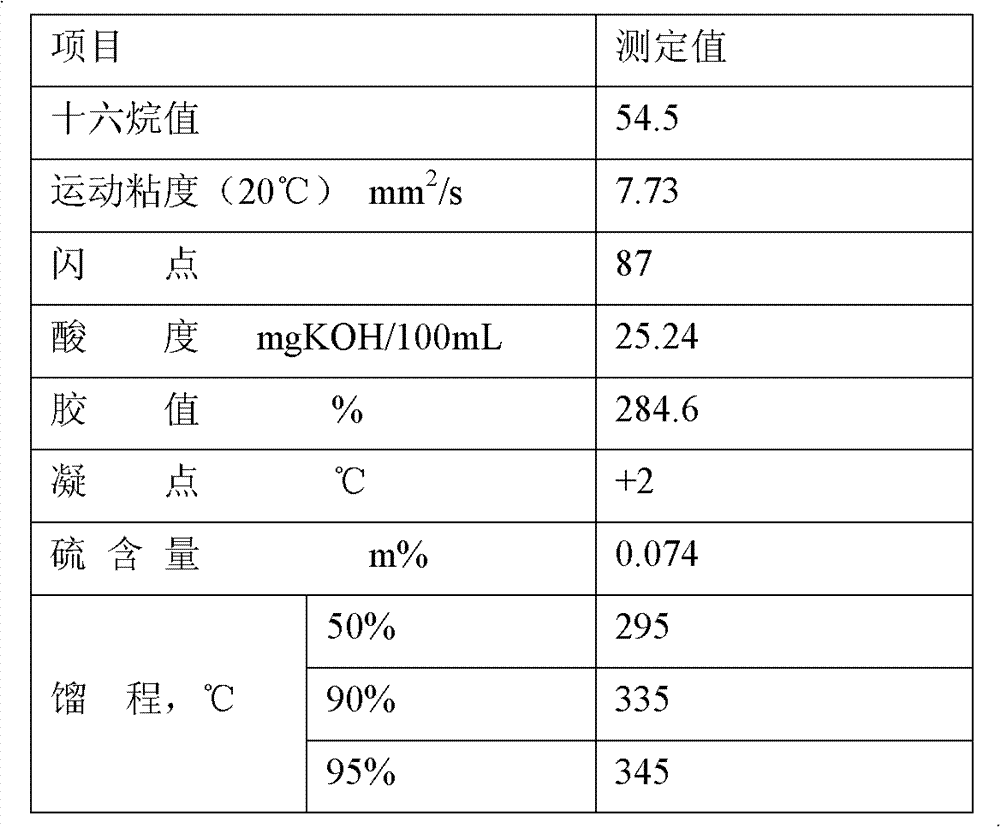

Catalytic cracking co-catalyst for producing diesel oil and its preparing method

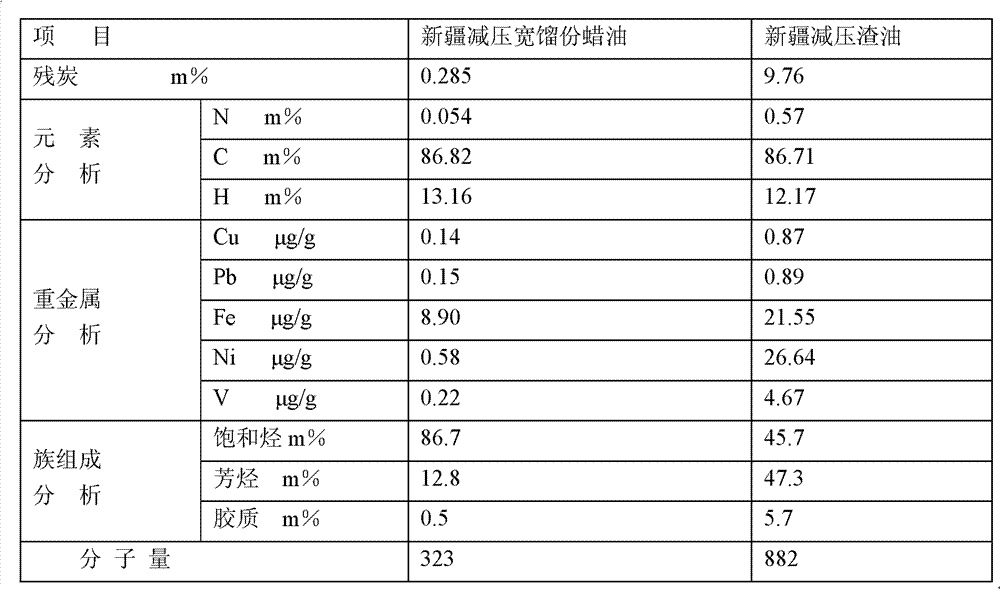

InactiveCN1683474AReasonable hole structureReasonable strengthCatalytic crackingIn situ crystallizationSodium oxide

The catalytic cracking co-catalyst for increasing diesel oil yield is prepared through roasting kaolin at over 900 deg.c for in-situ crystallization. The co-catalyst contains type-Y zeolite in 5-20 wt%, as well as magnesia 0.5-3 wt%, RE oxide 0.5-5 wt%, and sodium oxide less than 0.6 wt%, and the zeolite has Si / Al ratio of 4.0-6.0. Adding certain amount of the catalytic cracking co-catalyst without altering the main catalyst in the oil refining apparatus can raise diesel oil yield of FCC catalyzed apparatus, improve product distribution, raise available catalyst utilization, and improve the activity stability of the catalyst system and heavy metal resistance.

Owner:PETROCHINA CO LTD

Compound type cracking catalyst and preparation method thereof

InactiveCN102133542AGood hydrothermal stabilityImprove pollutionCatalytic crackingMolecular sieve catalystsIn situ crystallizationMolecular sieve

The invention discloses a compound type cracking catalyst which contains the following materials according to dry basis mass: 20-70% of in-situ crystallization Y-shaped molecular sieve / matrix composite material, 0.3-12% of MFI structural molecular sieve, and 30-75% of clay and inorganic oxide bonding agent. The in-situ crystallization Y-shaped molecular sieve / matrix composite material is the matrix formed after the in-situ crystallization is conducted on kaolin, and is one or a mixture of REY, REHY, HY, REUSY and USY formed by modification of Nay combined by surface in-situ crystallization. The catalyst has excellent capability of resisting heavy metal pollution and heavy oil cracking, and good coking selection.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing kaolin in-situ crystallization ZSM-5 molecular sieve

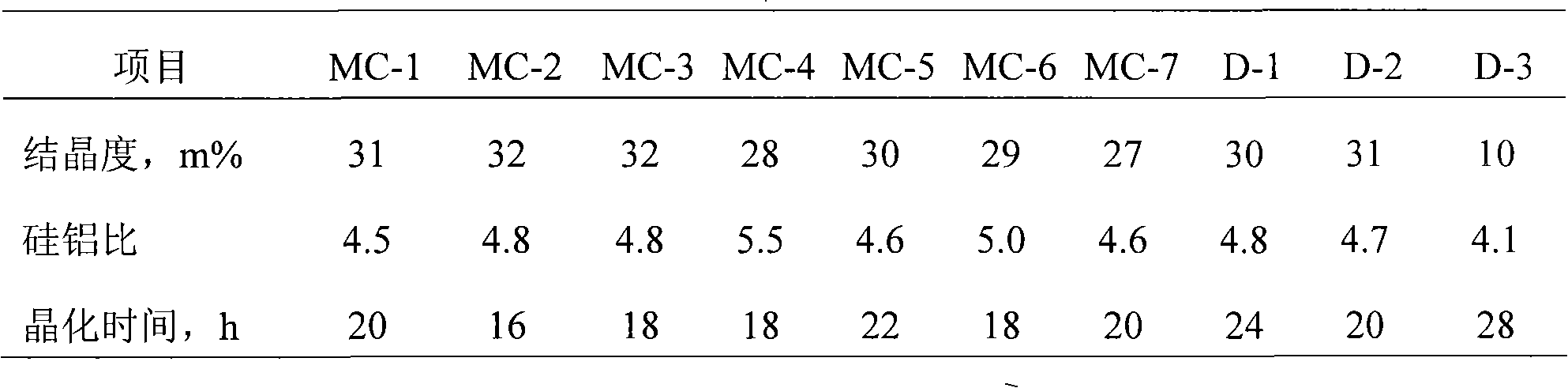

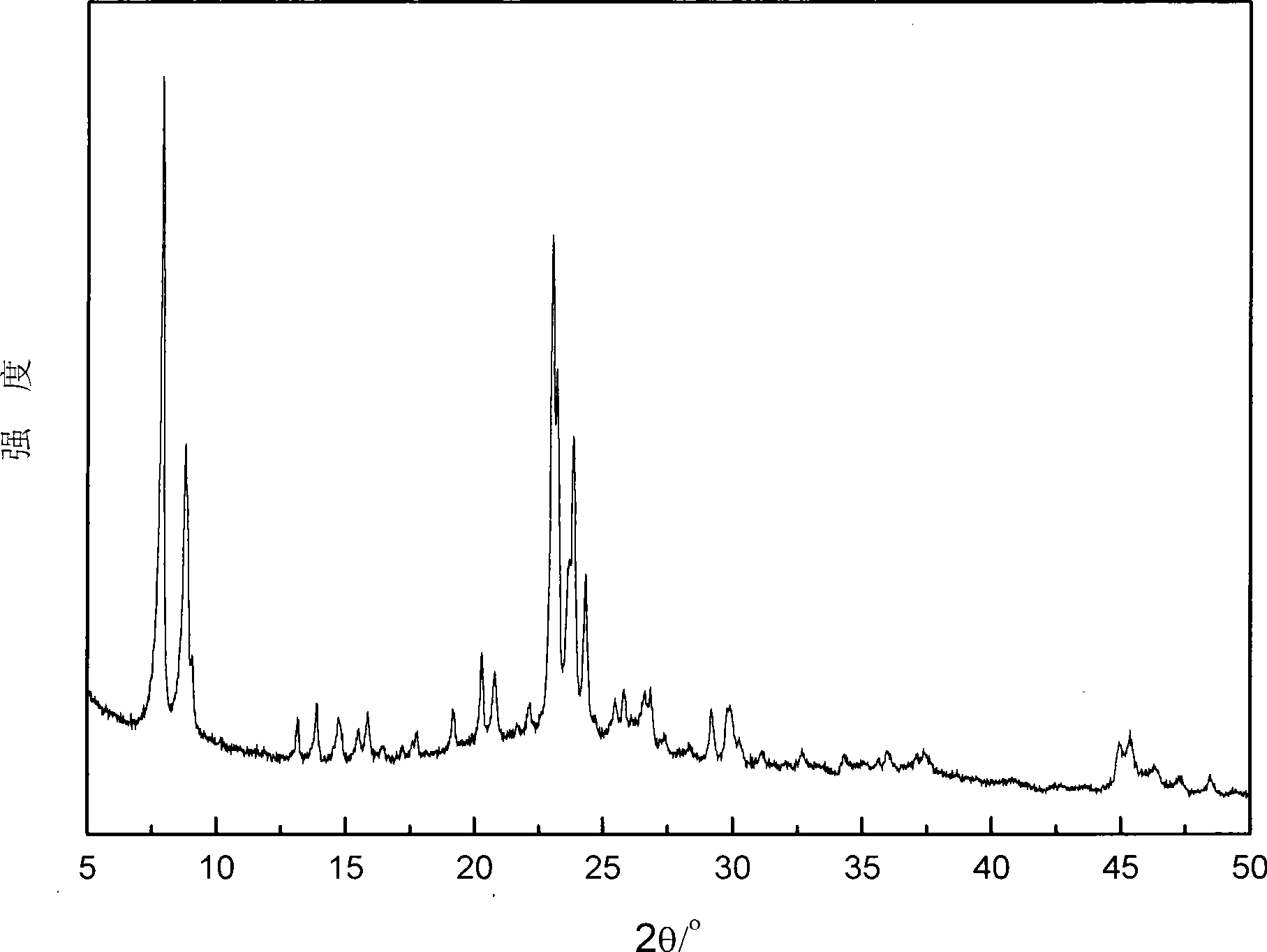

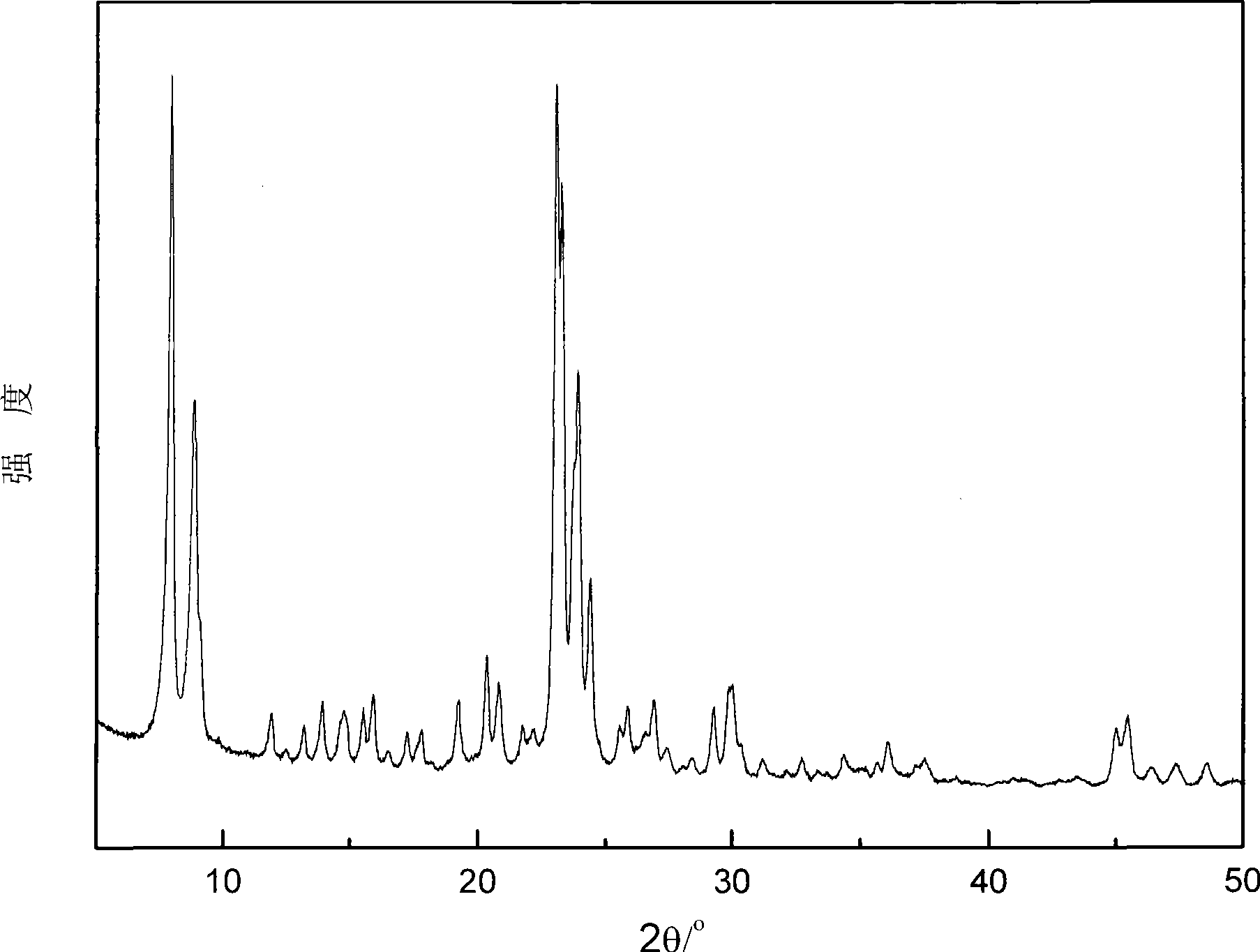

ActiveCN101332995AGood hydrothermal stabilityEffective protectionPentasil aluminosilicate zeoliteIn situ crystallizationCrystallinity

The invention relates to a preparation method of kaolin in situ crystallization ZSM-5 molecular sieves and is characterized in that the internal and external surfaces of modified kaolin are provided with ZSM-5 molecular sieves by in situ crystallization; calculated by relative crystallinity, the relative content of the ZSM-5 molecular sieves in the kaolin is 30-80 %. The in situ crystallization ZSM-5 molecular sieves of the invention have the advantages of high crystallinity, small crystal grain, high activity and good stability.

Owner:北京惠尔三吉绿色化学科技有限公司 +1

In-situ crystallization cracking catalyst and preparation method thereof

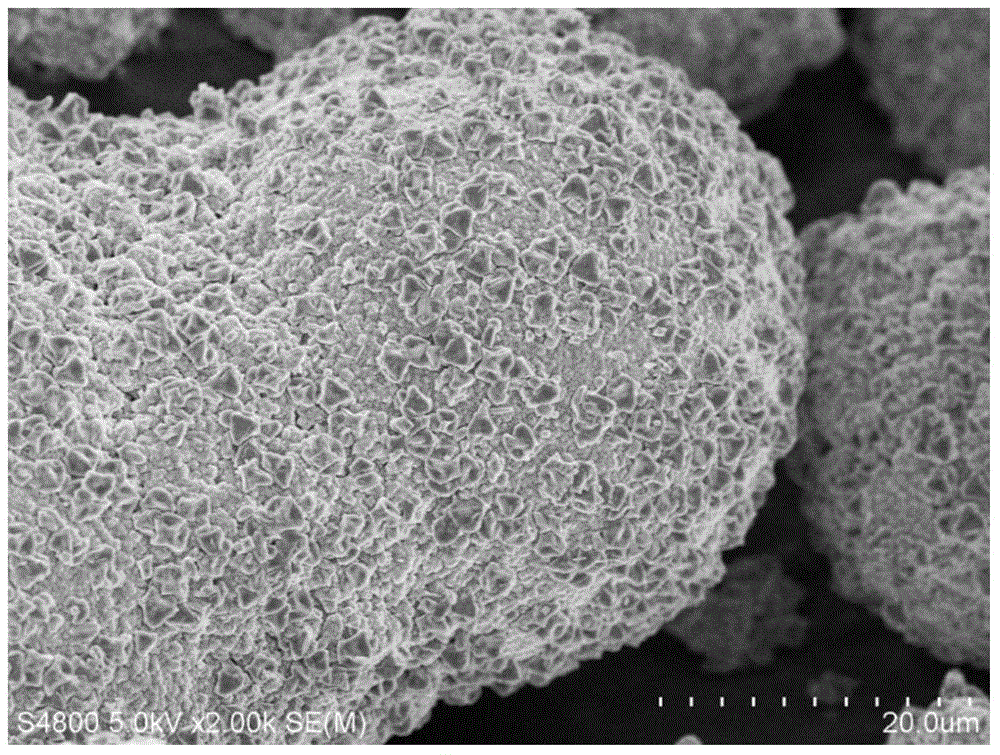

ActiveCN101250428AHigh crystallinityLow selectivityCatalytic crackingIn situ crystallizationMicrosphere

The invention relates to an in-situ crystallization type cracking catalyst and the process for preparation, which is characterized in that the process for preparation comprises mixing roasting kaolin microsphere, water glass, sodium hydroxide and guiding agent, and then crystallizing in original position after heating up to 80-110 DEG C, adding aluminum source in the in the process of crystallizing during 1-48hours, and getting crystallization product, filtering and washing the crystallization product, exchanging, roasting, lowering natrium, modifying to get cracking catalyst, wherein the cracking catalyst contains Y-shaped molecular screen with high degree of crystallization and high silica alumina ratio, which is suitable for catalyzing and cracking heavy oil.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing ZSM-5 zeolite by in situ crystallization

ActiveCN101462740AHigh zeolite contentHigh activityMolecular sieve catalystsPentasil aluminosilicate zeoliteIn situ crystallizationAdhesive

The invention relates to a method for preparing ZSM-5 zeolite through in-situ crystallization, which comprises that: kaolin slurry containing kaolin, adhesive and water is prepared into kaolin microspheres through spray drying, and the prepared kaolin microspheres are baked; silicon-enriched clay slurry containing silicon-enriched clay, adhesive and water is prepared into silicon-enriched clay microspheres through spray drying, and the prepared silicon-enriched clay microspheres are baked; and the respectively baked kaolin microspheres and silicon-enriched clay microspheres are mixed with a water solution containing alkali, and the mixture is subjected to in-situ hydrothermal crystallization to obtain crystallization product, wherein the mol ratio of SiO2 to Al2O3 in the silicon-enriched clay is more than 2. The ZSM-5 zeolite prepared by the method has high content of zeolite and rich middle holes, so the ZSM-5 zeolite can be used as a catalyst in the field of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

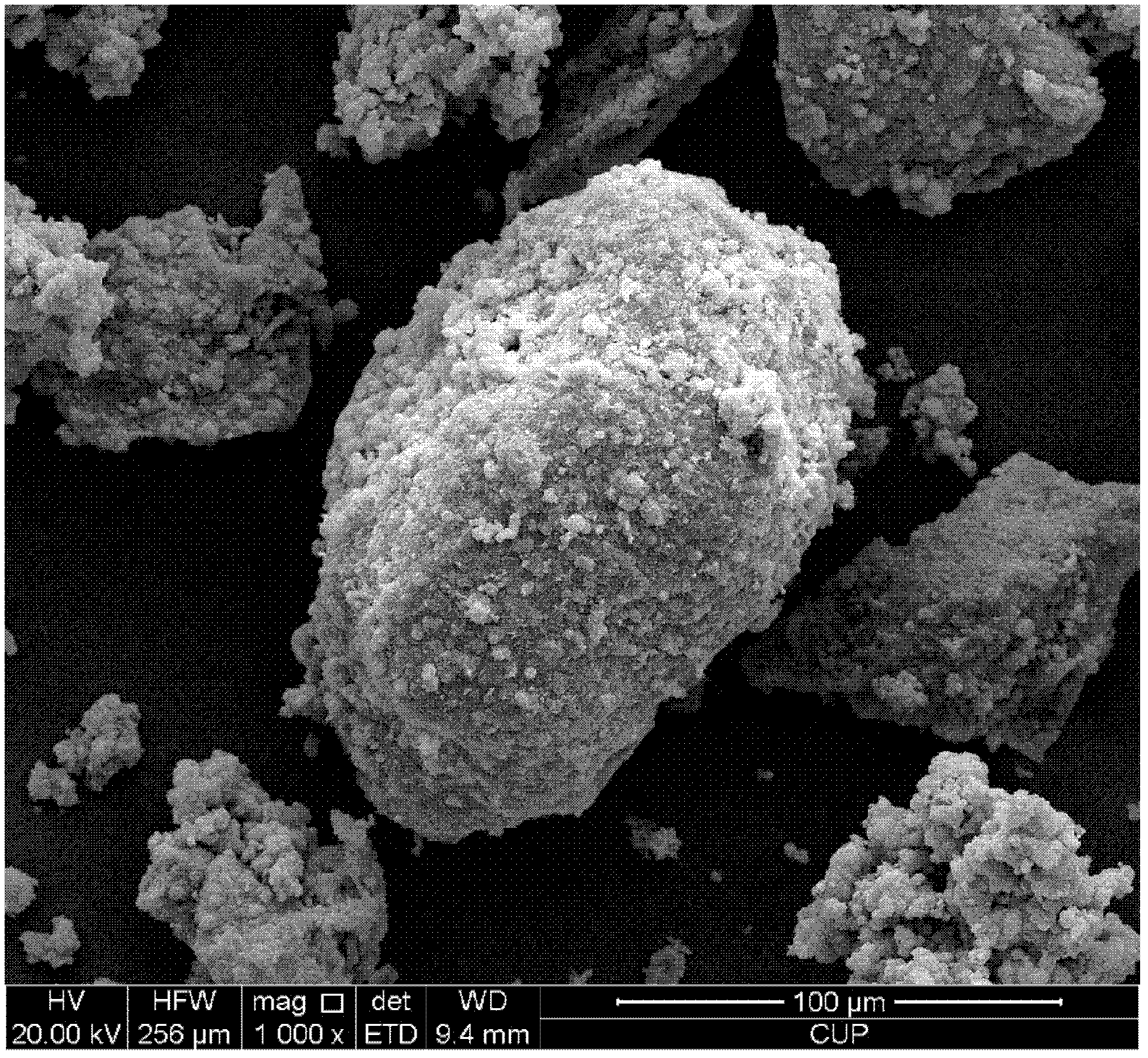

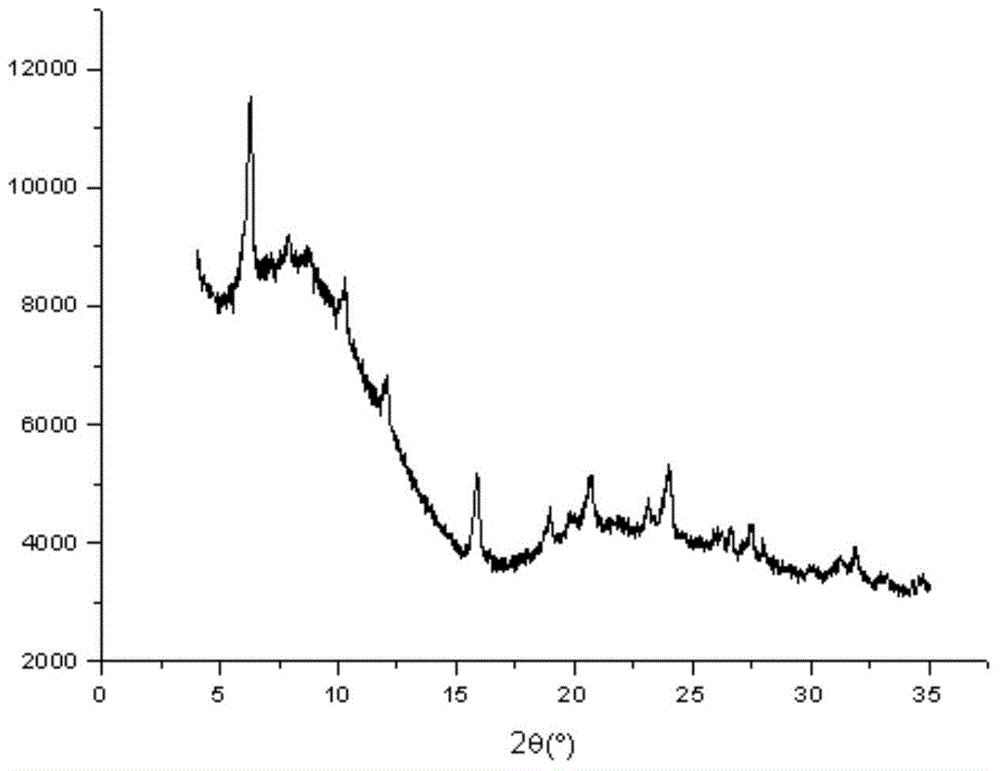

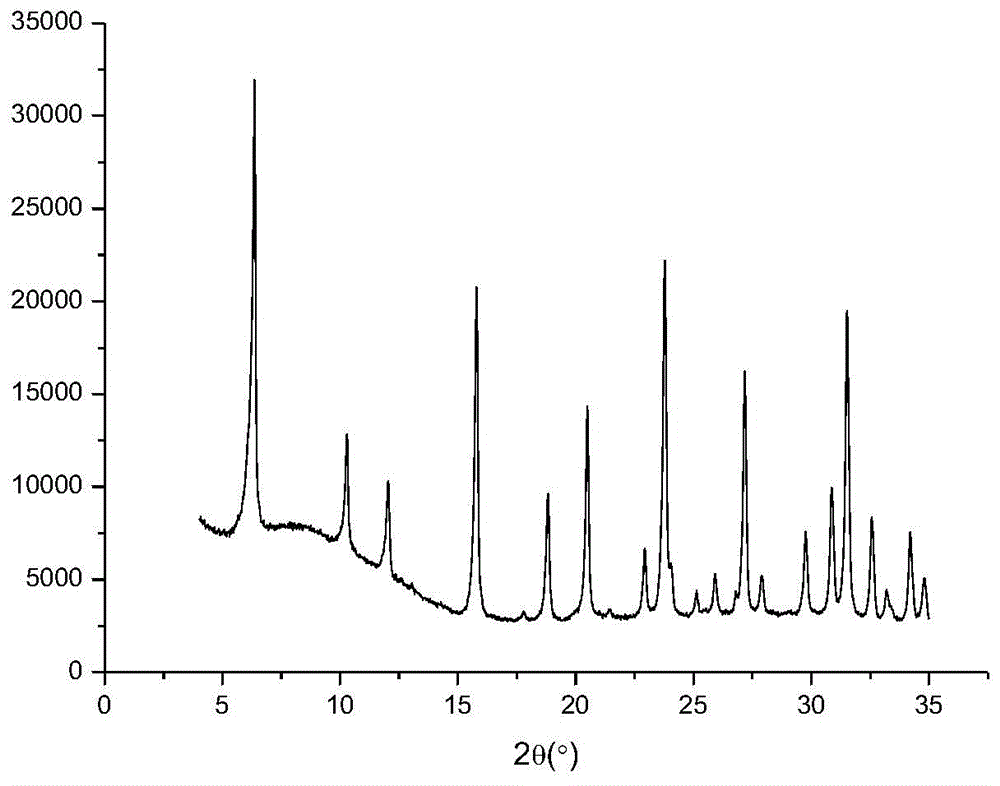

NaY molecular sieve/natural mineral composite material having multistage pore structure and preparation method thereof

ActiveCN103043680ALower synthesis costReduce manufacturing costFaujasite aluminosilicate zeoliteIn situ crystallizationMolecular sieve

The invention belongs to the technical field of petrochemical industry, and relates to a NaY molecular sieve / natural mineral composite material having a multistage pore structure and a preparation method thereof. The composite material is a crystal product formed through in-situ crystallization by taking a natural kaolin mineral and a natural kieselguhr mineral as entire silicon sources and aluminum sources for molecular sieve synthesis and using the minerals as substrates for molecular sieve growth. In the composite material, the mass percent of the NaY molecular sieve is 25-50%, and the silicon-aluminum ratio of the NaY molecular sieve is 3-5.5. The invention widens the raw material sources in the preparation of the molecular sieve / natural mineral composite material through an in-situ synthesis method, and can simultaneously greatly lower the production cost of the molecular sieve / natural mineral composite material.

Owner:PETROCHINA CO LTD +1

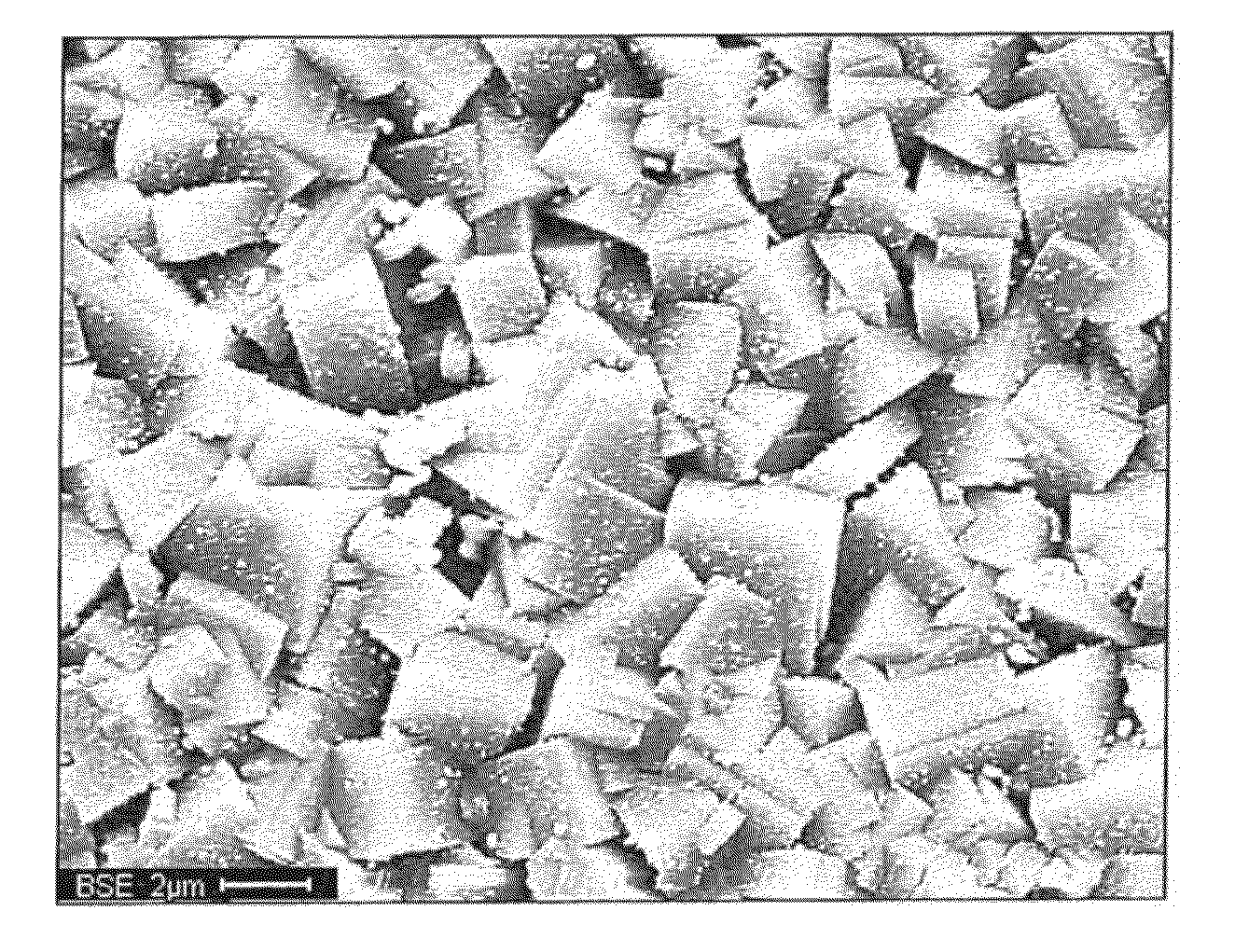

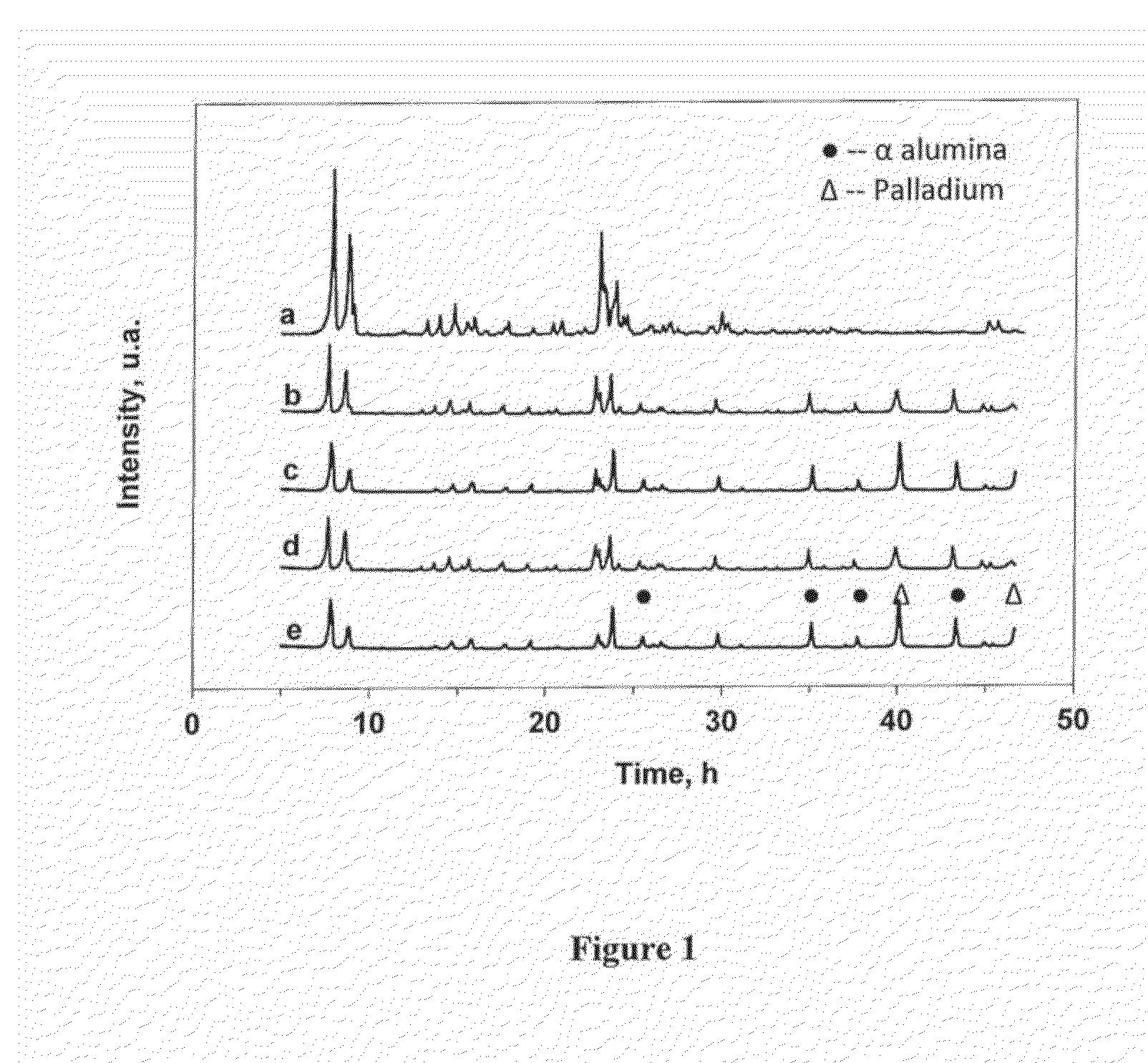

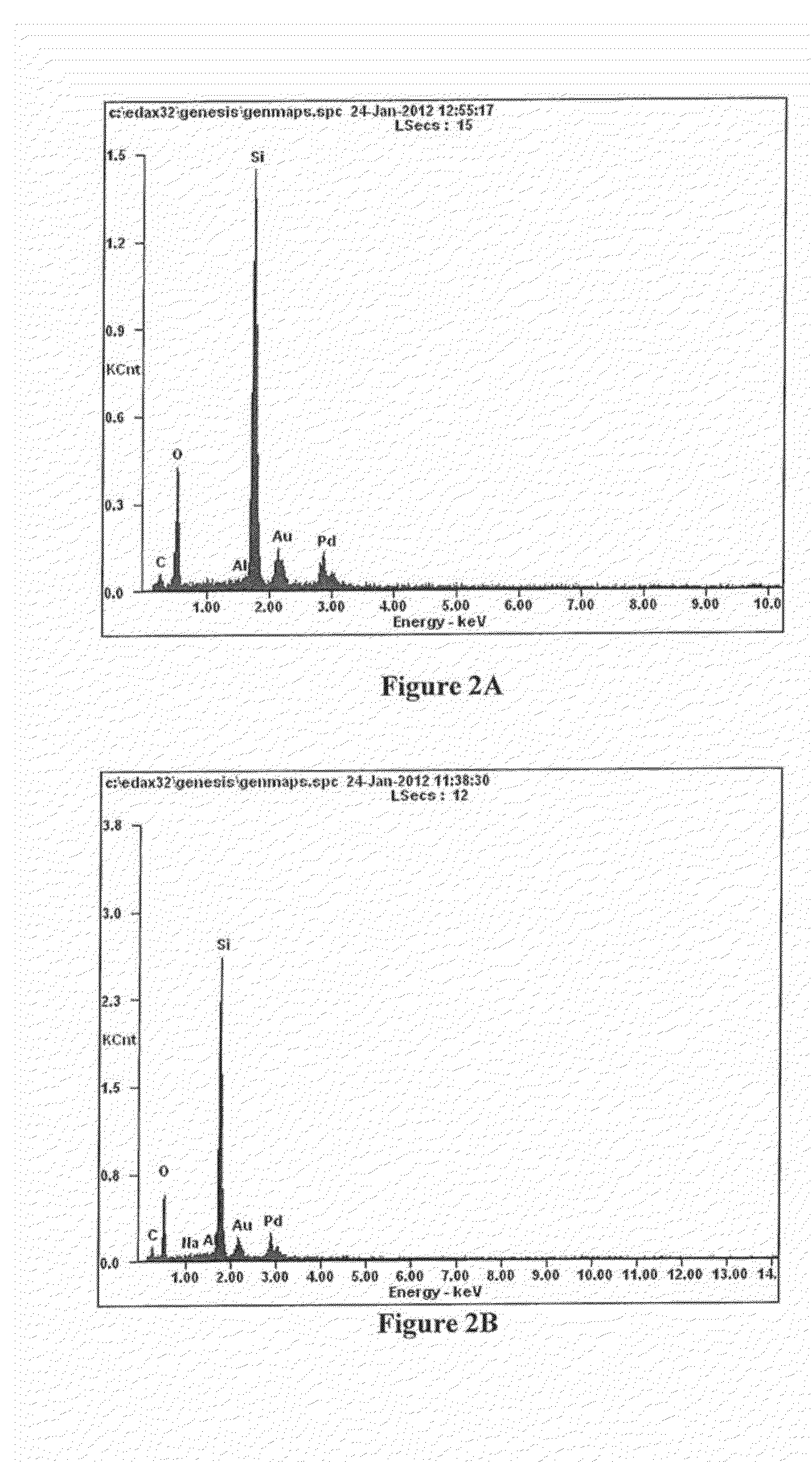

Metal doped zeolite membrane for gas separation

The present invention discloses composite inorganic membranes, methods for making the same, and methods of separating gases, vapors, and liquids using the same. The composite zeolite membrane is prepared by TS-1 zeolite membrane synthesis, and subsequent palladium doping. In the composite zeolite membrane synthesis, two different methods can be employed, including in-situ crystallization of one or more layers of zeolite crystals an a porous membrane substrate, and a second growth method by in-situ crystallization of a continuous second layer of zeolite crystals on a seed layer of MFI zeolite crystals supported on a porous membrane substrate. The membranes in the form of disks, tubes, or hollow fibers have high gas selectivity over other small gases, very good impurity resistance, and excellent thermal and chemical stability over polymer membranes and other inorganic membranes for gas, vapor, and liquid, separations.

Owner:BETTERGY

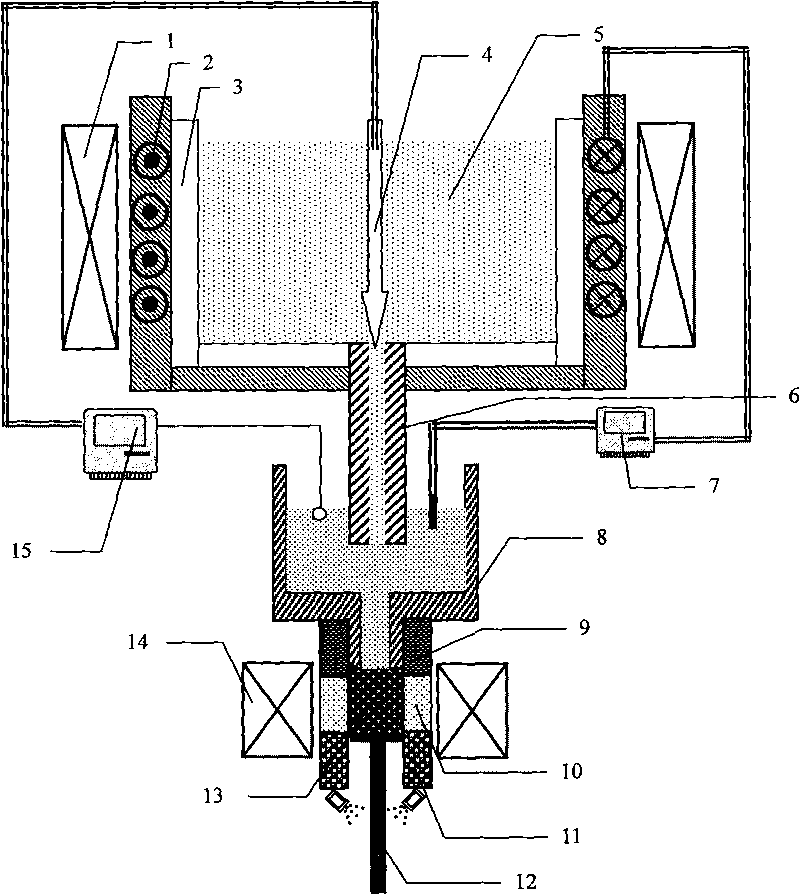

Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

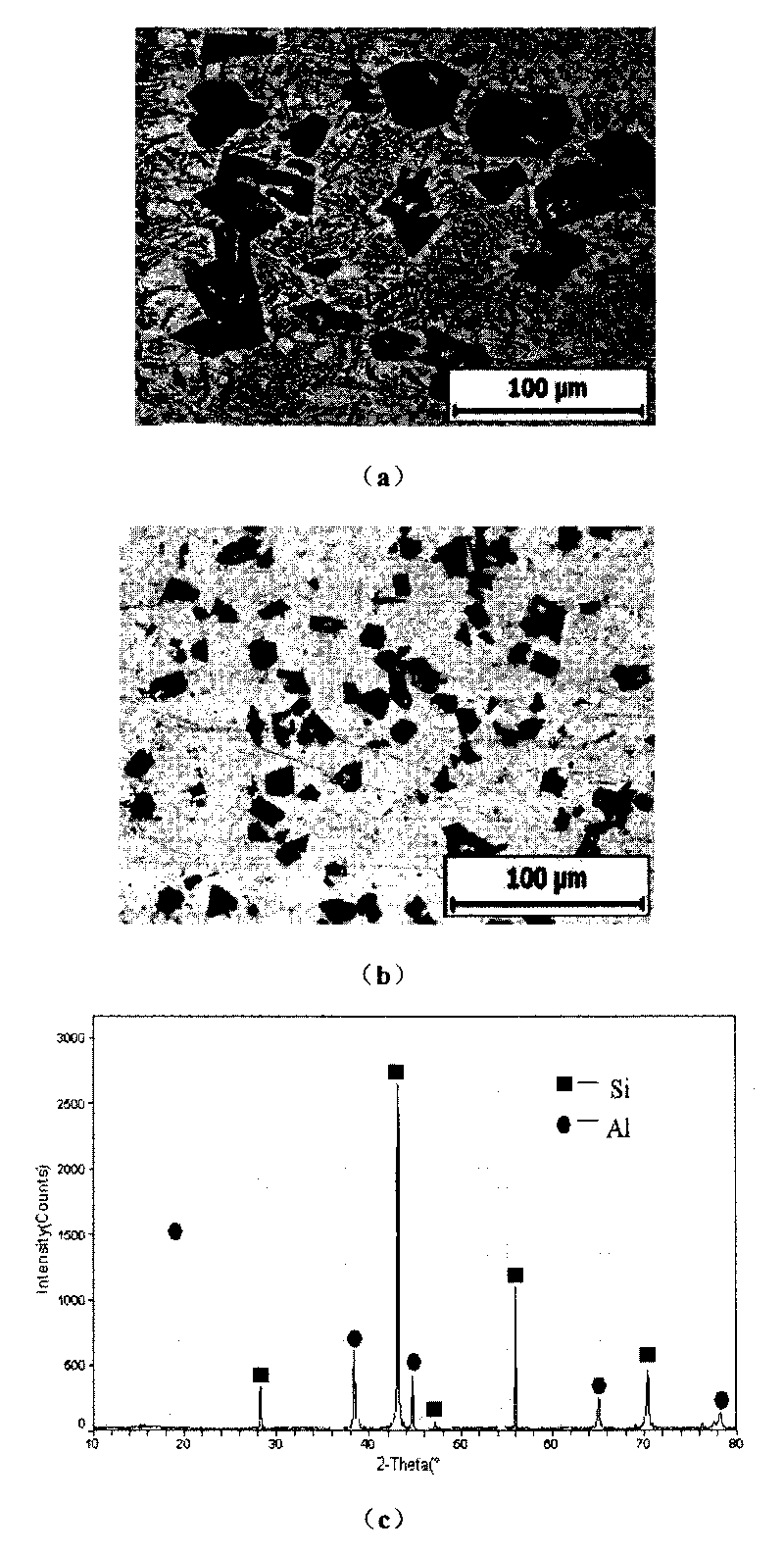

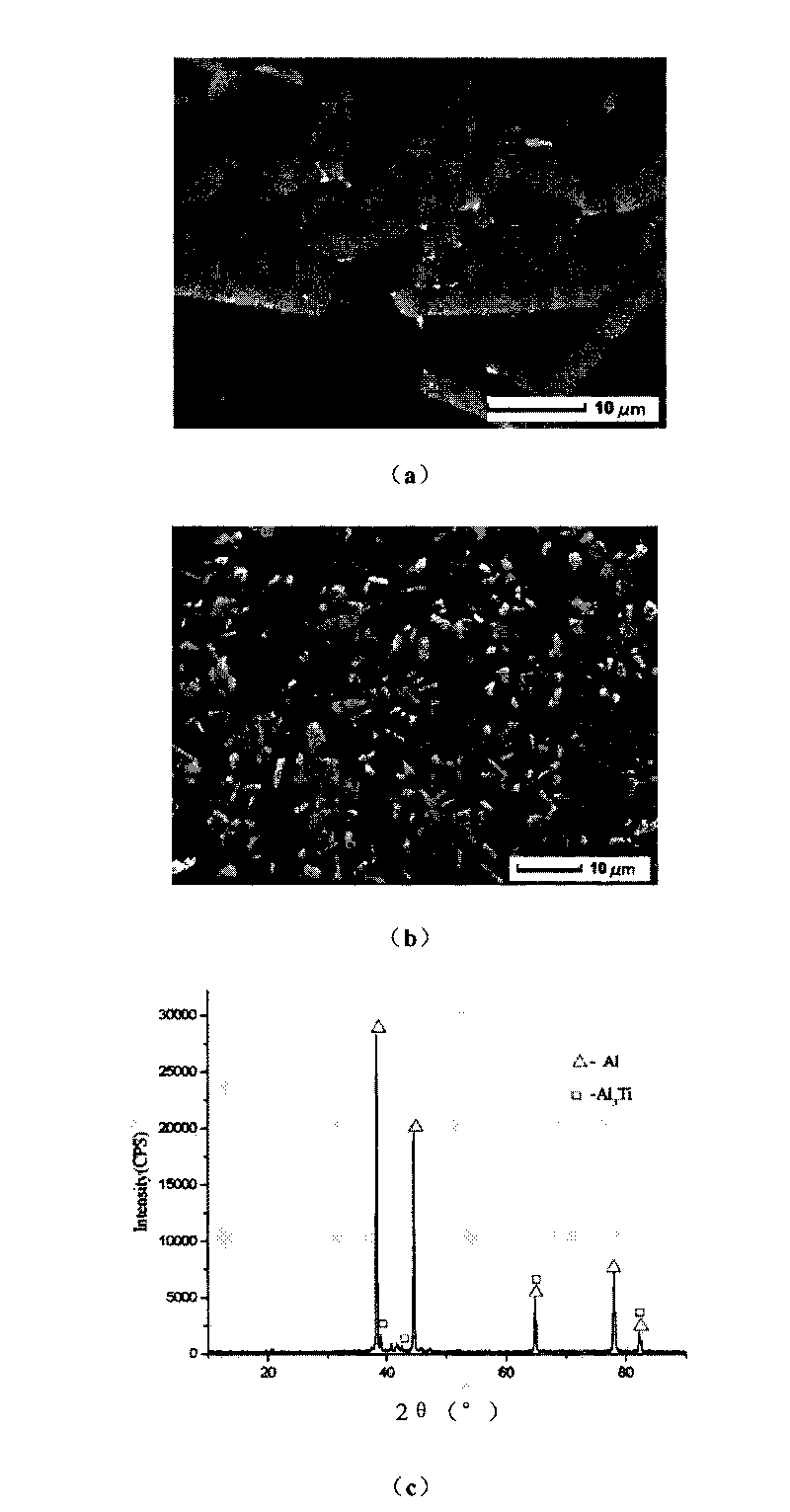

The invention provides a method and a device for preparing high-performance aluminum-base composite material under the action of the pulsed magnetic field with the in situ crystallization method, belonging to the technical field of material preparation. The method comprises the following steps: smelting to synthesize compound material melt at the temperature of 10-200 DEG C higher than the compound material melt liquidus temperature and pouring the compound material melt into a specially-designed crystallizer to make the compound material melt solidify under the action of the pulsed magnetic field. The pulsed magnetic field has the key parameters of the pulse width of 1-500 ms and the amplitude strength of 0.1-50T. The pulsed electromagnetic force is applied to the process of solidifying the compound material melt under the action of the pulsed magnetic field so as to refine the matrix structure and the particle reinforced phase of the compound material at the same time, control the growth of the particle reinforced phase in cluster, increase the bonding strength of the interface of the particle reinforced phase and the matrix and obviously improve the performance of the composite material.

Owner:JIANGSU UNIV

Method for preparing in situ crystallization type catalytic cracking catalyst

ActiveCN101537368AReduce build timeShort build timeMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIn situ crystallization

The invention provides a method for preparing an in situ crystallization type catalyst by adding components with a silicon-aluminum structure unit in a certain proportion. The method is characterized in that: kaoline with meso position grain diameter used as a raw material is added with water to form a pulp, the pulp undergoes spray forming to form an earth ball, and the earth ball is roasted to form a roasted earth ball. The roasted earth ball undergoes the crystallized reaction with sodium silicate, the components with the silicon-aluminum structure unit, a guiding agent and the like to from a crystallized product of which the content of NaY zeolite is between 15 and 60 percent and the silicon-aluminum ratio is 3.5-5.5; and the crystallized product is exchanged and roasted to obtain the catalyst needed. Because the components with the silicon-aluminum structure unit are used as sources of partial silicon, aluminum and sodium, the method has the advantages of realizing the preparation of the in situ crystallization type molecular sieve in a short period of time, further shortening flow, improving yield and lowering production cost.

Owner:PETROCHINA CO LTD

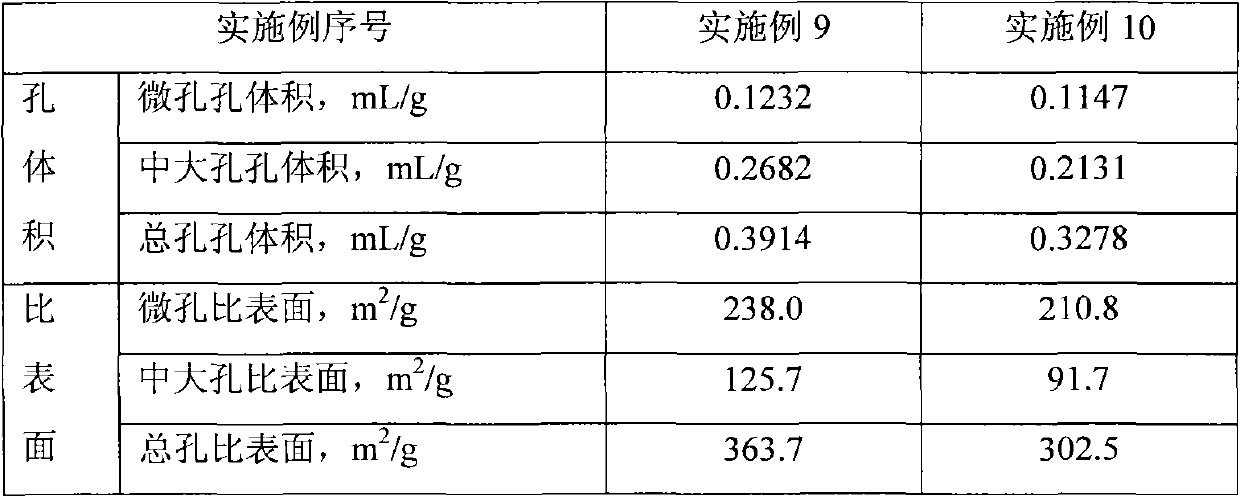

Method for improving pore structure of kaolin microsphere in-situ crystallization product

ActiveCN102019196AHigh molecular weightRegular structureMolecular sieve catalystsCatalyst activation/preparationPolyvinyl alcoholMicrosphere

The invention relates to a method for improving the pore structure of a kaolin microsphere in-situ crystallization product. The method comprises the following steps of: preparing kaolin spray microspheres with the particle sizes of between 20 and 110 mu m by using mixed kaolin grout by spray drying, wherein the mixed grout comprises kaolin, deionized water, a dispersant and an organic pore cannelforming template agent; the dispersant is sodium silicate or sodium pyrophosphate; and the organic pore cannel forming template agent is polyvinyl pyrrolidone or polyvinyl alcohol; baking the spray microspheres at the temperature of between 900 and 1,100 DEG C for 1 to 3 hours so as to obtain kaolin baked microspheres; mixing the kaolin baked microspheres with the mullite content of between 2 and12 percent, sodium silicate, a directing agent, solution of sodium hydroxide and deionized water; crystalizing the mixture at the temperature of between 90 and 95 DEG C for 16 to 36 hours; and filtering and drying so as to obtain a crystallization product which has a medium / large-pore structure and comprises a NaY molecular sieve. The crystallization product has a well-developed large-pore structure and the abrasion index of not more than 1.5 percent and comprises 20 to 50 percent of NaY molecular sieve.

Owner:PETROCHINA CO LTD +1

Catalytic cracking auxiliary agent for increasing heavy oil conversion performance and preparation method thereof

The invention provides a catalytic cracking additive for improving the transformation ability of heavy oil and the preparation method. The catalytic cracking additive is produced by spray shaping, roasting, in-situ crystallization and composite elements modification after natural sepiolite is mixed with natural kaolinite mineral or with one or two roasting kaolinite mineral. Provided with high activity, high heavy metal resistance and good selectivity in cracking reaction, the additive can improve the transformation ability of heavy oil and reduce the olefin content and increase gasoline octane number.

Owner:姚华

Method for preparing ZSM-5 zeolite by in situ crystallization

ActiveCN101462741AMesopore richHigh activityMolecular sieve catalystsPentasil aluminosilicate zeoliteIn situ crystallizationMicrosphere

The invention relates to a method for preparing ZSM-5 zeolite through in-situ crystallization, which comprises that: slurry containing kaolin and water is prepared into microspheres through spray drying; the prepared microspheres are baked; and the baked microspheres are mixed with a water solution containing alkali, and the mixture is subjected to in-situ hydrothermal crystallization to obtain crystallization product, wherein the slurry also contains silicon-enriched clay, and the mol ratio of SiO2 to Al2O3 in the silicon-enriched clay is more than 2. The ZSM-5 zeolite prepared by the method has high content of zeolite and rich middle holes, so the ZSM-5 zeolite can be used as a catalyst in the field of petrochemical industry, in particular as a catalytic agent in the FCC process to improve propylene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for in-situ synthesis of Y-type molecular sieve

ActiveCN101618882AImprove crystallization efficiencyImprove propertiesFaujasite aluminosilicate zeoliteChemistryIn situ crystallization

The invention relates to a method for the synthesis of a Y-type molecular sieve, which comprises the following steps: (1) making coal-series kaolin and a binder into slurry; (2) spray drying the slurry and making the spray-drying product into microspheres; (3) roasting the microspheres; (4) mixing the microspheres with an alkaline crystallizing solution containing an organic template to crystallize the microspheres under a hydrothermal condition; and (5) obtaining an in-situ crystallization product by filtering and washing. Using the coal-series kaolin as a raw material for the in-situ molecular sieve synthesis, the method expands raw material sources and reduces the production cost of products. And the product of the method is large in specific surface area and high in crystallinity and can be used in reaction processes such as catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chitosan-hydroxylapatite in-situ loaded icariin composite microspheres

InactiveCN103495210APromote formationPromote wound healingMicroballoon preparationProsthesisOsteoblastMicrosphere

The invention discloses chitosan-hydroxylapatite in-situ loaded icariin composite microspheres and a preparation method thereof. The preparation method is characterized in that a micro-capsule forming device is adopted, chitosan is used as an organic substrate, and soluble calcium salt and soluble phosphate are used as precursors of inorganic phase nanometer hydroxylapatite; the in-situ crystal induction effects of hydroxyl radicals and amino radicals in the chitosan on the hydroxylapatite are used for adjusting and controlling the in-site heterogeneous nucleation crystallization of an inorganic mineral on the organic substrate; and meanwhile, a traditional Chinese medicine, namely icariin which has the effect of promoting proliferation and differentiation on osteoblast is compounded, and the chitosan-hydroxylapatite in-situ loaded icariin composite microspheres are prepared through in-situ simulation. The chitosan-hydroxylapatite in-situ loaded icariin composite microspheres are bone filling materials, have good biocompatibility and biodegradability and are expected to serve as repair materials for bone tissue defects to be widely applied in clinic; the preparation processes are simple and easy; and the method is mild.

Owner:FUZHOU UNIV

Recycling method for catalytic cracking waste catalyst

InactiveCN106140296AReduce energy consumptionHigh activityMolecular sieve catalystsIn situ crystallizationMicrosphere

The invention discloses a recycling method for a catalytic cracking waste catalyst. According to the method, the catalytic cracking waste catalyst and calcined kaolin microspheres serve as main raw materials, under the situation of supplementing a silicon source and not adding an external aluminum source, a fresh catalytic cracking catalyst is prepared through an in-situ crystallization method, and the catalytic cracking waste catalyst is recycled. Compared with an existing catalytic cracking waste catalyst recycling method, the recycling waste for the catalytic cracking waste catalyst is simple and low in energy consumption, and the prepared fresh catalytic cracking catalyst can be subjected to industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for quick in situ crystallization synthesis of faujasite

The invention relates to a method for quick in situ crystallization synthesis of faujasite, which comprises the following steps: (1) dissolving alkali sodium salt, aluminum containing compounds and water glass in water or evenly mixing alkali sodium salt, aluminum containing compounds and the water glass with the water; (2) adding kaolin into the mixing solution for pulping; (3) ageing the mixing pulp while stirring the mixing pulp; (5) adding a guide agent metering a Y molecular sieve; (6) transferring the mixture to a reaction kettle for crystallization for less than 20 hours; and (7) filtering and water-washing the crystallization product to obtain the in situ crystallization product. By using the method, the in situ crystallization synthesis of the faujasite is realized in a mode of adding an aluminum source, so that the crystallizing time is greatly shortened, the product properties are improved, and the synthesized faujasite can be used as a component of hydrogenation cracking catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing in-situ crystallization type catalytic cracking catalyst

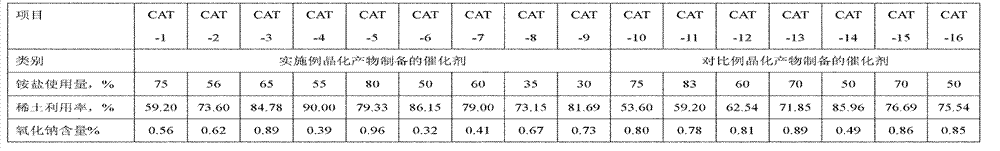

ActiveCN103240113AImprove responseReduce usageCatalyst carriersCatalytic crackingFiltrationMicrosphere

Method for preparing in-situ crystallization type catalytic cracking catalyst The method comprises: (1) using kaolin as a raw material to prepare in-situ crystallization products: adding deionized water, a binder, a poly dimethyl diallyl ammonium chloride auxiliary agent into kaolin, obtaining kaolin spray microballoons by spray drying prepared mixed seriflux, roasting, mixing roasted microballoons with a guiding agent, and then obtaining the in-situ crystallization products with 50-70% of NaY zeolite after hydrothermal crystallization, filtration, washing with water and drying, wherein the adding amount of poly dimethyl diallyl ammonium chloride auxiliary is 1-10% of the quantity of kaolin; (2) exchanging and roasting the in-situ crystallization products: fully mixing the in-situ crystallization products and 0.01-3N acid solution in a liquid-solid mass ratio of 4-15:1 under 20-100 DEG C, regulating a pH value in a range of 2.8-6.0, treating for 10-100min, then adding one or more of ammonium salts, rare earth or phosphor for exchanging, and roasting, to obtain the in-situ crystallization type catalytic cracking catalyst.

Owner:PETROCHINA CO LTD

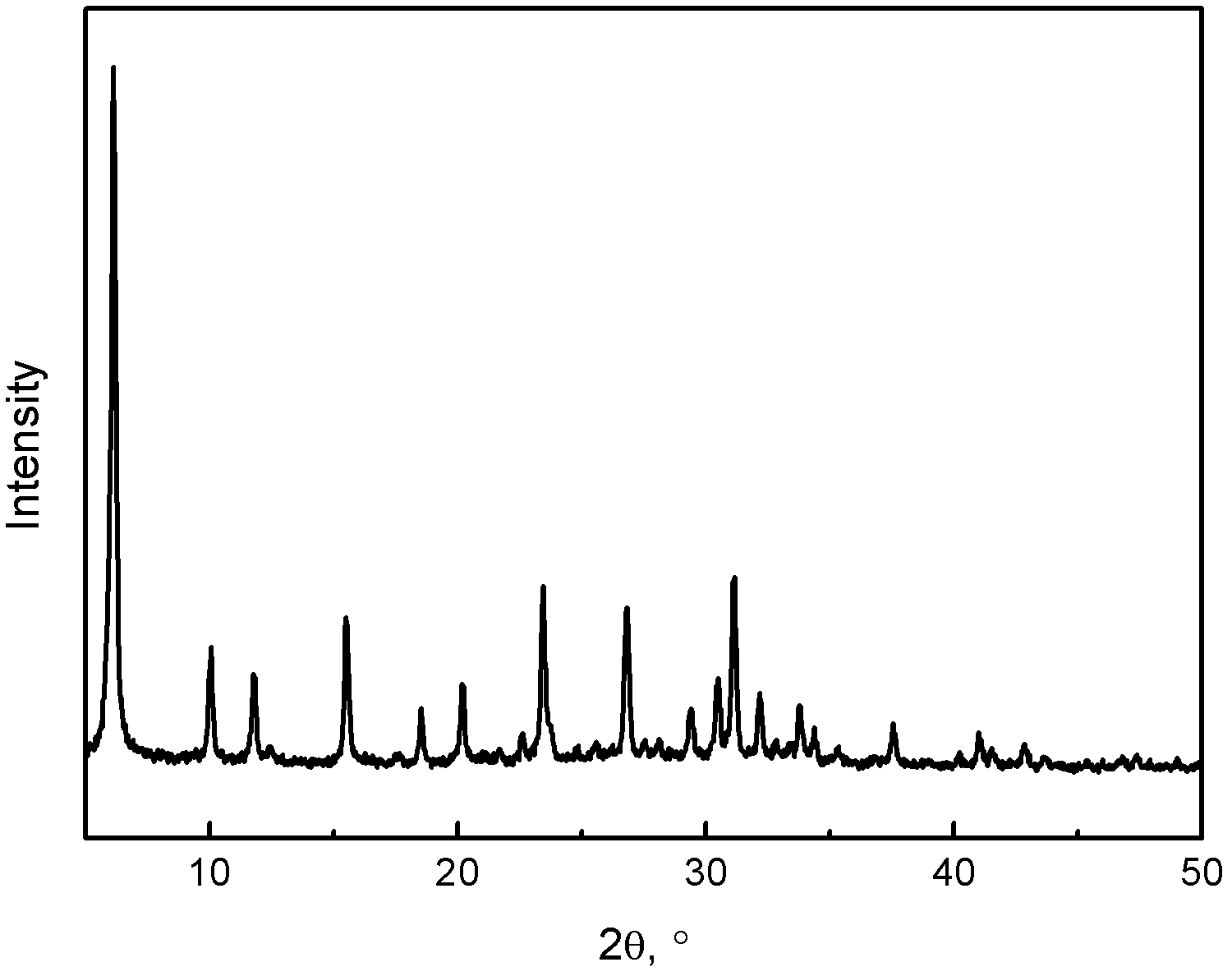

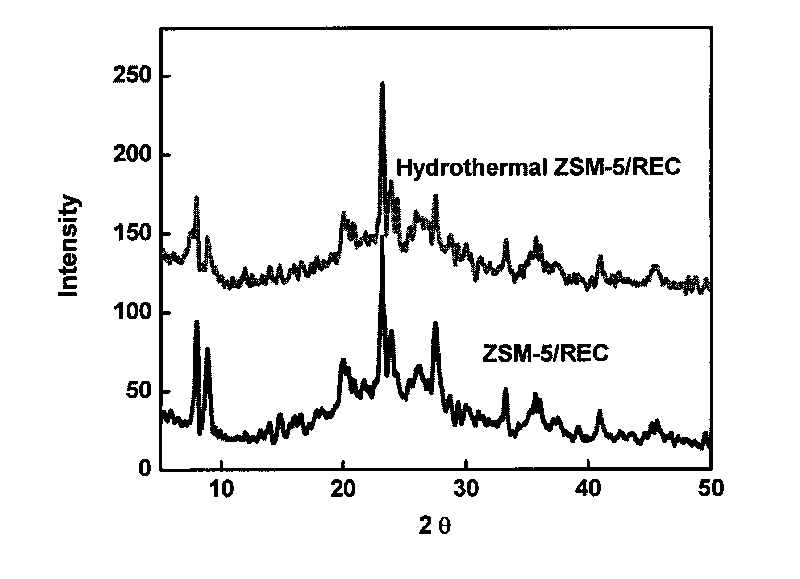

ZSM-5/rectorite composite catalytic material and preparation method thereof

ActiveCN101722024AExpand the range of raw materialsGranular regulationMolecular sieve catalystsIn situ crystallizationSynthesis methods

The invention provides a ZSM-5 / rectorite composite catalytic material and a preparation method thereof. The composite material is a crystal product formed by in-situ crystallization and by using a natural rectorite mineral to provide an aluminum source and part of silicon source for synthesizing molecular sieves and using the natural rectorite mineral as a matrix for growing the molecular sieves. In the composite material, the content of the ZSM-5 molecular sieves is no less than 10 mass percent, and the silicon to aluminum ratio of the ZSM-5 molecular sieves is 20 to 60. The ZSM-5 / rectorite composite catalytic material provided by the invention has excellent hydrothermal stability. The material expands the range of the raw materials used for preparing molecular sieve materials by an in-situ synthesis method as well as the application range of the natural rectorite mineral.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

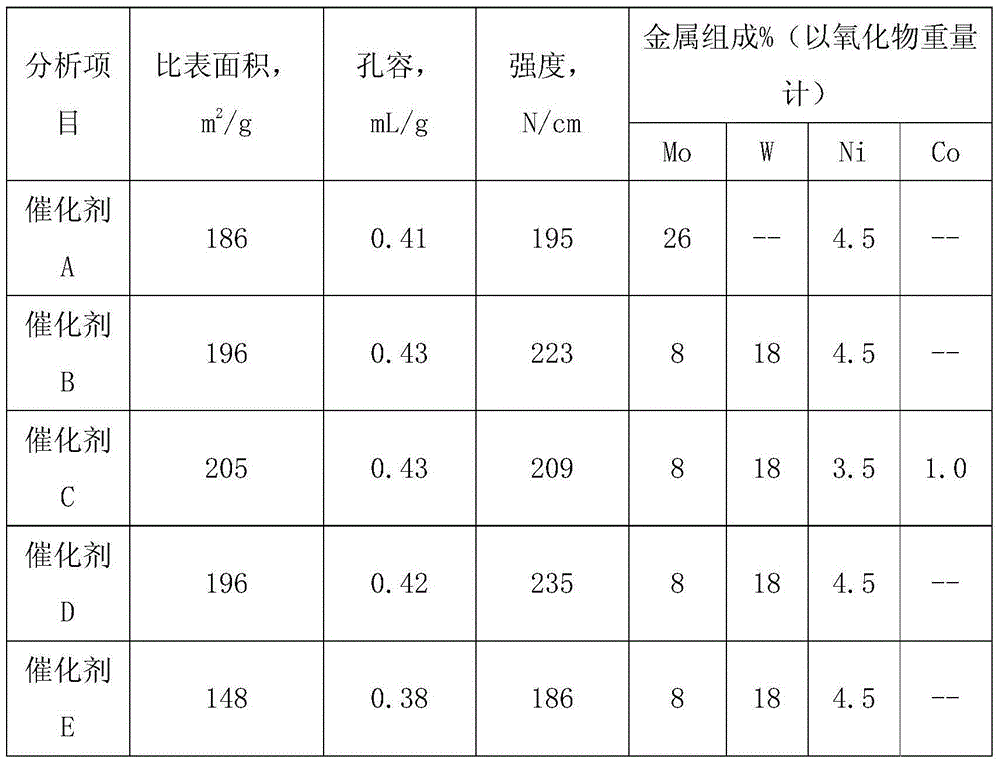

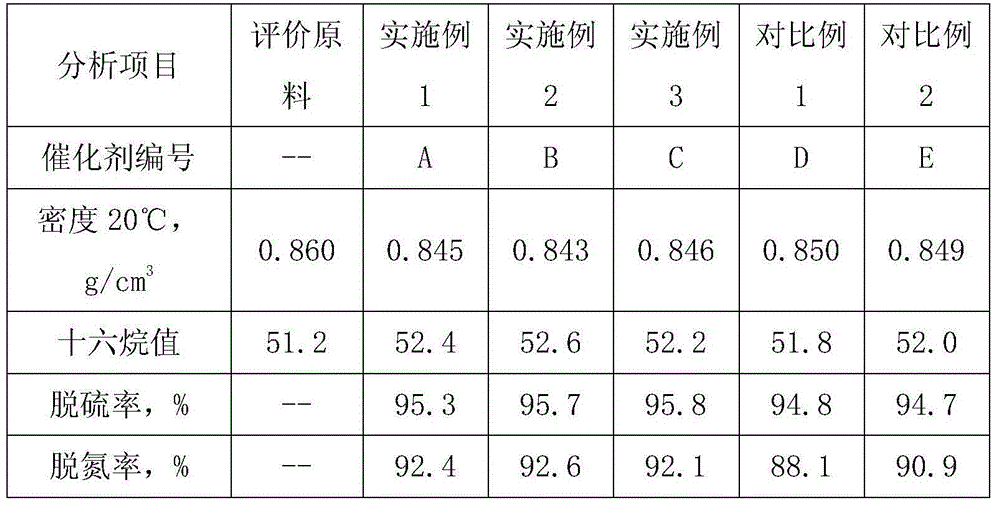

Process improvement method of vulcanized hydrogenation refining catalyst

ActiveCN104646010ALow costNo storage securityMetal/metal-oxides/metal-hydroxide catalystsIn situ crystallizationInorganic salts

The invention relates to a process improvement method of a vulcanized hydrogenation refining catalyst. The process improvement method is characterized by comprising the following steps: soaking macroporous alumina powder by adopting a dipping solution containing active metal, carrying out the in-situ crystallization, adding the binder, mixing the binder, carrying out the forming and drying, and then carrying out the roasting under the protection of inert gas to obtain the vulcanized hydrogenation refining catalyst. The method is characterized in that the dipping solution contains an inorganic salt precursor of active metal ammonium molybdate and / or ammonium tungstate and Ni and / or Co and also contains an organic vulcanizing agent, a complexing agent, a dispersing agent and the binder; the in-situ crystallization reaction is carried out in a closed vessel after the dipping solution soaks the macroporous alumina powder to prepare the vulcanized catalyst in one step. The method is simple in procedures, low in cost and uniform in dispersion of active metal.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing NaY molecular sieve by in-situ crystallization

ActiveCN102464333AMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIn situ crystallization

The invention relates to a method for preparing NaY molecular sieve by in-situ crystallization, which comprises the following steps: taking kaolin as a raw material, adding deionized water, decomposing a compound with boiling point at the temperature of less than 150 DEG C or equal to 150 DEG C, spray drying the prepared mixed slurry to obtain the kaolin spray microballoon, roasting, carrying outmixed crystallizing with silicon source, aqueous alkali and a guiding agent, filtering a filter cake, washing and drying; decomposing a compound with boiling point at the temperature of less than 150DEG C, wherein the addition amount accounts for 2-10% of kaolin mass.

Owner:PETROCHINA CO LTD

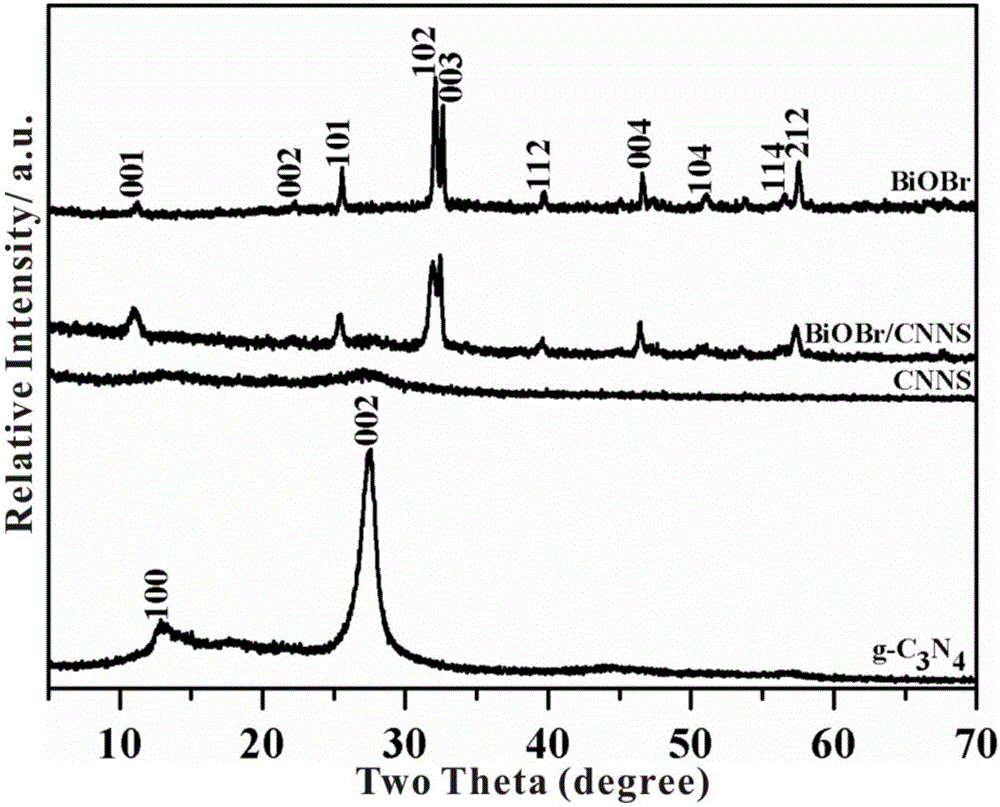

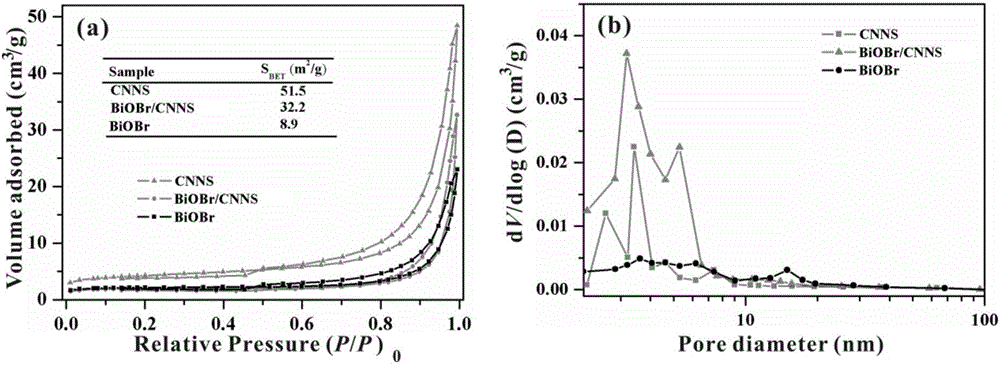

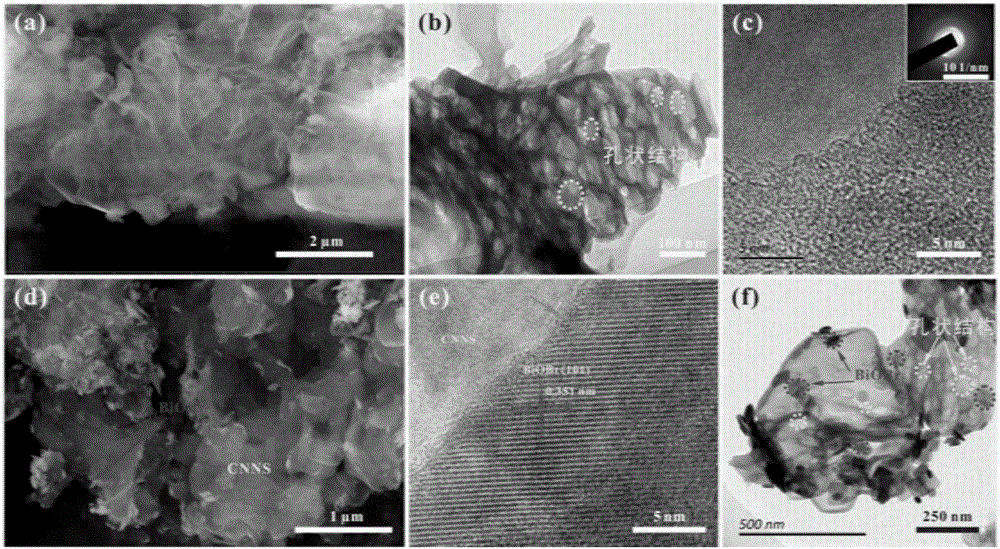

Composite photocatalyst and preparation method thereof

ActiveCN106799251AHigh catalytic efficiencyPromote degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationIn situ crystallizationArgon atmosphere

The invention discloses a composite photocatalyst and a preparation method of the composite photocatalyst, and relates to the field of photocatalysis. The preparation method of the composite photocatalyst comprises the steps that urea is taken as a raw material and calcinated in an argon atmosphere; a porous graphite phase carbon nitride (g-C3N4) nanosheet is prepared by combining ultrasonication; a BiOBr nanosheet is uniformly dispersed on the surface of the g-C3N4 nanosheet (CNNS) by utilizing a simple backflow process based on an in-situ crystallization technique to construct a layered BiOBr nanosheet / g-C3N4 nanosheet composite photocatalysis material. The preparation method is simple in technology, low in synthesis temperature, low in equipment requirement and low in cost; the raw material is easy to obtain. Compared with a commercial P25 catalyst, the prepared composite photocatalyst presents very high photocatalytic degradation efficiency on rhodamine B (RhB), and has a good degradation effect on bisphenol A (BPA).

Owner:YANCHENG INST OF TECH

Method for quick in situ synthesis of catalytic cracking catalyst

ActiveCN101619228AShorten crystallization timeCatalytic crackingMolecular sieve catalystsIn situ crystallizationMicrosphere

The invention relates to a method for quick in situ synthesis of a catalytic cracking catalyst. The method comprises the following steps: (1) mixing kaolin, a binding agent and water into slurry; (2) spraying, drying and shaping the liquid to obtain micro spheres; (3) baking the micro spheres; (4) mixing the baked micro spheres and the alkali crystallization solution, and crystallizing the mixture under a hydrothermal condition; and (5) filtering and water-washing the crystallization product to obtain the in situ crystallization product. In the method, the aluminum source is added in the in situ synthesis process of the catalytic cracking catalyst, so that the crystallizing speed is greatly improved, the crystallizing time is shortened, the synthetic efficiency is improved, and the cost of the catalyst is reduced. Compared with the prior catalyst, the catalytic cracking catalyst prepared by the method has better using performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

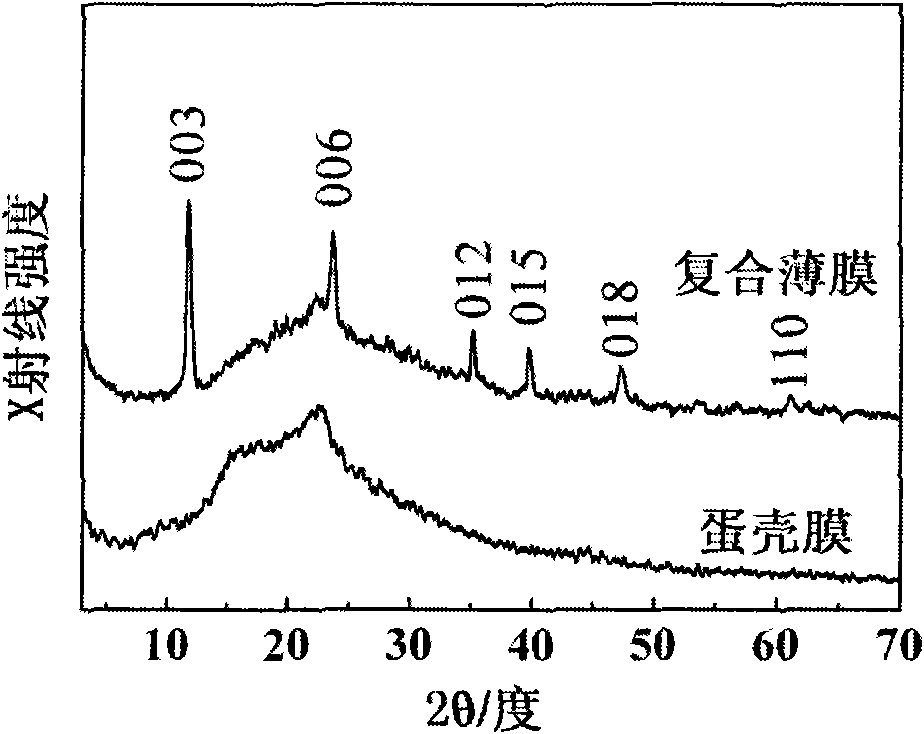

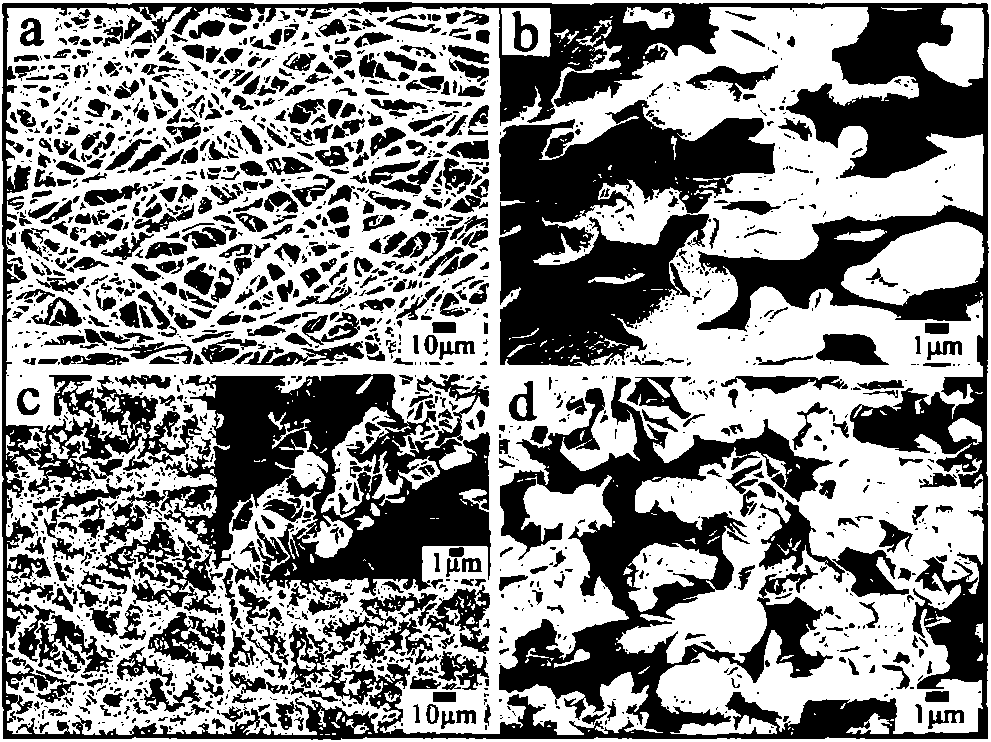

Hydrotalcite-like compound/eggshell membrane composite film and preparation method thereof

InactiveCN101766992AGood performance in removing hexavalent chromiumImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesIn situ crystallizationComposite film

The invention discloses a hydrotalcite-like compound / eggshell membrane composite film and a preparation method thereof and belongs to the technical field of preparation of composite-function film materials, and the composite film is researched as a chromyl adsorbent. The invention has the technical scheme that the eggshell membrane is used as a substrate and a template, and the hydrotalcite-like compound is fixed to the surface of the eggshell membrane by using an in-situ growth method, thereby obtaining an inorganic-biological composite film with a reticular structure. The invention uses the biological substrate eggshell membrane as the substrate and template for the first time, adopts an in-situ crystallization method to prepare the hydrotalcite-like compound / eggshell membrane inorganic-biological composite film, and makes a preliminary research into the applications of hydrotalcite-like materials in the field of biology. The composite film has favorable adsorbability as a chromyl adsorbent, and especially can carry out adsorption under the acidic conditions of a lower pH value, thereby saving the cost and meeting the requirements of the environment.

Owner:BEIJING UNIV OF CHEM TECH

Recycling method of mother liquor for SAPO-34 molecular sieve synthesis

ActiveCN102992349AAchieve recyclingReduce manufacturing costMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesIn situ crystallizationMolecular sieve

The invention discloses a recycling method of mother liquor for SAPO-34 molecular sieve hydro-thermal synthesis, and relates to the technical field of molecular sieve synthesis. The method comprises the following steps: recovering mother liquor obtained by SAPO-34 molecular sieve hydro-thermal synthesis crystallization and separation, additionally adding a silicon source, an aluminium source, and a phosphorus source into the mother liquor used as a raw material, mixing, adding a substrate material, a binder, and a pore forming agent, preparing microsphere raw powder by spraying molding, putting the roasted microspheres and an aqueous solution of an organic template together into a stainless steel reaction vessel, performing in-situ crystallization to prepare a spherical SAPO-34 molecular sieve catalyst which can be used directly in a fluidized bed device.

Owner:陕西煤化工技术工程中心有限公司

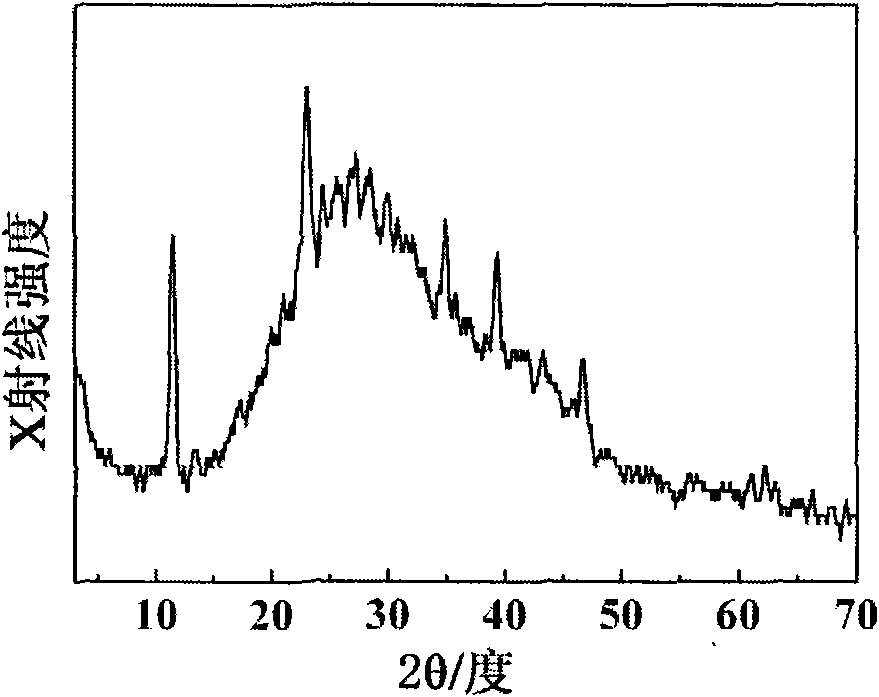

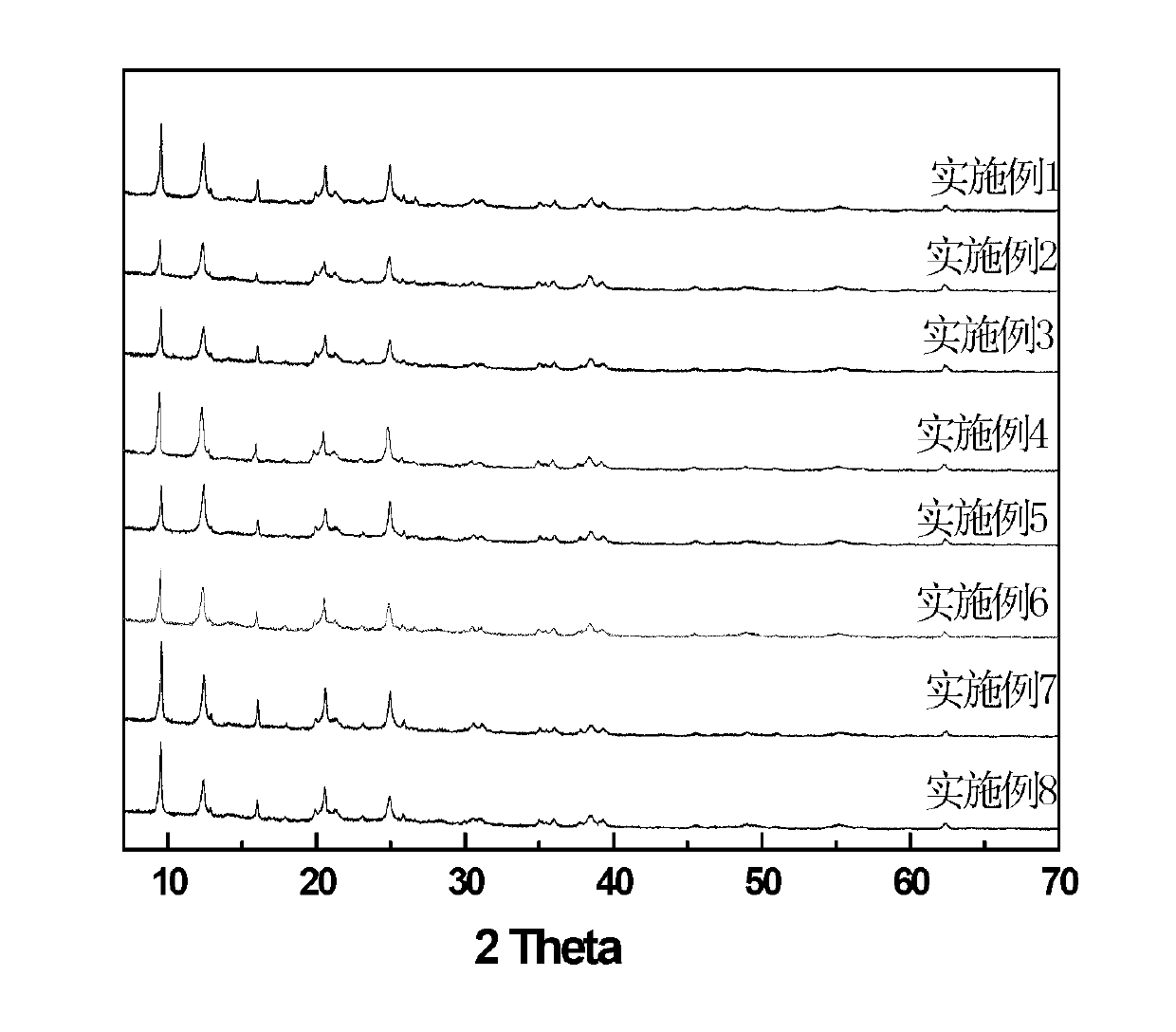

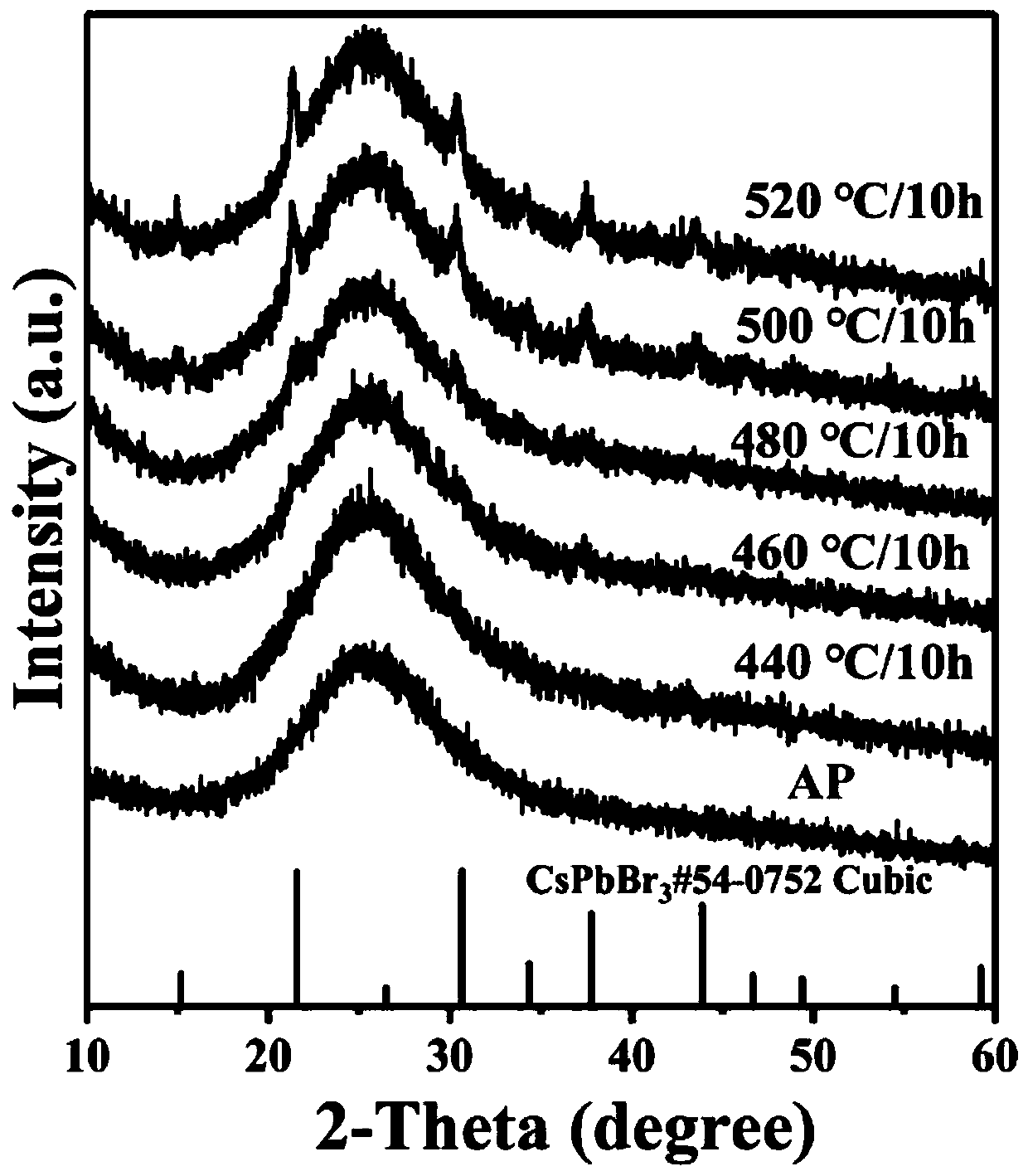

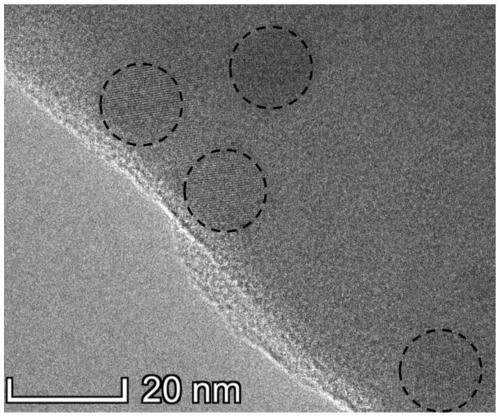

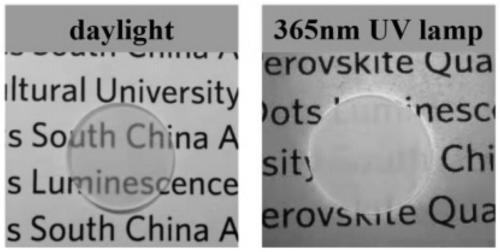

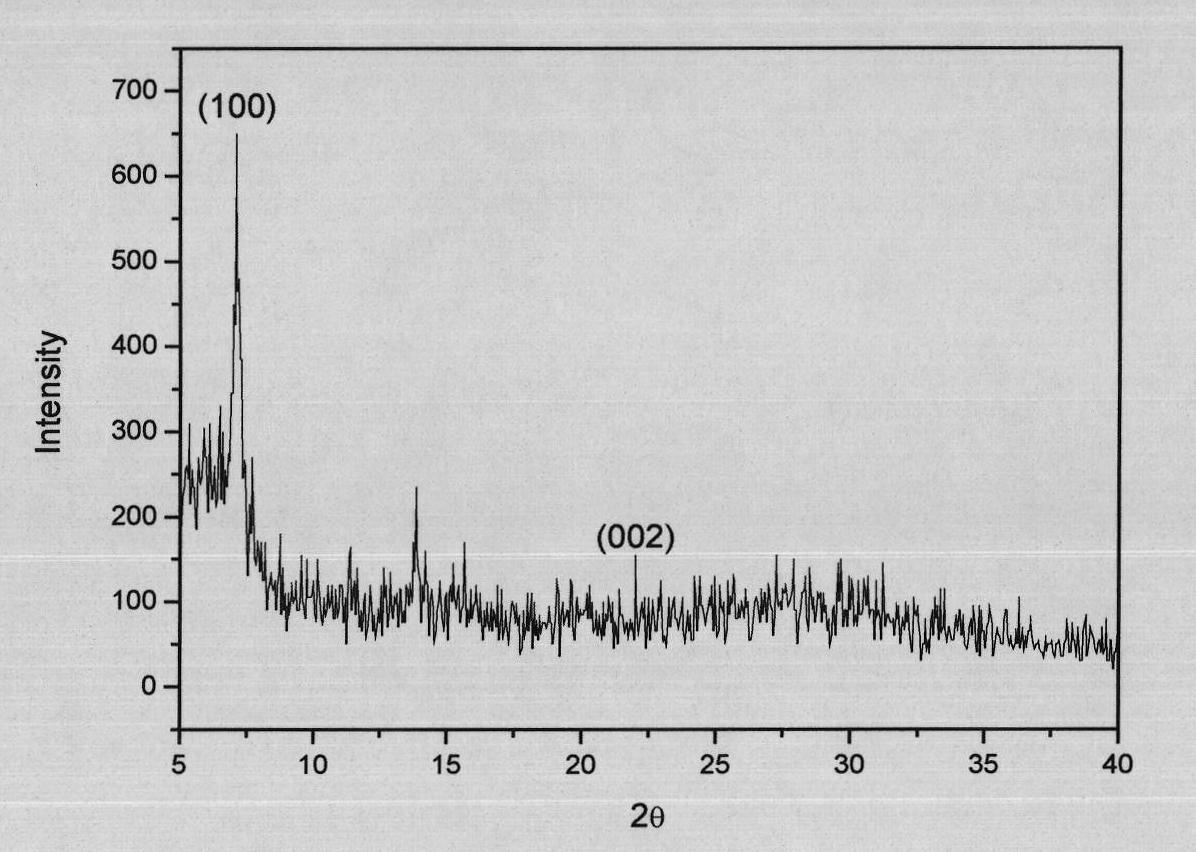

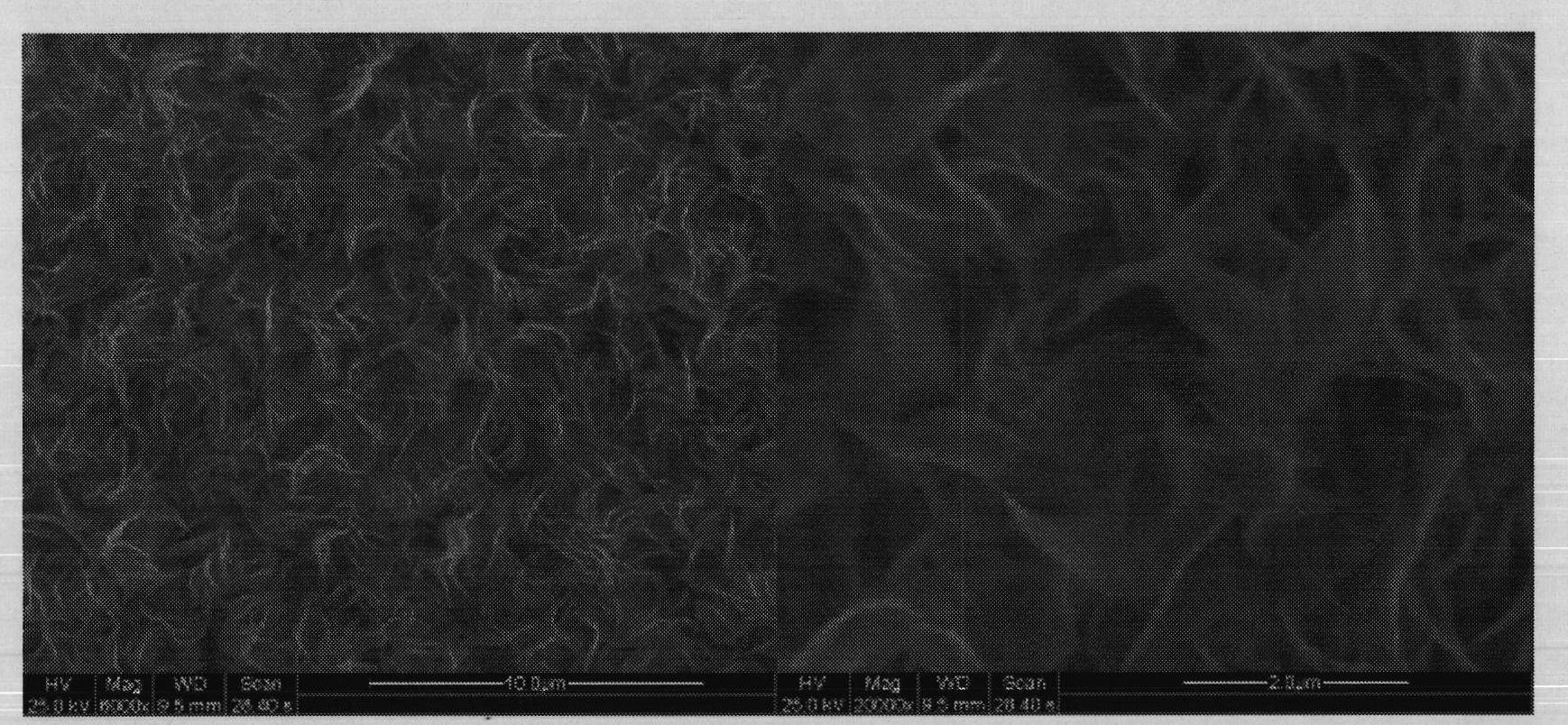

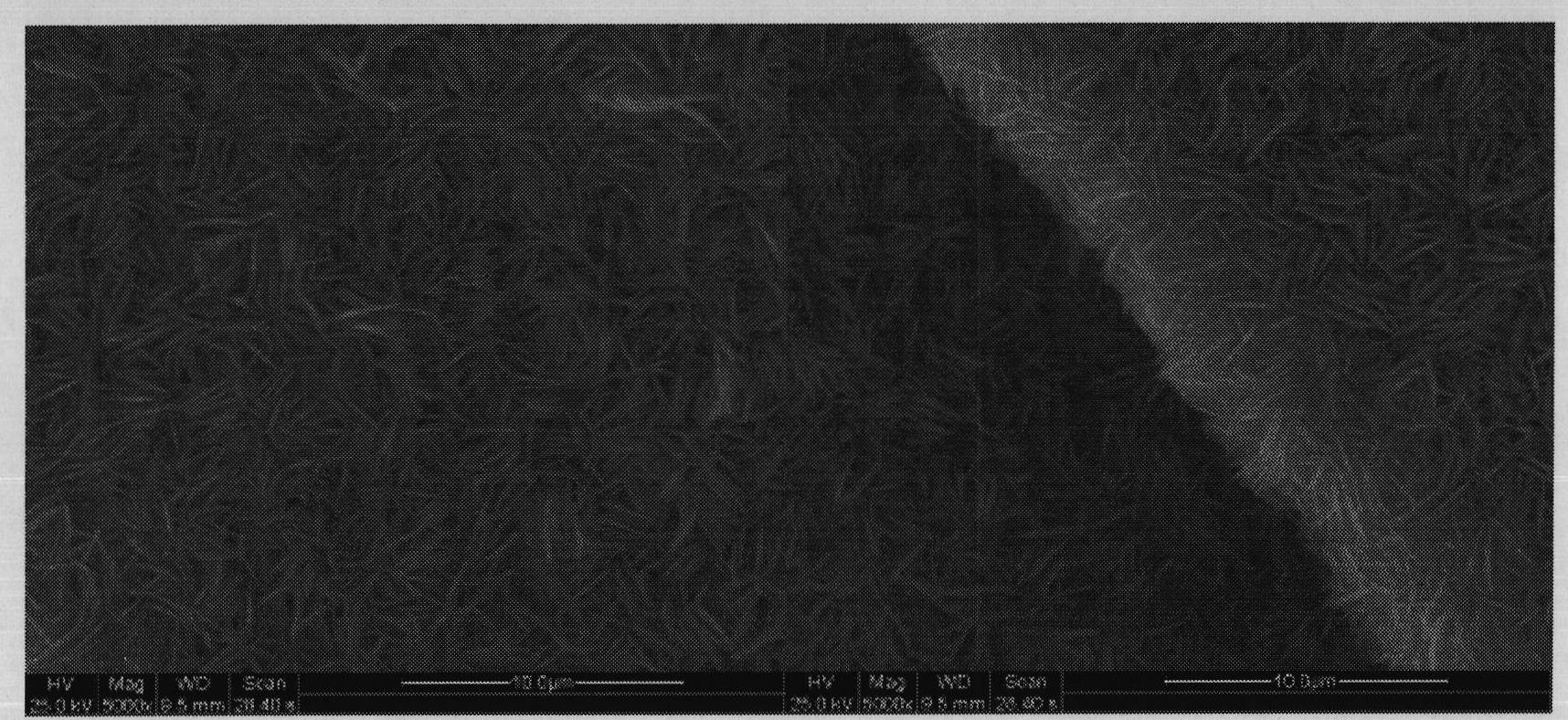

CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display of wide color gamut and preparation method and application thereof

ActiveCN110294597AImprove internal quantum efficiencyImprove thermal stabilitySemiconductor devicesFluorescenceGermanium dioxide

The invention belongs to the technical field of display of fully-organic perovskite quantum dots, and discloses a CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display ofwide color gamut and a preparation method and application thereof. The CsPbBr3 perovskite quantum dot fluorescent glass comprises the following components in percentage by mole: 0 to 45% of SiO2 (silicon dioxide), 0 to 45% of GeO2 (germanium dioxide), 30 to 40% of B2O3 (boron oxide), 2 to 8% of Al2O3 (aluminum oxide), 3 to 7% of MCO3 (metal carbonate), 1 to 5% of ZnO (zinc oxide), 5 to 15% of CsBr(cesium bromide) or Cs2CO3 (cesium carbonate), 2 to 10% of PbBr2 (lead bromide) or PbO (lead oxide), and 3 to 15% of NaBr (sodium bromide) or KBr (potassium-bromide), wherein M is Ca (calcium) or Sr(strontium); the sum of the components in percentage by mole is 100%. The CsPbBr3 perovskite quantum dot fluorescent glass has the advantages that the technology is simple, and the operation is easy;after in-situ crystallization, the quantum efficiency is higher, the light emitting stability is obviously improved, and the broad application prospect is realized.

Owner:SOUTH CHINA AGRI UNIV

Microporous aluminophosphate molecular sieve membranes for highly selective separations

ActiveUS20100311565A1High selectivityGood chemical and thermal stabilitySolid sorbent liquid separationPretreated surfacesMolecular sieveIn situ crystallization

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

Molecular sieve film and preparation method thereof

InactiveCN101962196AGood repeatabilitySimple and fast operationPretreated surfacesMolecular-sieve and base-exchange phosphatesIn situ crystallizationMolecular sieve

The invention relates to a molecular sieve film and a preparation method thereof, in particular to an aligned nano laminar AFI or CHA type molecular sieve film and an in-situ preparation method thereof based on layer-by-layer film coating and vapor-phase transfer. The molecular sieve film is composed of nano laminar AFI or CHA type molecular sieve crystals in aligned arrangement. The method comprises the following steps: successively coating two film-coating liquids on a glass sheet support, and then carrying out in-situ crystallization by vapor-phase transfer. The layer-by-layer film-coating preparation method does not need the introduction of crystal seeds or the aging of a synthesis liquid, has the advantages of convenient operation and high film-forming repeatability and can realize the industrial expanded production easily. By simultaneously combining vapor-phase transfer to carry out crystallization, the invention greatly reduces the preparation cost of the molecular sieve film and is beneficial to the cyclic utilization of the template agent.

Owner:NANJING UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com