Patents

Literature

57 results about "Sodium reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst of catalyzing, cracking for reducing sulfur content in gasoline and preparation process thereof

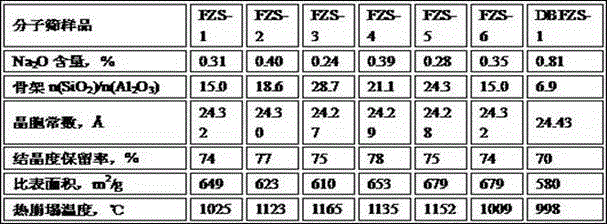

InactiveCN1597850AGood dispersionGood hydrothermal stabilityCatalytic crackingMolecular sieveIn situ crystallization

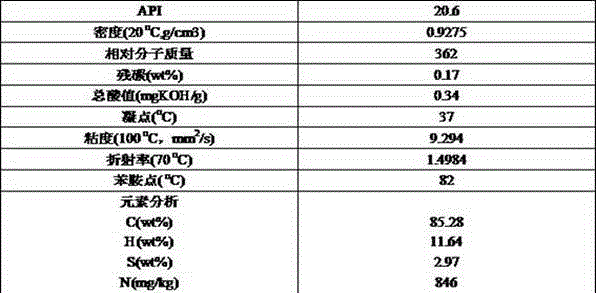

The invention is a catalytic cracking catalyst to reduce sulfur content of gasoline and its preparing method, synthesis gama-type molecular sieve by kaoline in-situ crystallization and making exchange sodium reduction or / and rare-earth ion exchange processing to prepare it, and its characteristic: the weight percent of sodium oxide contained in it is less than 0.75%, the ratio of zeolite to silica-alumina is above 4.5, and it adds one or several of the sourish metal elements: Cu, Zn, Fe, Al, Ni, Zr, Sn, Ga, Ti and V in weight percent of 0.1-10%. It has good zeolite dispersivity and excellent hydrothermal stability, good catalytic cracking property, and excellent function of reducing sulfur content of gasoline. It can be used by mixing with routine FCC catalyst and also be singly applied in the catalytic cracking process course.

Owner:PETROCHINA CO LTD

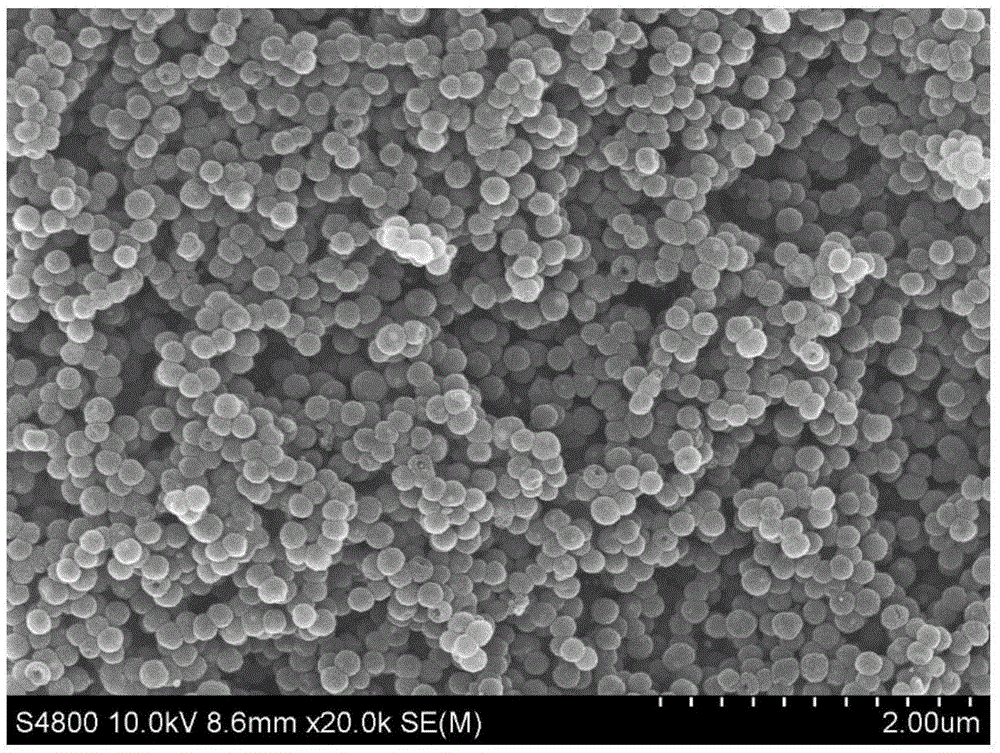

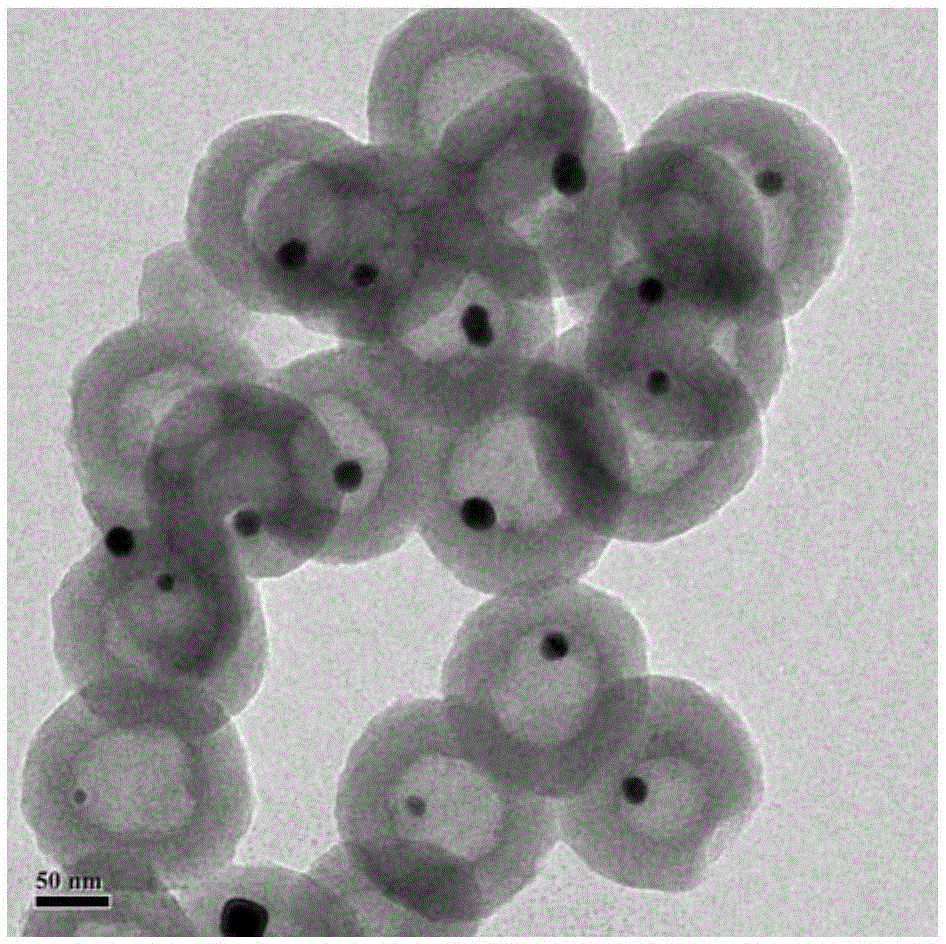

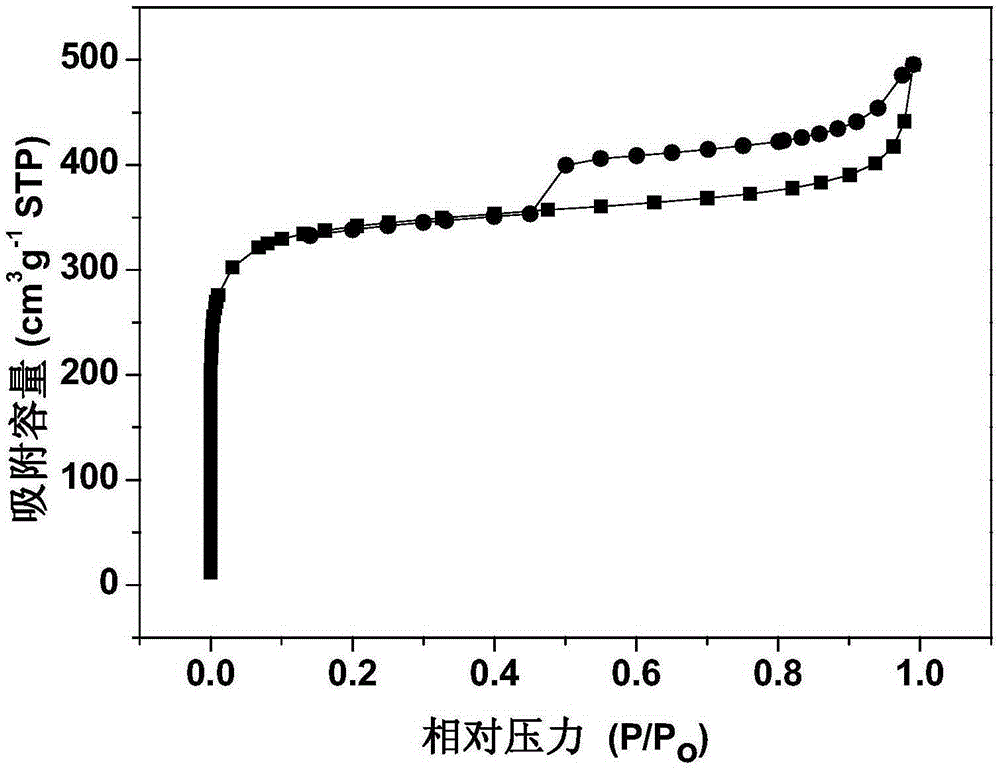

Yolk-eggshell structure Au@ hollow carbon nanosphere composite material and preparation and application thereof

The invention discloses a yolk-eggshell structure Au@ hollow carbon nanosphere composite material and preparation and application thereof. A preparation method includes the following steps that sodium citrate is adopted for reducing chlorogoldacid, and nanogold hydrosol is prepared; the nanogold hydrosol, organic monomers, water and a Triton X-100 aqueous solution are stirred and mixed; then, an initiating agent is added into a system to initiate polymerization of the monomers, and precursors are prepared; the organic monomers are composed of aniline and pyrrole; and under the inert atmosphere, the precursors are processed in a high-temperature carbonizing manner so that the yolk-eggshell structure Au@ hollow carbon nanosphere composite material can be prepared. According to the preparation method, the tedious steps that a template is prepared, complicated surface modification is needed and the template is removed are not needed, and preparation is easy and convenient. The specific surface area and the size of the prepared material can be regulated and controlled through the carbonization condition and the concentration of the organic monomers, the specific surface area is high, and the prepared material has a good catalytic effect on nitrobenzene and p-nitrophenol.

Owner:SUN YAT SEN UNIV

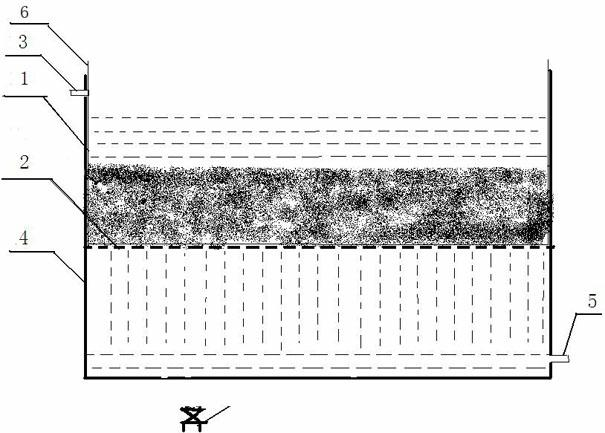

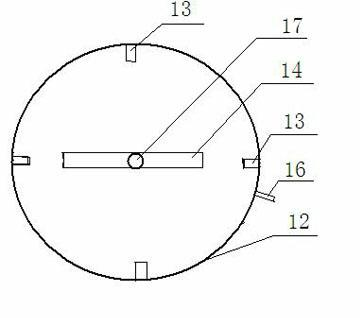

Rinsing method and device of potassium fluotantalate product obtained through sodium reduction

The invention relates to a rinsing method and device of a potassium fluotantalate product obtained through sodium reduction. The rinsing method comprises the following steps: using sodium to reduce potassium fluotantalate and obtain coagulum, crushing the coagulum, diafiltrating, rinsing, stirring to rinse, pickling, and drying to obtain raw tantalum powder. The obtained tantalum powder has high purity and good porosity and can be used to prepare condensed tantalum powder which is particularly suitable for the manufacture of the electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

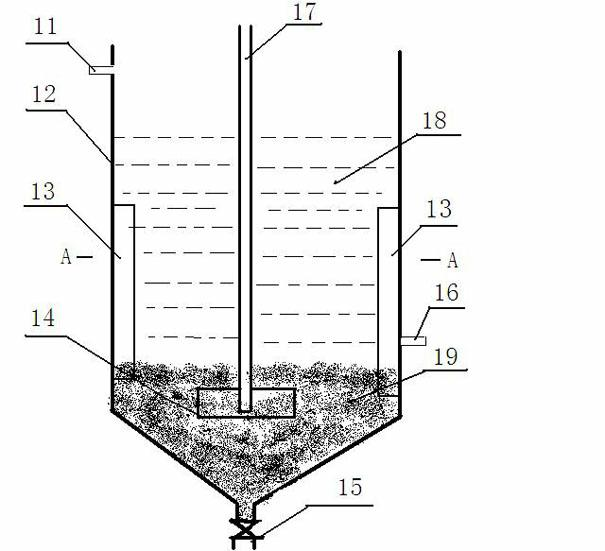

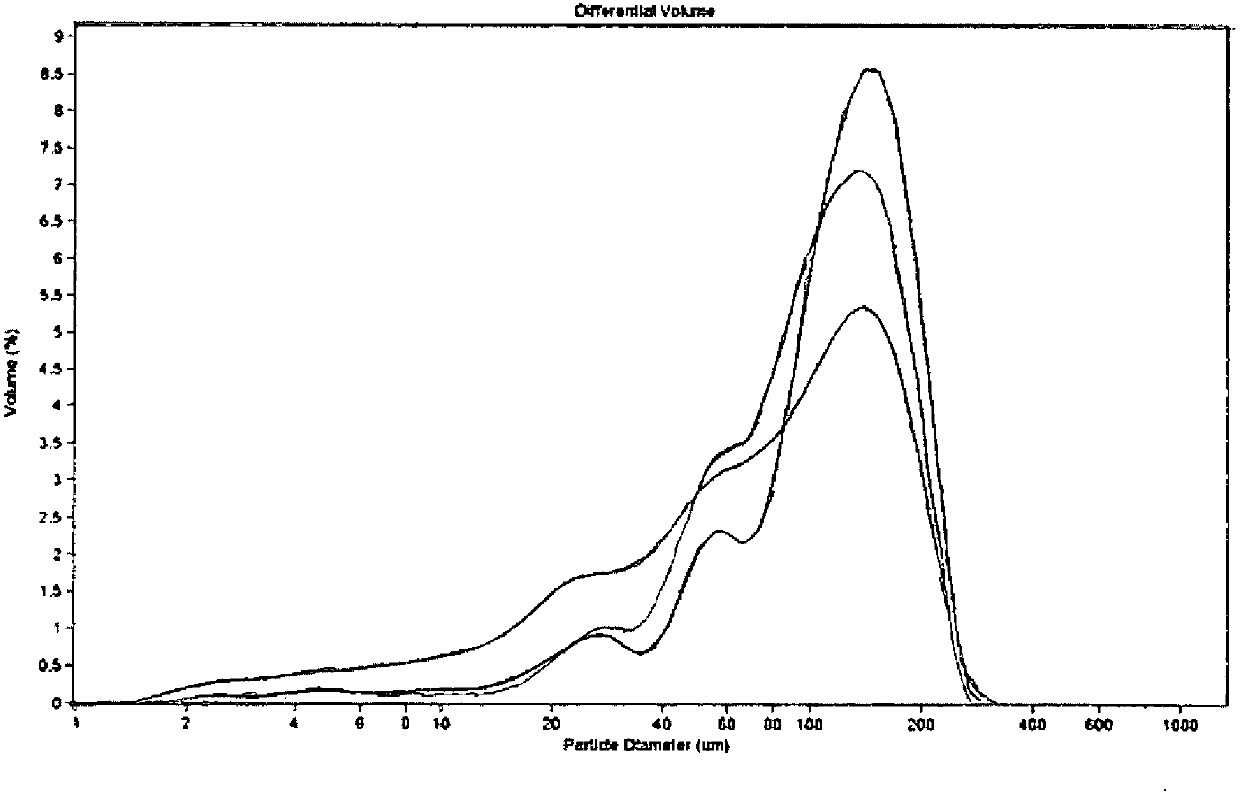

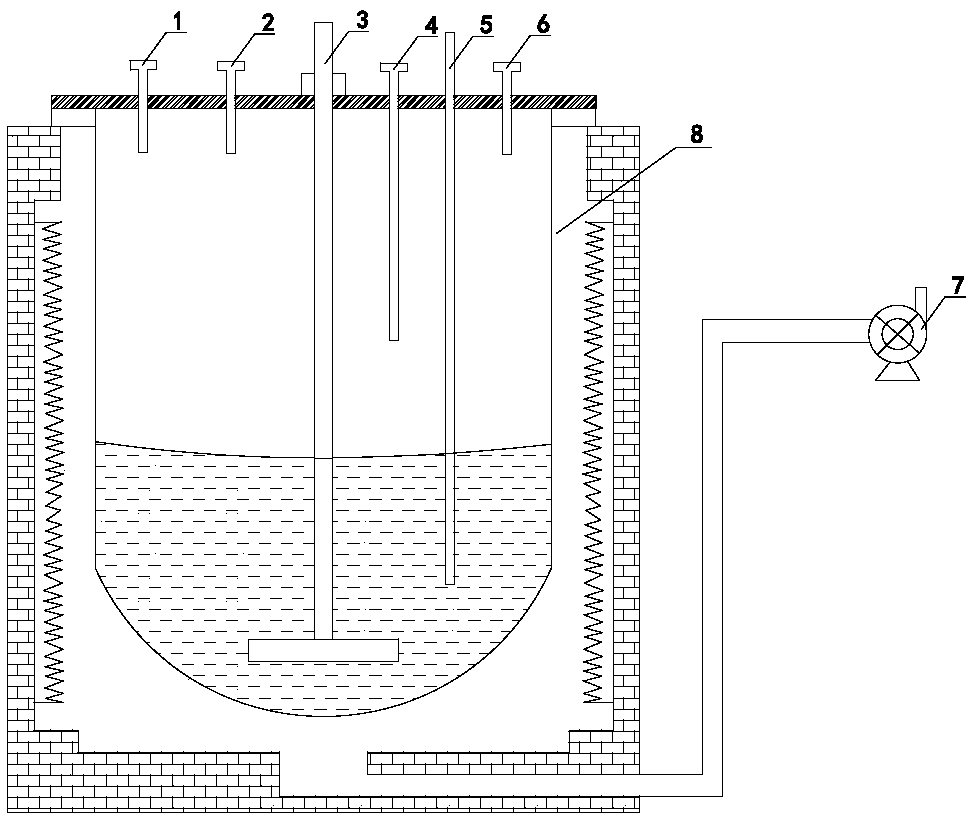

Stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium

The invention relates to a stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium. The water-washing method comprises the following steps of: performing stirring water-washing on the tantalum powder obtained by reducing potassium fluotantalate (K2TaF7) via metallic sodium (Na) which removes alkali metal haloids in an electrolyte solution, so as to remove harmful and indissolvable ultrafine-particle impurities in the tantalum powder; and then performing acid-washing and drying to obtain the initial tantalum powder. The method is high in the yield of tantalum powder; and the obtained tantalum powder is high in purity, good in particle size distribution and porosity, and especially suitable for manufacturing a tantalum electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

Recovery, balance adjustment and comprehensive utilization technology for mixing alkali in indigo blue production

ActiveCN102924956AGood profitLess investmentCarbonate preparationIndigoid dyesResource savingPotassium hydroxide

A purpose of the invention is to achieve sodium reduction, potassium retention, and no use or less use of potassium hydroxide based on recovery utilization of mixing alkali and potassium-sodium balance adjustment in an indigo blue production process. According to the present invention, waste alkali residue, washing alkali water and surplus sodium hydroxide in oxidation alkali in the existing production are utilized, bicarbonate or carbon dioxide, and a plurality of ways are applied and introduced to the concentrate, and difference between dissolubility of sodium carbonate and potassium carbonate and a common ion effect are delicately utilized to generate sodium carbonate precipitate and separate, such that removal of surplus sodium hydroxide in the liquid alkali is achieved without introduction of new impurities, the sodium carbonate product is co-produced, about 0.5 ton of the potassium hydroxide is saved and about 1 ton of the sodium carbonate is by-produced when per ton of the indigo blue product is produced, and a new process route with characteristics of alkali resource comprehensive utilization and delicate potassium and sodium balance is developed. With the present invention, characteristics of low investment, resource saving, cleaning, environmental protection, economy, novelty, strong practicality and wide generalization application value are provided, significant theory and application values are provided for the circular economy and sustainable development strategy, ??and wide social benefits, economic benefits and ecological benefits are provided.

Owner:JIANGSU TAIFENG CHEM +1

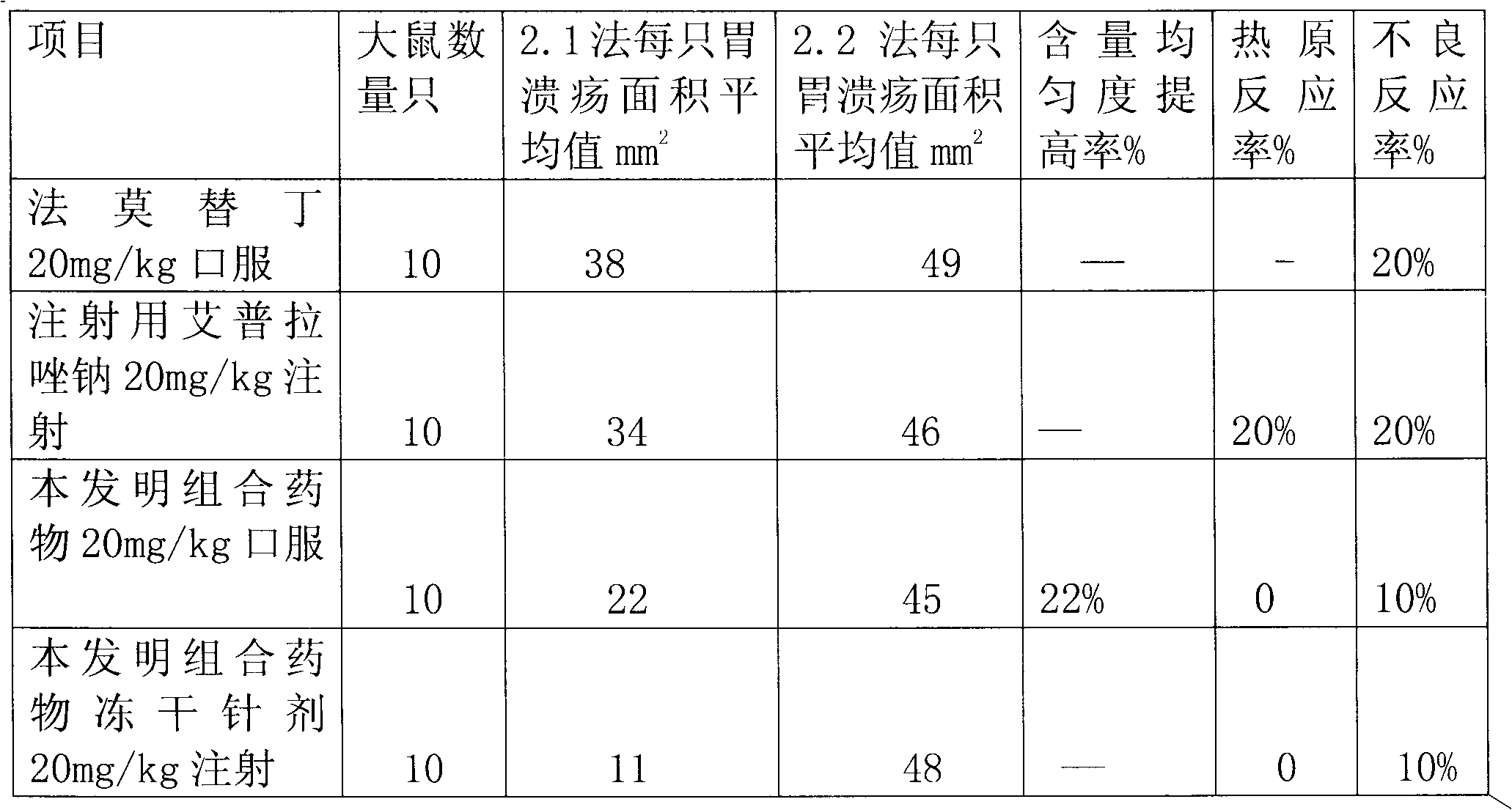

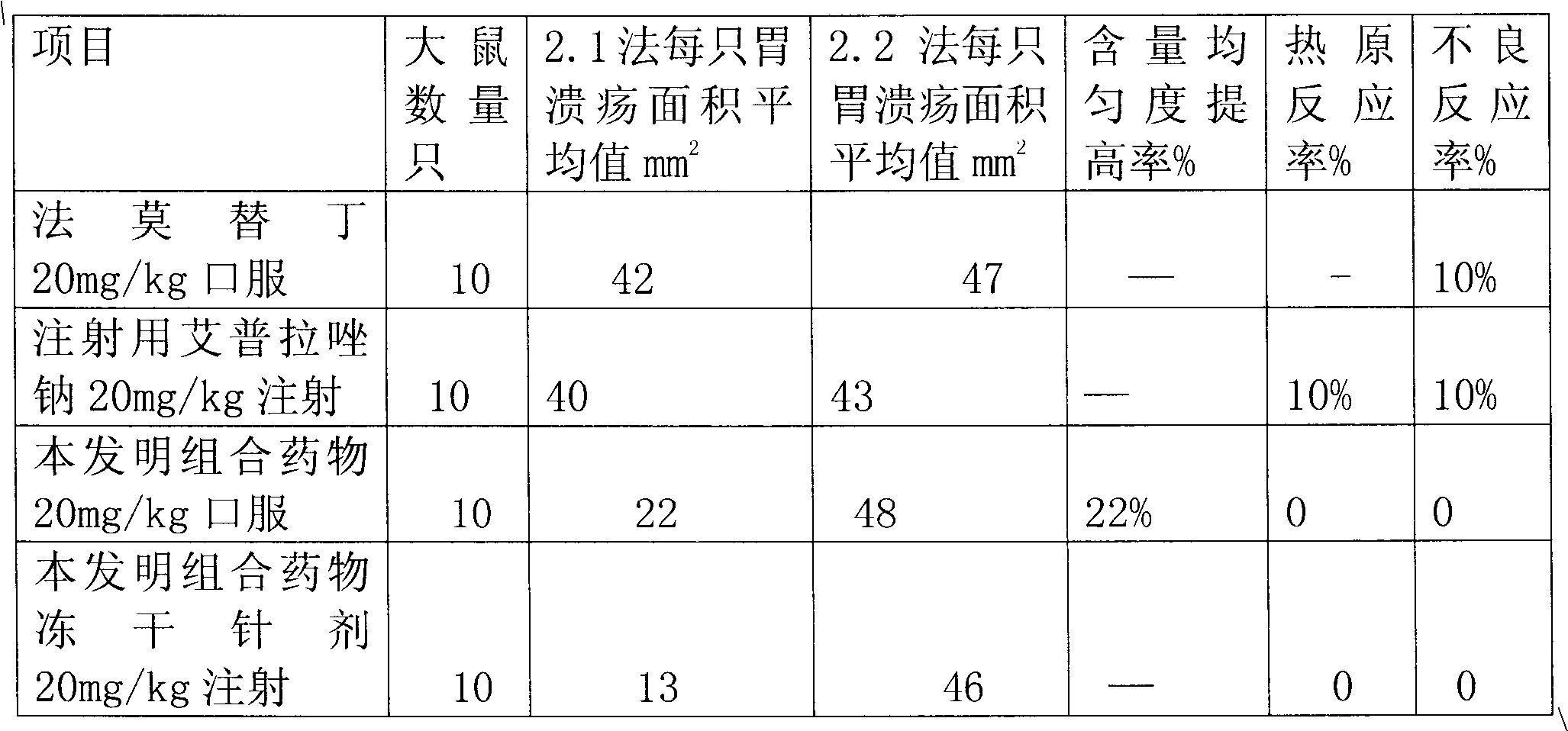

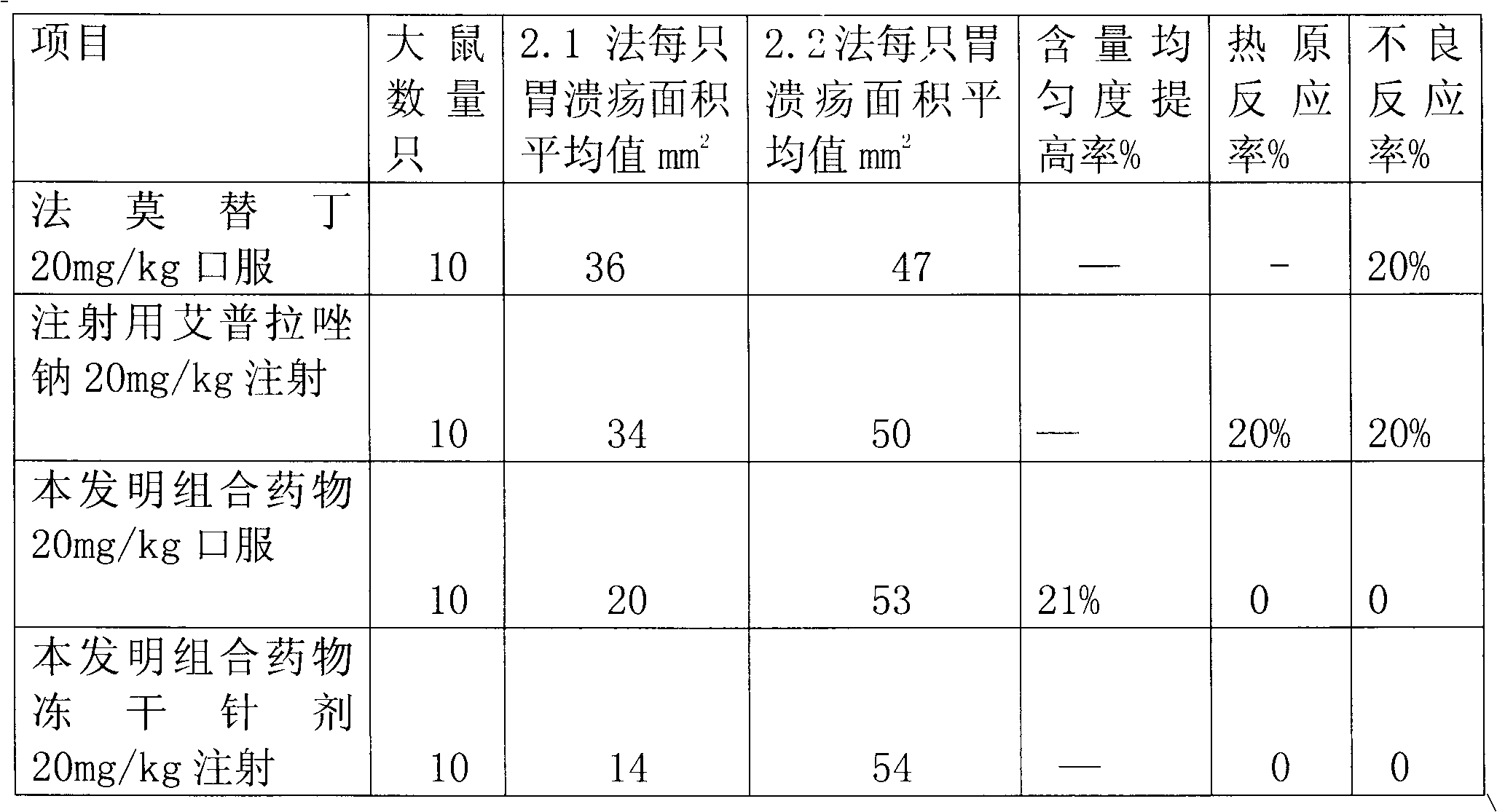

Combination medicament of ilaprazole sodium and preparation process thereof

InactiveCN102058593AEliminate adverse reactionsGood regeneration performanceOrganic active ingredientsDigestive systemCoated tabletsFreeze-drying

The invention provides a combination medicament of ilaprazole sodium. The medicament is characterized by comprising the following raw materials in percentage by weight: 5-10 percent of ilaprazole sodium, 25-35 percent of reduction composition containing glutathione and tiopronin with a weight ratio of 1:10 and 45-55 percent of diammonium glycyrrhizinate. The invention also provides a preparation process of the medicament. According to a pharmaceutically acceptable dosage of the ilaprazole sodium, the combination medicament can be respectively prepared into medical preparations of the dosage forms of injections of the combination medicament of the ilaprazole sodium, freeze-drying injections of combination medicament of the ilaprazole sodium, coated tablets of the combination medicament of the ilaprazole sodium, enteric capsules, sprays, and the like and is used for treating gastric ulcer.

Owner:吴赣英

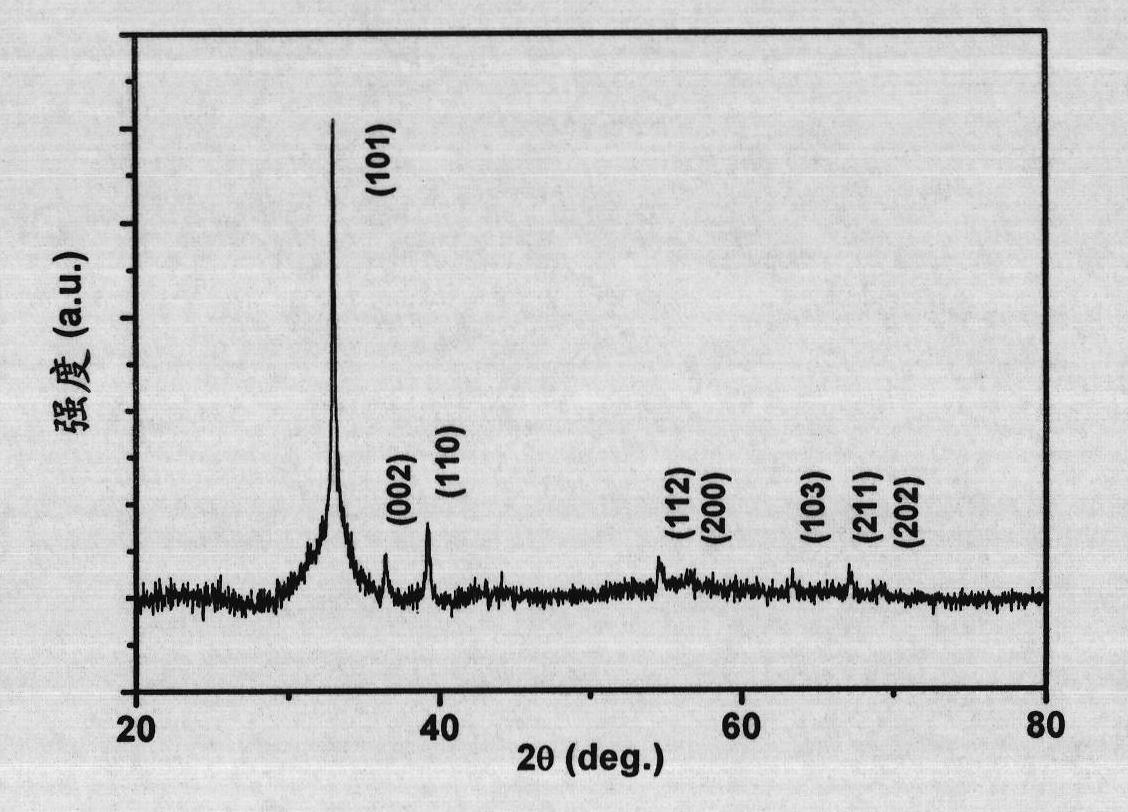

Preparation method of catalytic cracking catalyst

ActiveCN106732745AHigh crystallinity retentionImprove thermal stabilityCatalytic crackingMolecular sieve catalystsHigh concentrationGas phase

The invention relates to a preparation method of a catalytic cracking catalyst. According to the method, the NaY molecular sieve raw powder and halogen-containing gas are contact to perform gas phase ion exchange reaction; the sodium reduction and the ultra-stabilization of the NaY molecular sieve raw powder are completed in one step; the low-sodium high-silica-alumina-ratio molecular sieve is prepared. According to the method, different kinds of clay raw ores are compounded and are treated by high-concentration acid to obtain acid active composite clay; then, the low-sodium high-silica-alumina-ratio molecular sieve, the acid active composite clay, bonding agents, rare earth and decationized water are mixed and pulped; then, spraying granulation is performed; roasting and curing are performed; washing and drying are not needed; a finished product of the catalytic cracking catalyst is obtained. The catalytic cracking catalyst has the advantages that the olefin content in the gasoline can be obviously reduced; the light oil yield is improved; the preparation flow process of the catalyst is short; no ammonia and no nitrogen are discharged.

Owner:REZEL CATALYSTS CORP

Preparation method and application of metallic indium nanometer particle ink

The invention discloses a preparation method for preparing metallic indium nanometer particle ink, which comprises the following steps: (1) dissolving indium chloride in polyalcohol, and adding stabilizing agents; (2) dissolving sodium-containing reducing agents in a polyalcohol solution to be prepared to a reducing agent solution; (3) fast injecting the reducing agent solution obtained in the second step into the solution prepared in the first step for reaction when the reducing agent solution is still hot, and obtaining metallic indium nanometer particles through centrifugation, washing and drying; and (4) dissolving the metallic indium nanometer particles in a special solvent for preparing the nanometer particle ink. The invention also discloses an application method of the metallic indium nanometer particle ink to the preparation of copper-indium sulfide films. The invention has the advantages of simple reaction, easy implementation of the reaction reaction, low cost, high yield and the like, and prepared films have compact and smooth surfaces, crystal grains have large dimension, and the films do not have obvious impure phases.

Owner:ZHEJIANG UNIV

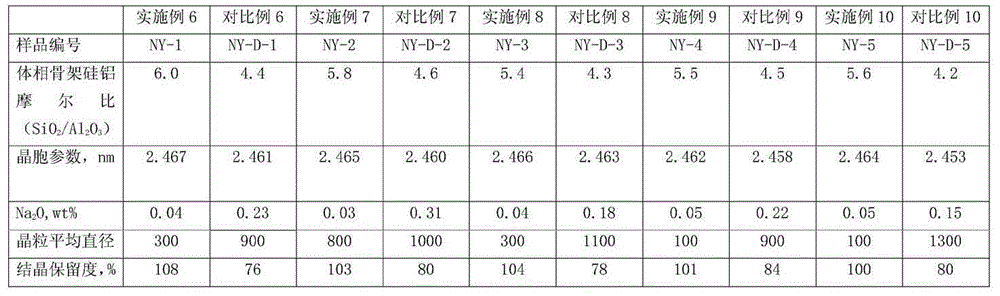

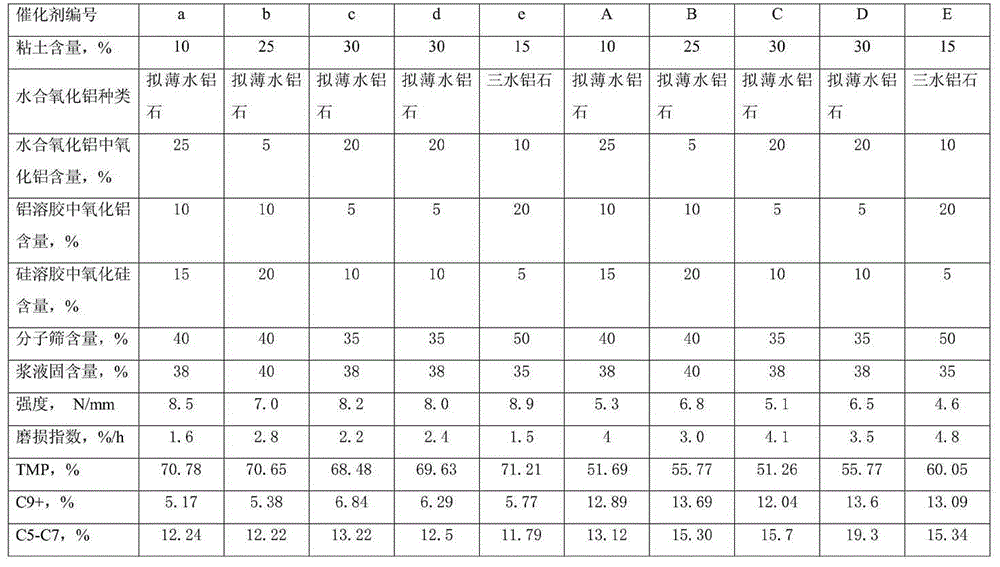

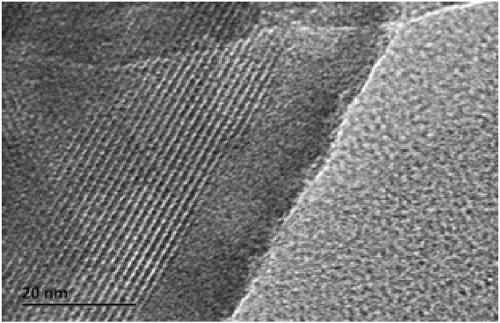

Preparation method of catalyst containing small-grain Y-type molecular sieve

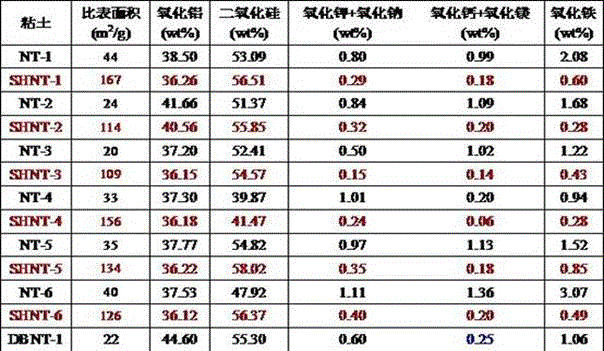

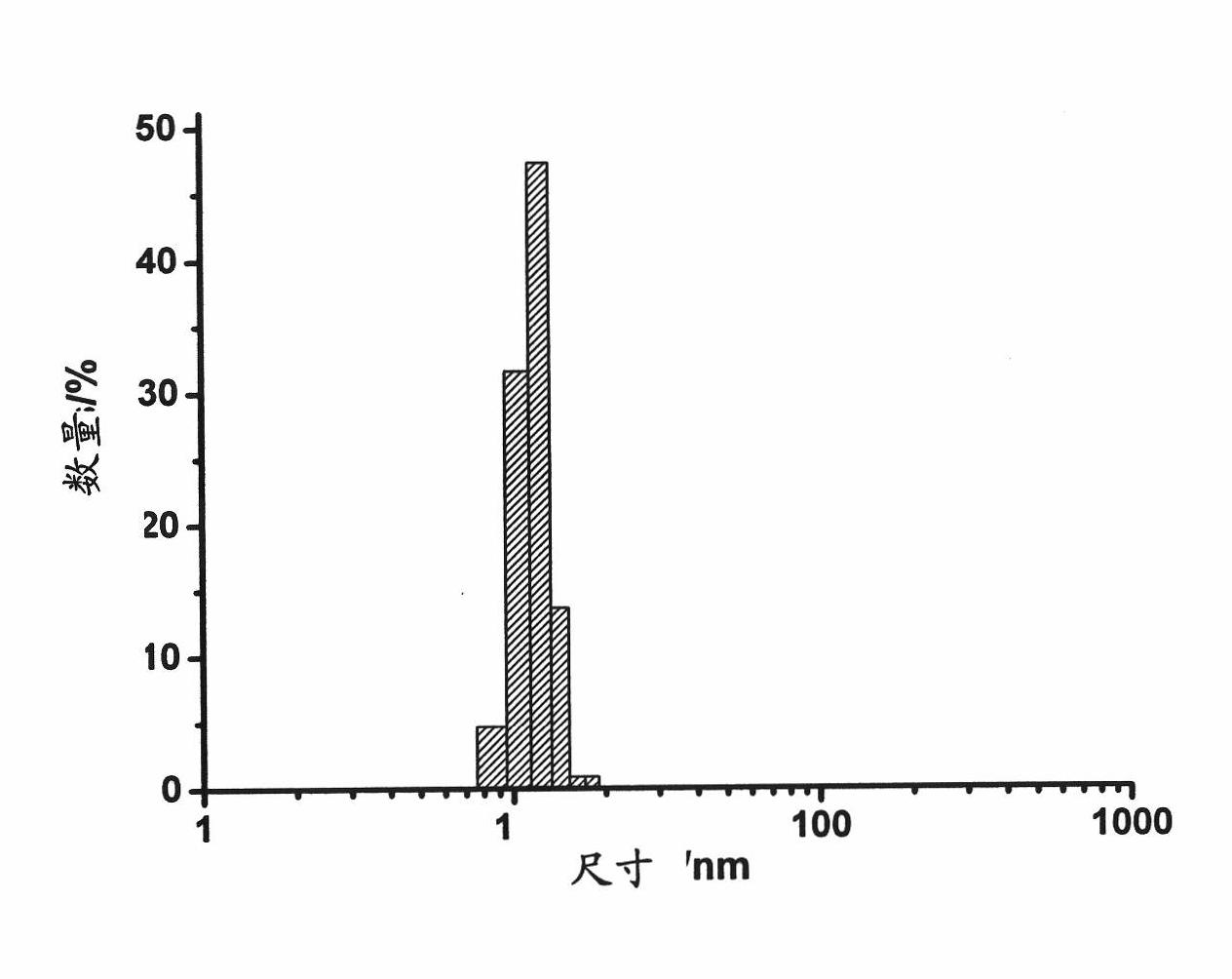

ActiveCN105080590ASave raw materialsRaw materials are easy to getMolecular sieve catalystsFaujasite aluminosilicate zeoliteSlurryMixing tank

The invention provides a preparation method of a catalyst containing a small-grain Y-type molecular sieve. The preparation method comprises steps of mixing raw materials including a small-grain Y-type molecular sieve, alumina sol, hydrated alumina, silica sol, clay, acid and water to obtain slurry and moulding to obtain the catalyst. The preparation method is characterized in that the small-grain Y-type molecular sieve is prepared from the following steps: successively adding a guiding agent, a silicon source, an aluminium source and water into a mixing tank under synthesis conditions of a NaY molecular sieve so as to obtain a mixture A, carrying out hydrothermal crystallization on the mixture A and recovering an obtained product, carrying out ammonium exchange for sodium reduction on the product, carrying out a hydro-thermal treatment, beating, adding silica sol with pH of 2-4 and C2-C4 organic alcohols, adjusting pH to 3-6 with citric acid, fully mixing at the temperature of 80-120 DEG C, washing and drying. The catalyst prepared by the above method has good mechanical strength and has better catalytic performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

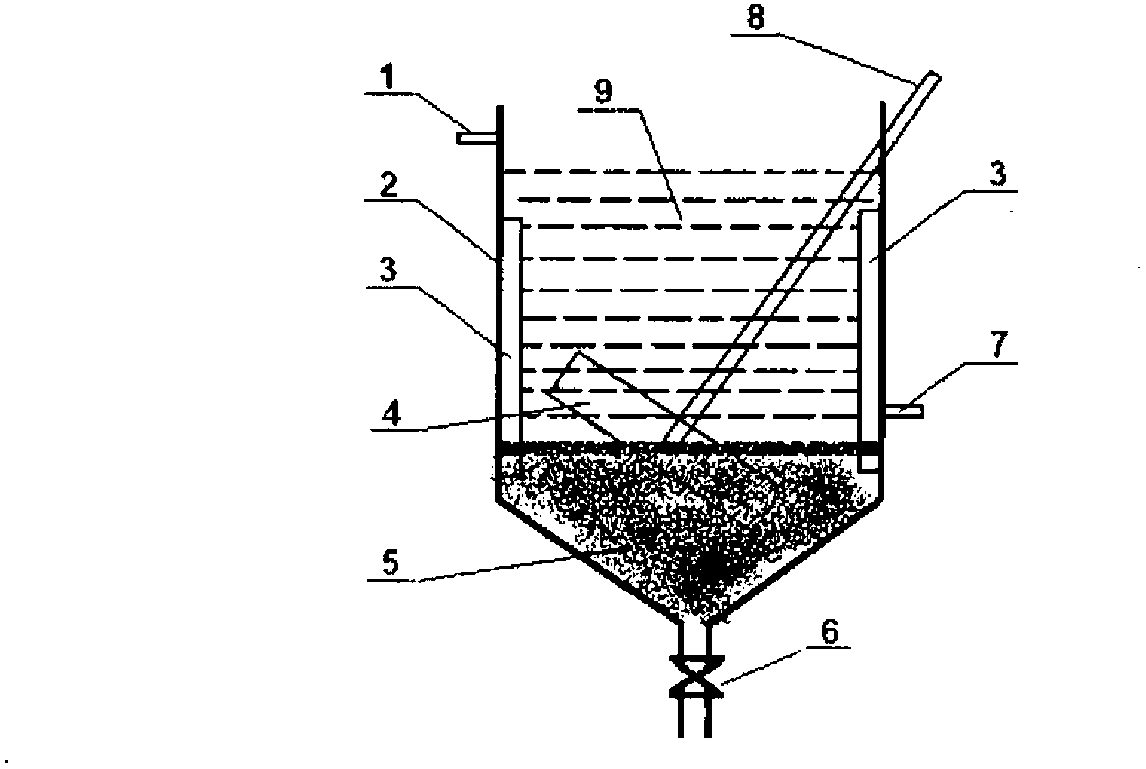

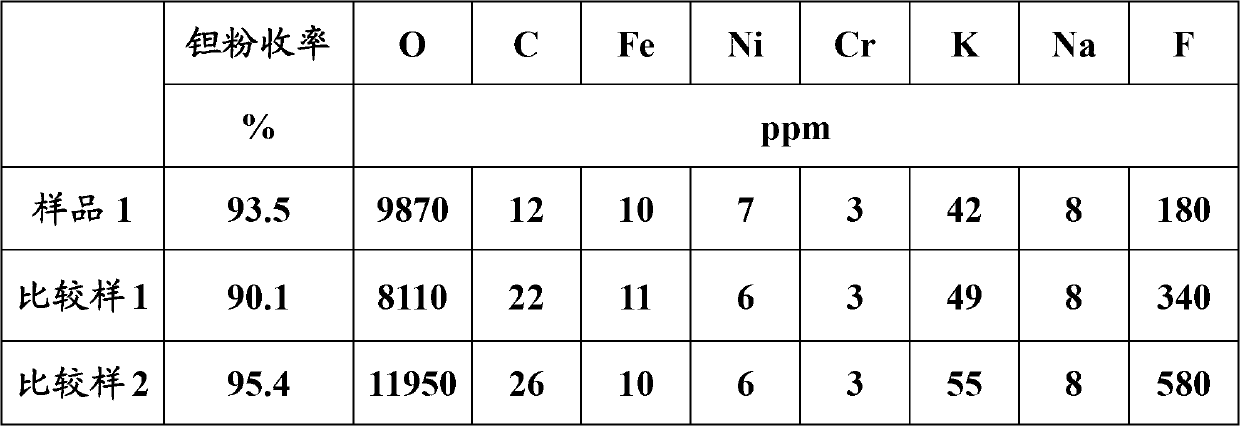

Method for preparing target-level high-purity tantalum powder

The invention relates to a method for preparing target-level high-purity tantalum powder. According to the method for preparing the target-level high-purity tantalum powder, a block-shaped mixture of tantalum powder prepared through potassium fluotantalate sodium reduction and one or more of diluted slats including NaCl, KCl and KF is filtered and washed with pure water, when the conductivity of filtering and washing liquid is smaller than 5000 us / cm, the filtered and washed mixture is poured into a horizontal type ball mine for wet-type ball milling, the mixture is taken out, acid pickling, suction filtration and drying are conducted on the mixture, so that raw tantalum powder is obtained, thermal treatment, oxygen reduction, oxygen-reduction acid pickling, secondary drying and detection are conducted on the raw tantalum powder, and then the target-level high-purity tantalum powder is obtained. According to the method for preparing target-level high-purity tantalum powder, the technology is simple, the production cost is low, the tantalum powder prepared according to the method is large in apparent density, high in purity, low in oxygen content and capable of meeting the requirement of a target for the purity and the density of materials, and therefore tantalum target cost and tantalum alloy target cost are greatly reduced.

Owner:NINGXIA ORIENT TANTALUM IND +1

Heavy Oil Catalytic Cracking Catalyst and Preparation Method Therefor

ActiveUS20150080209A1Increase heightHigh heavy-oil-conversion capacityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveRare earth

The present invention relates to a heavy oil catalytic cracking catalyst and preparation method thereof. The catalyst comprises 2 to 50% by weight of an ultra-stable rare earth type Y molecular sieve, 0.5 to 30% by weight of one or more other molecular sieves, 0.5 to 70% by weight of clay, 1.0 to 65% by weight of high-temperature-resistant inorganic oxides, and 0.01 to 12.5% by weight of rare earth oxide. The ultra-stable rare earth type Y molecular sieve is obtained as follows: the raw material, NaY molecular sieve, is subjected to a rare earth exchange and a dispersing pre-exchange, and the molecular sieve slurry is filtered, washed and subjected to a first calcination to produce a “one-exchange one-calcination” rare earth sodium Y molecular sieve, wherein the order of the rare earth exchange and the dispersing pre-exchange is not limited; and the “one-exchange one-calcination” rare earth sodium Y molecular sieve is further subjected to ammonium salt exchange for sodium reduction and a second calcination. The catalyst provided in the present invention is characteristic in its high heavy-oil-conversion capacity, a high total liquid yield and a high light oil yield.

Owner:PETROCHINA CO LTD

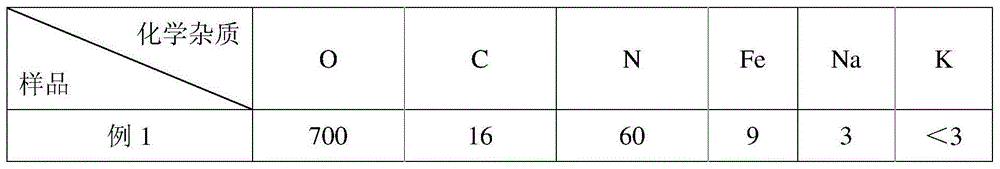

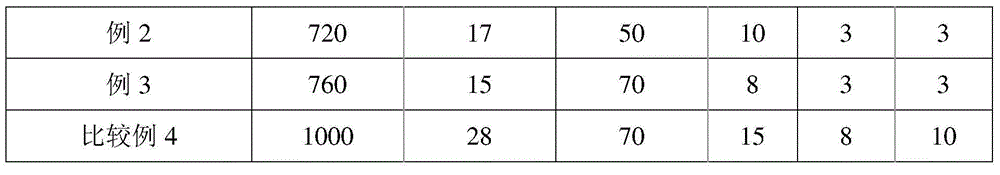

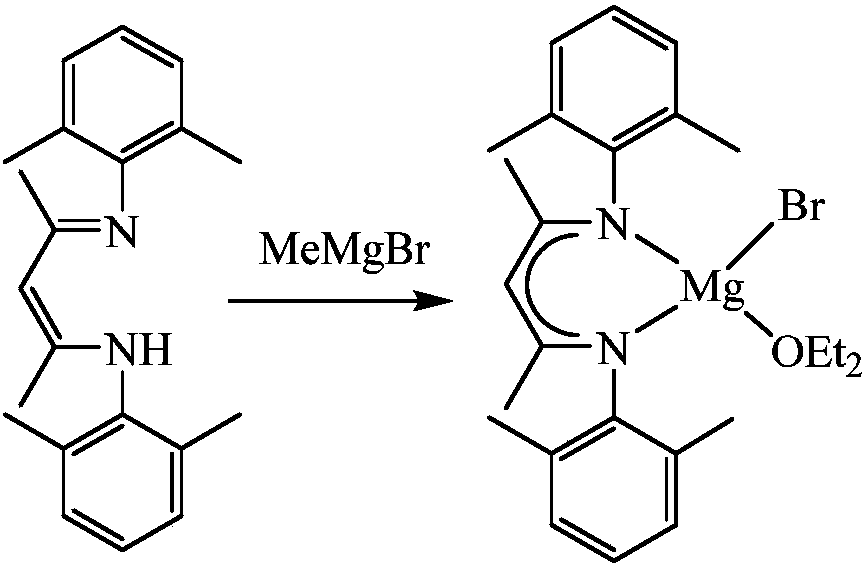

Beta-diimine univalence magnesium compound, preparation method and application thereof in aldosterone silicon cyanide

InactiveCN107556195AEasy to purifyLow toxicityCarboxylic acid nitrile preparationOrganic compound preparationGrignard reagentSilanes

The invention discloses a β-diimine monovalent magnesium compound and its preparation and application in silanization of aldehydes and ketones. The preparation method is as follows: under anhydrous and oxygen-free conditions, β-diimine ligand reacts with Grignard reagent to generate magnesium bromide, and then reduces it with sodium to obtain yellow crystal, which is β-diimine monovalent magnesium compound. The β-diimine monovalent magnesium compound of the present invention has simple synthesis, convenient separation and purification, clear structure, and high yield; it has high activity as a catalyst to catalyze the reaction of aldehydes or ketones with trimethylsilyl cyanide, and the substrate is universal wide sex.

Owner:NANJING FORESTRY UNIV +1

DDGS as a Low-Cost Flavor Enhancer and Sodium Reduction Enabler

New uses of distiller's grain and solubles (DGS) are provided, including beneficial use of the natural flavor of DGS as a flavorant or sodium potentiator. A low-cost alternative to sodium and other flavorants is thereby provided.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

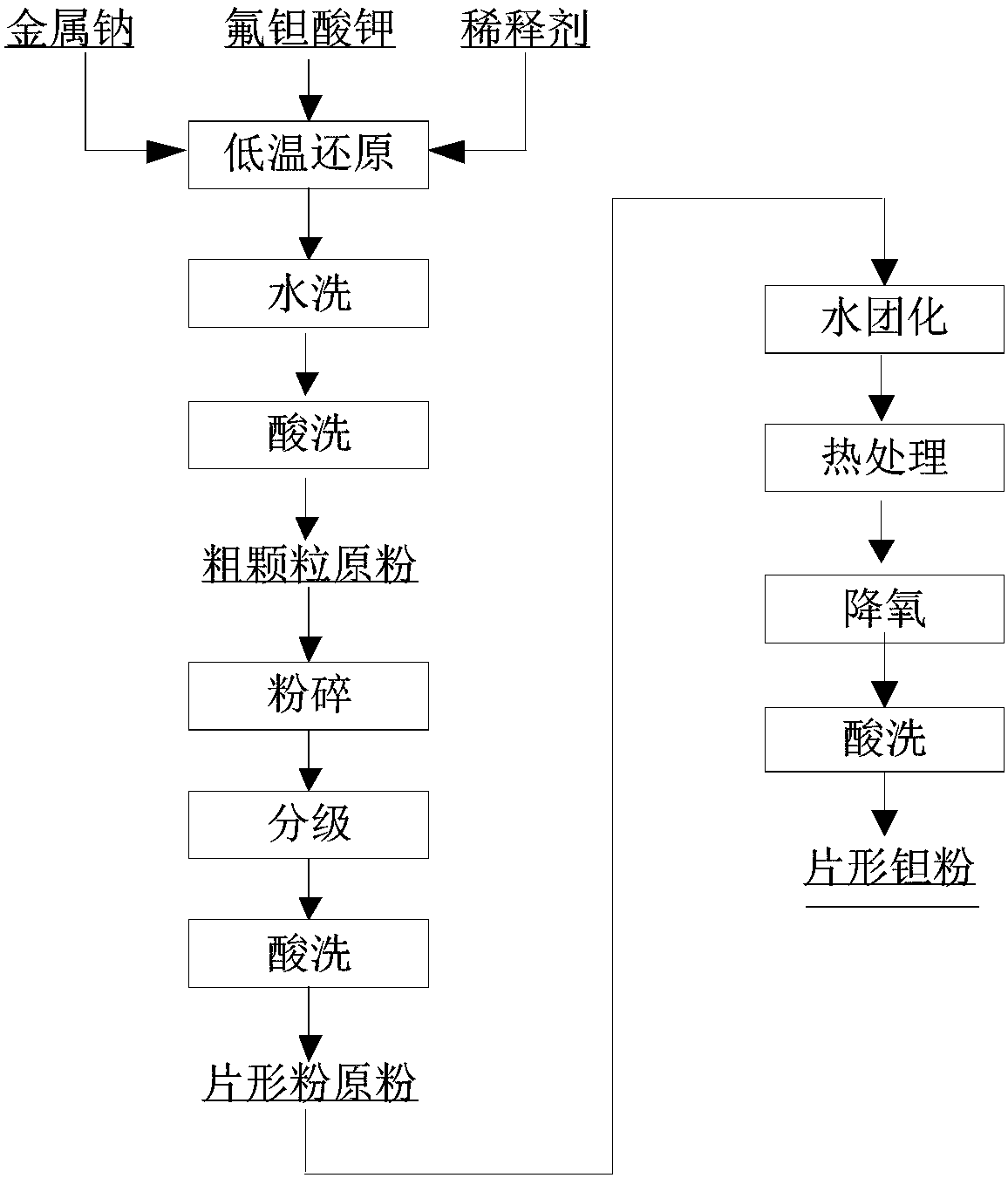

Ultrafine chip high-pressure tantalum powder production process

ActiveCN108080654ALow impurity contentShorten production timeTransportation and packagingMetal-working apparatusPrillSodium reduction

Owner:江门富祥电子材料有限公司

Low-sodium salting agent and preparation method thereof

InactiveCN107874228ASolve the smellStrong preferenceFood ingredient as taste affecting agentNatural extract food ingredientsMaillard reactionSalty taste

A low-sodium salting agent is prepared from raw materials in percentage by weight as follows: 3%-10% of salty peptide prepared by a Maillard reaction, 5%-35% of non-sodium salty minerals, 2%-10% of fruit and vegetable powder or fruit and vegetable extracts, 0.1%-2% of a sour powder substance, 5%-20% of a umami substance and 30%-80% of table salt, wherein the sum of the weight percentages of all the raw materials is 100%. The salting agent solves the odor problem of low-sodium salt, the salty taste can be felt in the oral cavity in the gradual dissolution process, so that the salting agent haslong taste preservation time, comprehensive taste and high overall preference, a low-sodium salting product is formed, the sodium reduction proportion is high, the salting agent can be blended according to demands of consumers, and the sodium reduction proportion reaches 20%-70%.

Owner:TIANJIN CHUNFA BIO TECH GRP

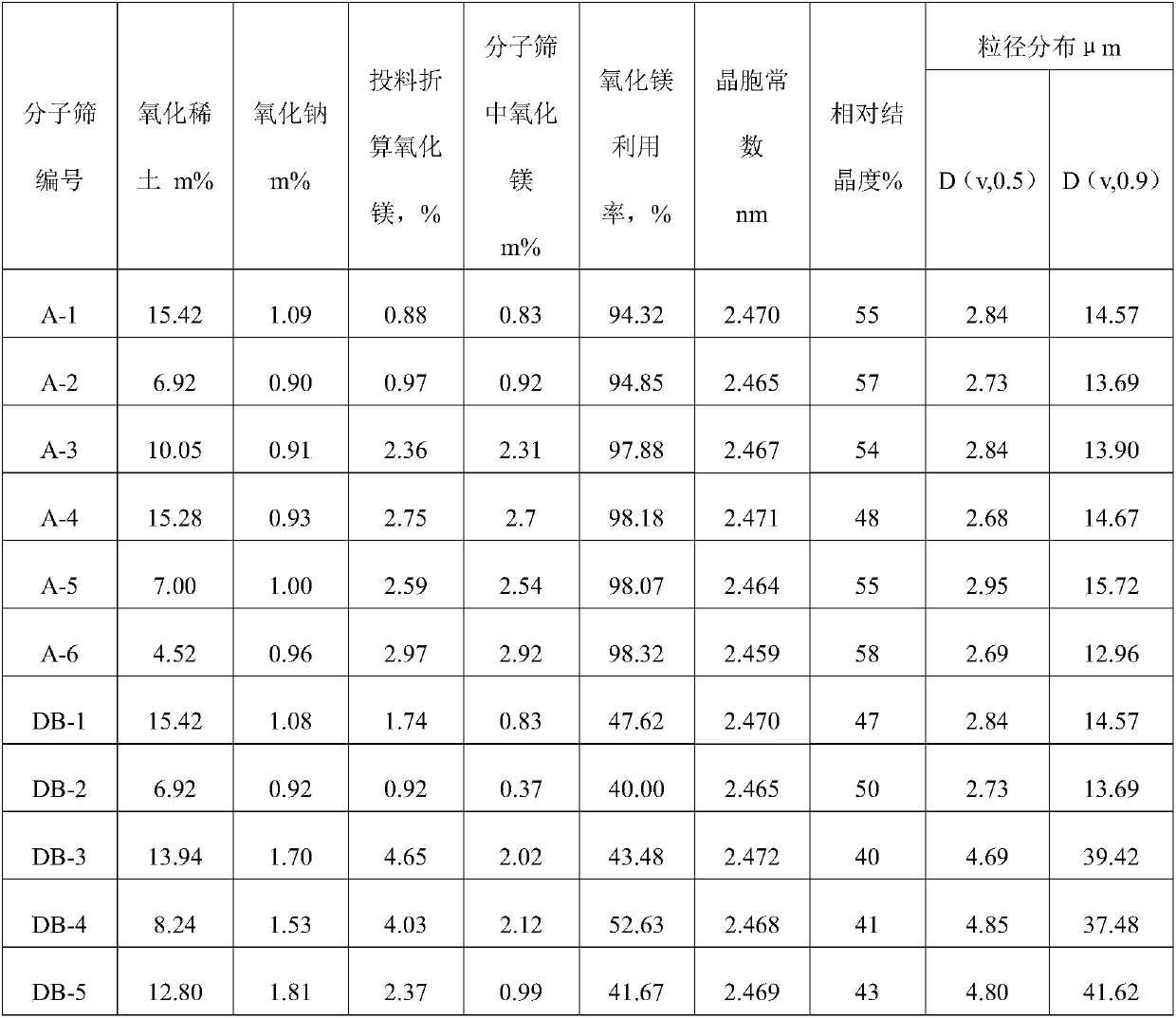

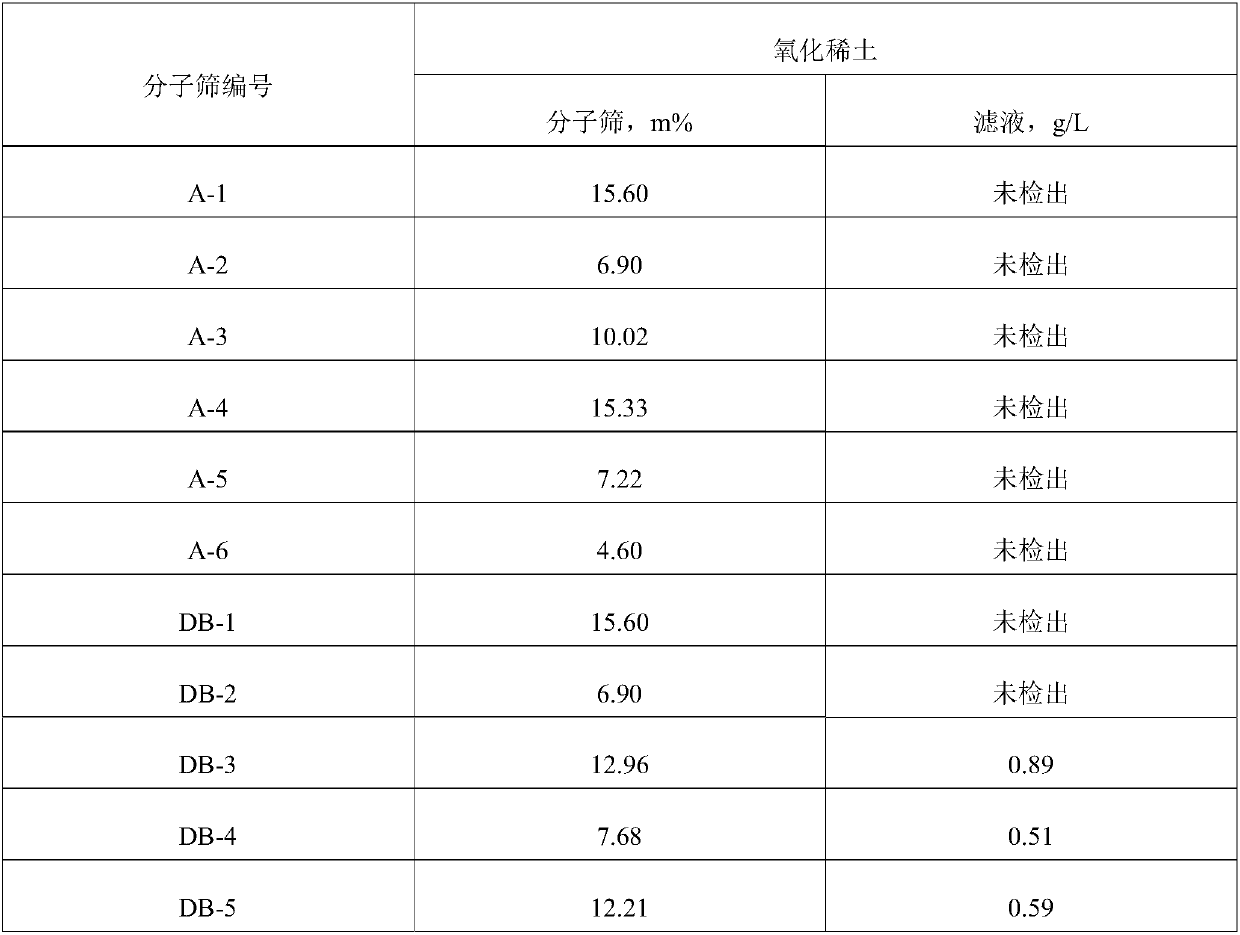

Preparation method of magnesium salt precipitation modified Y-type molecular sieve

InactiveCN110193375AReduce cracking activityHigh cracking activityCatalytic crackingMolecular sieve catalystsMolecular sieveMagnesium salt

The invention relates to a preparation method of a magnesium salt precipitation modified Y-type molecular sieve. NaY zeolite (the silicon-aluminum ratio is more than 4.0 and the crystallinity is morethan 75%) is taken as a raw material, and rare earth exchange, dispersion exchange and first roasting are carried out to obtain a ''once exchange and once roasting'' rare earth- NaY molecular sieve; the ''once exchange and once roasting'' rare earth- NaY molecular sieve is subjected to exchange sodium reduction modification, magnesium salt precipitation modification, and second roasting treatmentto obtain the magnesium salt precipitation modified Y-type molecular sieve, wherein the magnesium salt precipitation modification can be carried out before the second roasting, after the second roasting, or simultaneously before and after the second roasting, and the sequence is not particularly limited. A cracking catalyst prepared by adopting the molecular sieve can control the proportion of different reactions in the cracking process, reduces further cracking of light oil and improves the yield of the light oil.

Owner:PETROCHINA CO LTD

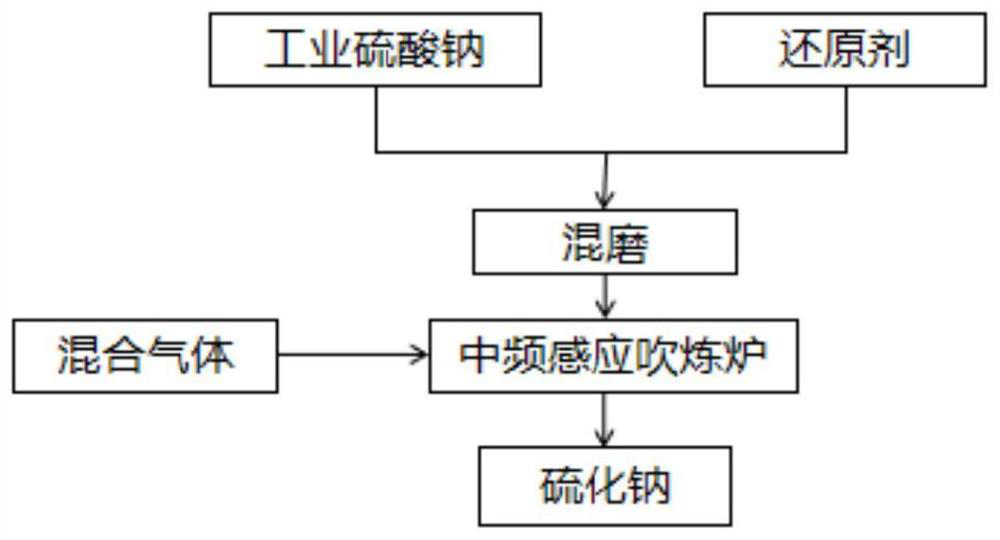

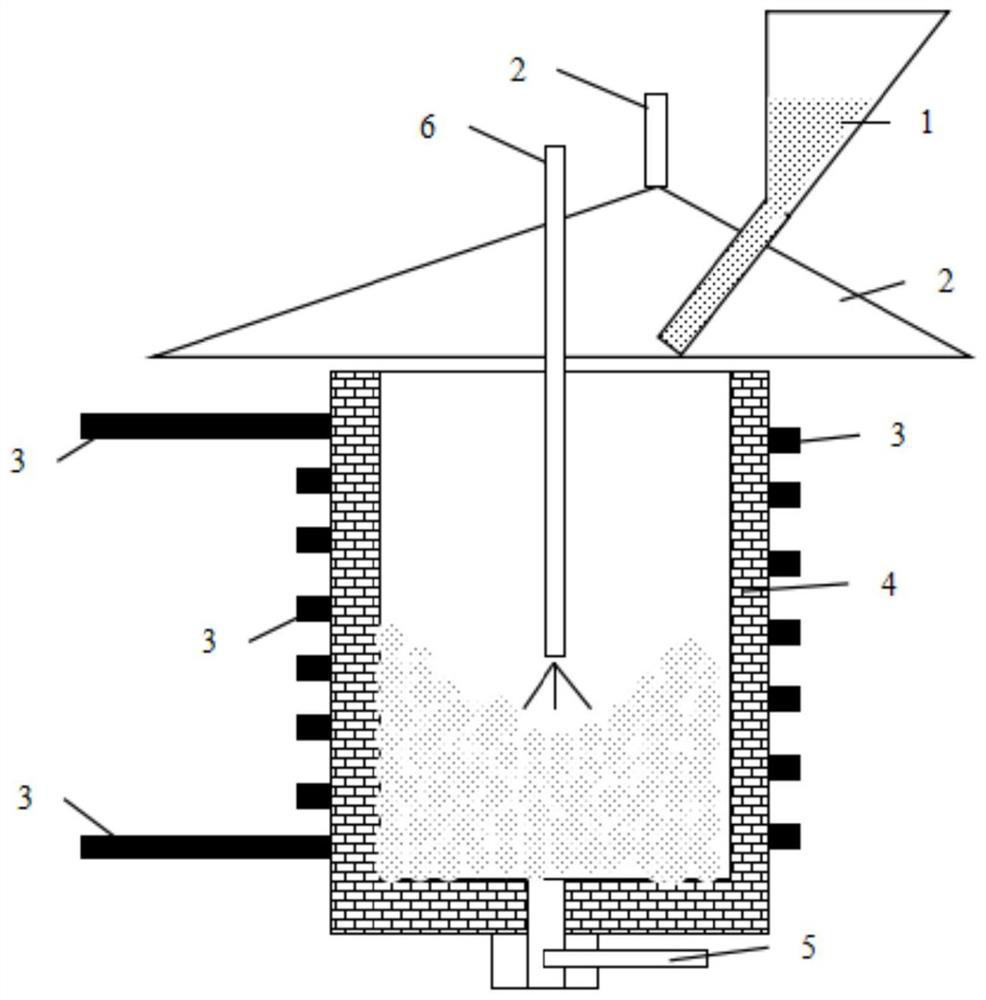

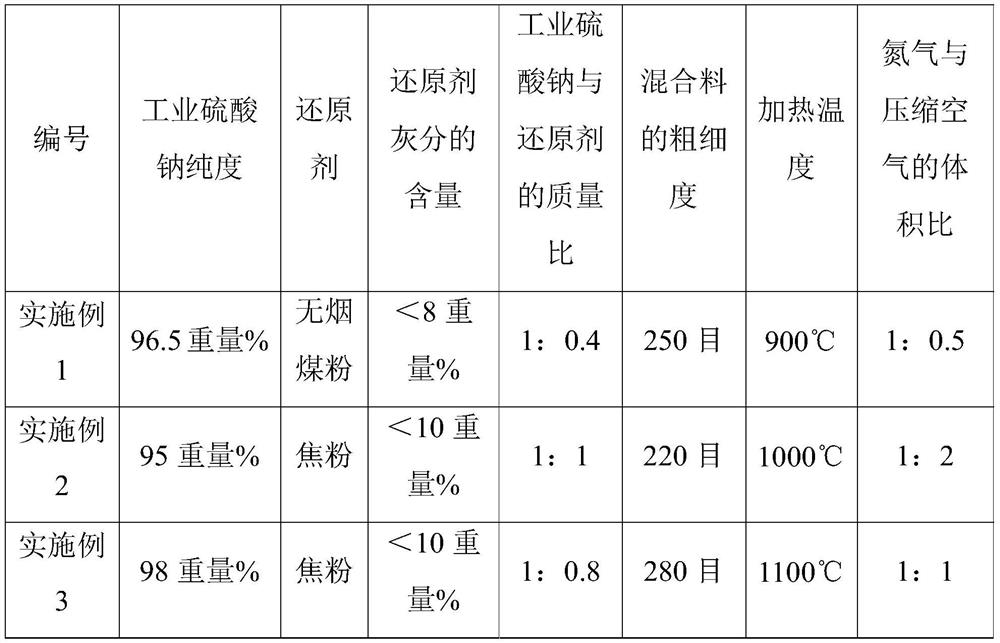

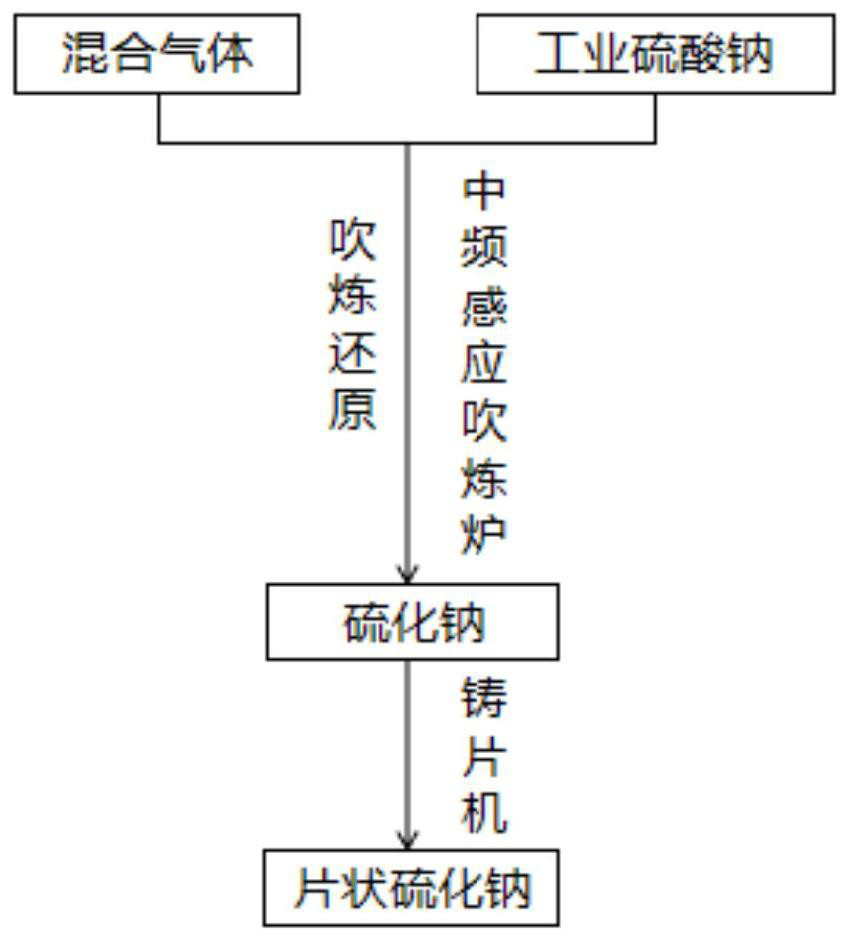

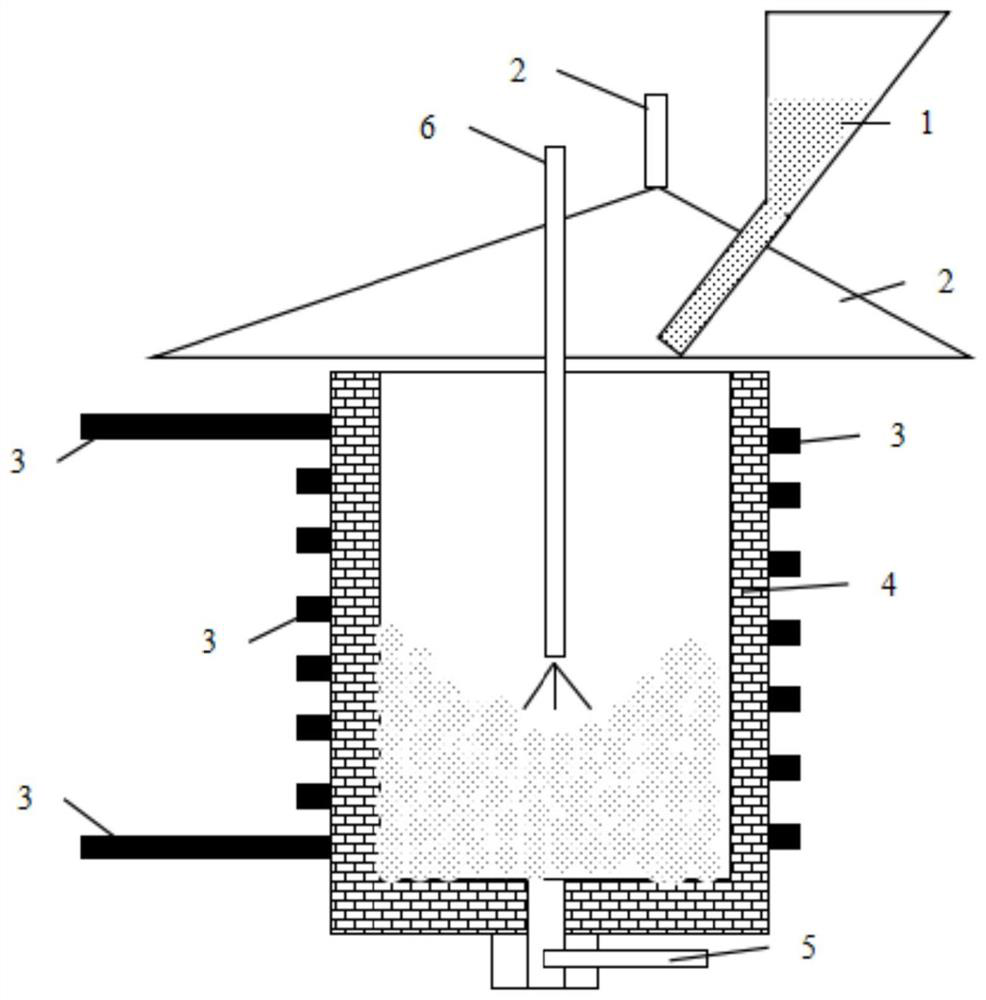

Method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate

InactiveCN112010266AReduce corrosionEasy to operateAlkali metal sulfides/polysulfidesSodium reductionSodium sulfate

The invention relates to the technical field of sodium sulfide preparation, and discloses a method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate. The method comprisesthe following steps: (1) mixing industrial sodium sulfate with a reducing agent, and carrying out ball milling to obtain a mixture with the fineness of less than or equal to 200 meshes, (2) adding the mixture obtained in the step (1) into a medium-frequency induction converting furnace, heating to a molten state, blowing mixed gas for converting reduction, reducing molten sodium sulfate into molten sodium sulfide, and pouring the molten sodium sulfide out of the medium-frequency induction converting furnace, and (3) pouring and molding the molten sodium sulfide poured out in the step (2), wherein in the step (1), the mass ratio of the industrial sodium sulfate to the reducing agent is 1: 0.4-1. According to the method, industrial sodium sulfate is used as a raw material, a reducing agentis added, the industrial sodium sulfate is molten and reduced into sodium sulfide through a full-fire method, the method is simple, environmentally friendly and small in equipment corrosion, and the prepared sodium sulfide is high in purity and content up to 90 wt% or above.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate

InactiveCN112028031AHigh purityReduce lossAlkali metal sulfides/polysulfidesPhysical chemistrySodium reduction

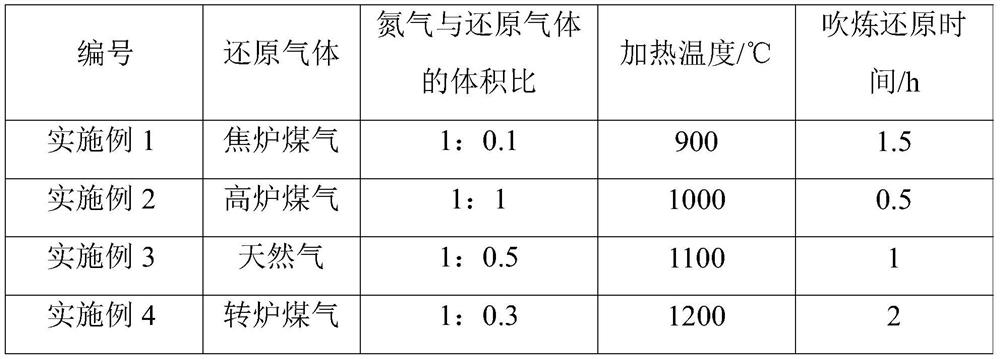

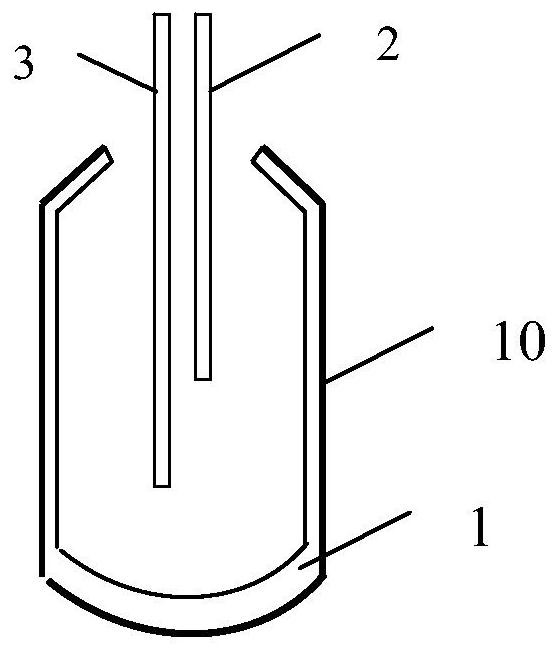

The invention relates to the technical field of sodium sulfide preparation, and discloses a method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate. The method comprisesthe following steps: (1) adding industrial sodium sulfate into a medium-frequency induction converting furnace for heating to a molten state; then mixed gas of nitrogen and reducing gas is injected into the molten sodium sulfate for converting reduction, the molten sodium sulfate is reduced into molten sodium sulfide, then the molten sodium sulfide is poured out of the medium-frequency inductionconverting furnace, and the volume ratio of the nitrogen to the reducing gas is 1: 0.1-1; and (2) pouring and molding the molten sodium sulfide poured out in the step (1). According to the method, industrial sodium sulfate is used as a raw material, a medium-frequency induction converting furnace is used as reduction equipment, mixed gas is blown for converting reduction, the method is simple andenvironmentally friendly, equipment corrosion is small, and the prepared sodium sulfide is high in purity.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of method for preparing sodium sulfide by reduction of molten state of industrial sodium sulfate

ActiveCN110589775BReduce corrosionEasy to operateAlkali metal sulfides/polysulfidesPhysical chemistryEngineering

The invention relates to the technical field of sodium sulfide preparation, and discloses a method for preparing sodium sulfide through reduction of industrial sodium sulfate in molten state. The method comprises the following steps: (1) purifying industrial sodium sulfate; (2) adding the purified industrial sodium sulfate as a raw material into a blowing furnace, igniting and heating the industrial sodium sulfate raw material into molten sodium sulfate, and then spraying Blowing reducing gas for blowing reduction, reducing the molten sodium sulfate to molten sodium sulfide; (3) pouring the molten sodium sulfide out of the blowing furnace, casting and cooling to obtain sodium sulfide. The method uses industrial sodium sulfate with a content of more than 90% as a raw material, uses a blowing furnace as a reduction equipment, and adopts a full-fire method to melt and reduce industrial sodium sulfate to sodium sulfide. The method is simple and environmentally friendly, and the equipment is less corrosive. The purity of sodium is high, and the content is as high as more than 90%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

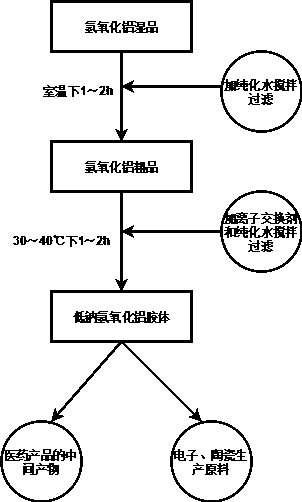

Purification technology of colloid compound

ActiveCN109809454ARetain activityLow costIon-exchange process apparatusMaterial nanotechnologyIon exchangeColloid

The invention discloses a purification technology of a colloid compound, and belongs to an important sodium removing step during a drug-almagate preparation process. The purification technology comprises the following steps: mixing the colloid compound with water, stirring, and filtering, thus obtaining a colloid compound crude product; then adding an ion exchanger, stirring, and filtering, thus obtaining a purified colloid compound. According to the purification technology disclosed by the invention, the problems of high raw material cost, complicated technology, complicated operation and thelike existing in the prior art as technologies such as an organic aluminum method, a high-purity aluminum spark discharge method and a sol-gel method are overcome, and the purification technology hasthe advantages that the cost is low, the process is simplified, drying is not required, a sodium reduction effect is remarkable, and the like.

Owner:湖南九典宏阳制药有限公司

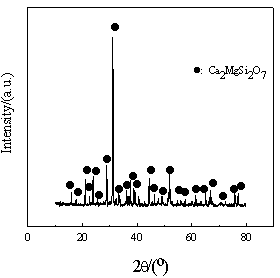

Method for preparing calcium magnesium silicate powder

InactiveCN104140108AReduce reunionLow heat treatment temperatureAlkaline-earth metal silicatesEvaporationCalcium magnesium

The invention relates to a method for preparing calcium magnesium silicate powder and belongs to the field of preparation of inorganic nonmetal superfine powder. The method comprises the following steps: firstly, weighing calcium nitrate, magnesium nitrate, sodium silicate and a reducer in a molar ratio being (1-2):(1-2):(1-2):(6-30); and then, fully dissolving calcium nitrate, magnesium nitrate and the reducer in deionizer water firstly, then, dissolving sodium silicate in water to prepare a sodium silicate aqueous solution, pouring the sodium silicate aqueous solution into the aqueous solution formed by calcium nitrate, magnesium nitrate and the reducer, then heating the aqueous solution by a magnetic stirrer to 90 DEG C-100 DEG C, continuously stirring for 0.3 hour-1 hour, and directly transferring the solution to a high temperature sintering furnace which is pre-heated to 650 DEG C-800 DEG C, wherein severe combustion happens along with water evaporation to obtain a fluffy foam-like product. By adopting sodium silicate which is relatively low in cost as a raw material, the method facilitates actual application. The prepared powder is good in dispersion and fine in granule. The equipment and the process are simple.

Owner:SHANGHAI INST OF TECH

High Light Received Heavy Oil Catalytic Cracking Catalyst and Preparation Method Therefor

ActiveUS20150011378A1High yieldModerate coke selectivityCatalytic crackingMolecular sieve catalystsMagnesium saltRare earth

The present invention relates to a heavy oil catalytic cracking catalyst having a high yield of light oil and preparation methods thereof. The catalyst comprises 2 to 50% by weight of a magnesium-modified ultra-stable rare earth type Y molecular sieve, 0.5 to 30% by weight of one or more other molecular sieves, 0.5 to 70% by weight of clay, 1.0 to 65% by weight of high-temperature-resistant inorganic oxides, and 0.01 to 12.5% by weight of rare earth oxide. The magnesium-modified ultra-stable rare earth type Y molecular sieve is obtained by the following manner: the raw material, a NaY molecular sieve, is subjected to a rare earth exchange, a dispersing pre-exchange, a magnesium salt exchange modification, an ammonium salt exchange for sodium reduction, a second exchange and a second calcination. The catalyst provided in the present invention is characteristic in its high conversion capacity of heavy oil and a high yield of light oil.

Owner:PETROCHINA CO LTD

High light received heavy oil catalytic cracking catalyst and preparation method therefor

ActiveUS9889439B2High yieldIncrease capacityCatalytic crackingMolecular sieve catalystsMolecular sieveMagnesium salt

The present invention relates to a heavy oil catalytic cracking catalyst having a high yield of light oil and preparation methods thereof. The catalyst comprises 2 to 50% by weight of a magnesium-modified ultra-stable rare earth type Y molecular sieve, 0.5 to 30% by weight of one or more other molecular sieves, 0.5 to 70% by weight of clay, 1.0 to 65% by weight of high-temperature-resistant inorganic oxides, and 0.01 to 12.5% by weight of rare earth oxide. The magnesium-modified ultra-stable rare earth type Y molecular sieve is obtained by the following manner: the raw material, a NaY molecular sieve, is subjected to a rare earth exchange, a dispersing pre-exchange, a magnesium salt exchange modification, an ammonium salt exchange for sodium reduction, a second exchange and a second calcination. The catalyst provided in the present invention is characteristic in its high conversion capacity of heavy oil and a high yield of light oil.

Owner:PETROCHINA CO LTD

Method for improving vanadium yield in slag in process of sodium reduction

ActiveCN111378830AHigh yieldDoes not represent or limit the scope of rights protectionSlagPhysical chemistry

The invention relates to a method for improving vanadium yield in slag in the process of sodium reduction. The method comprises the following steps that (1) mixing pretreatment is conducted on alkaliliquor, vanadium-bearing minerals and sodium sources to obtain a mixture; and (2) sodium reduction is conducted on the mixture obtained in the step (1) to obtain sodium slag, wherein, vanadium extraction is conducted on sodium slag to obtain sodium vanadate, and the alkali liquor is liquid after crystallization produced during sodium vanadate crystallization. By means of the method, recycling, pretreatment and coupling of sodium reduction are conducted on the alkali liquor produced in the process of vanadium extraction to adjust and control the migration and distribution of vanadium in the sodium process, so that more vanadium in the sodium reduction process enters the sodium slag, and the vanadium yield in the slag is increased by more than 20%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

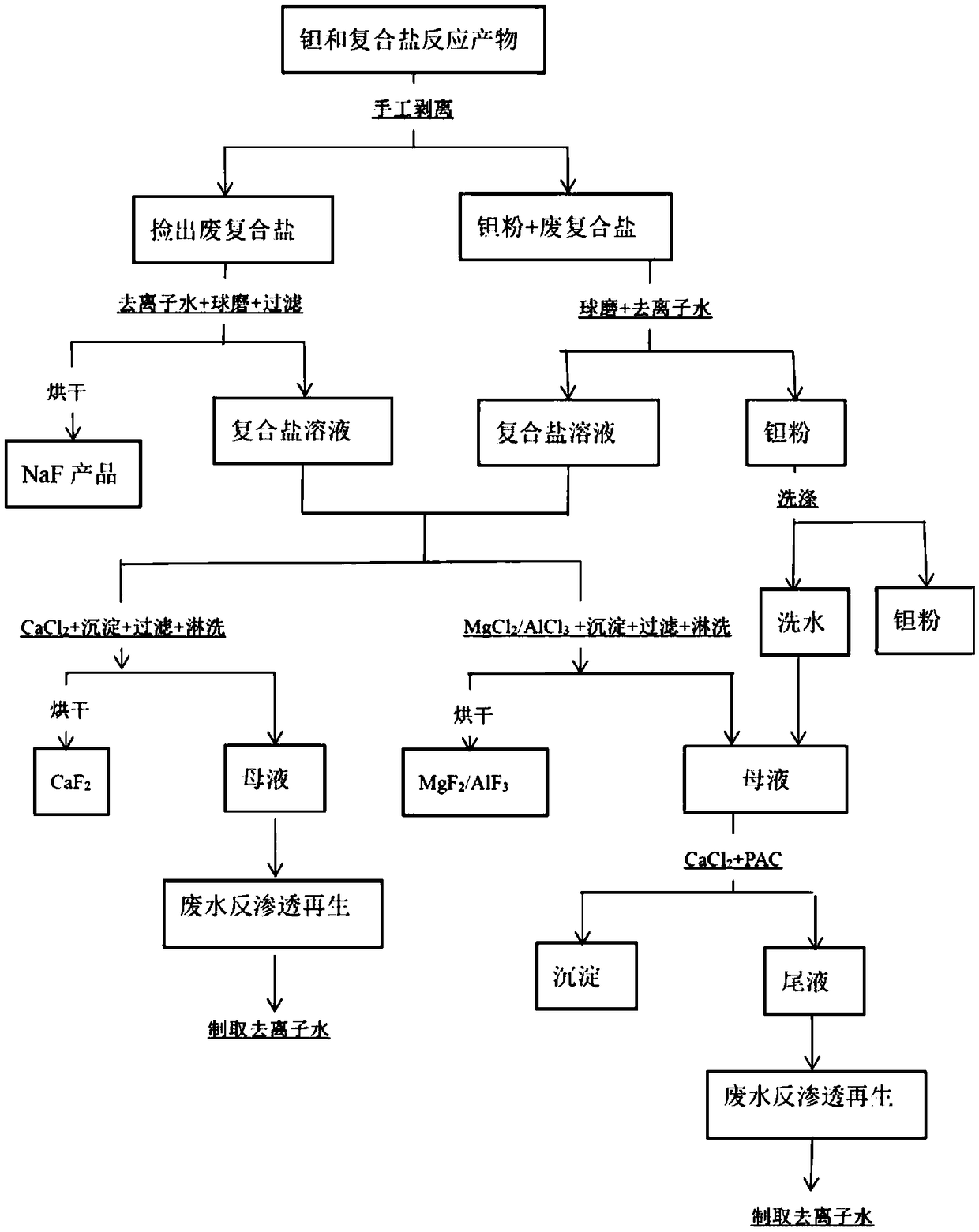

Method for treating waste compound salt by-products and waste washing water of tantalum powder production by sodium reduction method

ActiveCN109399669ASolve the real problemReduce the amount of washing waterMagnesium fluoridesWater contaminantsAluminium chlorideDissolution

The invention relates to a method for treating waste compound salt by-products and waste washing water of tantalum powder production by a sodium reduction method. The method involved in the inventionis characterized in that cooled tantalum and compound salt reaction products are used as raw materials; firstly, the waste compound salt by-products floating above the tantalum powder are peeled, andafter peeled products are dissolved in water and are filtered, a sodium fluoride precipitate and a compound salt solution can be obtained; after the peeling, the remaining products are subjected to ball grinding and dissolution so as to obtain an approximate saturated sodium fluoride solution, and the two solutions are combined and are added into metal chloride for precipitation reaction so as toobtain metal fluoride precipitates and fluorine-containing mother liquid; when calcium chloride is used as a precipitant, the obtained mother liquid can be directly discharged, and when magnesium chloride or aluminum chloride is used as the precipitant, the mother liquid can be directly discharged after simple purification treatment; and the dischargeable mother liquid can be subjected to reverseosmosis regeneration treatment. The method involved in the invention has the advantages that the washing water quantity is reduced; the valuable products are recovered; the problem of great lime consumption is solved; meanwhile, fluorine ions can easily reach the discharging standards; and the method has simple process steps and is suitable for industrial application.

Owner:株洲高力新材料有限公司

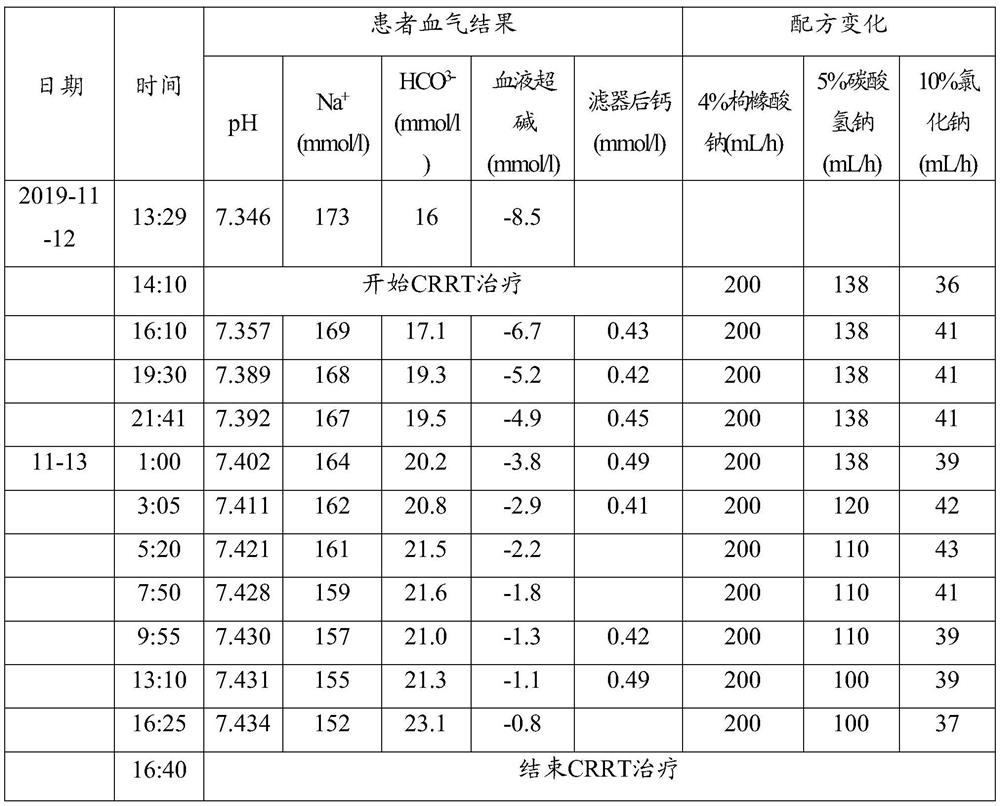

Precise sodium adjusting method for displacement liquid formula

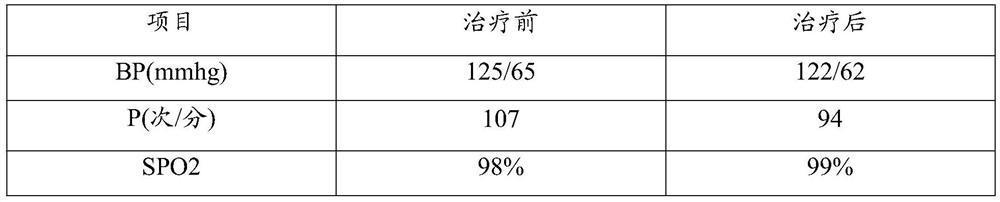

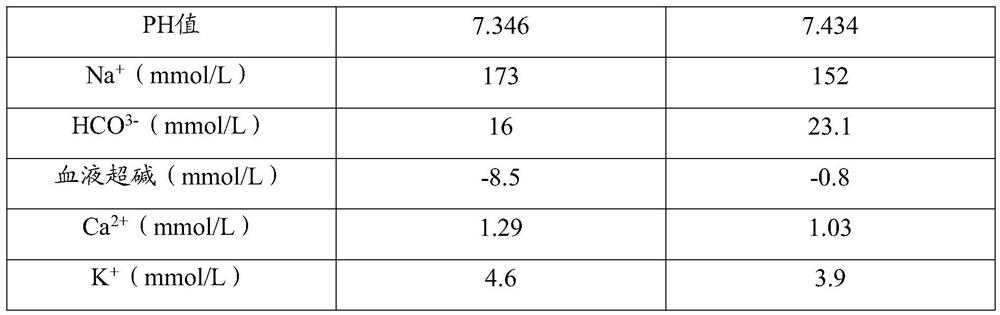

PendingCN111821532AEasy to masterSolve the anticoagulation problemOrganic active ingredientsMetabolism disorderFormularyHypernatremia

The invention relates to the technical field of clinical medicine, in particular to a precise sodium adjusting method for a displacement liquid formula. For patients with metabolic acidosis or withoutacid-base balance disorders, the amount I1 of 10% sodium chloride solution added to an initial displacement liquid can be obtained by a formula 1 and a formula 2, and for patients with metabolic alkalosis, the amount I6 of 10% sodium chloride solution added to the initial displacement liquid can be obtained by a formula 7 and a formula 8. The simple and easy-to-master formulas are adopted, the sodium ion concentration of the displacement liquid is precisely adjusted to achieve a controlled sodium reduction effect, the sodium reduction effect is accurate, the sodium reduction is balanced and stable every hour, and the sodium is adjusted individually according to different patients, the anti-coagulation problem in CRRT treatment for severe hypernatronemia accompanied by active bleeding patients is solved, meanwhile, the occurrence of complications during the anticoagulation process is prevented, balanced and stable sodium reduction is realized, and the occurrence of cerebral edema is reduced.

Owner:NANHUA HOSPITAL AFFILIATED TO UNIV OF SOUTH CHINA

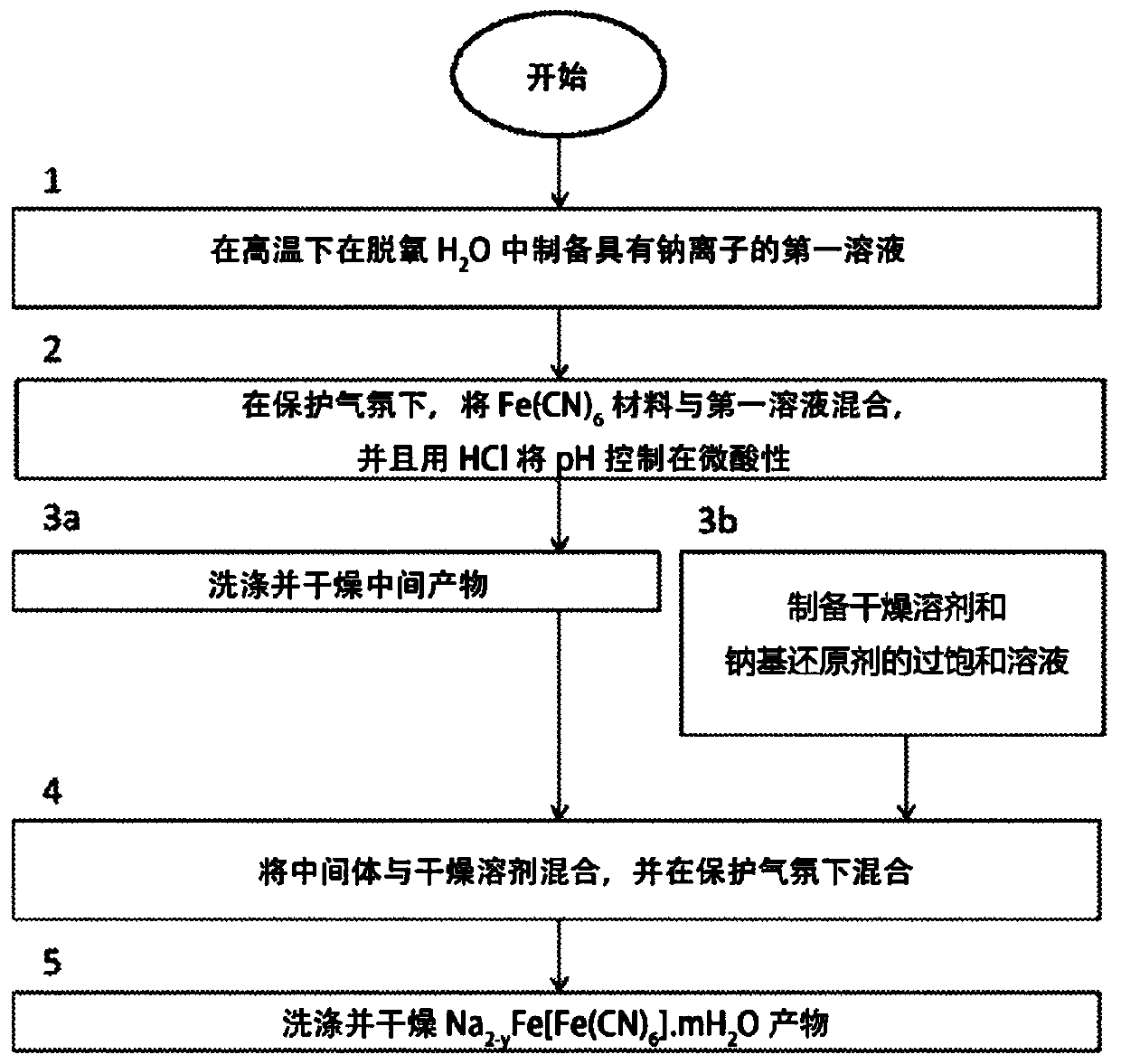

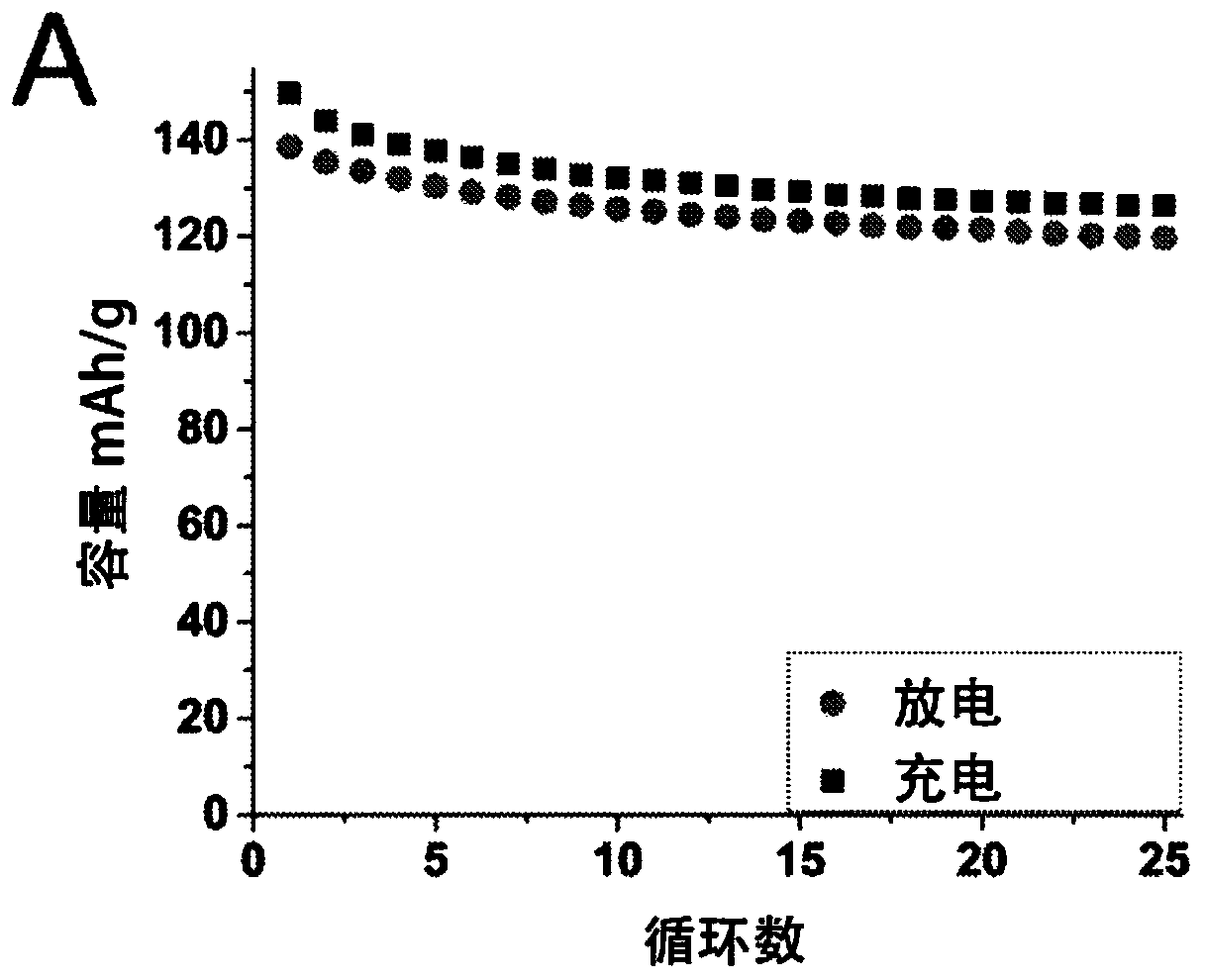

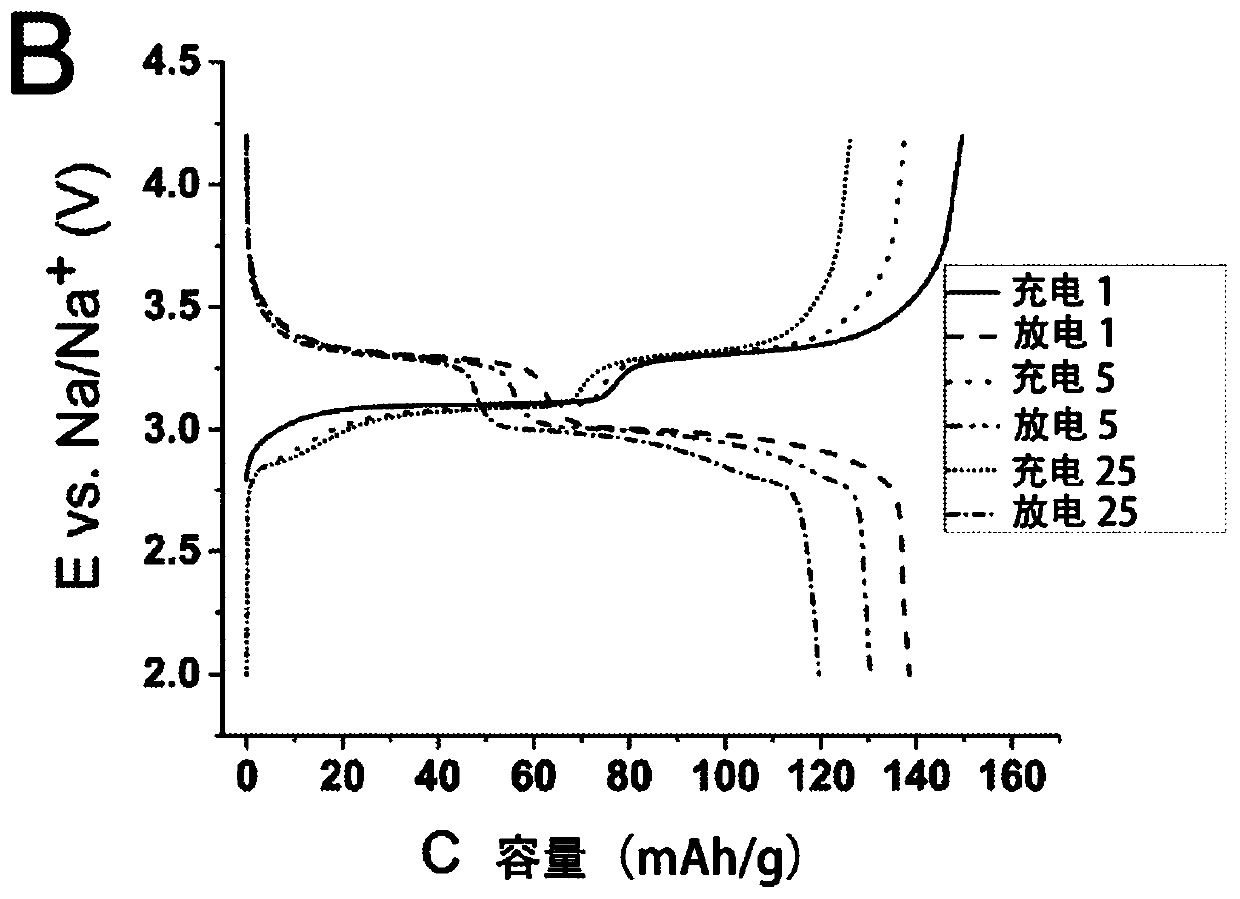

Method of producing a sodium iron(II)-hexacyanoferrate(II) material

ActiveCN109715558AExcellent electrochemical propertiesEnergy cost minimizationIron cyanidesSecondary cellsSodium reductionSupersaturation

The present invention relates to a method of producing a sodium iron(ll)- hexacyanoferrate(ll) (Na2-xFe[Fe(CN)6].mH2O), where x is < 0.4) material commonly referred to as Prussian White. The method comprises the steps of acid decomposition of Na4Fe(CN)6.10H2O to a powder of Na2-xFe[Fe(CN)6].mH2O, drying and enriching the sodium content in the Na2-xFe[Fe(CN)6].mH2O powder by mixing the powder witha saturated or supersaturated solution of a reducing agent containing sodium in dry solvent under an inert gas. The steps of acid decomposition and enriching the sodium content are performed under non-hydrothermal conditions.

Owner:ALTRIS AB

Preparation method of coralline high-purity tantalum powder

The invention provides a preparation method of coralline high-purity tantalum powder, and the mehtod comprises the following steps of (1) activating needle-shaped potassium fluotantalate into powder;(2) making NaCl free of water; (3) filtering and purifying the metal sodium to obtain purified sodium; (4) filling powdery potassium fluotantalate and NaCl into a reduction tank, hoisting the reduction tank into a well chamber reduction furnace, vacuumizing, filling argon for replacement, heating to 100 DEG C, inputting purified sodium, and continuously heating; (5) when the temperature increasesto 750 DEG C, carrying out sodium reduction; (6) after the sodium injection is finished, keeping constant temperature, lifting out the reduction tank, naturally cooling, taking out and crushing into amixture; (7) washing with water and acid to obtain washing powder; and (8) carrying out heat treatment on the washing powder, taking out of the furnace, sieving, and analyzing the qualified undersizeto obtain the coralline high-purity tantalum powder. By controlling the reaction process of preparing the tantalum powder by reducing potassium fluotantalate with the sodium metal, the preparation method of coralline high-purity tantalum powder can absorb metal impurities as little as possible and prevent the reaction product metal tantalum from being oxidized, and can directly prepare the coralliform high-purity tantalum powder with low metal impurity content and low oxygen content.

Owner:CONGHUA TANTALUM & NIOBIUM SMELTERY

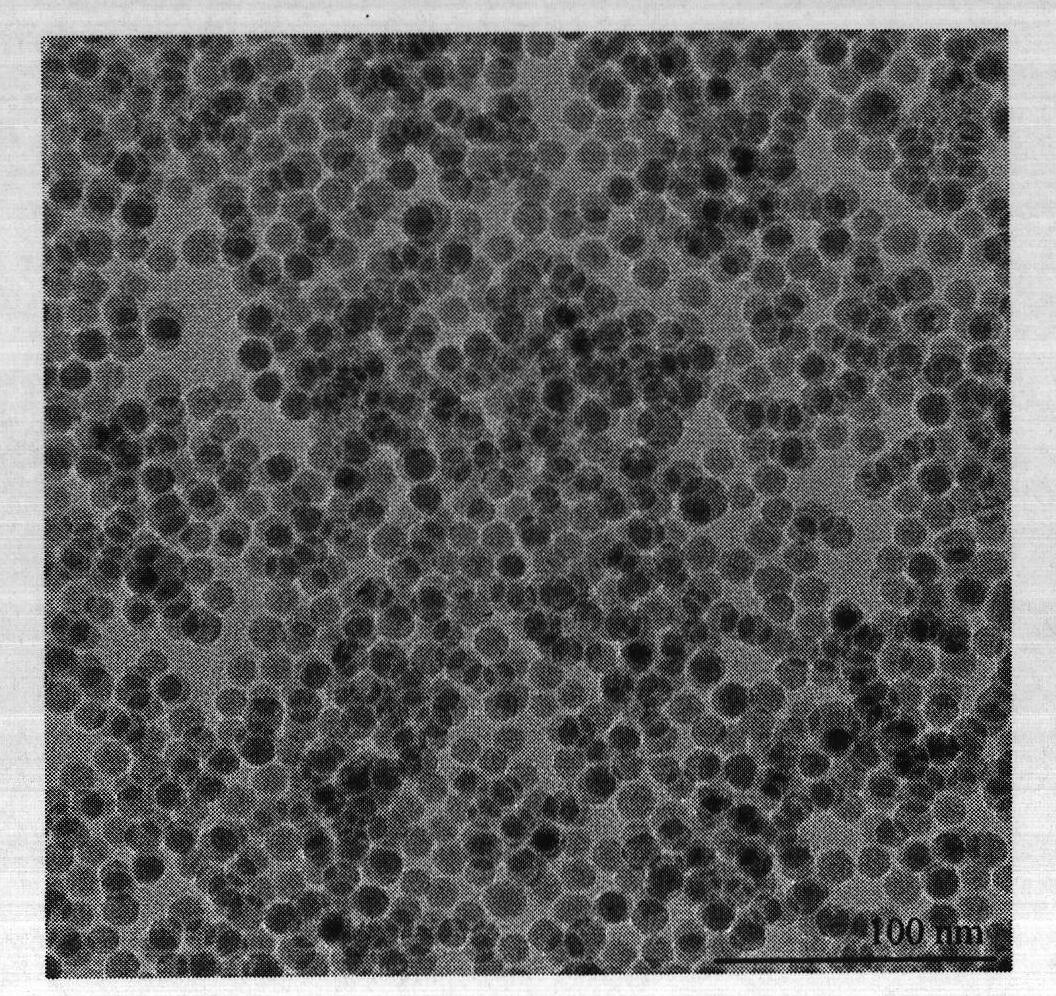

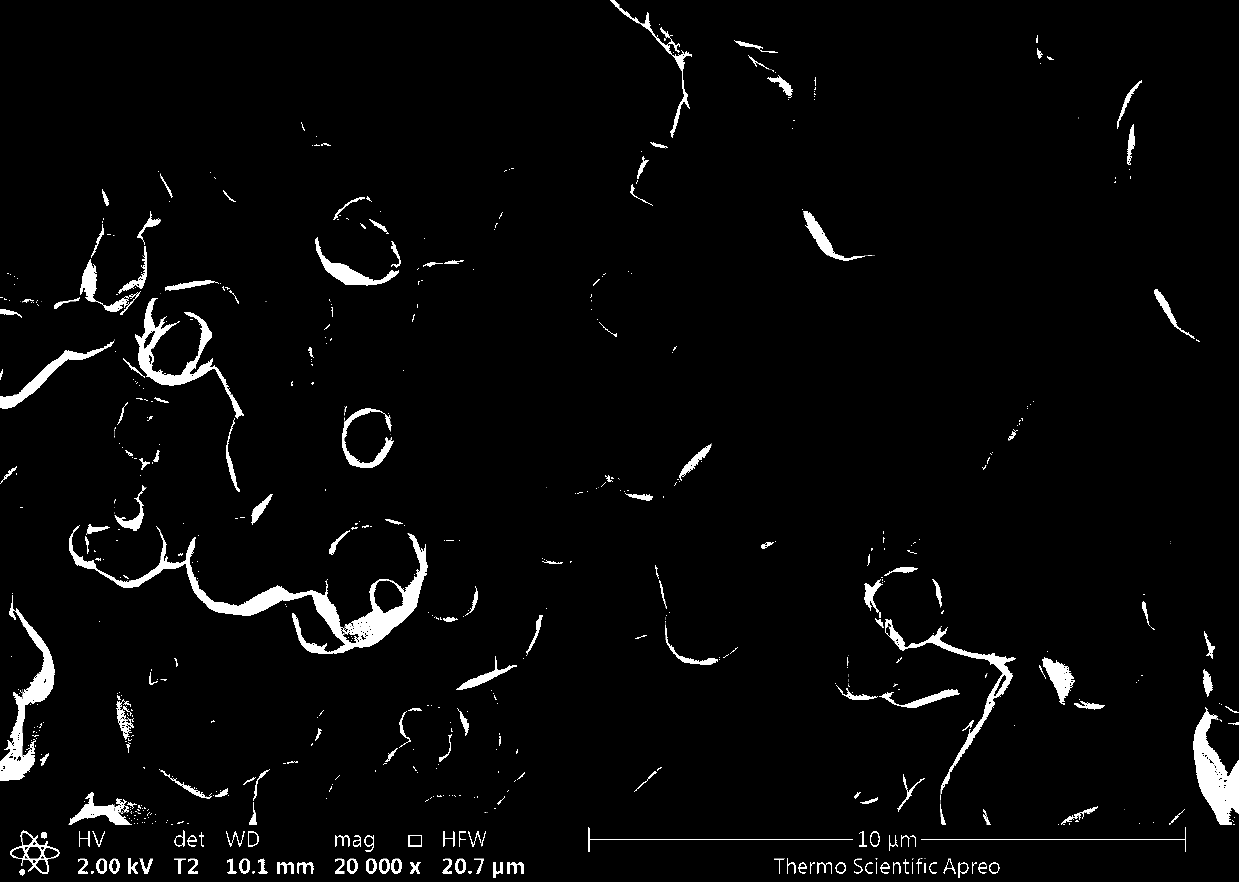

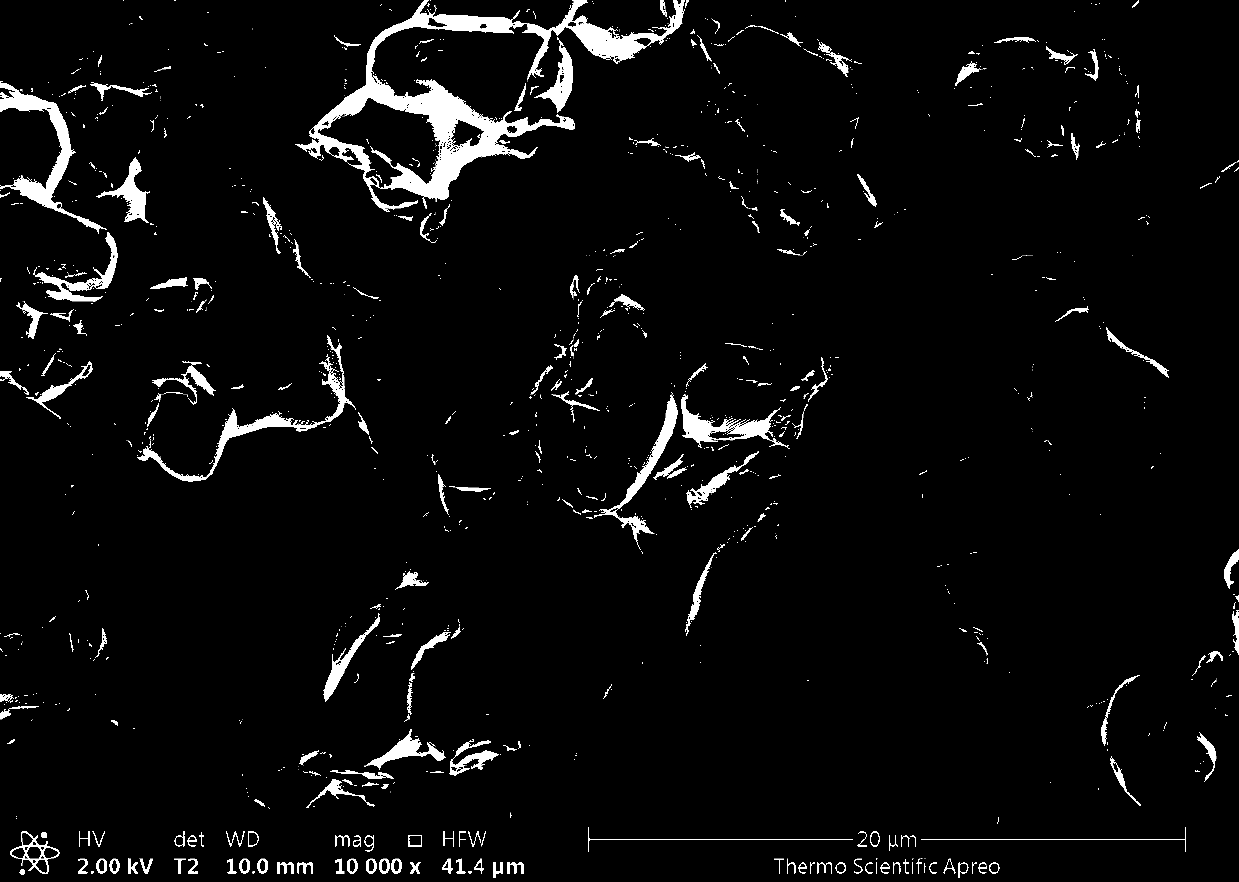

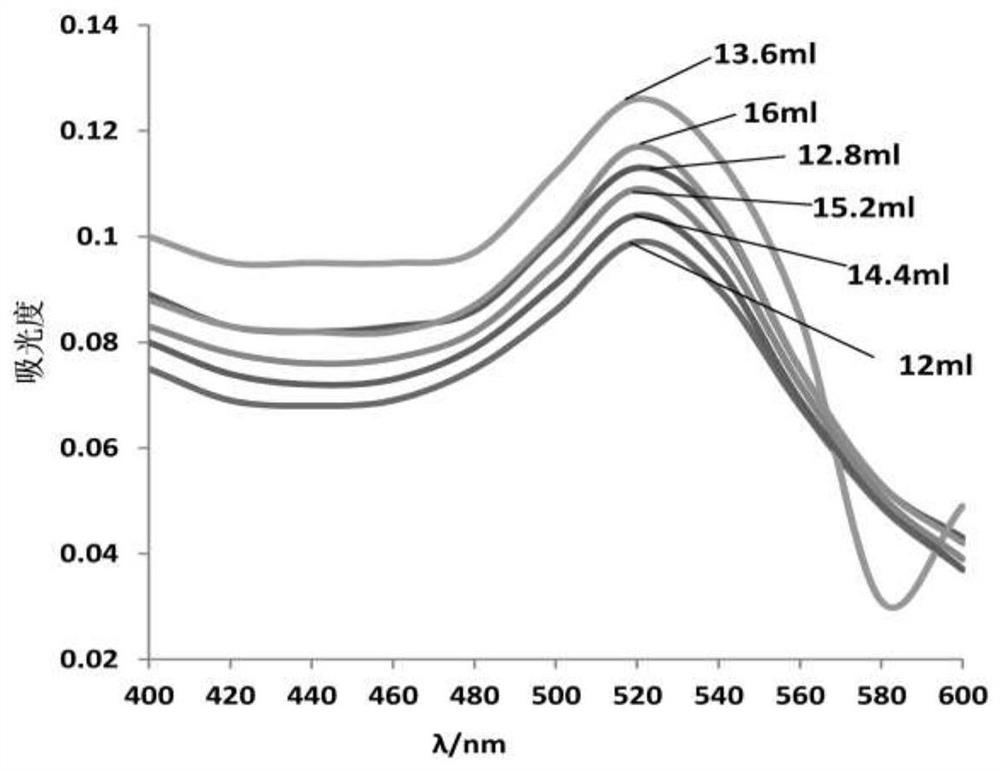

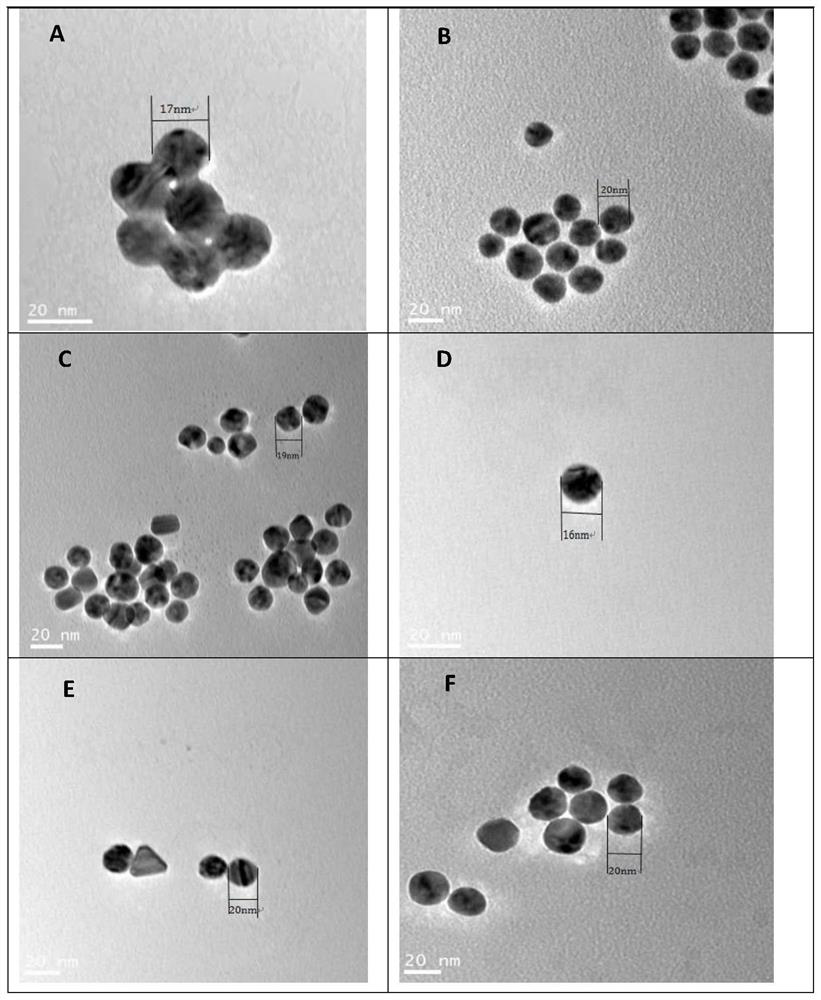

Gold nanoparticles with uniform particle size extracted based on sodium citrate reduction method and preparation method of gold nanoparticles

PendingCN111940754AEasy to operateGood repeatabilityMaterial nanotechnologyTransportation and packagingNanoparticleCytotoxicity

The invention discloses gold nanoparticles with uniform particle size extracted based on a sodium citrate reduction method and a preparation method of the gold nanoparticles. According to the preparation method, on the basis of an experiment of preparing gold nanoparticles by a classic sodium citrate reduction method, an electric furnace is selected for heating, 1% PVP is used as a protective agent, and the dosage of a 1% sodium citrate reducing agent is controlled within a range of 12-16ml; and the gold nanoparticles prepared under the condition is uniform in particle size, the particle sizeis 18 + / -2 nm, the gold nanoparticles prepared through the preparation method has the advantages of being good in dispersity, good in stability and free of cytotoxicity, and the method is easy to operate and high in repeatability.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Heavy oil catalytic cracking catalyst and preparation method therefor

ActiveUS9844772B2Increase heightIncrease capacityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveRare earth

The present invention relates to a heavy oil catalytic cracking catalyst and preparation method thereof. The catalyst comprises 2 to 50% by weight of an ultra-stable rare earth type Y molecular sieve, 0.5 to 30% by weight of one or more other molecular sieves, 0.5 to 70% by weight of clay, 1.0 to 65% by weight of high-temperature-resistant inorganic oxides, and 0.01 to 12.5% by weight of rare earth oxide. The ultra-stable rare earth type Y molecular sieve is obtained as follows: the raw material, NaY molecular sieve, is subjected to a rare earth exchange and a dispersing pre-exchange, and the molecular sieve slurry is filtered, washed and subjected to a first calcination to produce a “one-exchange one-calcination” rare earth sodium Y molecular sieve, wherein the order of the rare earth exchange and the dispersing pre-exchange is not limited; and the “one-exchange one-calcination” rare earth sodium Y molecular sieve is further subjected to ammonium salt exchange for sodium reduction and a second calcination. The catalyst provided in the present invention is characteristic in its high heavy-oil-conversion capacity, a high total liquid yield and a high light oil yield.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com