Method for preparing target-level high-purity tantalum powder

A tantalum powder and high-purity technology is applied in the field of preparation of target-grade high-purity tantalum powder, which can solve the problem of high manufacturing cost and achieve the effects of improving purity, low production cost and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

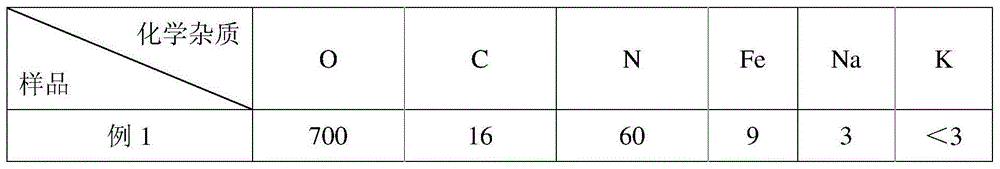

Embodiment 1

[0026] Use NaCl as the diluted salt to prepare the sodium-reduced tantalum powder. After the reduction, the mixed lump material of the sodium-reduced tantalum powder and the diluted salt NaCl is added to pure water and washed for 10 hours. When the conductivity of the filtrate is When it is 3000us / cm, it shows that most of the salt in the tantalum powder has been removed, and then the filtered and washed material is poured into a horizontal ball mill for ball milling. The weight ratio of the material to the ball is controlled at 1:2.5. The liquid ratio is controlled at 1:0.8, and the ball milling time is 5 hours. Then take out the material and carry out pickling, and the acid solution is composed of HNO with a mass concentration of 10%. 3 , 2% H 2 o 2 , add 0.5% HF, pickle for 2 hours, let it stand still, then soak for 1.5 hours, then rinse with pure water, filter with suction, and dry under vacuum (120°C / 14h) to get the original powder of tantalum powder . The raw tantalu...

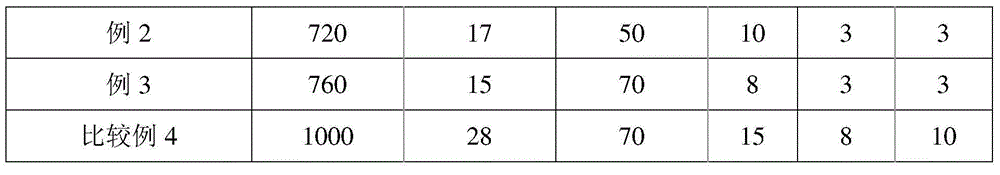

Embodiment 2

[0028] Use KCl as the diluted salt to prepare the sodium-reduced tantalum powder. After the reduction, add the mixed block material of the sodium-reduced tantalum powder and the diluted salt KCl to pure water for 15 hours, and when the conductivity of the filtrate is When it is 1500us / cm, it shows that most of the salt in the tantalum powder has been removed, and then the filtered and washed material is poured into a horizontal ball mill for ball milling. The weight ratio of the material to the ball is controlled at 1:4. The liquid ratio is controlled at 1:1, and the ball milling time is 8 hours. Then take out the material and carry out pickling, and the acid solution is composed of HNO with a mass concentration of 8%. 3 , 3% H 2 o 2 , add 0.7% HF pickling for 2.5h, let it stand still, then soak for 1h, then rinse with pure water, filter with suction, and dry under vacuum (150°C / 12h) to get the original tantalum powder. The raw tantalum powder also undergoes normal follow-u...

Embodiment 3

[0030]The mixed salt of KCl and NaCl is used as the diluted salt to prepare the sodium-reduced tantalum powder. After the reduction is completed, the mixed block material of the sodium-reduced tantalum powder and the diluted salt KCl and NaCl is added to pure water for 20 hours, and when When the conductivity of the filtrate is 1000us / cm, it indicates that most of the salt in the tantalum powder has been removed, and then the filtered and washed material is poured into a horizontal ball mill for ball milling, and the weight ratio of the material to the ball is controlled at 1:5 , the solid-to-liquid ratio of material to pure water is controlled at 1:1.5, and the ball milling time is 9 hours. Then take out the material and carry out pickling, and the acid solution is composed of HNO with a mass concentration of 10%. 3 , 2% H 2 o 2 , add 0.5% HF pickling for 2 hours, let it stand still, then soak for 1.5 hours, then rinse with pure water, filter with suction, and dry under vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com