Patents

Literature

55 results about "Common-ion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The common-ion effect states that in a chemical solution in which several species reversibly associate with each other by an equilibrium process, increasing the concentration of any one of its dissociated components by adding another chemical that also contains it will cause an increased amount of association. This result is a consequence of Le Chatelier's principle for the equilibrium reaction of the association/dissociation. The effect is commonly seen as an effect on the solubility of salts and other weak electrolytes. Adding an additional amount of one of the ions of the salt generally leads to increased precipitation of the salt, which reduces the concentration of both ions of the salt until the solubility equilibrium is reached. The effect is based on the fact that both the original salt and the other added chemical have one ion in common with each other.

Recovery, balance adjustment and comprehensive utilization technology for mixing alkali in indigo blue production

ActiveCN102924956AGood profitLess investmentCarbonate preparationIndigoid dyesResource savingPotassium hydroxide

A purpose of the invention is to achieve sodium reduction, potassium retention, and no use or less use of potassium hydroxide based on recovery utilization of mixing alkali and potassium-sodium balance adjustment in an indigo blue production process. According to the present invention, waste alkali residue, washing alkali water and surplus sodium hydroxide in oxidation alkali in the existing production are utilized, bicarbonate or carbon dioxide, and a plurality of ways are applied and introduced to the concentrate, and difference between dissolubility of sodium carbonate and potassium carbonate and a common ion effect are delicately utilized to generate sodium carbonate precipitate and separate, such that removal of surplus sodium hydroxide in the liquid alkali is achieved without introduction of new impurities, the sodium carbonate product is co-produced, about 0.5 ton of the potassium hydroxide is saved and about 1 ton of the sodium carbonate is by-produced when per ton of the indigo blue product is produced, and a new process route with characteristics of alkali resource comprehensive utilization and delicate potassium and sodium balance is developed. With the present invention, characteristics of low investment, resource saving, cleaning, environmental protection, economy, novelty, strong practicality and wide generalization application value are provided, significant theory and application values are provided for the circular economy and sustainable development strategy, ??and wide social benefits, economic benefits and ecological benefits are provided.

Owner:JIANGSU TAIFENG CHEM +1

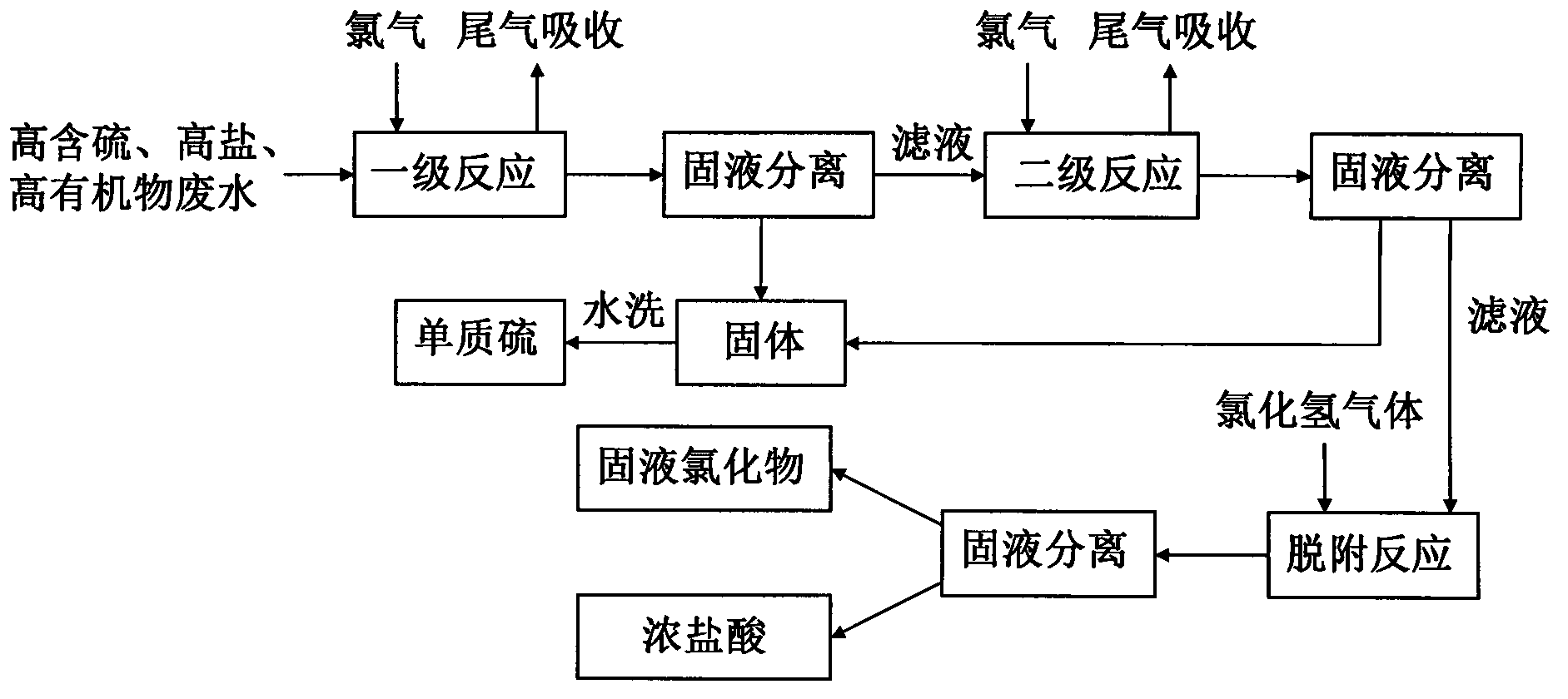

Method for treating high-sulfide high-salinity high-COD (Chemical Oxygen Demand) waste water

InactiveCN103241862AEasy to recycleGood removal effectMultistage water/sewage treatmentWater/sewage treatment by oxidationLiquid wasteIndustrial waste water

The invention belongs to the technical field of industrial sewage treatment and relates to a method for treating high-sulfide high-salinity high-COD (Chemical Oxygen Demand) waste water. The method comprises two steps namely a chlorine oxidation stage and a hydrogen chloride gas desalination stage and specifically comprises the following steps: introducing a certain amount of chlorine to the waste water, wherein organic substances contained in the waste water are decomposed and removed due to the oxidizing action of the chlorine, sulfides are oxidized to be separated out in a form of elemental sulfur; carrying out solid-liquid separation, and then recovering elemental sulfur; introducing a certain amount of hydrogen chloride gases to waste liquor subjected to the solid-liquid separation in the chlorine oxidation stage, wherein clear and transparent hydrochloric acid is retained because chlorine salt contained in the waste water with common-ion effect is gradually separated out; and carrying out solid-liquid separation, and then recovering the chlorine salt and the hydrochloric acid. The process disclosed by the invention can be carried out under constant pressure, not only can efficiently remove the sulfides, the organic substances and the inorganic salt out of industrial waste water, but also can recover the elemental sulfur, the chlorine salt and the hydrochloric acid through separation, thereby realizing the zero discharge of the waste water.

Owner:TIANJIN HUICHANG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for reducing content of NaCl in LiCl

The invention provides a method for reducing content of NaCl in LiCl, and the method comprises the following steps: (1) dissolving NaCl-containing coarse LiCl solid into water at a mass ratio of (0.3-0.8):1, or concentrating a NaCl-containing LiCl solution until the solution is saturated; (2) introducing volatile hydrogen chloride gas or direct concentrated hydrochloric acid into the solution obtained by the step (1), so that the NaCl is separated out from the solution in a crystallizing way due to the common-ion effect, the LiCl is still remained in the solution, and the NaCl can be effectively eliminated from the solution after filtration; and (3) eliminating the volatile hydrogen chloride or concentrated hydrochloric acid from the solution in a heating way to obtain a LiCl solution. The method can be used for effectively eliminating the NaCl from a NaCl-LiCl mixture, so that the content of the NaCl in the LiCl can be reduced to be less than 1.8%, the content of the LiCl in the separated NaCl solid can be less than 1%.

Owner:LANZHOU UNIVERSITY

Method for crystallizing N-carbamylglutamic acid with mixed acid

ActiveCN105601542APrevent precipitationHigh purityUrea derivatives preparationOrganic compound preparationCarbamylglutamic acidCommon-ion effect

The invention discloses a method for crystallizing N-carbamylglutamic acid with mixed acid. According to the method, two or more types of acid are sequentially added to an N-carbamylglutamic acid reaction solution for acidification; an obtained solution stands still at the temperature of 0-4 DEG C and stays overnight, and crystallization is conducted; suction filtration is conducted, obtained solid is dried, and a crude product of the N-carbamylglutamic acid is obtained. The acid is two or more of concentrated hydrochloric acid, concentrated nitric acid, concentrated sulfuric acid, concentrated phosphoric acid and other types of inorganic acid. Compared with an acidification method with a single type of acid, the method for crystallizing N-carbamylglutamic acid with mixed acid has the advantages that the mixed acid acidification reaction liquid is adopted, and the common ion effect caused by single acid acidification can be avoided, so that precipitation of sodium salt along with a product is avoided, crystallization purity of the product, namely the N-carbamylglutamic acid is effectively improved, and the maximum one-time crystallization purity of the product can reach 98.3%.

Owner:南京恒通医药开发有限公司

Method for separating and purifying sodium salts in arsenic alkali residue

InactiveCN104818387AEfficient separation and recoveryLow As contentProcess efficiency improvementSodium saltImpurity

The invention aims at providing a method for separating and purifying sodium salts in arsenic alkali residue. The method can help separate high-purity sodium carbonate and sodium arsenate from antimony smelting arsenic alkali residue to achieve recycling of the sodium carbonate and sodium arsenate. The method comprises condensing a sodium arsenate composite salt solution at 60-70 DEG C to separate out most of Na2CO3 out of the solution, at the moment, all As is in the solution. Both magnetic fields and ultrasound can change the thermodynamic properties of chemical compounds and affect the solubility, the crystallization induction time, the width of the metastable region and the crystallization manner. A filter liquor a contains large amounts of Na+, under the coupling action of specific temperature and the magnetic field and ultrasound of the corresponding intensity, strong common-ion effects enable most of sodium arsenate to crystalize from the solution and other impurity components to stay in the solution. Meanwhile, by performing the pretreatment in the step 3) on the filter liquor a before the ultrasound and magnetic field treatment, the content of arsenic in crystalized sodium arsenate can be improved.

Owner:NANCHANG HANGKONG UNIVERSITY

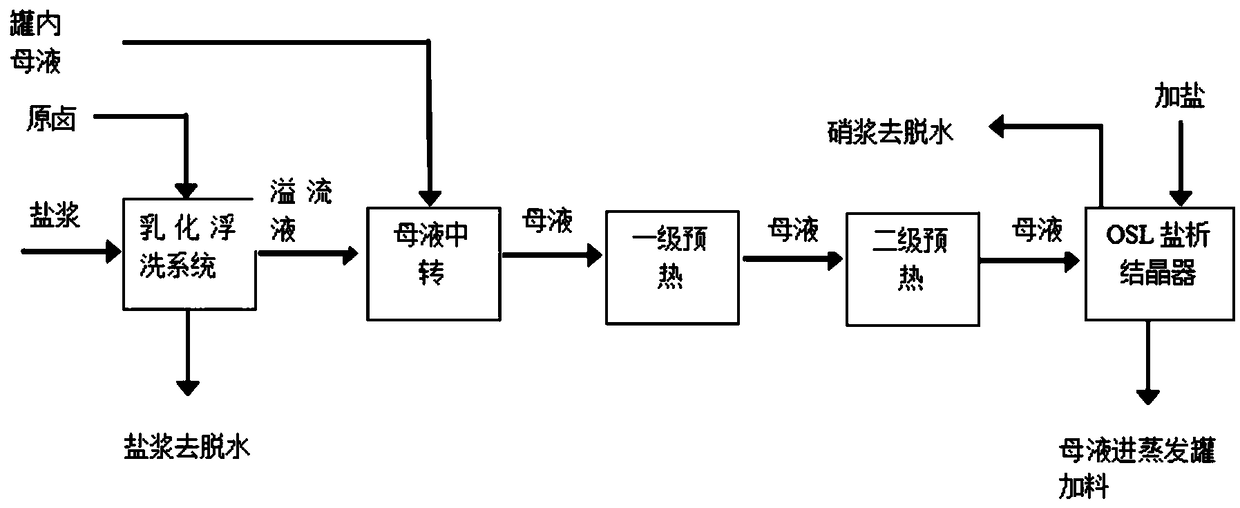

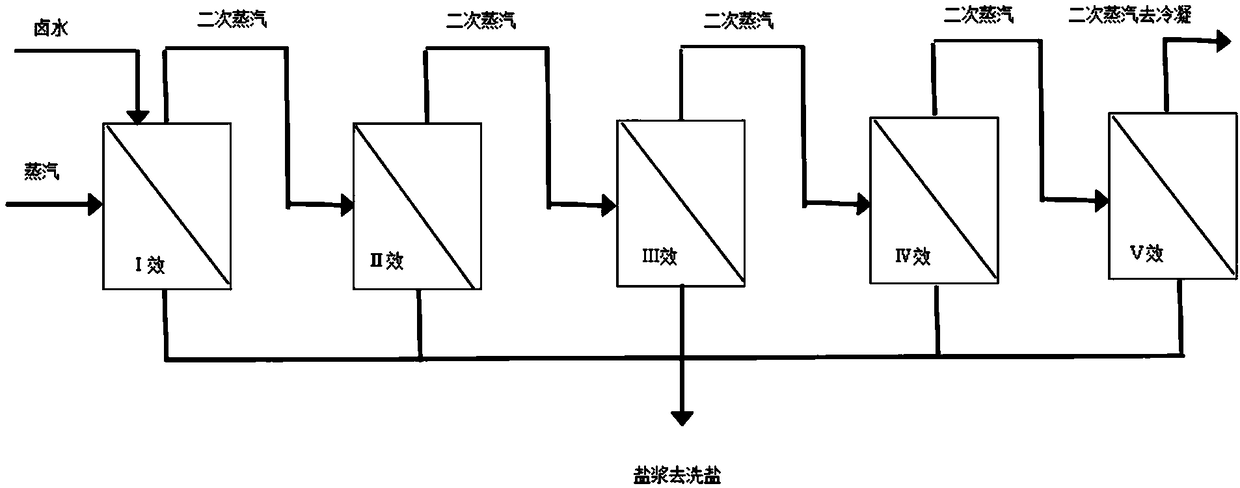

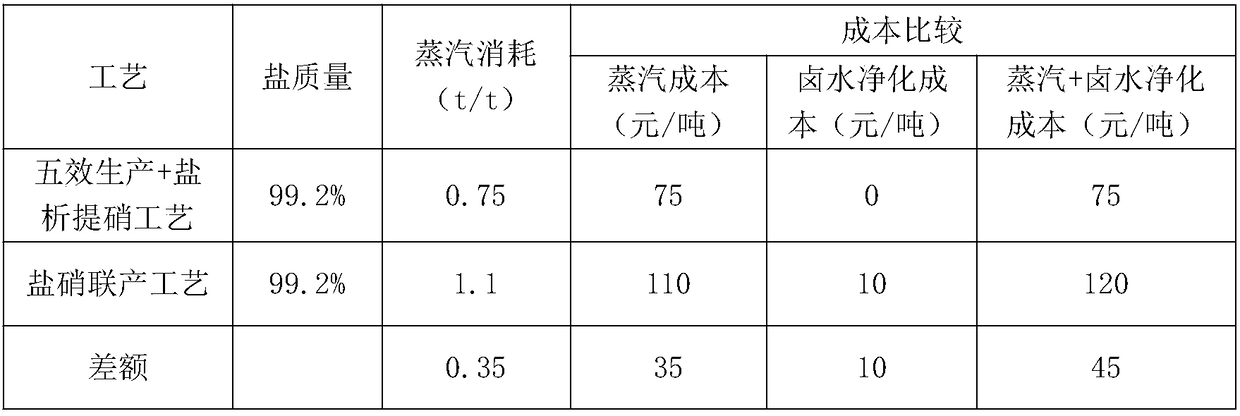

Production process for extracting mirabilite by continuous salting-out hot process

InactiveCN108314062AReduce manufacturing costSimple processAlkali metal sulfite/sulfate purificationAlkali metal chloridesCommon-ion effectCounter flow

The invention discloses a production process for extracting mirabilite by a continuous salting-out hot process and belongs to the technical field of salt-mirabilite coproduction. The production process comprises the following steps that three-stage counter-flow emulsification float washing is carried out on raw materials including brine and salt slurry in a salt washer, centrifugal dewatering anddrying are carried out on washed salt slurry is directly dewatered and dried centrifugally and then is packaged into finished salt, the discharged overflowing liquid and a little amount of mother liquor discharged from an evaporation tank enter a mother-liquor transferring barrel together, then after multi-stage preheating (the preheating heat source is all-effect residual condensate), the mother-liquor transferring barrel is conveyed into a crystallizer, the temperature is increased to 95-100 DEG C, simultaneously NaCl is added by 2%-4% of the solid content in the mother liquor, and the mirabilite is crystallized and precipitated according to the principle of common ion effect, then is taken out of the system, dewatered and dried to obtain a mirabilite product. The production process disclosed by the invention has the advantages of low steam consumption, low production cost, simple technological process, less equipment investment, simple operation and continuous and controllable production.

Owner:XIAOGAN GUANGYAN HUAYUAN SALT MFG

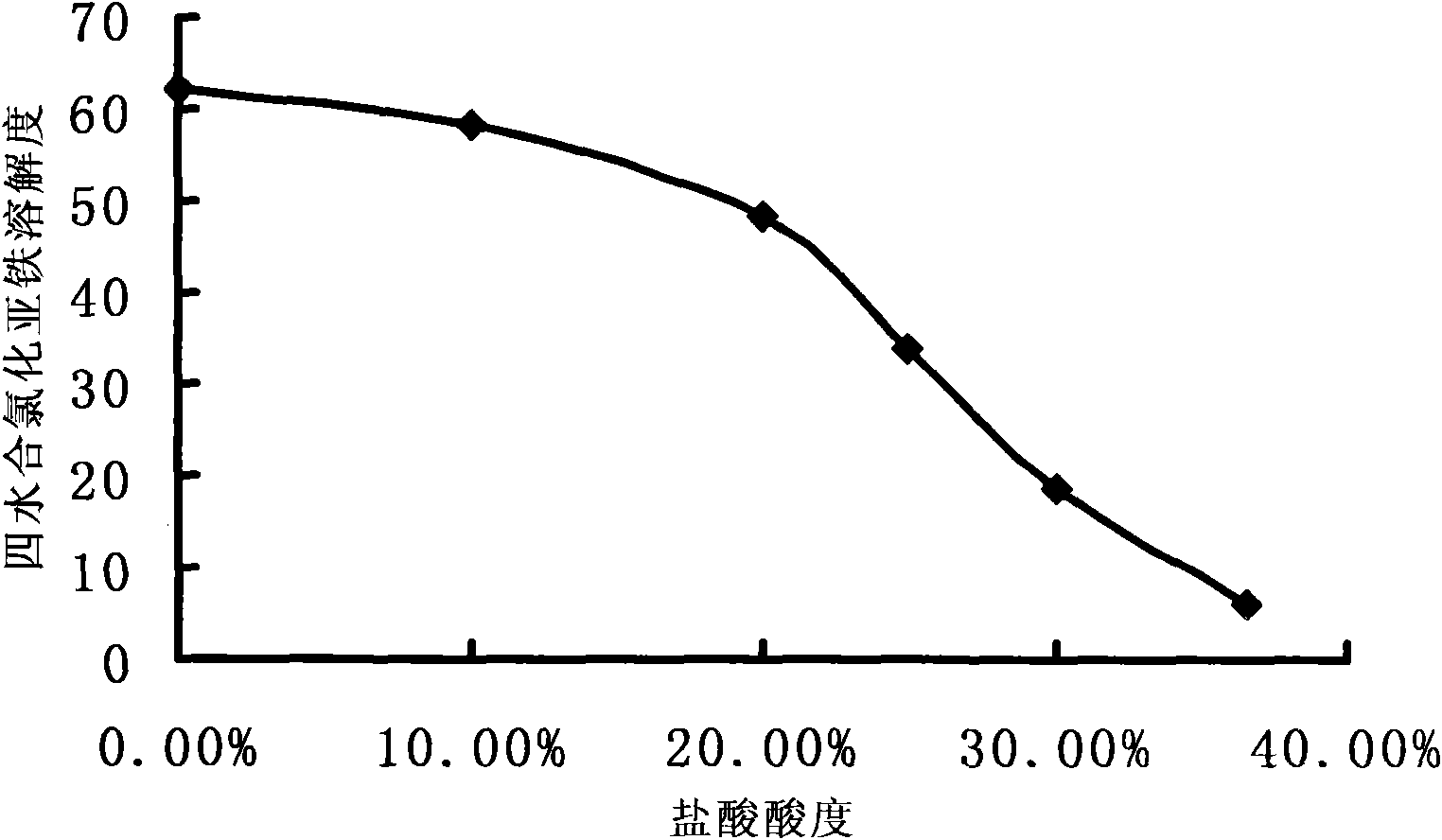

Process for treating industrial waste hydrochloric acid in recycling way through salt fractionation method

InactiveCN104495953ALow running costWill not cause secondary pollutionChlorine/hydrogen-chloride purificationCalcium/strontium/barium chloridesFractionationIron(II) chloride

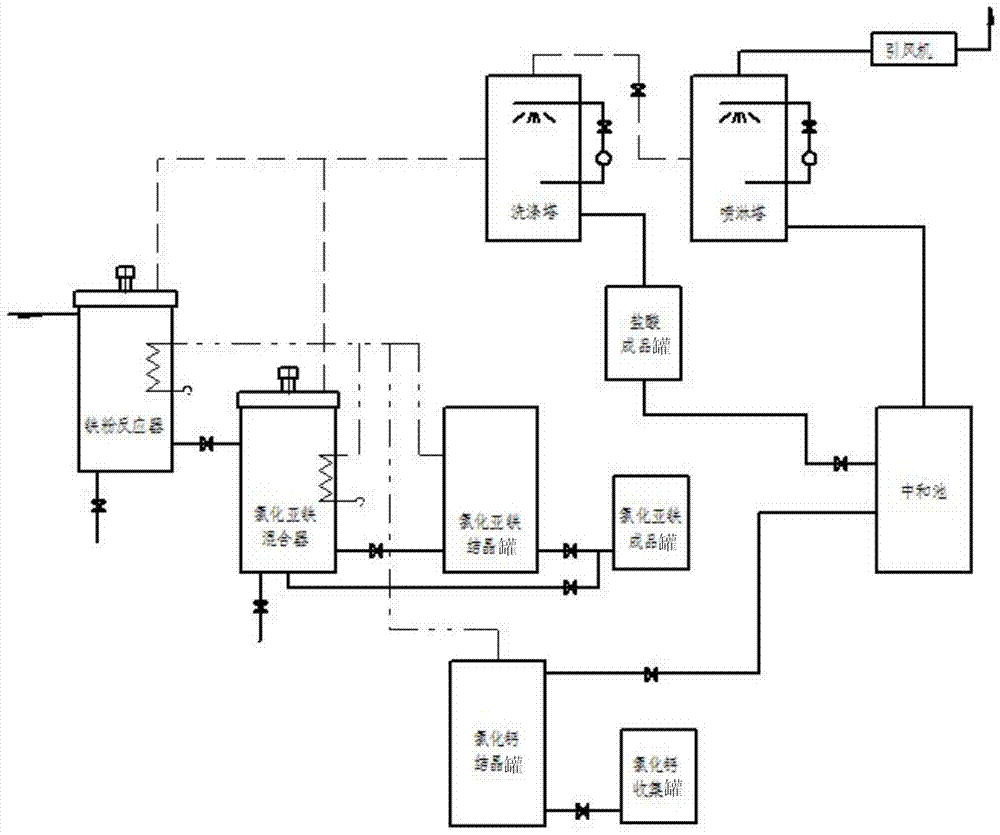

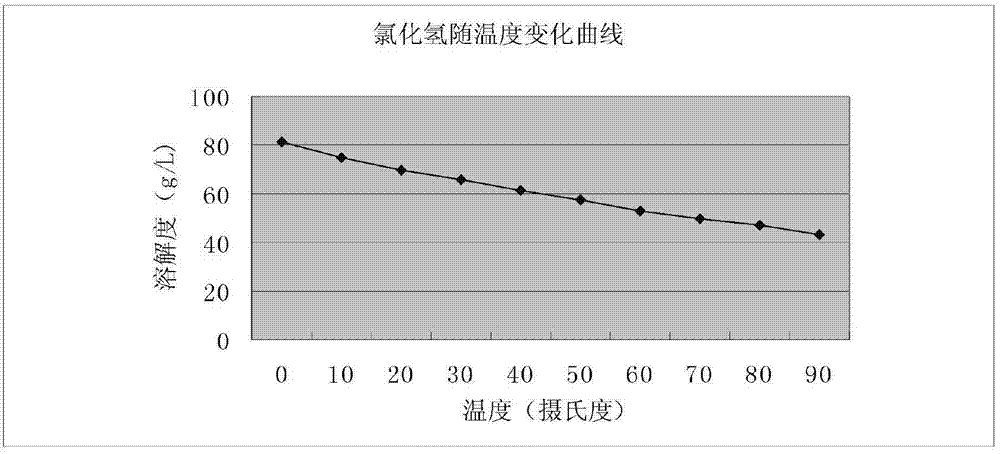

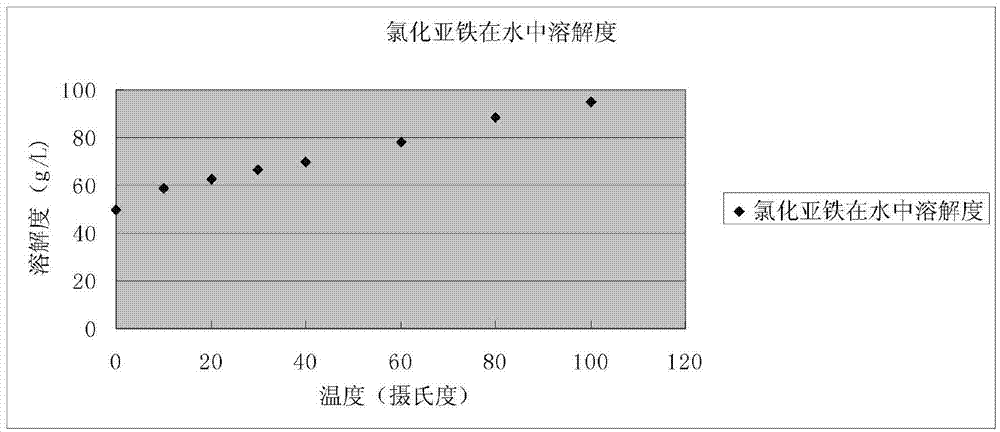

The invention relates to a process for treating industrial waste hydrochloric acid in a recycling way through a salt fractionation method. The treatment of the industrial waste hydrochloric acid is carried out in a treatment system, and the treatment process comprises the following steps of: (1) iron powder reaction; (2) mixing of ferrous chloride; (3) neutralization and crystallization of ferrous chloride; (4) recycling of a ferrous chloride crystal or solution; (5) neutralization and crystallization of calcium chloride; (6) condensing and absorbing a separated gas. According to the process, the ferrous chloride crystal or solution is added to the industrial waste hydrochloric acid by utilizing common-ion effect, concentration is carried out under the conditions of negative pressure and heating, the separated gas can be partially condensed into hydrochloric acid for recycling, the rest is absorbed by using calcium oxide or calcium hydroxide, and finished products are ferrous chloride, calcium chloride and hydrochloric acid, so that secondary pollution can not be caused, and small investment and low operation cost are achieved. The process disclosed by the invention is a new process for realizing the recycling application of the industrial waste hydrochloric acid and has wide application prospect.

Owner:TIANJIN VOCATIONAL INST

Method for eliminating calcium sulphate with bittern

InactiveCN101172686AIncreased sodium chloride contentLess quantityWater/sewage treatmentCommon-ion effectSalting out

The invention provides seawater processing technology, in particular to a method of removing calcium sulphate by use of brine. 5 to 13 degrees Be brine is added with industrial crude salt to make the brine concentration to 17 to 25 degrees Be and dissolve the calcium sulphate. According to the rule of brine dissolving salt and the salting-out theory as well as the common ion effect theory, the composition of the(5 to 13 degrees Be) brine is changed by adding the industrial crude salt to increase the sodium chloride content in the brine so as to increase the brine concentration up to 17 to 25 degrees Be, thereby reducing the solubility of the calcium sulphate and dissolving most of the calcium sulphate; besides, the dissolved brine can be directly used for producing the vacuum refined salt.

Owner:ENG TECH INST CO LTD OF CNSIC

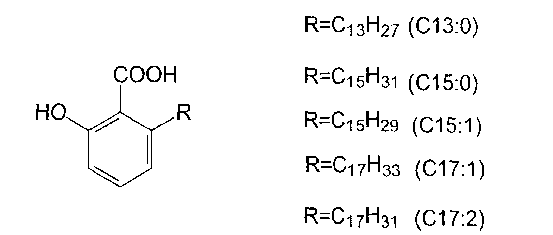

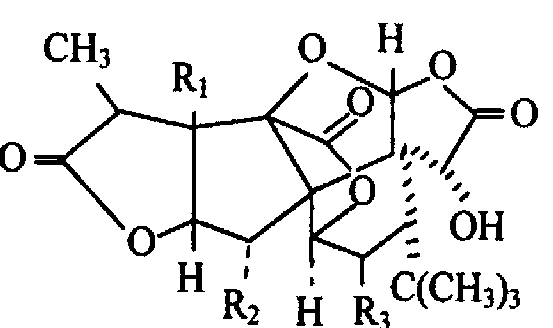

Industrialization production technology for extracting ginkgolic acid and bilobalide from Ginkgo testa

InactiveCN103159619AAchieve a large number of separationsEasy to operateBiocideDisinfectantsCommon-ion effectCuticle

The invention relates to an industrialization production technology for extracting ginkgolic acid and bilobalide from Ginkgo testa. The technology comprises the following steps: leaching Ginkgo testa; separating, concentrating and fractionating leaching extracts; adjusting a pH value of the concentrated liquid; isolating a crude extract of ginkgolic acid; crystallizing, recrystallizing, and decolorizing by alkali liquor and acid precipitation, and further purifying the ginkgolic acid; conducting extraction and back extraction on a concentrated mother liquor, after adjusting a pH value; acidifying, concentrating, cooling and filtering to obtain a bilobalide crude product; and dissolving the crude product with ethanol and conducting column separation to obtain bilobalide with high purity. The invention employs acid solution to regulate the pH value of the solution containing ginkgolic acid or bilobalide, and precipitates the ginkgolic acid or bilobalide by a common ion effect. The technology has the advantages of simple process, convenient operation, low cost, high extraction rate and high extraction purity, can rapidly extract ginkgolic acid and bilobalide in large amount from Ginkgo testa, and is suitable for requirements of industrial production.

Owner:张加明 +1

Method for preparing glycine by utilizing common ion effect

ActiveCN111196768AHigh yieldQuality improvementOrganic compound preparationAmino-carboxyl compound preparationCommon-ion effectPtru catalyst

The invention relates to a clean production process for preparing glycine in an alcohol-water mixed solvent by utilizing the common ion effect. A novel catalyst pyridine base compound or a traditionalcatalyst urotropine and paraformaldehyde is adopted as the catalyst. The method comprises the following steps: ammoniating ammonium chloroacetate in an alcohol-water mixed solvent under the conditionof a catalyst by introducing ammonia to synthesize glycine, carrying out centrifugal separation to obtain glycine, adding a solid chlorethamin into the mixed solvent obtained by centrifugation, cooling to 0-20 DEG C, and carrying out centrifugal separation to obtain ammonium chloride, and centrifugally separating ammonium chloride to obtain a circular reaction mixed solvent, and circularly carrying out a glycine synthesis reaction.

Owner:北京长邦科技有限公司

Bright pearl manufacturing method

ActiveCN104945207AFast dryingCompact structureInorganic oxygen-halogen salt explosive compositionsNon-explosive/non-thermic compositionsCommon-ion effectIsolation effect

The invention discloses a bright pearl manufacturing method. By means of the bright pearl manufacturing method, two granulating and drying processes are not needed, one-time forming is achieved in a facility for granulating, and finished product bright pearls can be obtained through one-time drying. An effective isolation effect is finally achieved through adding of potassium dichromate, interinfiltration between inner core medicine and outer package medicine under the action of hydrosolvent is eliminated, and the burning performance of bright pearl medicine is stabilized. Meanwhile, based on the dissolution common-ion effect of potassium dichromate and other oxides, the drying speed of the manufactured bright pearls is accelerated, the bright pearl structure is more dense, and larger impact force can be borne. The stability of the bright pearls is good based on the surface passivation action on live wave metal by the potassium dichromate, quality is stable, and the quality consistency of the bright pearls is good. In this way, the bright pearl quality and stability are effectively improved, the firing effect is guaranteed, the production process is simplified, the production cycle is shortened, potential safety hazards are reduced, and the manufacturing cost is lowered.

Owner:YANGZHOU OBAMA TECH DEV

New process for recycling pickling waste liquid

InactiveCN101891259AReduce solubilityWaste water treatment from metallurgical processWater/sewage treatmentLiquid wasteCommon-ion effect

The invention provides a convenient processing scheme for recycling a pickling waste liquid, which well solves the problems of high processing cost, resource waste and recontamination in the conventional method. Based on the common-ion effect of Cl<-> in an aqueous solution, HCl gas is introduced to separate out most of FeCl2; and the produced filtrate is hydrochloric acid liquid which is directly recycled to a pickling bay in a steel mill. The process has better economic benefits and social environmental benefits, and meets the requirements for clean production, circular economy, energy saving and consumption reduction.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

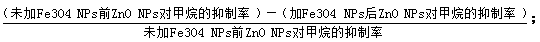

Method for reducing adverse effect of nano-zinc oxide on anaerobic biological treatment of sewage

ActiveCN109019852AEnhance resilienceReduce dissolutionTreatment with anaerobic digestion processesMethanationZno nanoparticles

The invention relates to a method for reducing the adverse effect of nano-zinc oxide on anaerobic biological treatment of sewage. The method includes: acclimation culture of inoculation sludge, preparation of dispersion liquid, anaerobic digestion and other steps. Nano-ferriferrous oxide can partially hinder the effective contact of nano-zinc oxide and microorganisms and strengthen the resistanceof extracellular polymers to nano-zinc oxide, the common ion effect between iron ions and zinc ions weakens the dissolution of zinc ions and the biotoxicity thereof, thus reducing the adverse effectsof nano-zinc oxide on anaerobic biological treatment of sewage. And further the action conditions of nano-ferriferrous oxide are controlled to establish an inter-species direct electron transfer approach between acid-forming bacteria and methanogens so as to optimize the methanation process, thus reaching the purpose of reducing the adverse effect of nano-zinc oxide on anaerobic biological treatment of sewage.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Comprehensive treatment method for chlorine-containing solid waste

ActiveCN109694092ATo achieve the purpose of comprehensive utilizationSuitable for industrial applicationsCalcium/strontium/barium sulfatesAlkali metal chloridesEnvironmental resistanceSlag

A comprehensive treatment method for chlorine-containing solid waste is characterized by comprising the steps: taking a solution containing magnesium chloride or / and magnesium sulfate as a washing liquid for the chlorine-containing solid waste, allowing obtained washed slag to return to be used as chlorination furnace charge, adding lime into the washing liquid, neutralizing to make impurities such as aluminum and iron precipitated and separated out, and filtering to obtain an impurity-removed post-liquid; and then adding sodium sulfate into the impurity-removed post-liquid, using a common ioneffect produced by chloridions, promoting chlorine to be precipitated and separated out in a form of sodium chloride solid, filtering to obtain sodium chloride crystals and a crystallization post-liquid, and allowing crystallized mother liquor to return to a washing process of the chlorine-containing solid waste for recycling, so as to realize the craft process of comprehensive utilization of thechlorine-containing solid waste. The method has the advantages of convenient operation, high operation efficiency, cleanliness and environmental protection, and is suitable for industrial applicationof treatment of the chlorine-containing solid waste.

Owner:CENT SOUTH UNIV +1

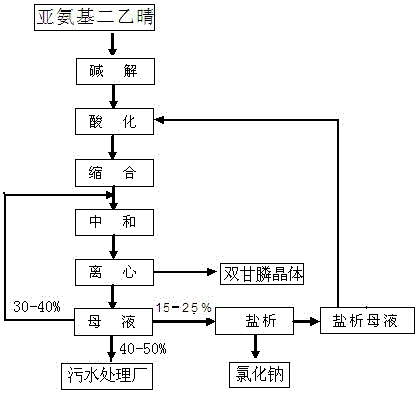

Method for treating N-phosphonomethyliminodiacetic acid mother liquor

InactiveCN106588980AReduce resource consumptionEmission reductionGroup 5/15 element organic compoundsAlkali metal halide purificationPhosphorous acidWater use

The invention discloses a method for treating an N-phosphonomethyliminodiacetic acid mother liquor. The method is as below: taking one part of the N-phosphonomethyliminodiacetic acid mother liquor as a salting-out mother liquor for by-product HCl tail gas from phosphorous acid production, performing salting out by the common ion effect of chloride ions and recovering sodium chloride; and using the salting-out residual mother liquor as an acid for an acidification reaction after alkaline hydrolysis of iminodiacetonitrile in the synthesis process of N-phosphonomethyliminodiacetic acid; and then taking the other part of the N-phosphonomethyliminodiacetic acid mother liquor as diluting water used in a condensation reaction. The method makes full use of the N-phosphonomethyliminodiacetic acid mother liquor formed after the synthesis of N-phosphonomethyliminodiacetic acid, and the N-phosphonomethyliminodiacetic acid mother liquor can be used as part of raw materials for a plurality of chemical reactions, and the method has the advantages of cost reduction and green environmental protection.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

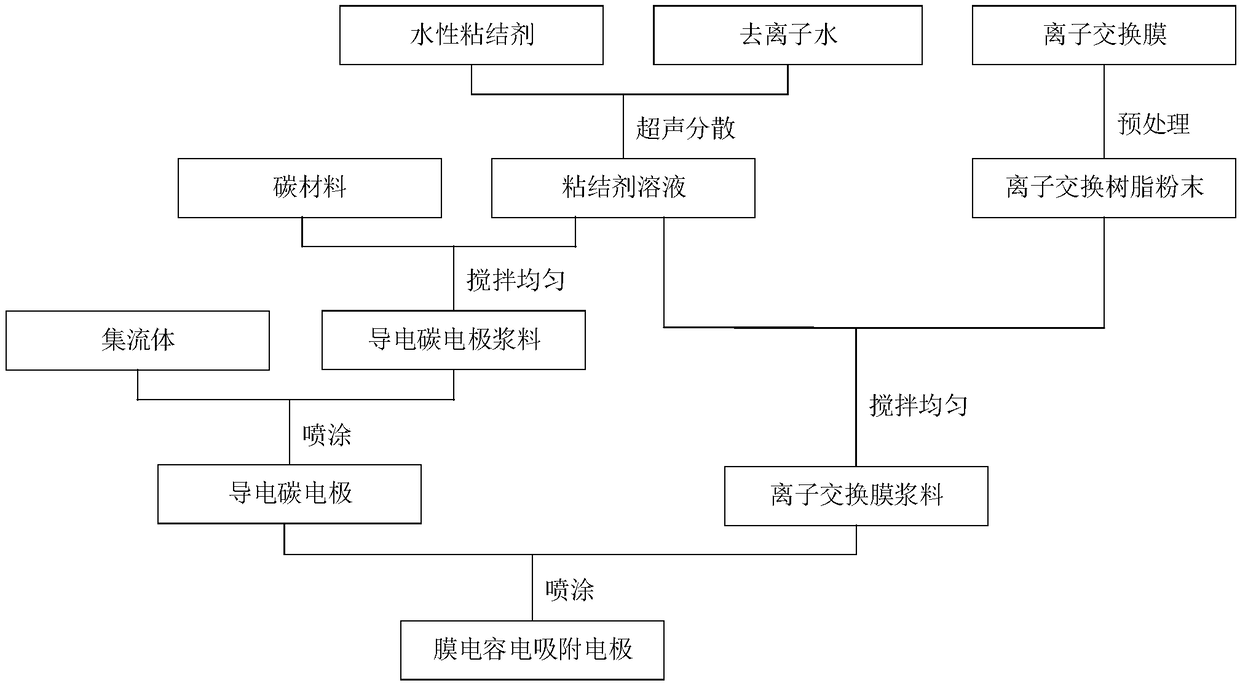

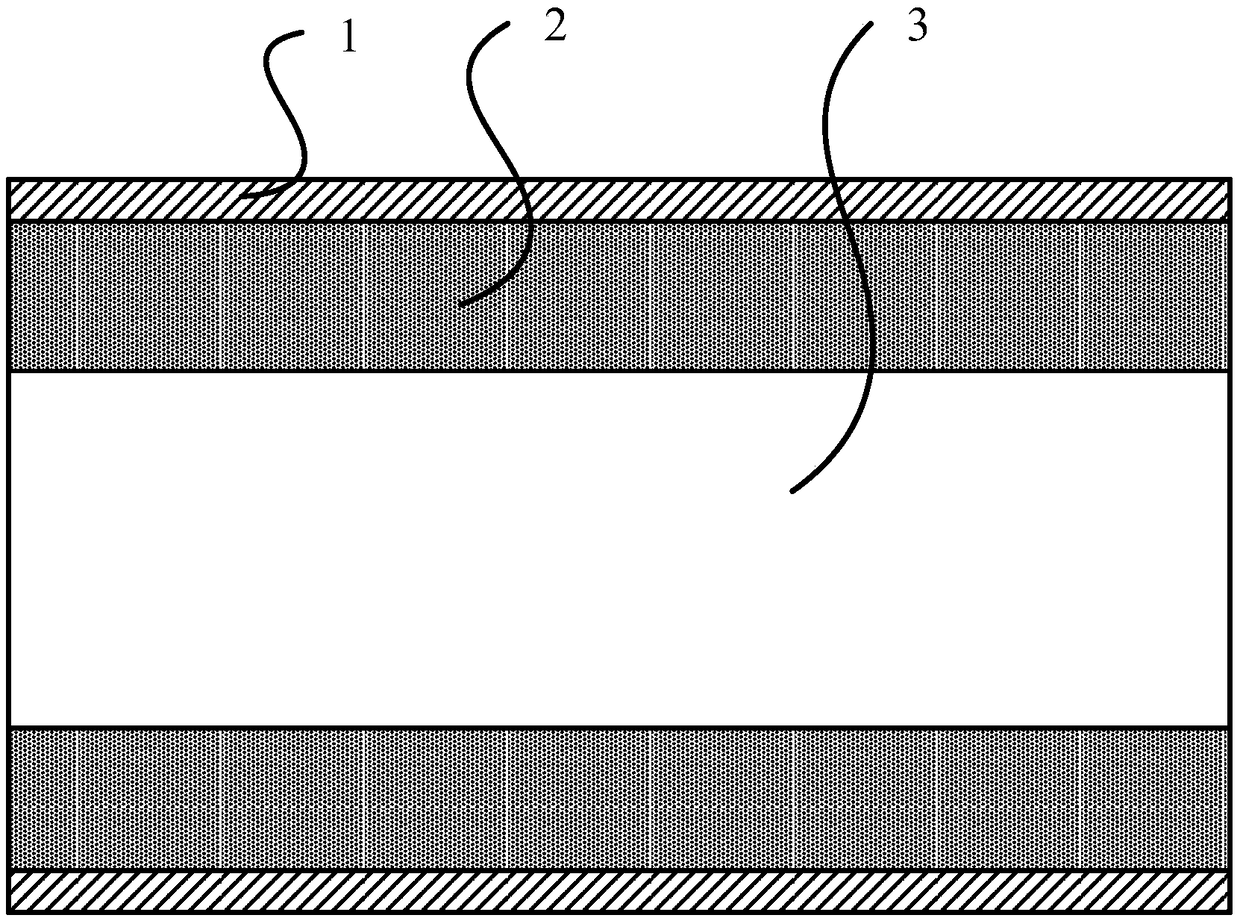

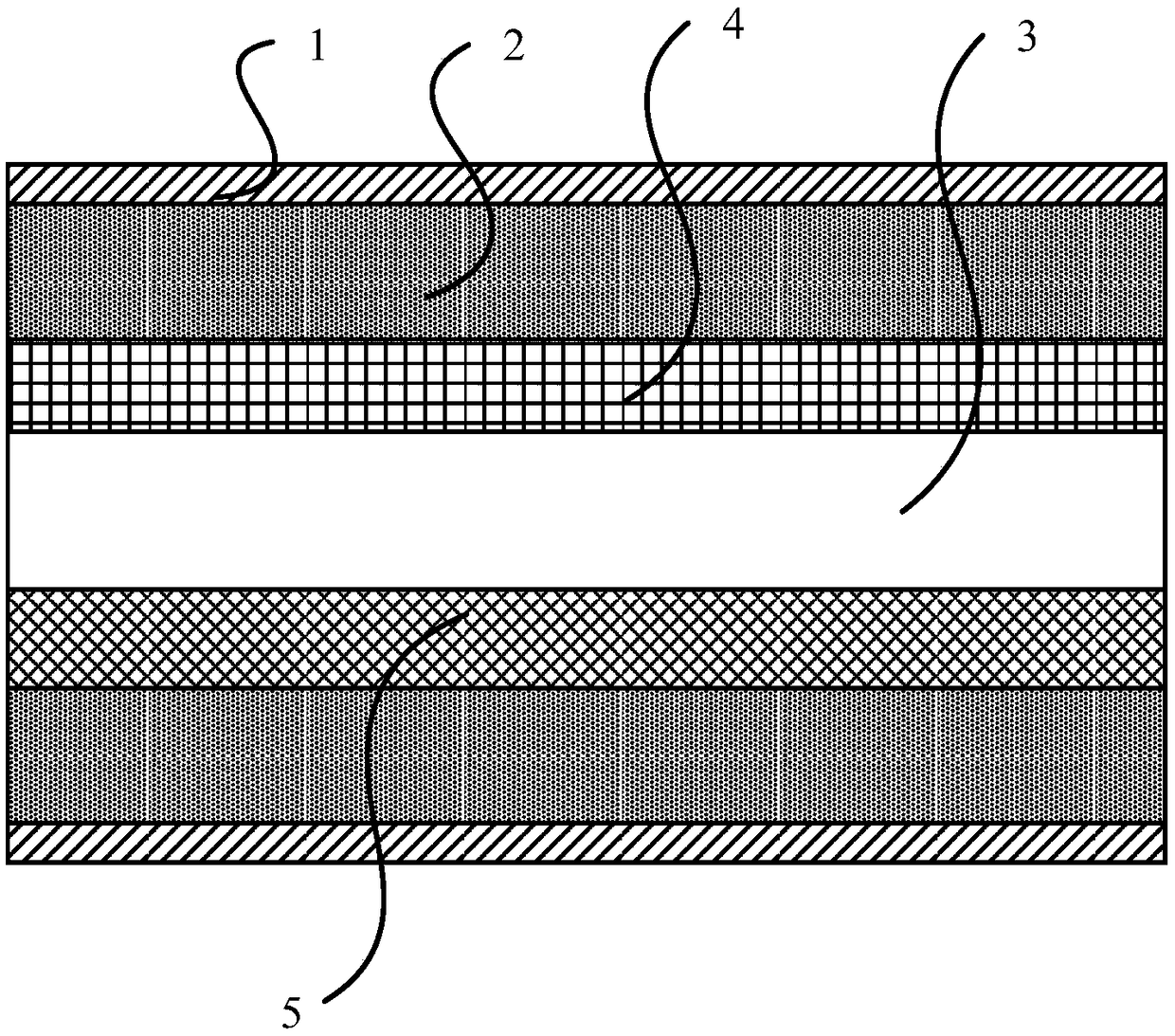

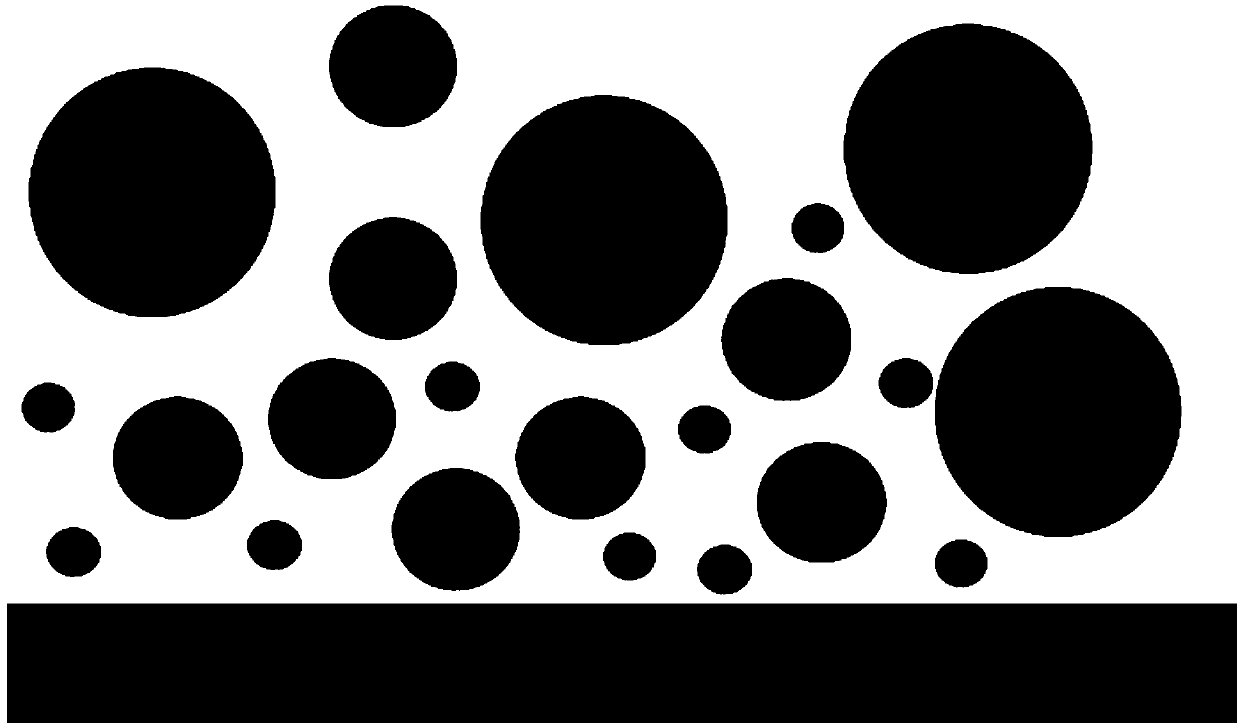

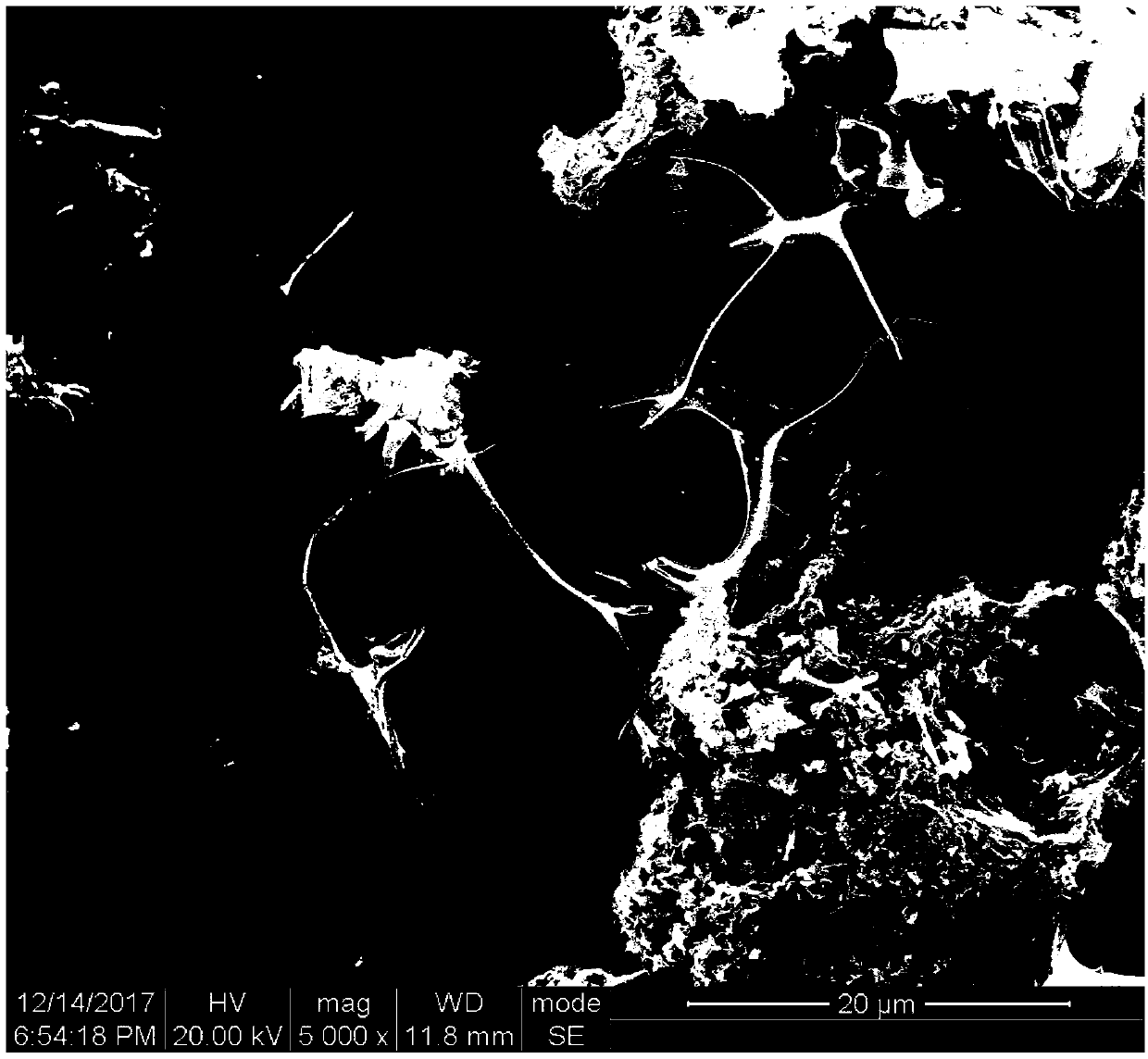

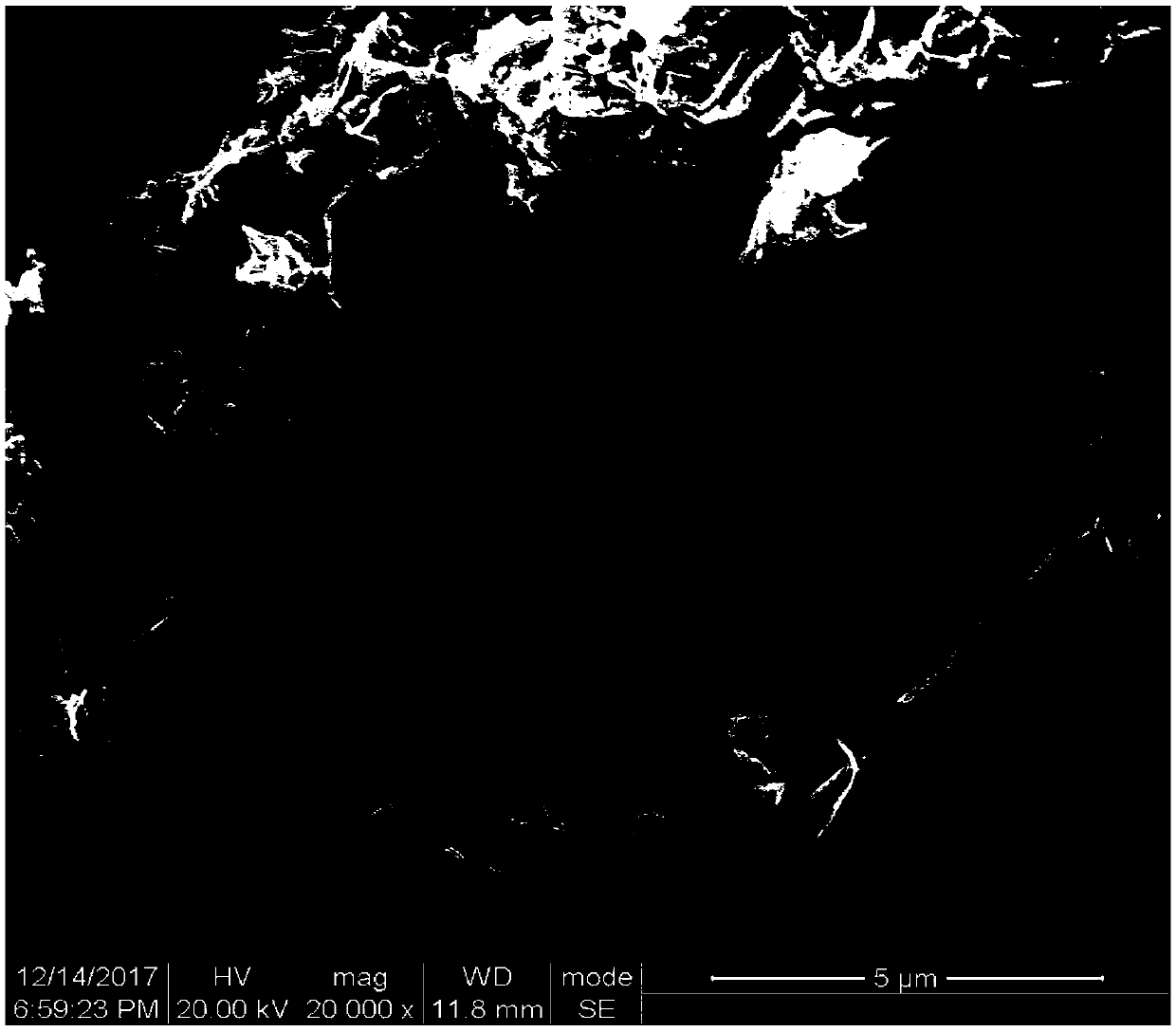

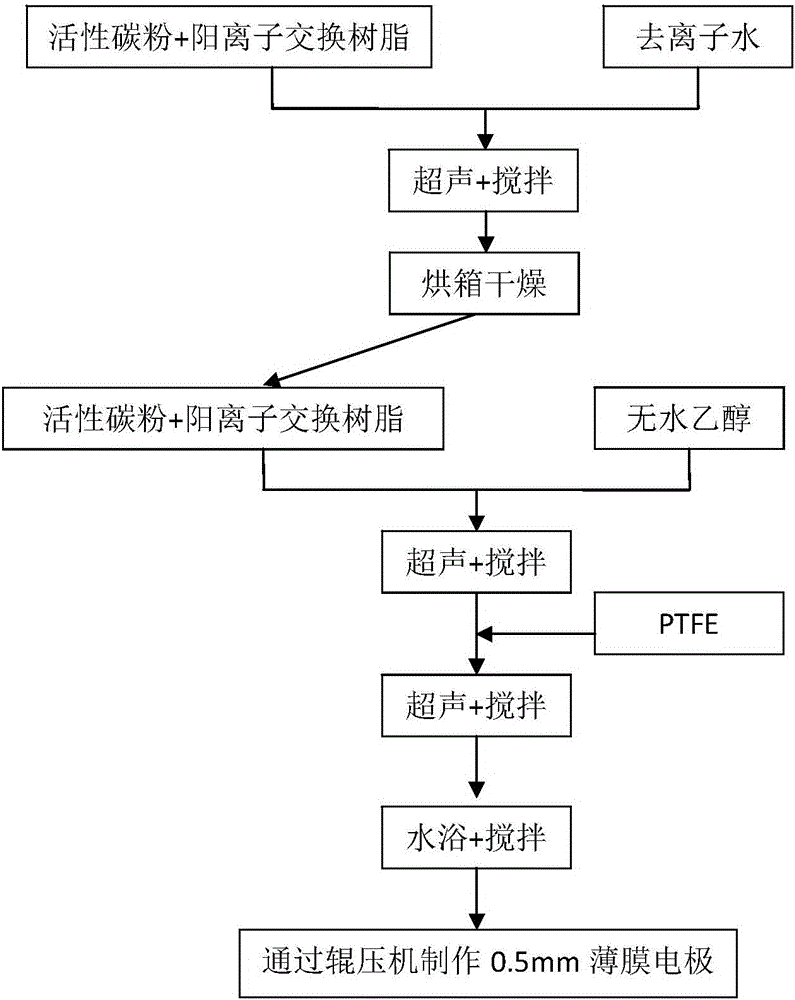

Preparation method of membrane capacitive deionization electrode and membrane capacitive deionization electrode

ActiveCN109502708AImprove migration speedImprove desalination efficiencyDispersed particle separationWater/sewage treatment by ion-exchangeCommon-ion effectCapacitance

The invention belongs to the field of water purification, and specifically relates to a preparation method of a membrane capacitive deionization electrode. The preparation method comprises the following steps: preparing conductive carbon electrode paste and ion exchange membrane layer paste respectively; preparing a conductive carbon electrode from the conductive carbon electrode paste; spraying the ion exchange membrane layer paste on the surface of the conductive carbon electrode; and performing vacuum drying to obtain the membrane capacitive deionization electrode. According to the preparation method involved in the invention, an ion exchange membrane and the conductive carbon electrode are integrated, so that the capacitive deionization effect is enhanced; the common ion effect is reduced; a channel is provided for ion migration; and migration diffusion resistance is lowered, thereby improving the desalting efficiency of the electrode, and lowering the energy consumption.

Owner:JIANGSU MAYMUSE ENVIRONMENTAL TECH CO LTD +1

Method for comprehensively utilizing sodium sulfate-sodium chloride mixed salt

ActiveCN114538471AFull and effective separabilityFull and effective useClimate change adaptationAmmonium salt fertilisersSodium bicarbonateCommon-ion effect

The invention discloses a method for comprehensively utilizing a sodium sulfate-sodium chloride mixed salt, which comprises the following steps: by taking the sodium sulfate-sodium chloride mixed salt and a solution thereof as raw materials and ammonium bicarbonate as a resolving agent, forcing Na < + > ions and Cl <-> ions in the solution to crystallize and separate out in the form of sodium bicarbonate and ammonium chloride by skillfully utilizing the same ion effect generated by HCO3 <-> ions and NH4 < + > ions; sodium, sulfate radicals and chlorine in the mixed salt are fully and effectively separated and utilized through gradient crystallization and reverse refining by utilizing a multi-phase crystallization-dissolution equilibrium relationship of sodium bicarbonate, ammonium bicarbonate, ammonium sulfate, ammonium chloride, ammonium sulfate and sodium chloride under different conditions, and three qualified products of sodium carbonate, ammonium sulfate and ammonium chloride are directly produced; the method has the advantages of simple process, high comprehensive utilization rate, good economic benefit, convenience in operation and the like, and is suitable for industrial production of comprehensive utilization of the sodium sulfate-sodium chloride mixed salt and the solution thereof.

Owner:宁波弗镁瑞环保科技有限公司

Method of separating and recovering ammonia from ammonia nitrogen wastewater

ActiveCN108947012AAchieve recyclingRealize resource managementWater contaminantsSludge treatment by pyrolysisCommon-ion effectSlag

The invention relates to a method of separating and recovering ammonia from ammonia nitrogen wastewater. The method comprises the following steps of: adding an excess vanadium-containing reagent to ammonia nitrogen wastewater; forcing ammonia nitrogen in the ammonia-nitrogen wastewater to be precipitated out in the form of ammonium salt by skillfully utilizing the common-ion effect generated by the vanadium-containing reagent, wherein the concentration of the ammonia nitrogen can be reduced to be less than or equal to 50mg / L; filtering to obtain ammonium enriched slag and a deaminated solution, and then adding a calcium-containing reagent or an iron-containing reagent to the deaminated solution so as to separate and recover the vanadium-containing reagent remaining therein, thereby causingV in the deaminated liquid to be less than or equal to 1mg / L; further decomposing the obtained ammonium enriched slag to obtain a product containing the vanadium reagent and ammonia (ammonium), thereby realizing the cyclic utilization of the vanadium-containing reagent in the ammonia-nitrogen wastewater treatment process and the resource treatment of ammonia-nitrogen wastewater to avoid the secondary pollution. The method has the advantages of simple process, simple operation, cleanness, environmental protection, economy, high efficiency and the like, and is suitable for industrial application of resource treatment of ammonia nitrogen wastewater.

Owner:CENT SOUTH UNIV +1

Mixed ion capacitor and preparation method thereof

InactiveCN109637817AIncrease migration ratePromote migrationHybrid capacitor electrolytesDouble layer capacitorsCommon-ion effectCapacity loss

The invention relates to a mixed ion capacitor and a preparation method thereof, belonging to the technical field of capacitors. There are no fewer than two types of anions or cations or there are nofewer than two types of anions and cations in the electrolyte of the capacitor of the invention. The anions or cations are different in ion volume or different in charge quantity, or the anions or cations are different in ion volume and charge quantity. The ion cage effect can be reduced, and the energy density of the capacitor can be improved. The common ion effect can be overcome, and the salting-out phenomenon can be avoided based on the diverse ion effect. The freedom of ions is improved, and the rate performance is improved while the cycling performance and stability of the capacitor areimproved. Moreover, the stack density of anions and cations on the surface of the electrode material can be improved, and the capacity loss in space can be reduced as much as possible so as to improvethe capacity of the capacitor. The cost can be reduced, the cost advantage of the capacitor can be developed while the performance is improved, and the competitive advantage of the capacitor in market can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

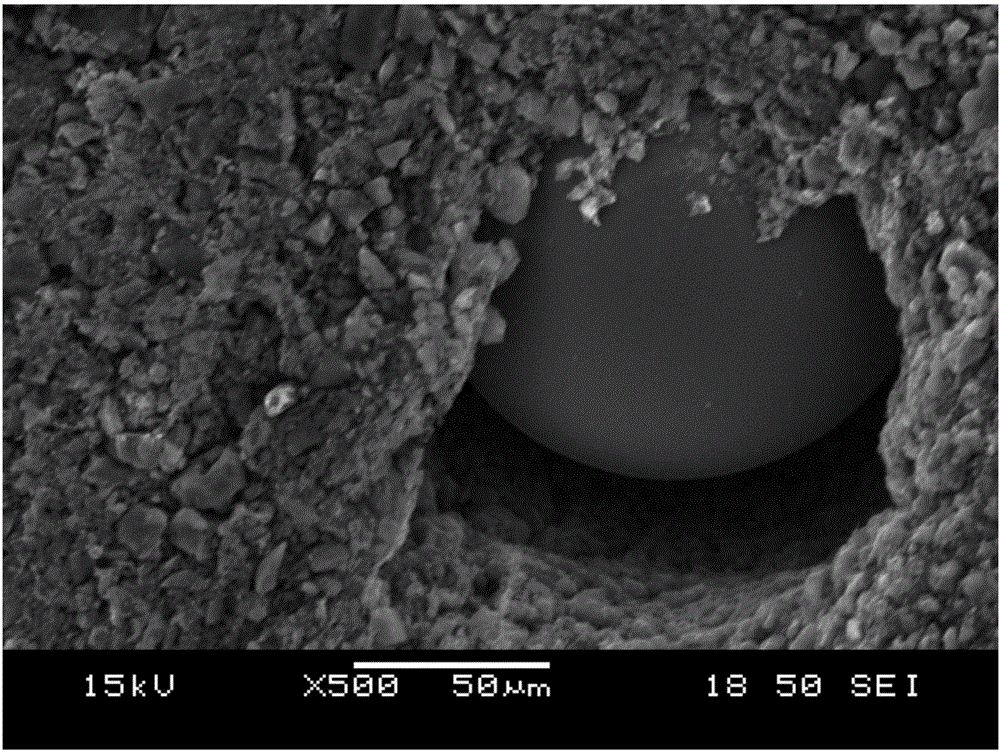

Preparation method of ion exchange resin substrate and activated carbon integrated electrode for capacitive desalination

ActiveCN105776451AImprove performanceReduce energy consumptionSeawater treatmentDispersed particle separationCapacitanceCommon-ion effect

The invention relates to an ion exchange resin substrate and activated carbon integrated electrode for capacitive desalination and a preparation method of the electrode. The electrode for capacitive desalination comprises a cathode and an anode, and cation exchange resin and anion exchange resin are respectively directly rolled and embedded into an activated carbon electrode and compactly pressed to an electrode structure formed on a stainless steel mesh. The preparation method includes cathode preparation and anode preparation. By direct embedding of cation and anion into the activated carbon electrode, influences of common ion effect can be avoided so as to improve desalination performance and electric charge efficiency, and a binding force between the electrode and an ion exchange material can be increased to realize performance stability. The ion exchange resin substrate and activated carbon integrated electrode is improved by 30% in performance and reduced by 5% in energy consumption as compared with an activated carbon roll electrode and improved by 85% in performance and reduced by 30% in energy consumption as compared with activated carbon cloth. Salt adsorption capacity of the electrode reaches 20.8mg / g, and electric charge efficiency reaches 87.4%.

Owner:TIANJIN UNIV

Method for purifying industrial manganese sulfate through cooperation of concentrated sulfuric acid and absolute ethyl alcohol

ActiveCN112830520AHigh purityRelieve the phenomenon that the viscosity is too high and difficult to dryManganese sulfatesManganese sulphateCommon-ion effect

The invention provides a method for purifying industrial manganese sulfate through cooperation of concentrated sulfuric acid and absolute ethyl alcohol, belonging to the technical field of manganese sulfate purification. According to the method, concentrated sulfuric acid and an industrial manganese sulfate solution are stirred and mixed at normal temperature, and manganese sulfate crystals are separated out by utilizing the same ion effect generated by excessive sulfate radicals, so calcium ions and magnesium ions in the industrial manganese sulfate solution are preliminarily separated; and a saturated manganese sulfate solution is prepared from the manganese sulfate crystals, and the saturated manganese sulfate solution and excessive concentrated sulfuric acid are recrystallized, so calcium and magnesium ions in the manganese sulfate solution can be further separated, and the purity of the manganese sulfate crystals is improved. According to the method, absolute ethyl alcohol is adopted for washing, the absolute ethyl alcohol has a separation effect on calcium and magnesium ions in the manganese sulfate crystals, and meanwhile, the phenomenon that the crystals are too high in viscosity and difficult to dry due to the fact that concentrated sulfuric acid is excessively used can be relieved. Meanwhile, the method is simple, low in cost and free of environmental pollution.

Owner:GUANGXI UNIV +1

Resource treatment method of rare-earth oxalic acid precipitation wastewater

ActiveCN109574181ATo achieve the purpose of resource managementEfficient separationWater contaminantsWater/sewage treatment by neutralisationCommon-ion effectOxalate

The invention discloses a resource treatment method of rare-earth oxalic acid precipitation wastewater. The method comprises the following steps of firstly adding oxalic acid into the oxalic acid precipitation wastewater, by utilizing a common ion effect generated by the oxalic acid and an ion, impelling residual rare earth in an obtained mixture to precipitate and separate out, filtering to obtain a rare-earth oxalic acid precipitate and precipitated liquid of the obtained mixture, afterwards, adding hydrochloric acid or introducing a HCl gas into the precipitated liquid, improving the acidity of a solution, freezing to impel the oxalic acid in the solution to crystallize and separate out, and by utilizing the characteristic that the solubility of the oxalic acid is decreased as the acidity of the solution is increased and a temperature is lowered, realizing the separation of the oxalic acid and the hydrochloric acid. The method has the advantages of being clean, environment-friendly,economical and efficient, and the like, and is suitable for the industrial application of the treatment of the oxalic acid precipitation wastewater in a rare earth smelting technical process.

Owner:CENT SOUTH UNIV +1

Preparation method of environmentally-friendly cellulose sponge material

The invention belongs to the technical field of celluloses, and particularly relates to a preparation method of an environmentally-friendly cellulose sponge material. The preparation method comprisesthe following steps: 1) preprocessing celluloses; 2) preparing a cellulose solution; and 3) preparing the cellulose sponge material. The cellulose sponge material prepared by the preparation method ofthe environmentally-friendly cellulose sponge material has a low production cost and a low environmental protection pressure, and can replace a cellulose sulfonate method currently adopted by enterprises. The prepared environmentally-friendly cellulose sponge material has good mechanical properties and a high water absorption rate. Low-temperature molding selected in the invention facilitates theformation of a Na2SO4 crystal compound, and the cellulose sponge is slowly molded under a natural condition. The added Na2SO4 can inhibit the activity of hydrogen ions by utilizing the common ion effect of Na2SO4 and sulfuric acid so as to prevent excessive degradation of celluloses. An aqueous NaOH / thiourea solution system selected in the invention has a high dissolving capacity, and the dissolving capacity of the aqueous NaOH / thiourea solution system gradually increases with the reduction of the temperature.

Owner:淮安市冰青建设工程管理有限公司

Method for preparing barium chloride by high-calcium witherite

InactiveCN109336158AHigh purityReduce consumptionCalcium/strontium/barium chloridesHigh concentrationSlag

The invention discloses a method for preparing barium chloride by high-calcium witherite. The method comprises the following raw materials by weight: 100 KG of high-calcium witherite with a barium carbonate content of 40-55 percent and a calcium carbonate content of 25-30 percent, and high-concentration hydrochloric acid with a concentration of 32 percent. The method for preparing the barium chloride by the high-calcium witherite, disclosed by the invention, has the benefits that by utilizing a common-ion effect, the high-concentration hydrochloric acid is adopted for reaction; the high-concentration hydrochloric acid is adopted for reaction with ores, calcium chloride produced by the reaction is fully dissolved in water brought by the hydrochloric acid, only a very small amount of produced barium chloride is dissolved in the water, and most of produced barium chloride exist in barium slag in a solid form; through primary filtration, a filtered liquid is a calcium chloride liquid, thecalcium chloride is removed, and then filter residues enter beating barrel for beating with water; the barium chloride in the barium slag is completely leached out to obtain barium chloride liquid with high purity, and then the barium chloride liquid is used for evaporative crystallization, so that the obtained product is high in purity and high in yield, and the steam consumption and the power consumption per ton of products are low.

Owner:宜昌华昊新材料科技有限公司

Treatment method of chlorine-containing wastewater in rare earth smelting technical process

PendingCN109574174ATo achieve the purpose of dechlorinationRealize closed loopWater contaminantsWater/sewage treatmentSodium bicarbonateEvaporation

The invention discloses a treatment method of chlorine-containing wastewater in a rare earth smelting technical process. The method comprises the following steps of firstly converting the chlorine-containing wastewater generated in the rare earth smelting process into a sodium chloride-containing solution through adding lime and sodium sulfate, then, adding hydrochloric acid used in the rare earthsmelting technical process or introducing a HCl gas into the sodium chloride-containing solution, by utilizing a common ion effect generated by a chlorine ion, impelling sodium chloride in an obtained mixture to precipitate and separate out, or adding sodium carbonate or / and sodium hydrogen carbonate, by utilizing the common ion effect generated by a sodium ion, impelling the sodium chloride in an another obtained mixture to precipitate and separate out, and filtering to obtain a sodium chloride crystal. Without evaporation concentration, chlorine in the chlorine-containing wastewater can beseparated. The method has the advantages of being clean, environment-friendly, economical and efficient, and the like, and is suitable for the industrial application of the treatment of the chlorine-containing wastewater in the rare earth smelting technical process.

Owner:CENT SOUTH UNIV +1

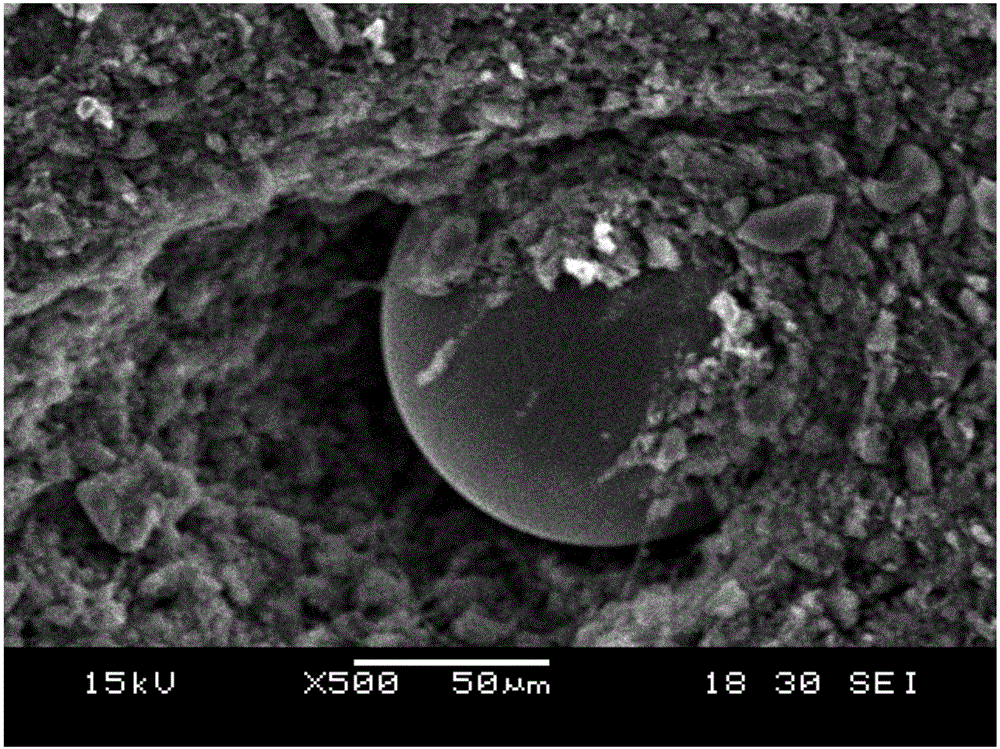

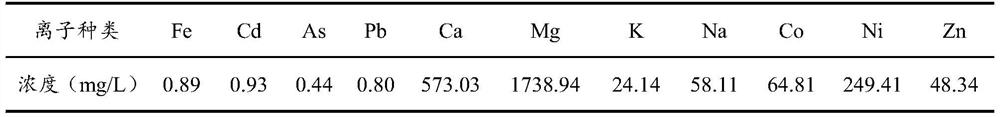

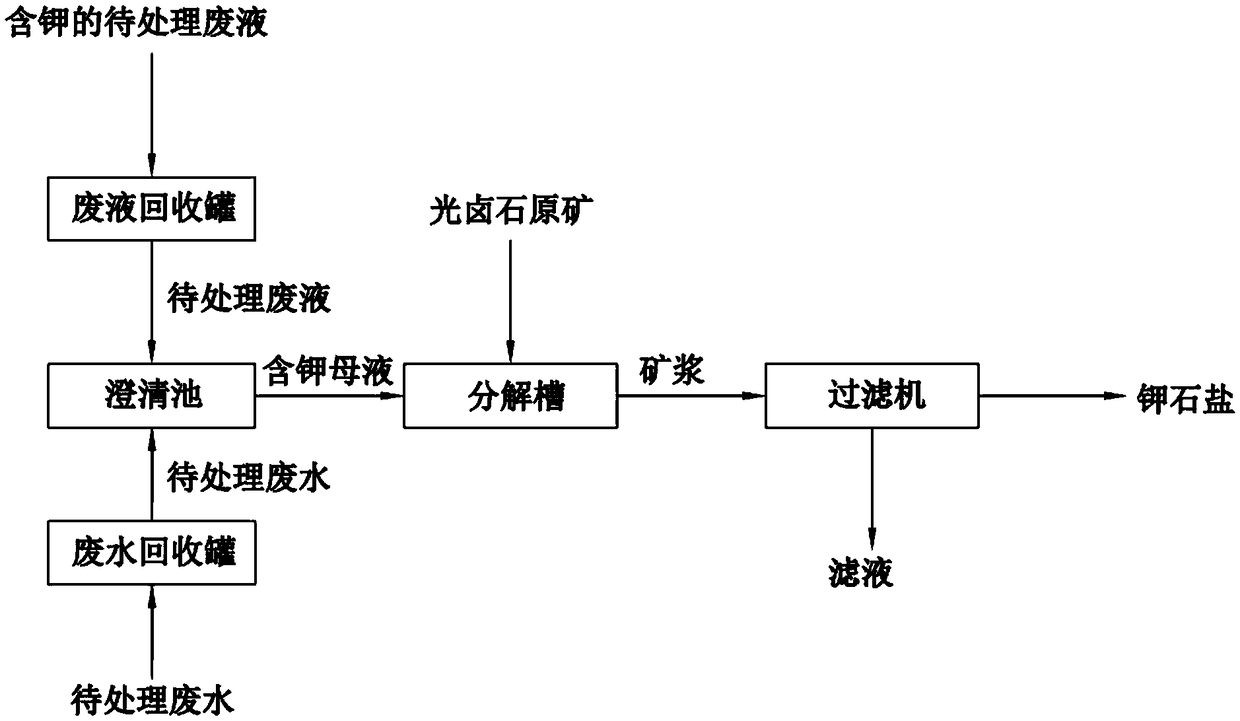

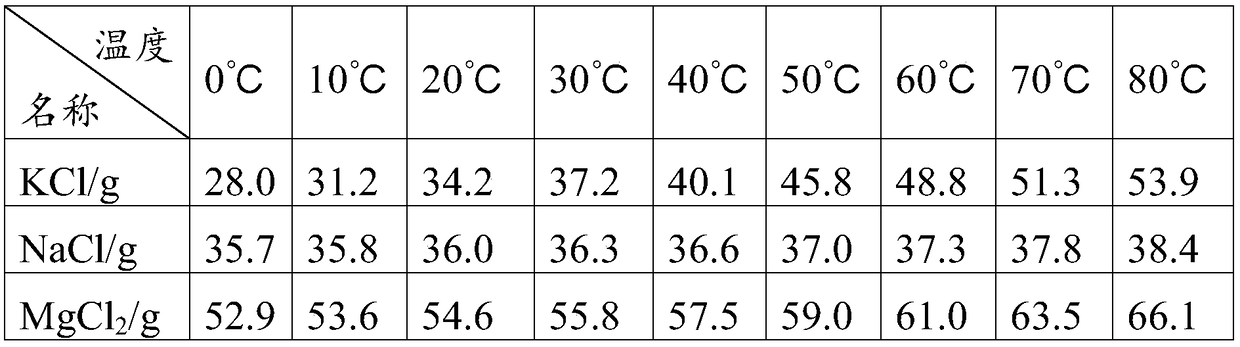

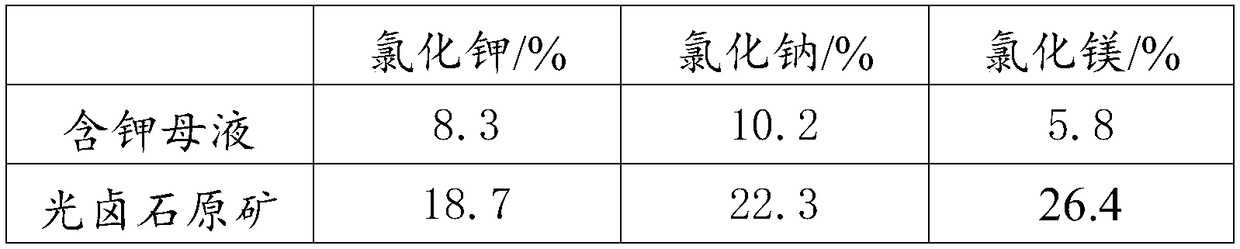

Production method of sylvinite

The invention discloses a production method of sylvinite. The production method of sylvinite comprises the following steps: proportioning potassium-containing to-be-treated waste liquor and to-be-treated wastewater to obtain a potassium-containing mother liquor; dissolving carnallite raw ores by the potassium-containing mother liquor to obtain ore pulp; and filtering the ore pulp to obtain the sylvinite. By proportioning the waste liquor and the wastewater to obtain the potassium-containing mother liquor and dissolving the carnallite raw ores by the potassium-containing mother liquor, magnesium chloride is dissolved massively and magnesium chloride is separated out in a saturated manner by means of a common ion effect, so that the sylvinite containing relatively high potassium quantity andmeeting the demands of refining potassium chloride is obtained, and water resources are saved. Influences on control 0f a follow-up production process and energy conservation and emission reduction are reduced as far as possible. Moreover, the carnallite raw ores are dissolved by the potassium-containing mother liquor, so that the baume degree of the ore pulp is increased, and the load of equipment is alleviated, therefore, the energy consumption and the loss of the equipment are further reduced to achieve the purpose of recycling resources, and the economical benefit is improved.

Owner:QINGHAI SALT LAKE IND

Cellulose foam material

The invention belongs to the technical field of celluloses, and particularly relates to a cellulose foam material. The cellulose foam material is prepared by adding a pore-forming agent sodium sulfateinto a cellulose solution and carrying out aging, regeneration, washing and drying processes, and the cellulose solution is prepared by dissolving a cellulose pulp in a mixed solution composed of urea / thiourea, sodium hydroxide and water. The cellulose foam material has the advantages of low production cost, low environmental protection pressure, good mechanical properties and high water absorption rate. Low-temperature molding selected in the invention facilitates the formation of a Na2SO4 crystal compound. The added Na2SO4 can inhibit the activity of hydrogen ions by utilizing the common ion effect of Na2SO4 and sulfuric acid so as to prevent excessive degradation of the cellulose. The elongation at break of the prepared cellulose foam material reaches 2.2% or above, the tensile strength is about 0.25 MPa, and the tearing strength is 0.2 KN.m.

Owner:淮安市冰青建设工程管理有限公司

A method for separating and purifying sodium salt in arsenic-alkali slag

InactiveCN104818387BEfficient separation and recoveryLow As contentProcess efficiency improvementSodium saltImpurity

The invention aims at providing a method for separating and purifying sodium salts in arsenic alkali residue. The method can help separate high-purity sodium carbonate and sodium arsenate from antimony smelting arsenic alkali residue to achieve recycling of the sodium carbonate and sodium arsenate. The method comprises condensing a sodium arsenate composite salt solution at 60-70 DEG C to separate out most of Na2CO3 out of the solution, at the moment, all As is in the solution. Both magnetic fields and ultrasound can change the thermodynamic properties of chemical compounds and affect the solubility, the crystallization induction time, the width of the metastable region and the crystallization manner. A filter liquor a contains large amounts of Na+, under the coupling action of specific temperature and the magnetic field and ultrasound of the corresponding intensity, strong common-ion effects enable most of sodium arsenate to crystalize from the solution and other impurity components to stay in the solution. Meanwhile, by performing the pretreatment in the step 3) on the filter liquor a before the ultrasound and magnetic field treatment, the content of arsenic in crystalized sodium arsenate can be improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Environmentally-friendly cellulose sponge material

The invention belongs to the technical field of celluloses, and particularly relates to an environmentally-friendly cellulose sponge material. The cellulose sponge material is prepared by adding a pore-forming agent sodium sulfate into a cellulose solution and carrying out aging, regeneration, washing and drying processes, and the cellulose solution is prepared by preprocessing cellulose with an aqueous sodium hydroxide solution and then placing the preprocessed cellulose in a sodium hydroxide / thiourea solution. The environmentally-friendly cellulose sponge material has good mechanical properties and a high water absorption rate. Low-temperature molding selected in the invention facilitates the formation of a Na2SO4 crystalline compound, and the cellulose sponge is slowly molded under a natural condition. The added Na2SO4 can inhibit the activity of hydrogen ions by utilizing the common ion effect of Na2SO4 and sulfuric acid so as to prevent excessive degradation of the cellulose. Theelongation at break of the prepared cellulose sponge reaches 2.0% or above, the tensile strength is 0.2 MPa, and the tearing strength is 0.17 KN.m.

Owner:淮安市冰青建设工程管理有限公司

Chloride-containing solution treatment method

InactiveCN109574175ARealize recycling of resourcesImprove dechlorination effectWater contaminantsWater/sewage treatmentCommon-ion effectSolution treatment

Disclosed is a chloride-containing solution treatment method. The chloride-containing solution treatment method comprises adding sodium-containing agent into chloride solution as converting agent to convert the chloride solution into sodium chloride-containing solution, then adding in chlorine-containing agent of sodium-containing agent as promoter to promote sodium chloride crystallization and separation, and through common ion effects produced by chlorine ions or sodium ions, promoting crystallization and separation of contained chlorine in form of sodium chloride, thereby being capable of separating the chlorine in the solution without evaporation and concentration. The chloride-containing solution treatment method has the advantages of being good in dechlorinating effects, clean, environmentally friendly, economical, high in efficiency and the like and is applicable to industrial application to chloride sewage treatment.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com