Patents

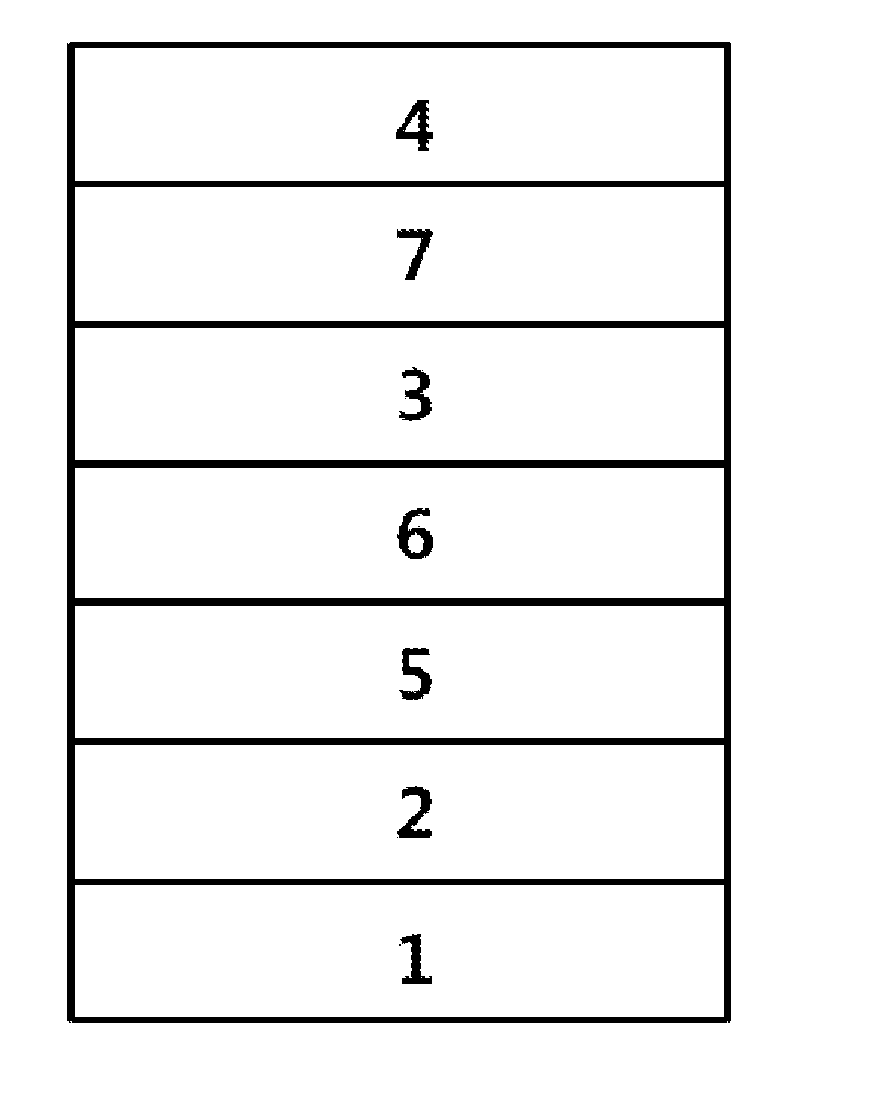

Literature

131results about "Indigoid dyes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

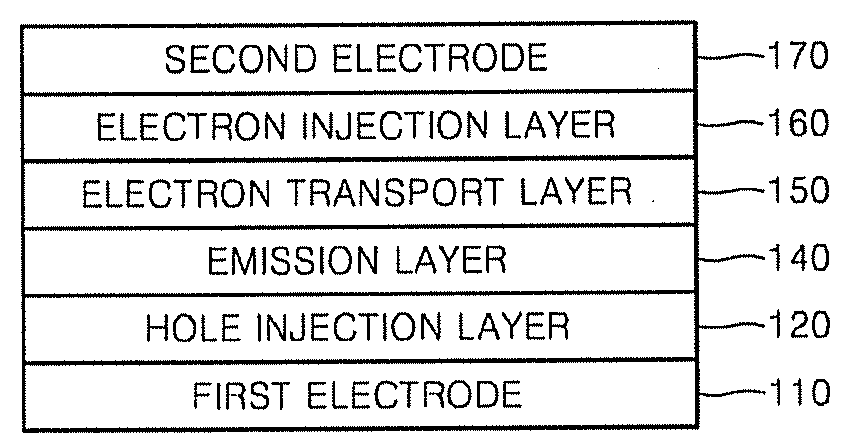

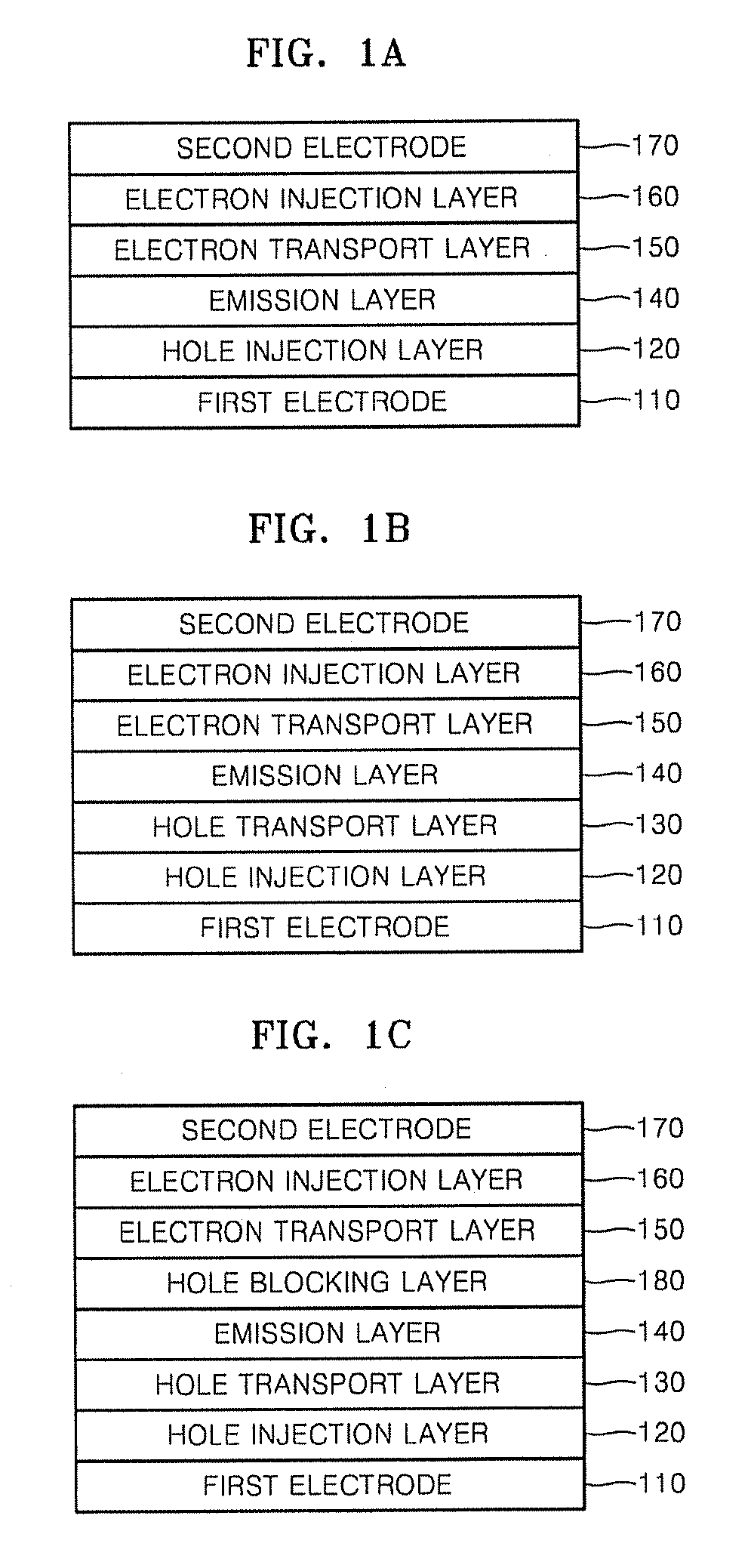

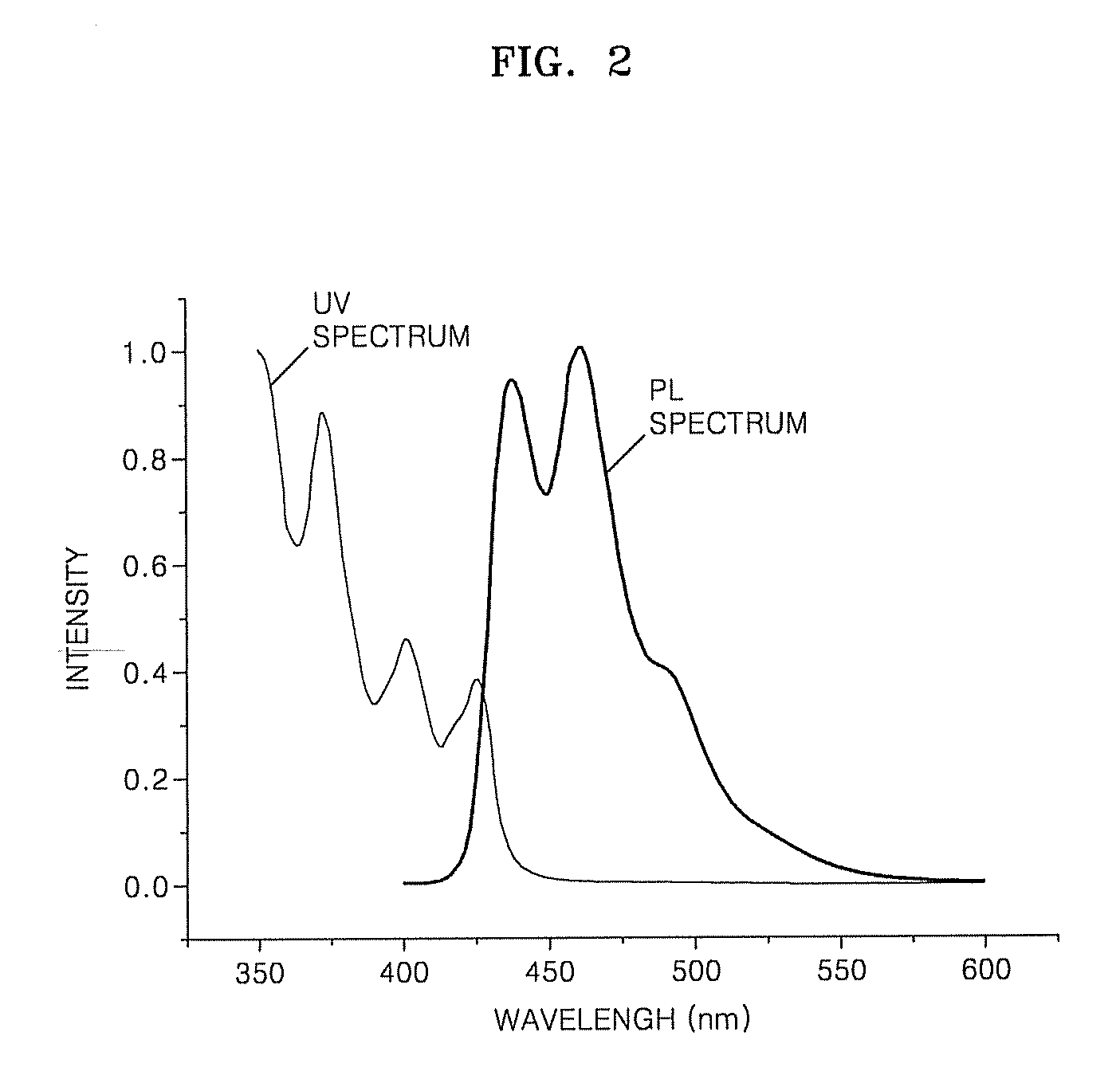

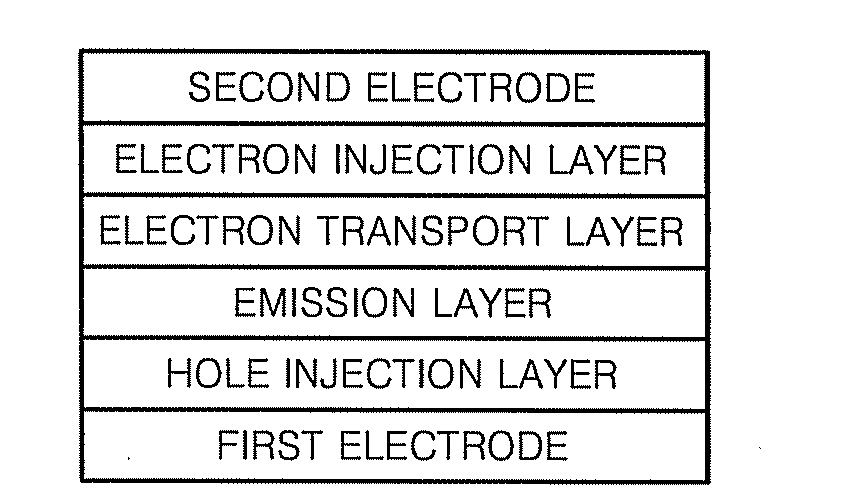

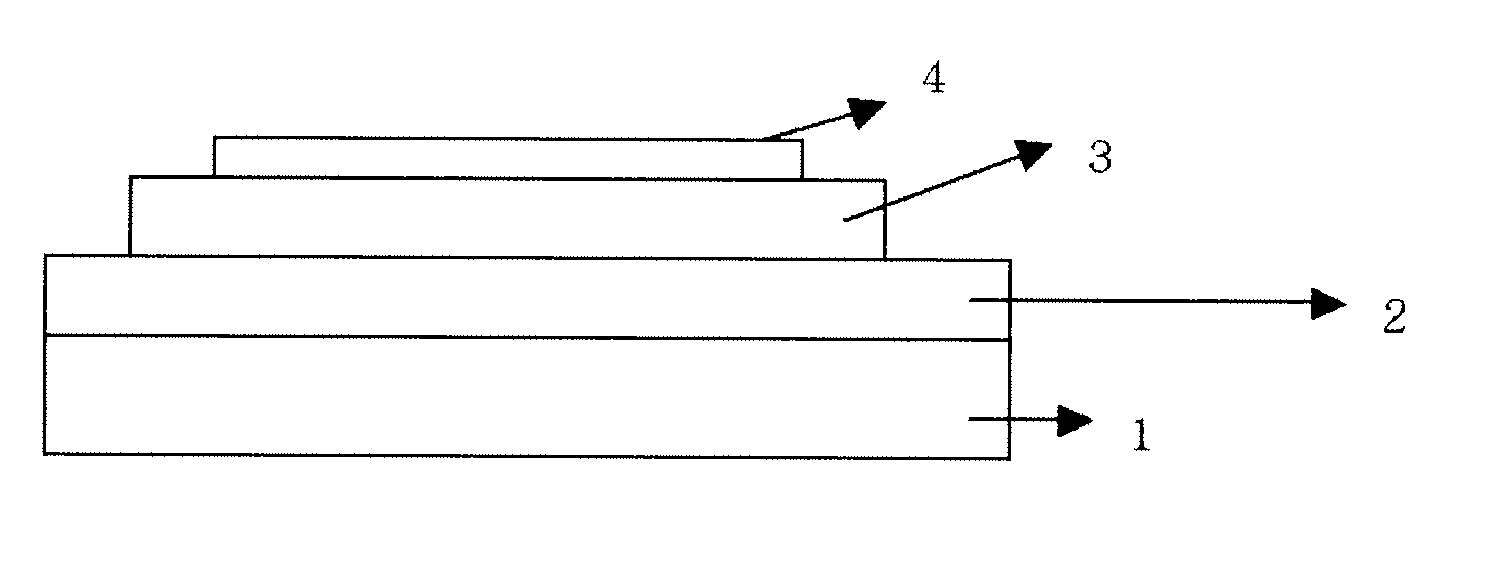

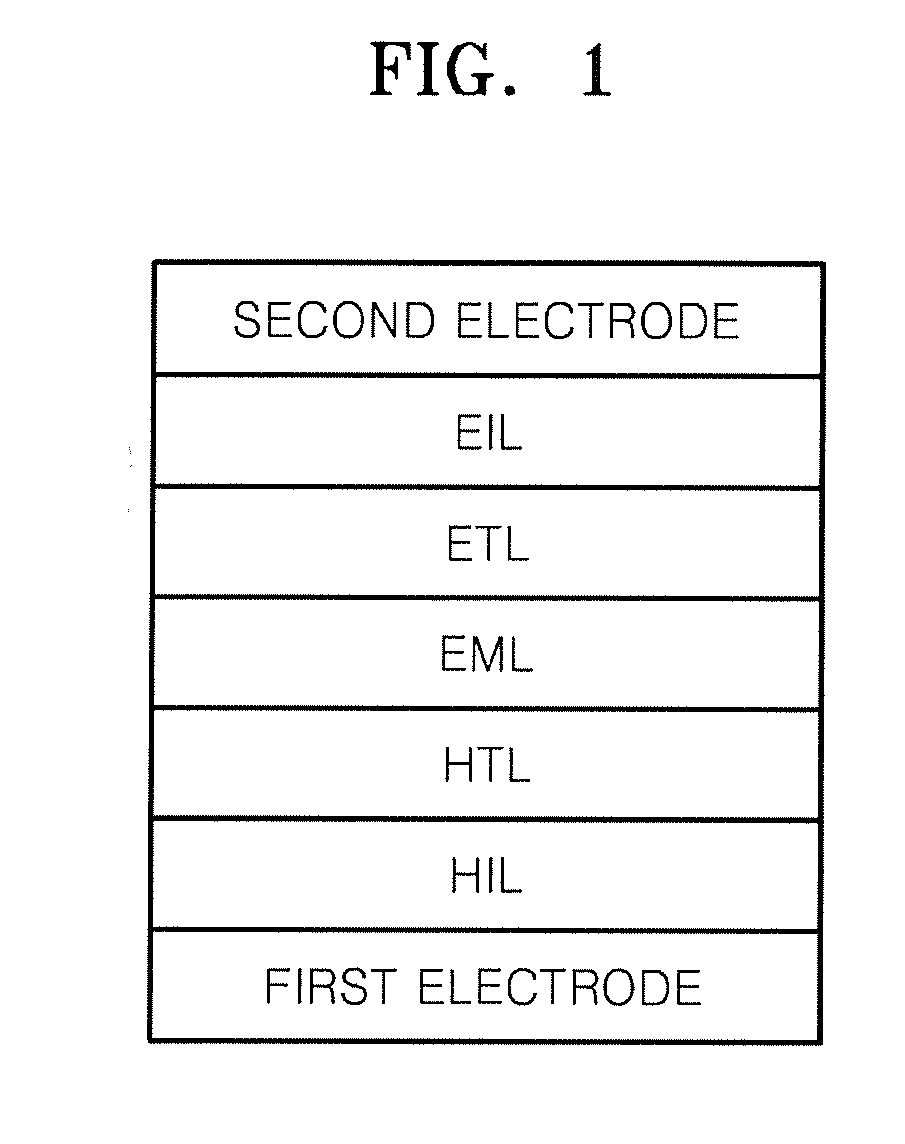

Organic light emitting compound, organic light emitting device comprising the same, and method of manufacturing the organic light emitting device

InactiveUS20080124455A1Improve solubilityImprove thermal stabilityOrganic chemistryDischarge tube luminescnet screensOrganic light emitting deviceHigh luminance

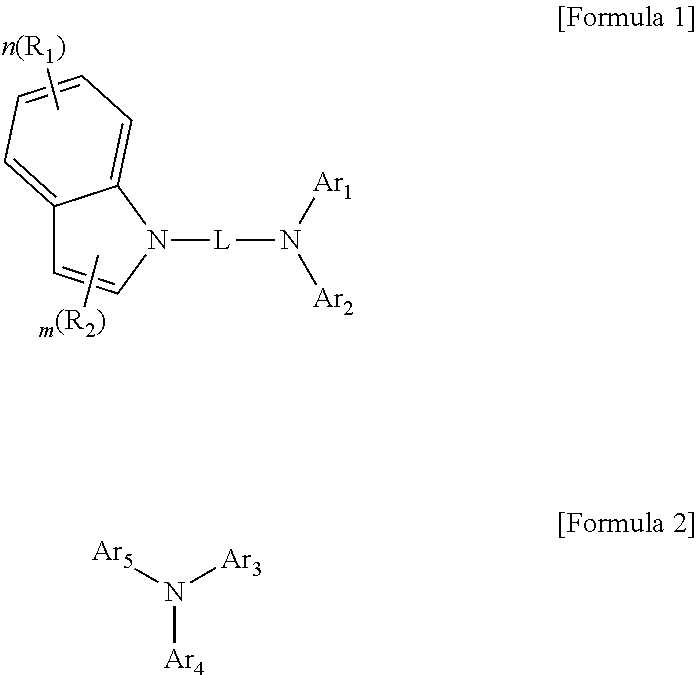

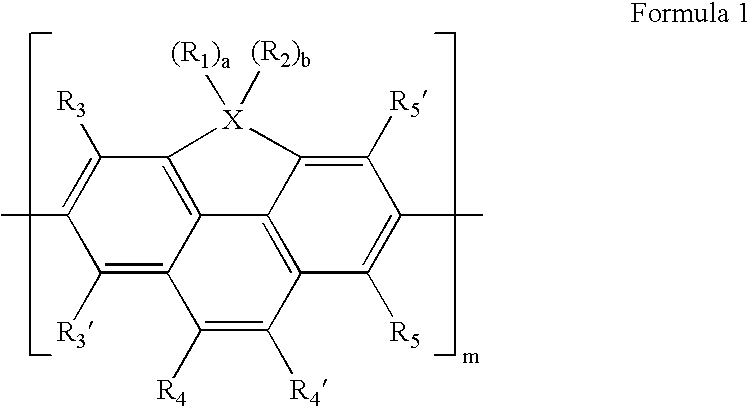

Provided are an organic light emitting compound represented by Formula 1 below, an organic light emitting device comprising the same, and a method of manufacturing the organic light emitting device:where CY1 and CY2 are each independently a fused C6-C50 aromatic ring, Ar1 is a substituted or unsubstituted C6-C50 arylene group, Ar2, Ar3, Ar4, and Ar5 are each independently a substituted or unsubstituted C6-C50 aryl group, m and n are independently 0-3, and R1 and R2 are substituent groups. An organic light emitting device comprising the organic light emitting compound has low turn-on voltage, high efficiency, high color purity and high luminance.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic light emitting compound and organic light emitting device comprising the same, and method of manufacturing the organic light emitting device

InactiveUS20080122344A1Improve solubilityImprove thermal stabilityOrganic chemistryDischarge tube luminescnet screensOrganic light emitting deviceHigh color

Provided are an organic light emitting compound represented by Formula 1 below, an organic light emitting device comprising the same, and a method of manufacturing the light emitting device:wherein CY1, CY2, Ar1, R1 and R2 are described in the detailed description of the invention. An organic light emitting device comprising the organic light emitting compound has low turn-on voltage, high efficiency, high color purity and high luminance.

Owner:SAMSUNG DISPLAY CO LTD

Inhibitors of HCV replication

Owner:BRISTOL MYERS SQUIBB CO

Multiple Component Materials Having A Color-Changing Composition

ActiveUS20110015599A1Effective adhesionImprove stabilityMaterial analysis by observing effect on chemical indicatorDecorative surface effectsOrganic acidColor changes

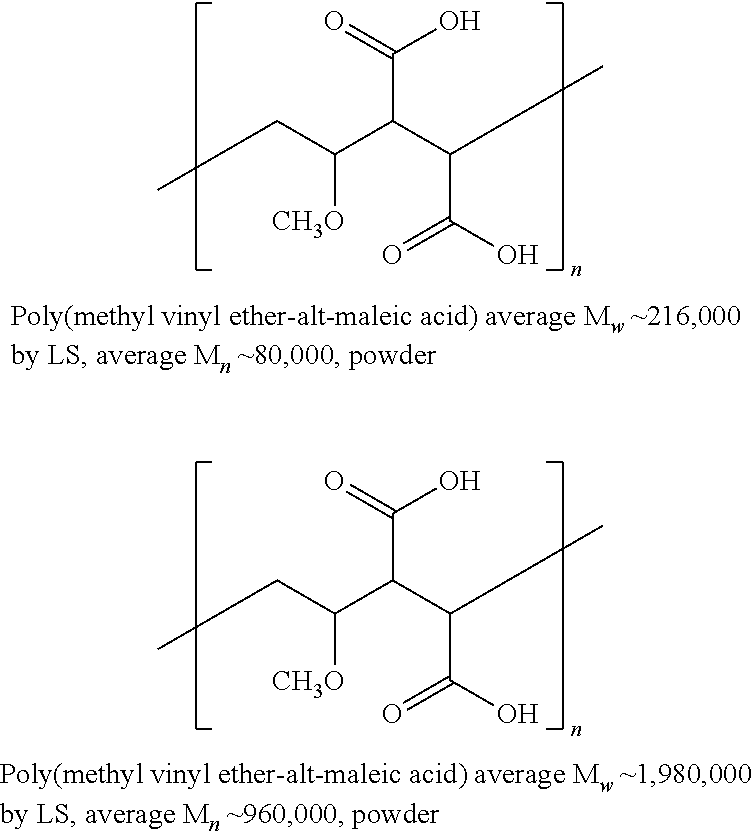

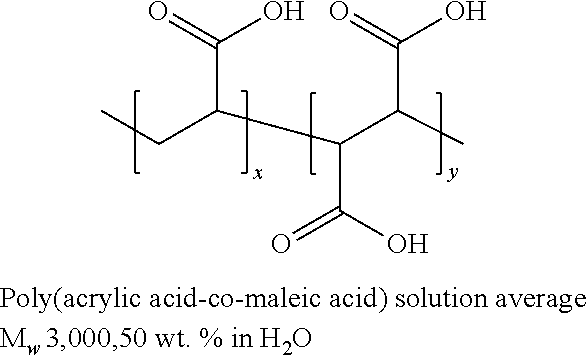

The present invention relates to a multiple-component material including a substrate and a printed layer on the substrate. The printed layer includes a color-changing composition to indicate a change in condition, such as a change in pH. The color-changing composition includes a matrix-forming component, a colorant, a surfactant and a pH adjuster. The pH adjuster includes a low molecular weight organic acid and a high molecular weight organic acid.

Owner:KIMBERLY-CLARK WORLDWIDE INC

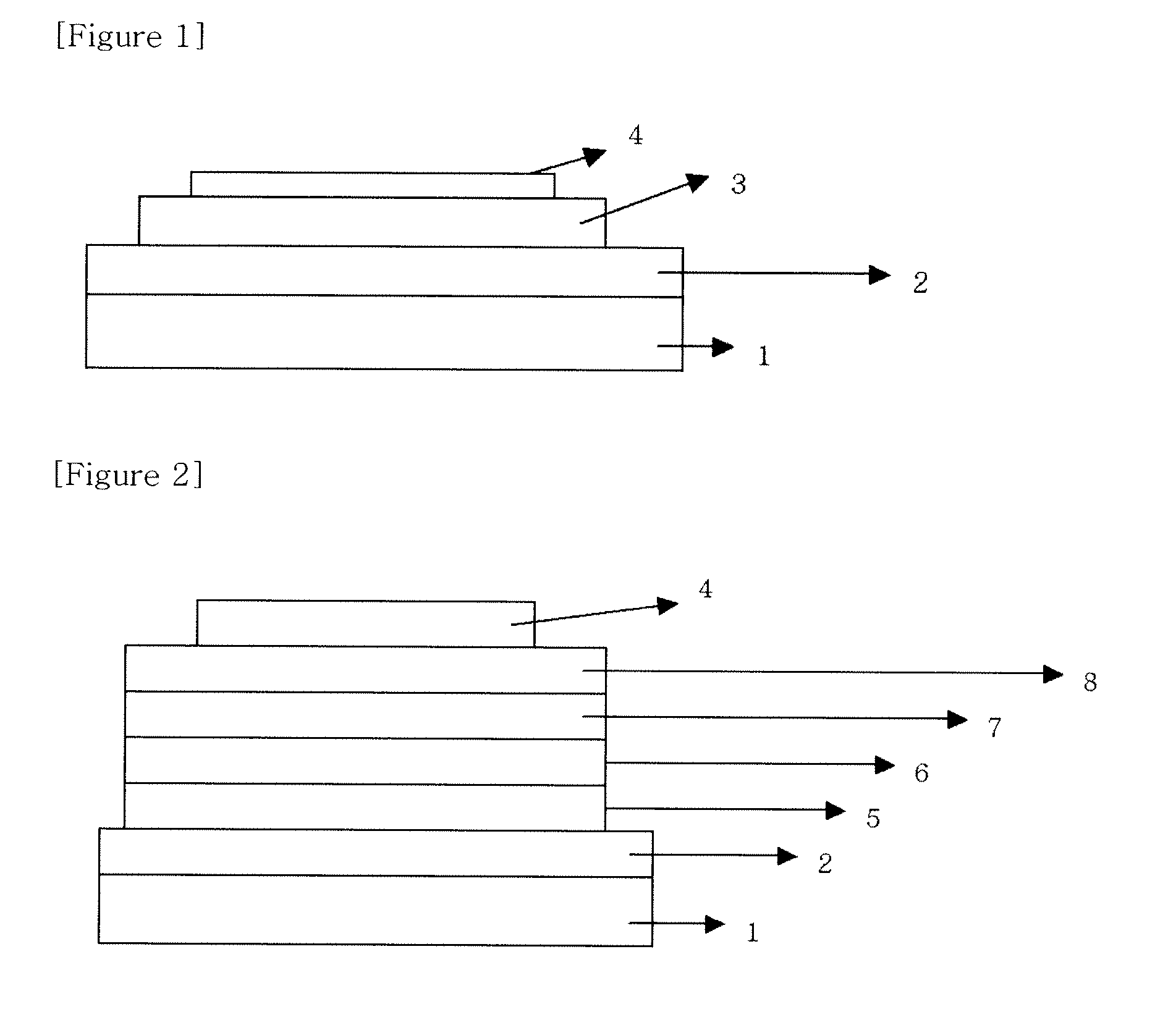

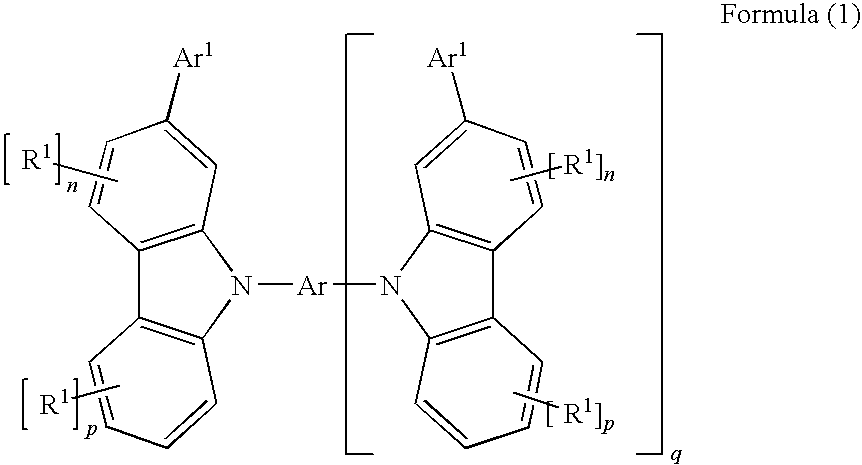

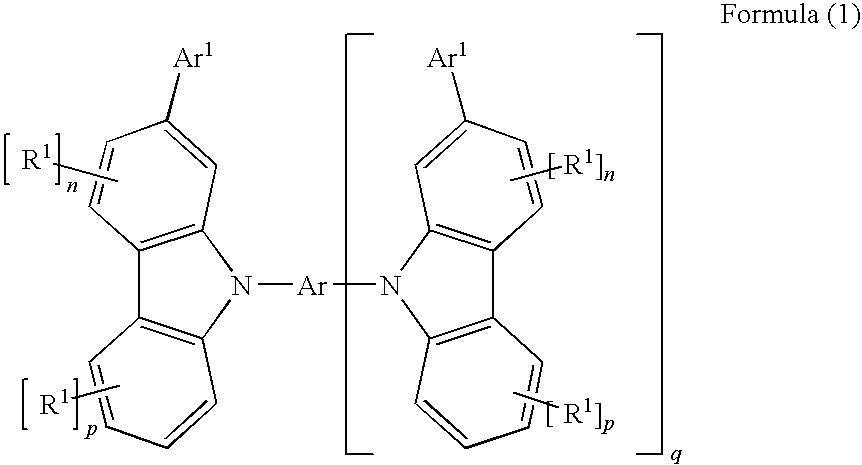

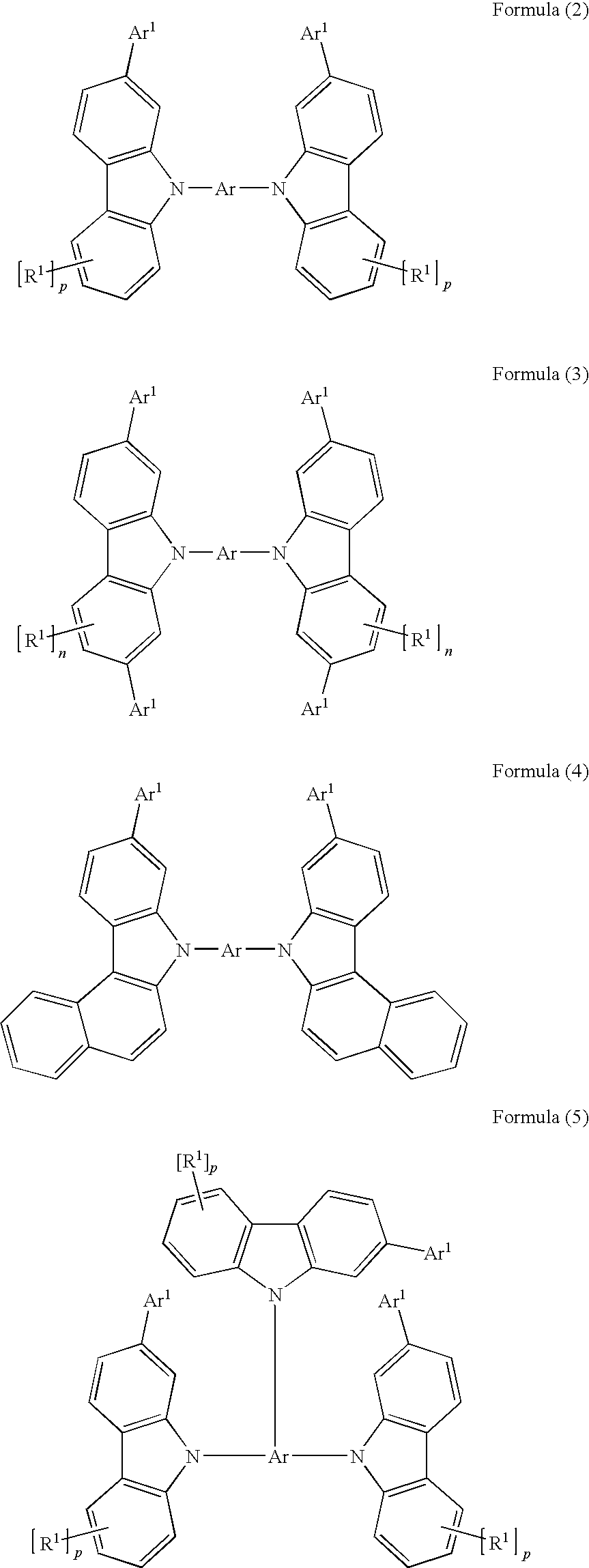

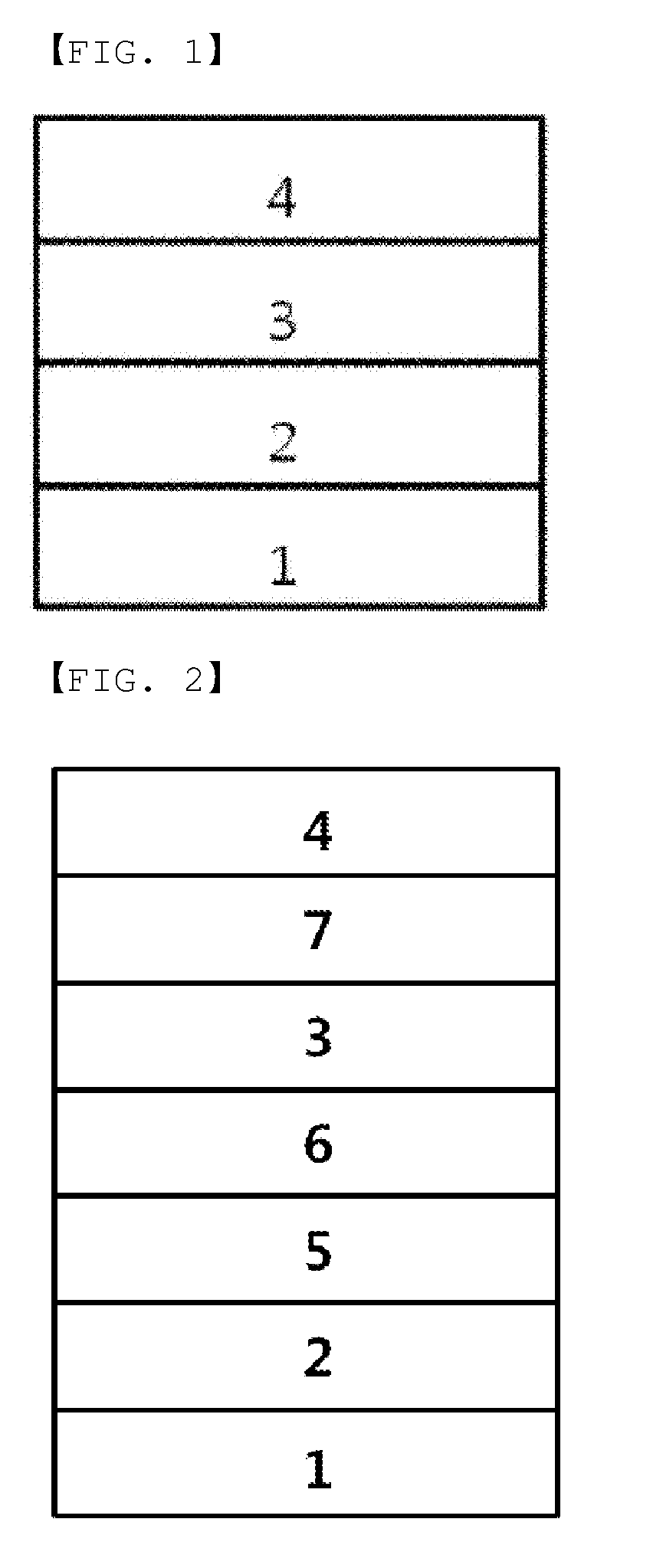

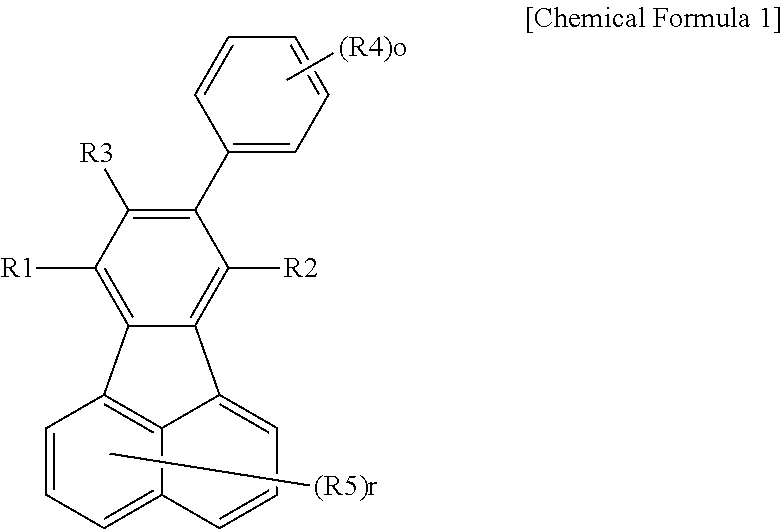

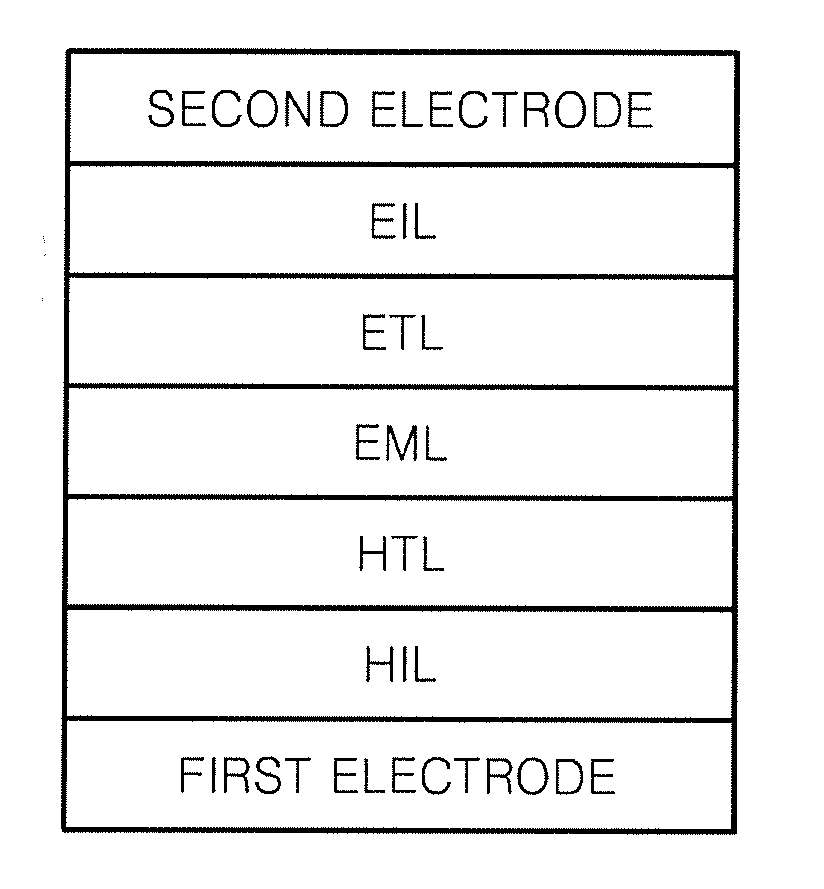

Compound, organic electric element using the same, and an electronic device thereof

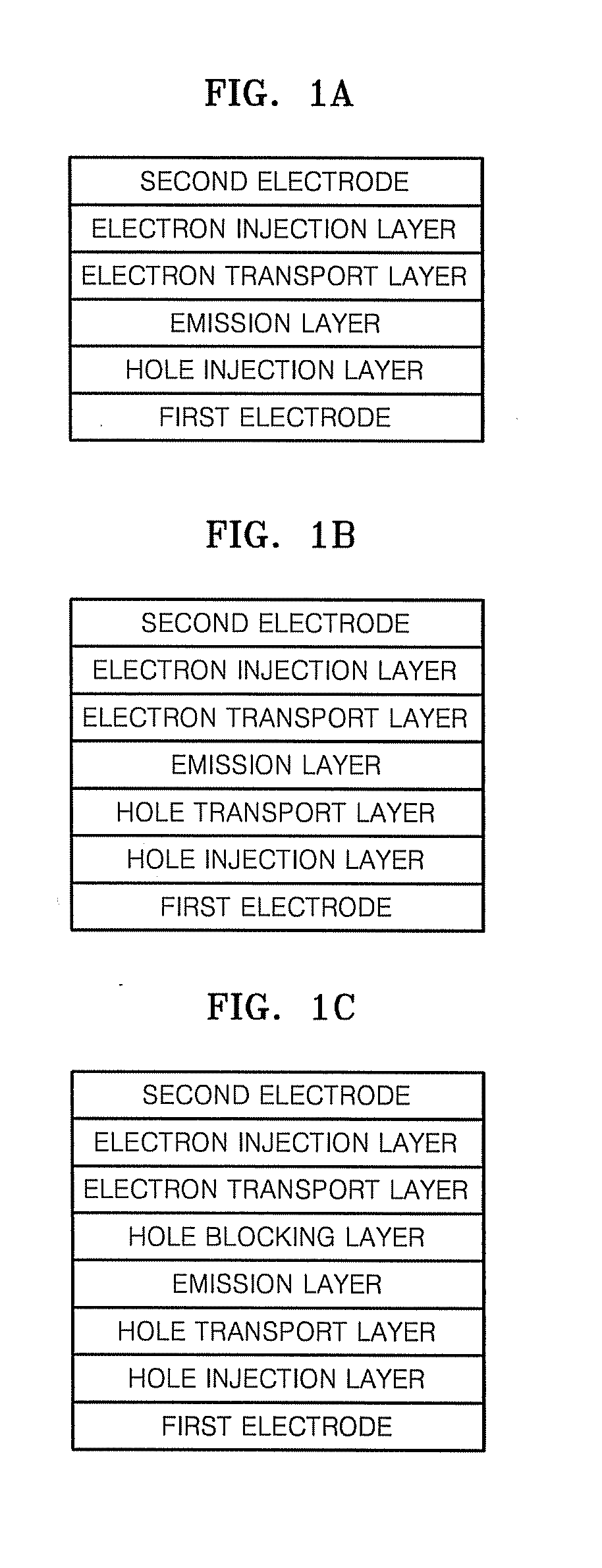

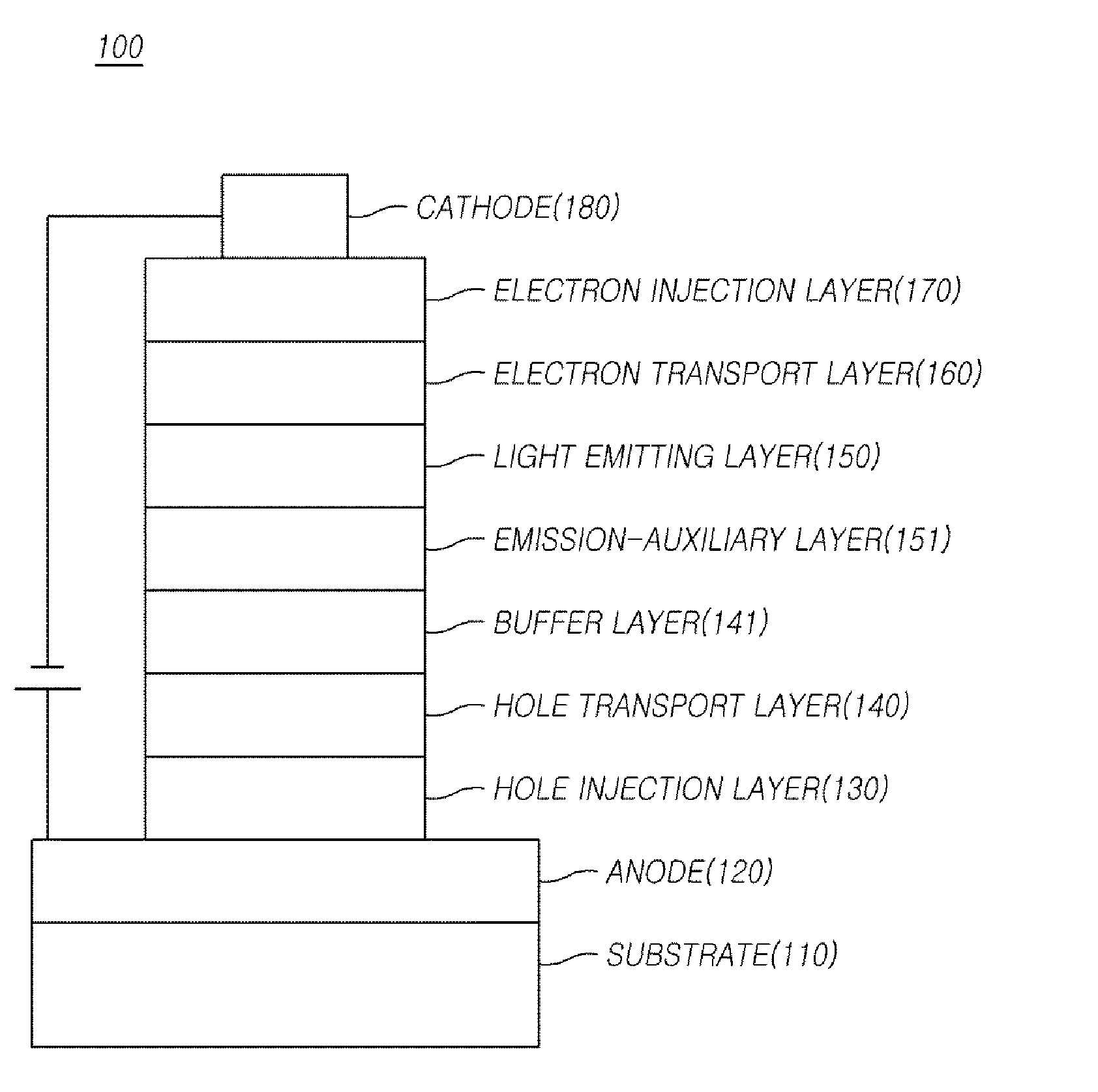

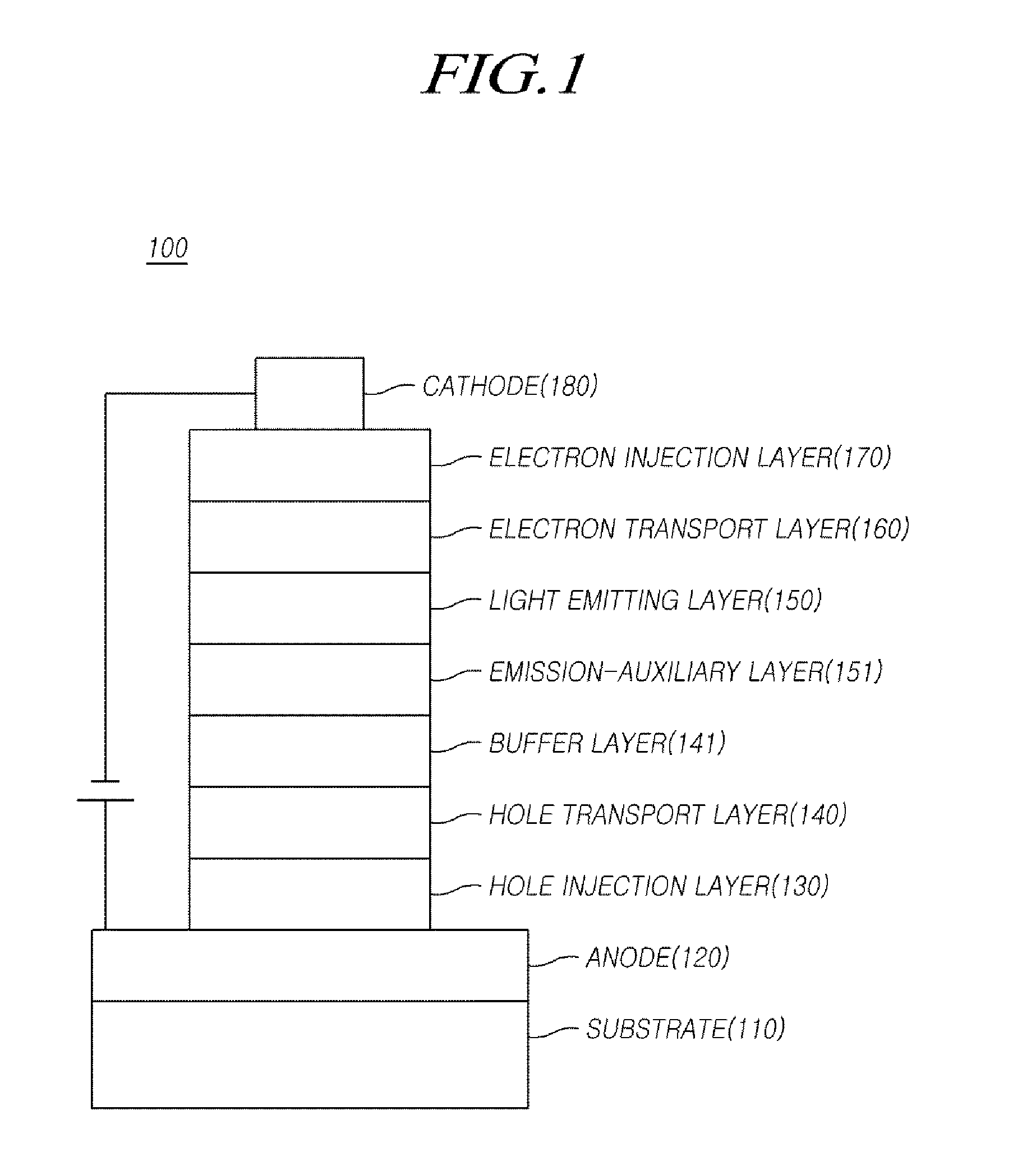

ActiveUS20140374722A1Improve heat resistanceReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerElectronic component

A compound represented by Formula 1. An organic electric element includes a first electrode, a second electrode, and an organic material layer including the compound of Formula 1. The organic material layer include a light emitting layer, a hole transport layer including a compound represented by Formula 2, and an emission-auxiliary layer including the compound represented by Formula 1. When the organic electric element includes the compound in the organic material layer, luminous efficiency, color purity, and life span can be improved.

Owner:DUK SAN NEOLUX

Composition For Dyeing Keratin Fibers and A Method of Dyeing Hair Using Same

A composition for dyeing keratin fibers that contains 0.1 to 30 percent of at least one substantially pure plant dye material obtained using solvent or supercritical CO2 extraction, combined with 0.01 to 5 percent of active metal in a metal or mineral salt capable of acting as a mordant as a two-part hair color system.

Owner:ADVANCED COSMETIC TECH

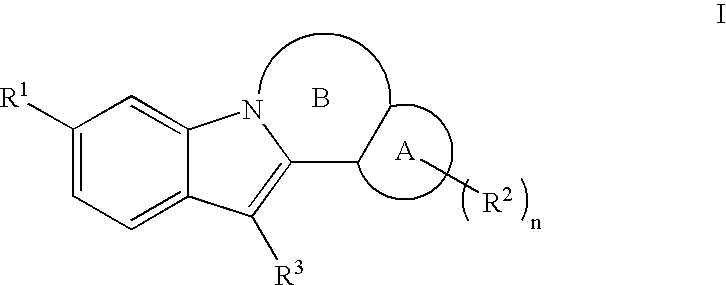

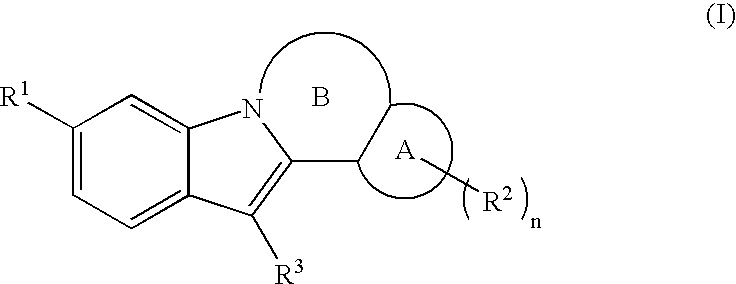

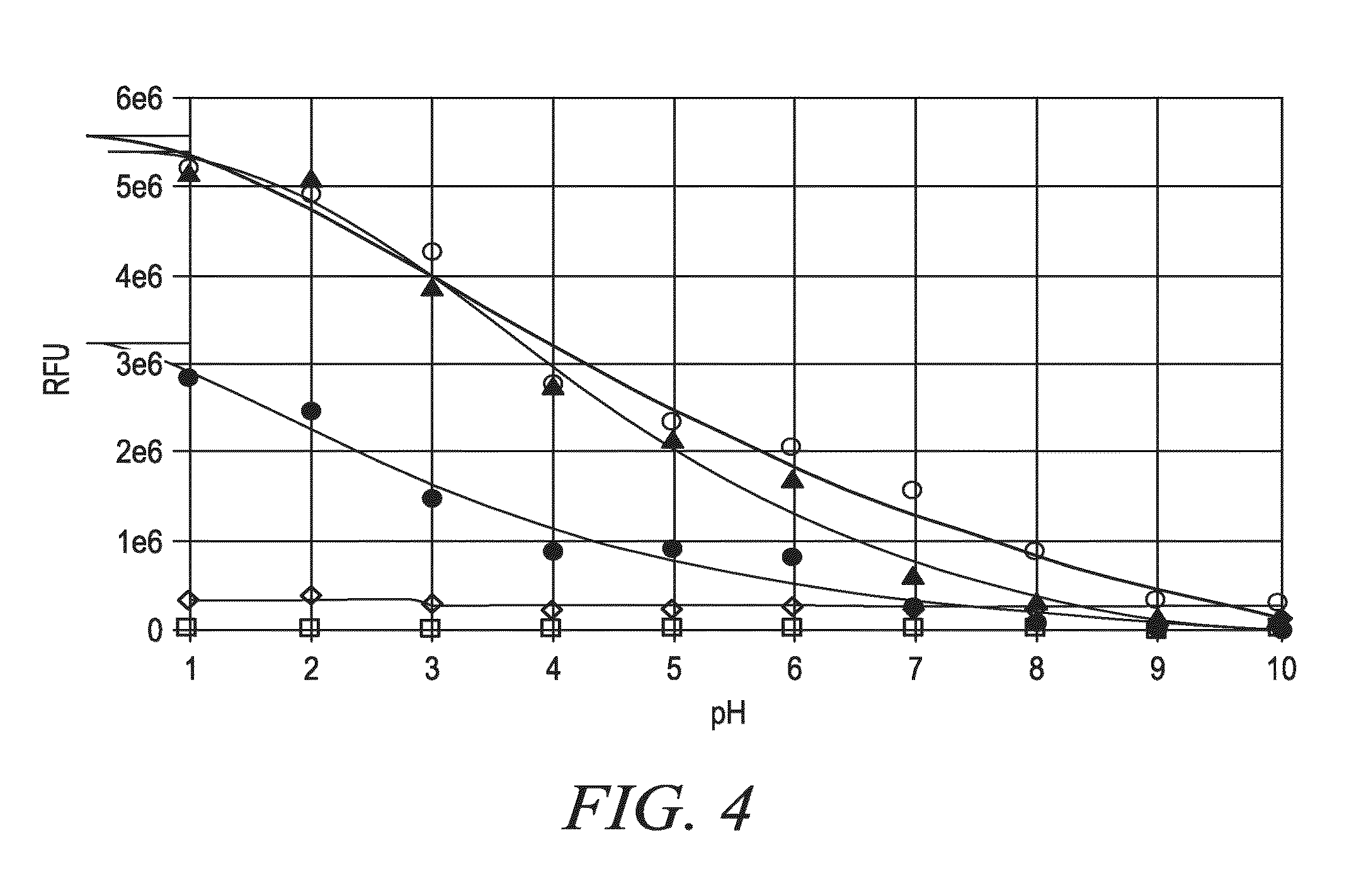

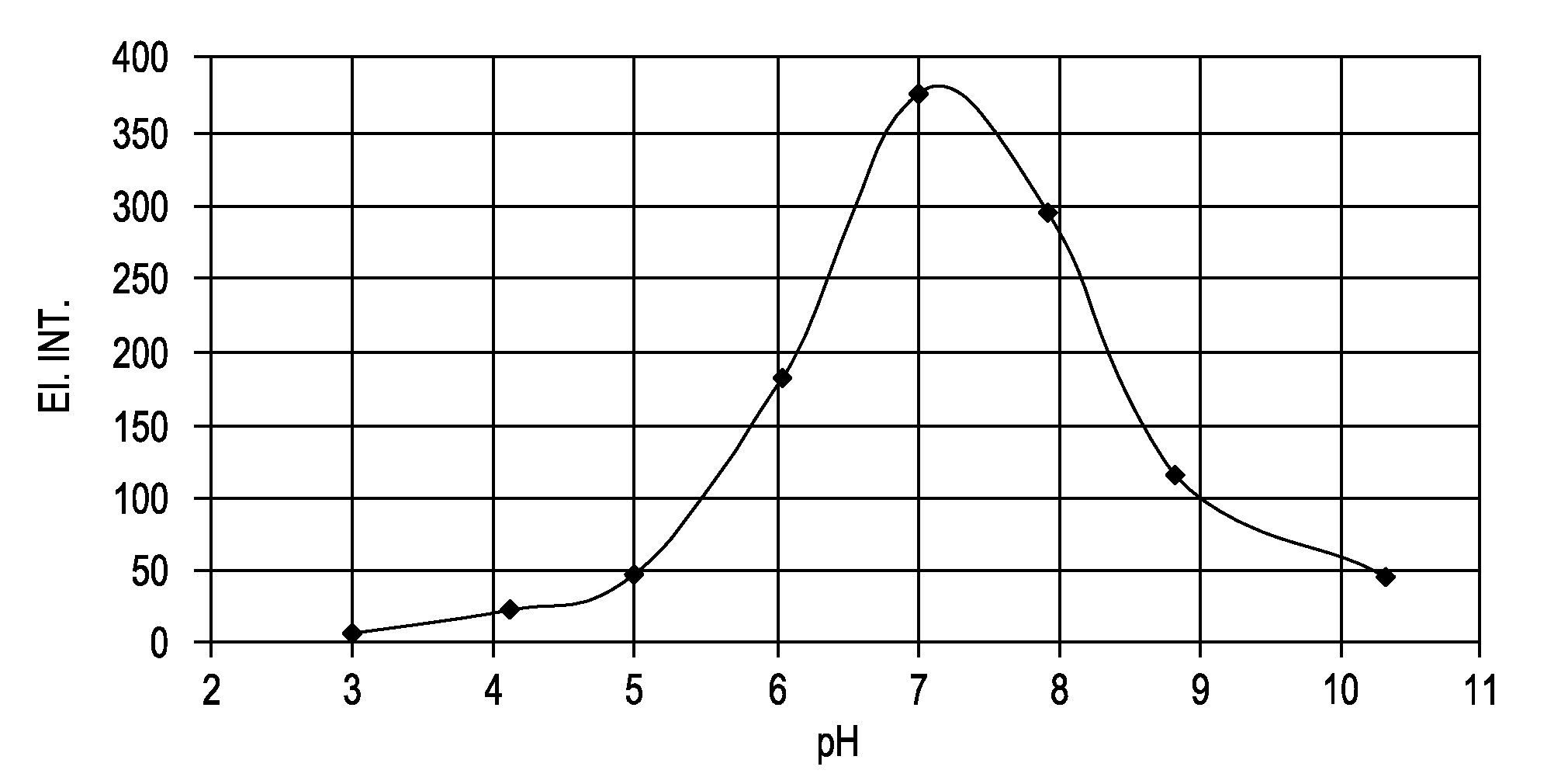

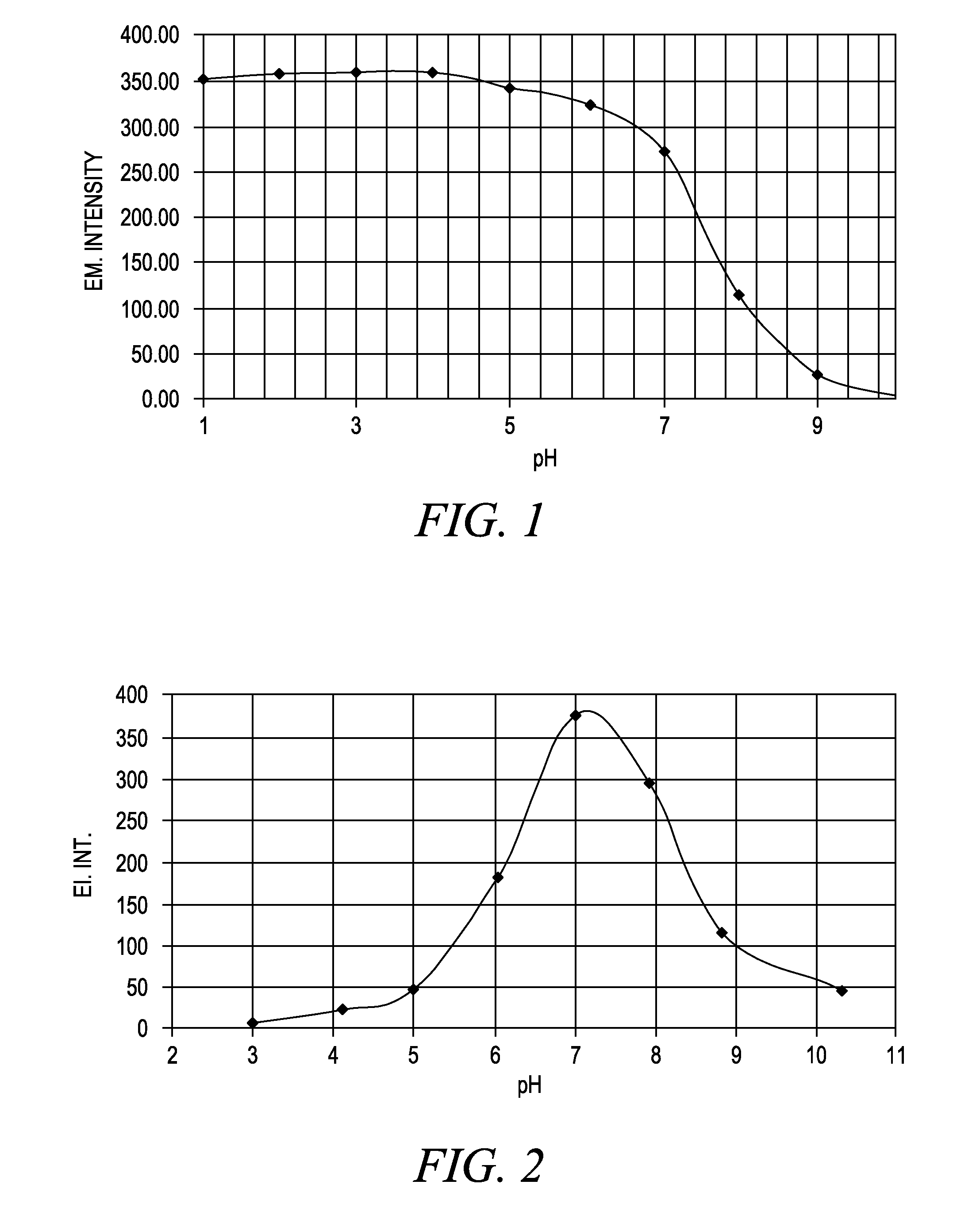

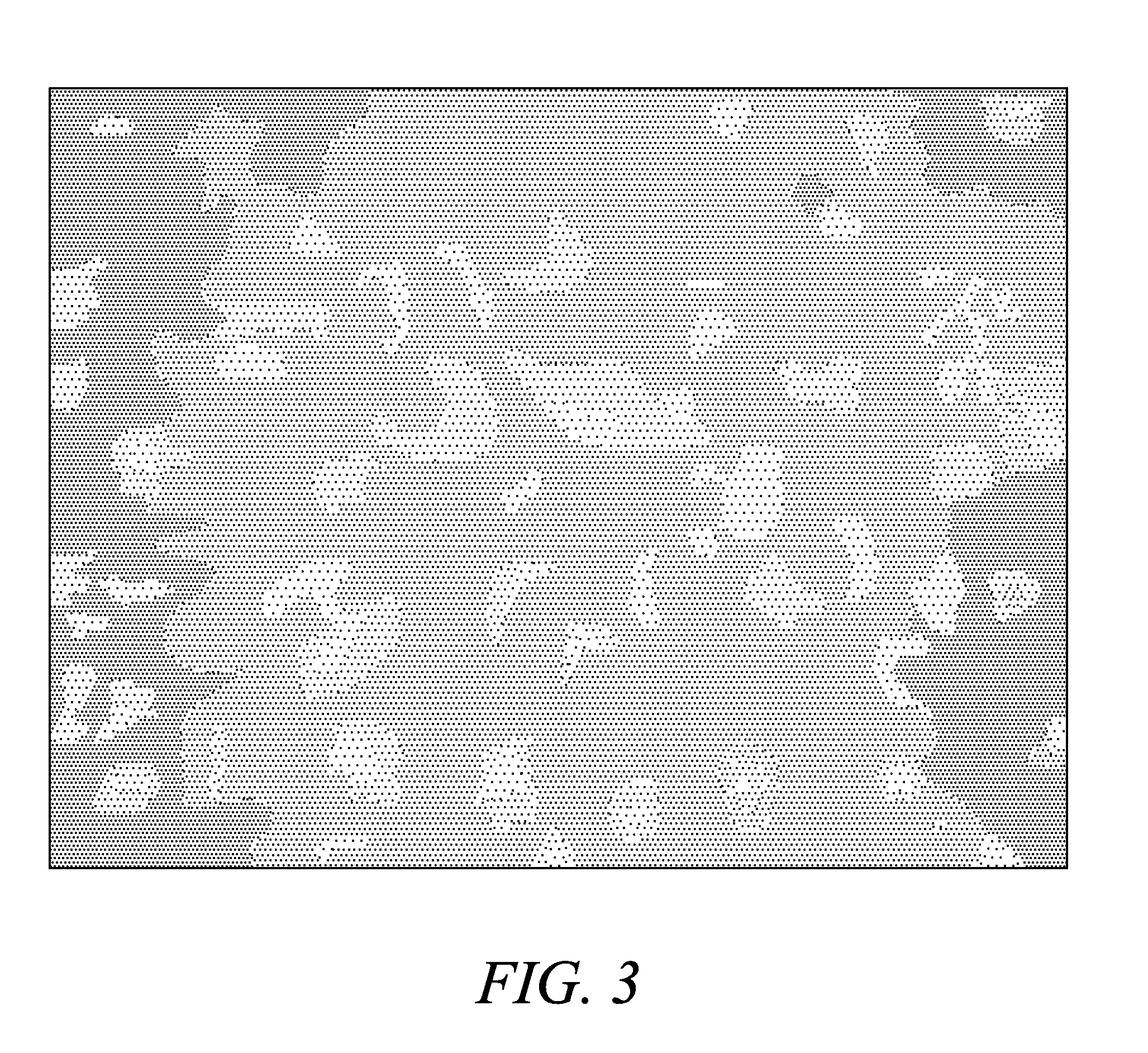

Fluorogenic ph sensitive dyes and their method of use

InactiveUS20130102021A1Group 3/13 element organic compoundsLuminescent compositionsAssayIntracellular

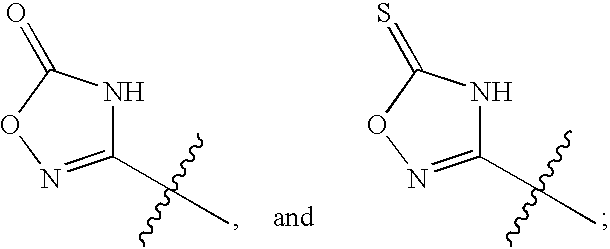

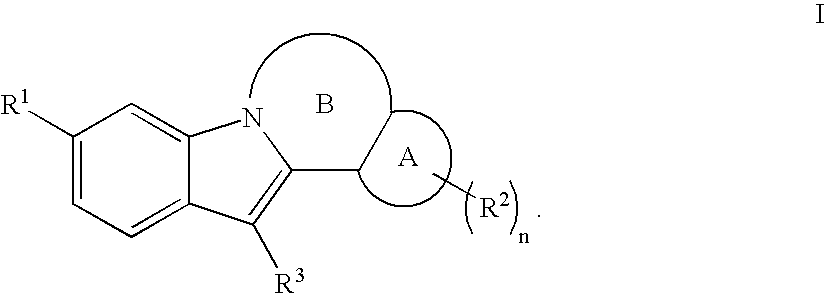

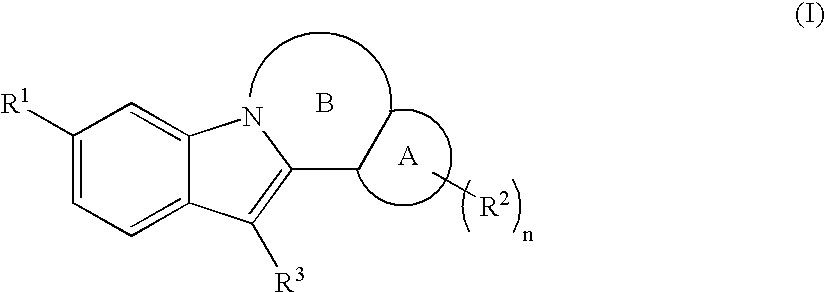

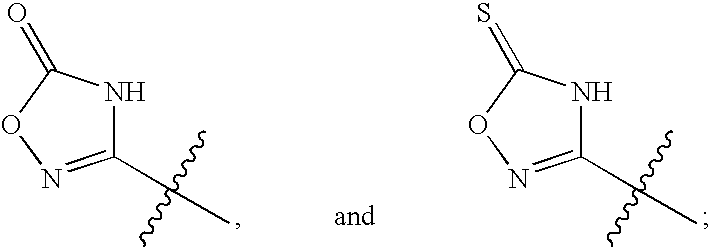

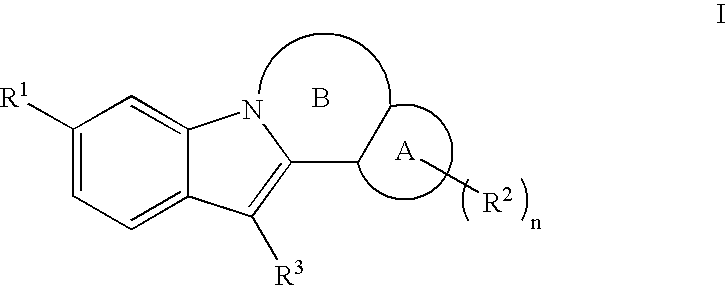

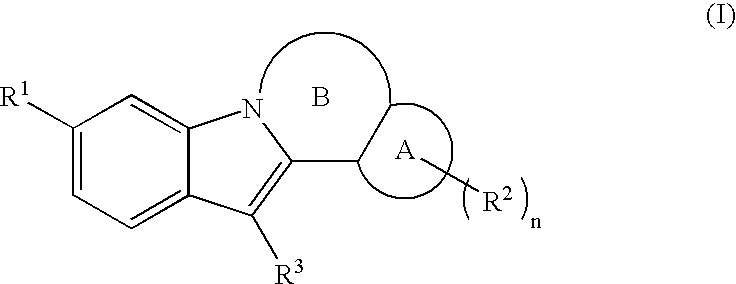

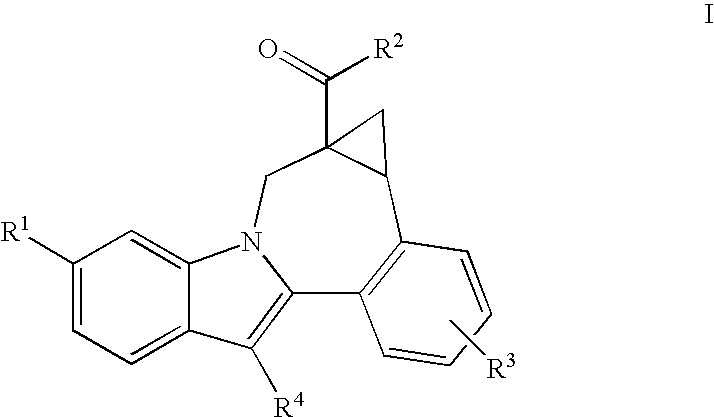

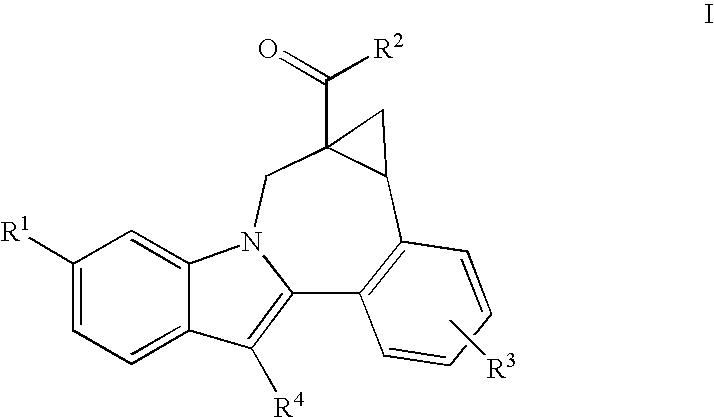

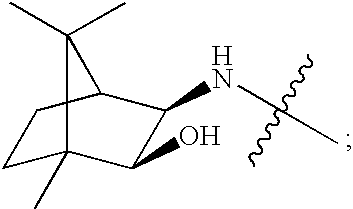

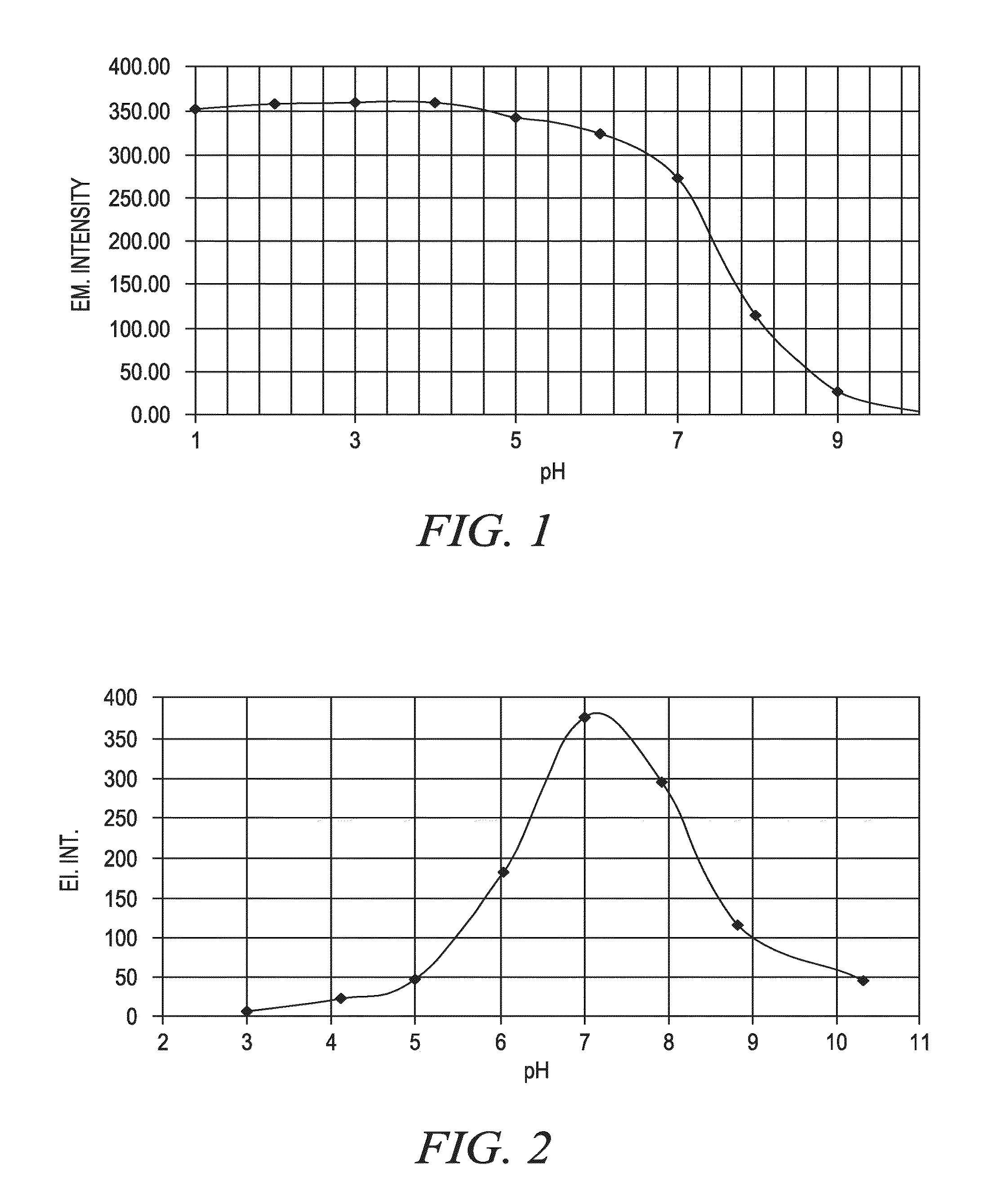

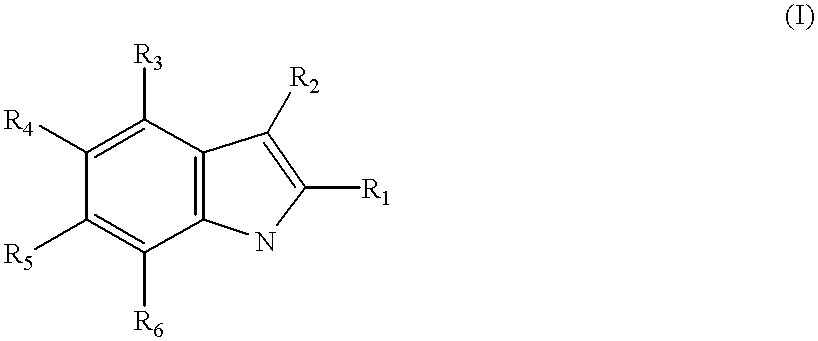

A new class of pH sensitive fluorescent dyes and assays relating thereto are described. The dyes and assays are particularly suited for biological applications including phagocytosis and monitoring intracellular processes. The pH sensitive fluorescent dyes of the present invention include compounds of Formula I:wherein the variables are described throughout the application.

Owner:LIFE TECH CORP

Material for organic electronic device, and organic electronic device using same

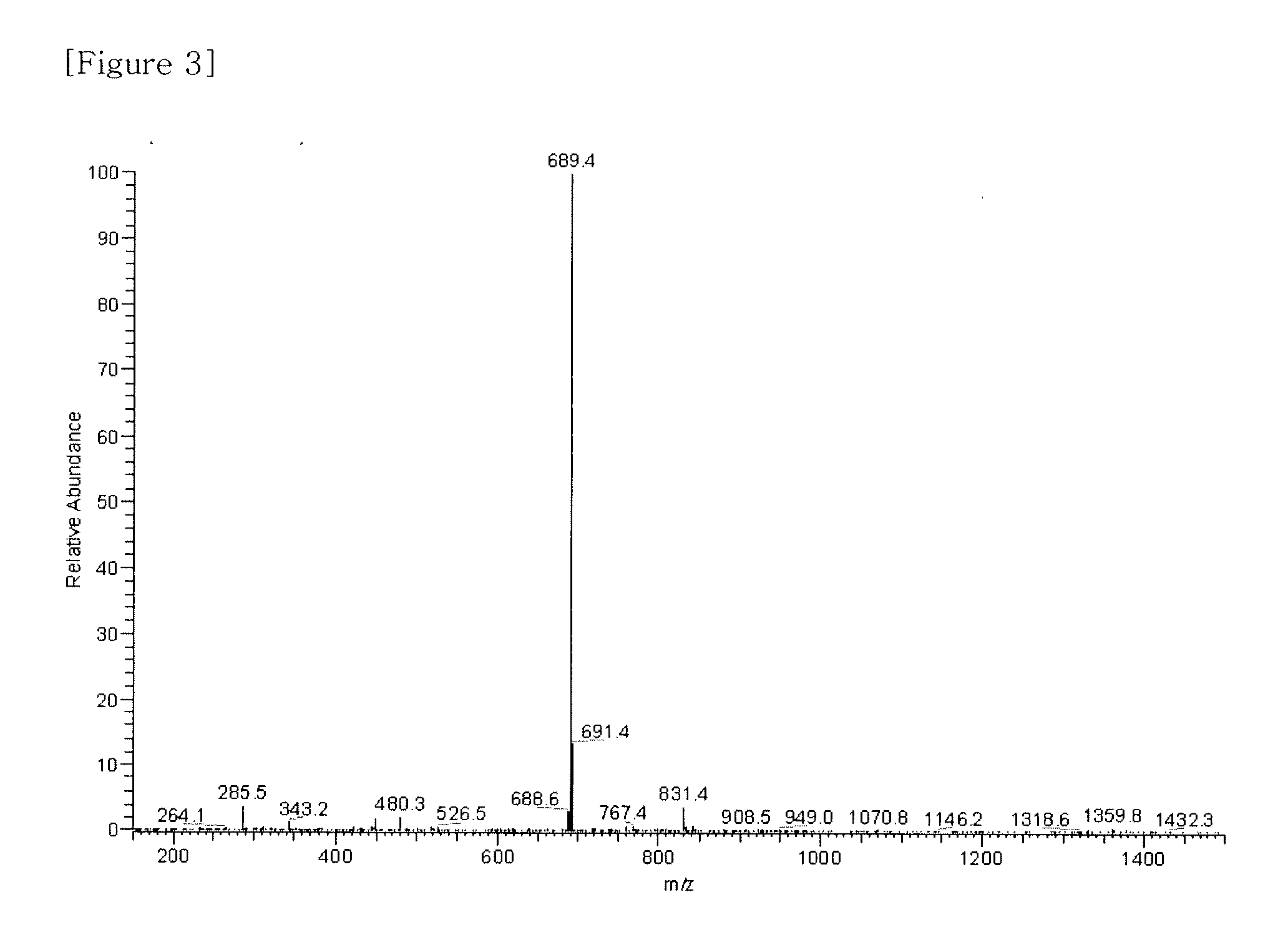

ActiveUS20110210318A1Reduce device voltageImprove lighting efficiencyOrganic chemistryFinal product manufactureLife timeThermal stability

The present invention provides a novel compound that is capable of largely improving a life time, efficiency, electrochemical stability, and thermal stability of an organic electronic device, and an organic electronic device that comprises an organic material layer comprising the compound.

Owner:LG CHEM LTD

Carbazole derivatives for organic electroluminescent devices

ActiveUS8343637B2Group 5/15 element organic compoundsFinal product manufactureOrganic electroluminescenceCarbazole derivative

Owner:MERCK PATENT GMBH

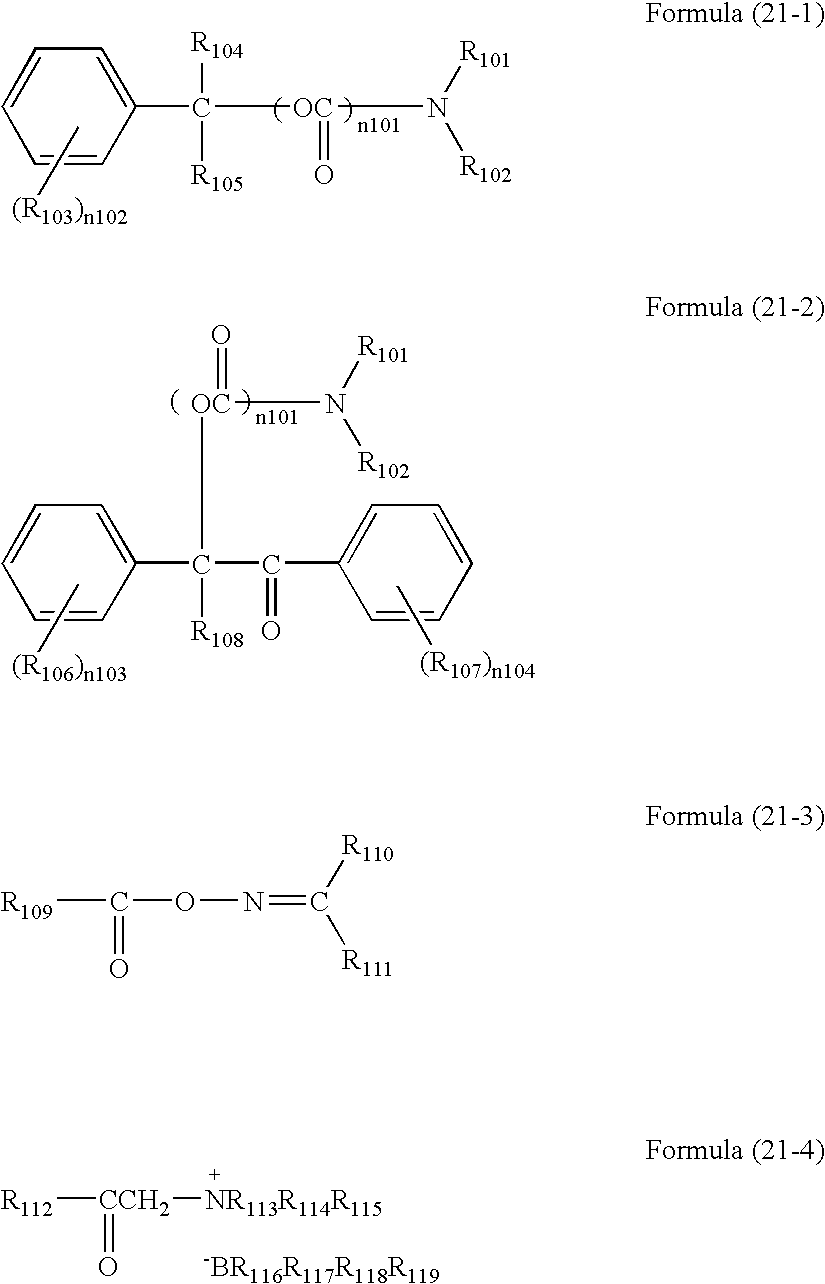

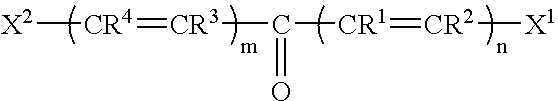

Two-photon absorption dye-containing material, three-dimensional refractive index modulation material, three-dimensional absorption index modulation material and three-dimensional optical recording material

InactiveUS20050019711A1Improve preservation qualityImprove spatial resolutionStyryl dyesMonoazo dyesTwo-photon absorptionOptical recording

To provide a two-photon absorption dye-containing material having a great off-resonant two-photon absorption cross section and comprising a two-photon absorption dye capable of decoloring itself through off-resonant two-photon absorption, useful for a three-dimensional refractive index or absorption index modulation material, a three-dimensional optical recording medium, three-dimensional refractive index modulation method and recording and reproducing method for a three-dimensional optical recording medium a two-photon absorption dye-containing material comprising at least a two-photon absorption dye capable of decoloring itself through two-photon absorption.

Owner:FUJIFILM CORP +1

Fluoranthene compound, and organic electronic device comprising same

ActiveUS20150236273A1Improve efficiencyReduce the driving voltageElectroluminescent light sourcesSolid-state devicesFluorantheneThermal stability

The present specification provides a novel fluoranthene compound significantly improving the life span, efficiency, electrical and chemical stability and thermal stability of an organic electronic device, and an organic electronic device that contains the compound in an organic compound layer.

Owner:LG CHEM LTD

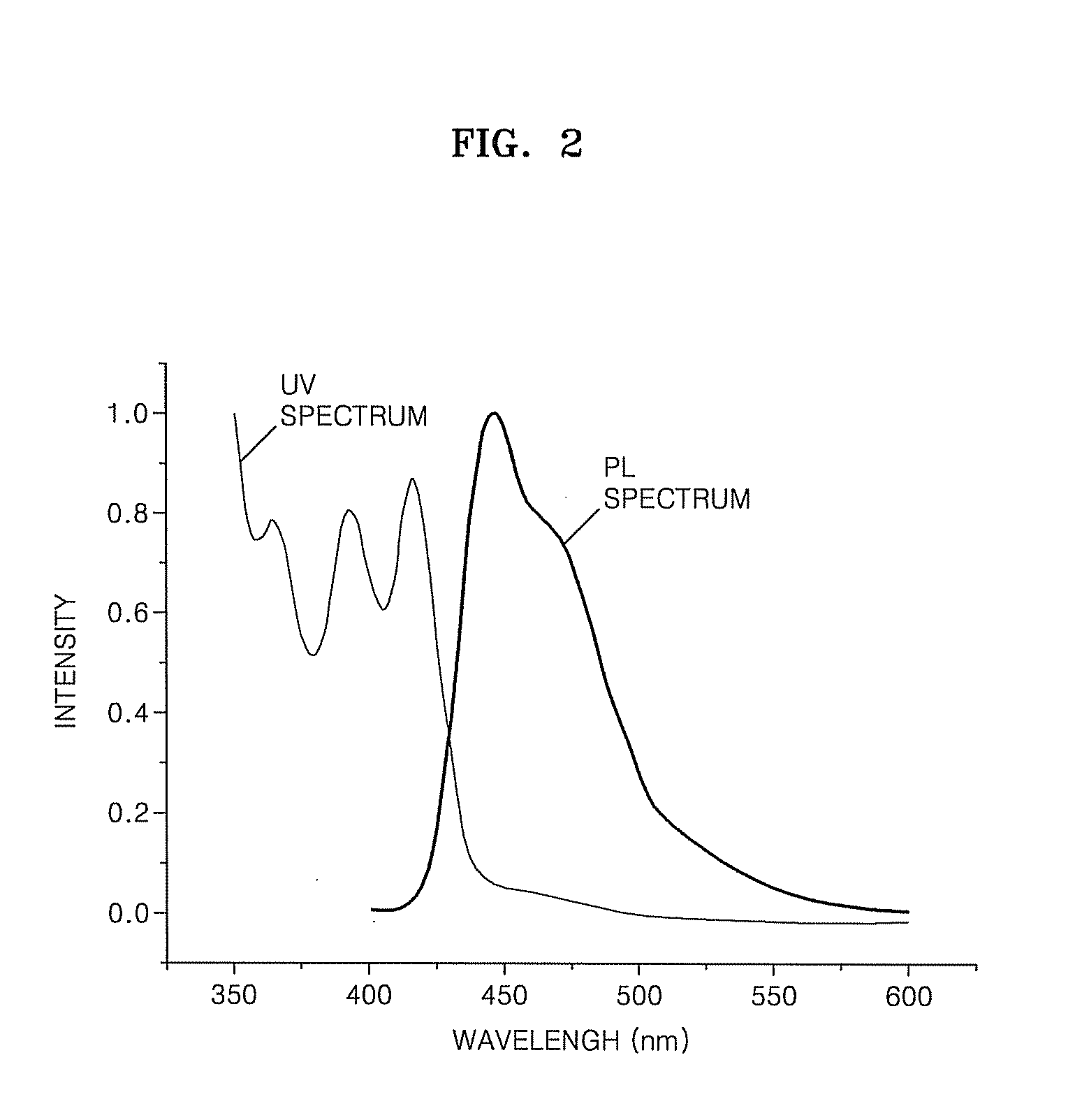

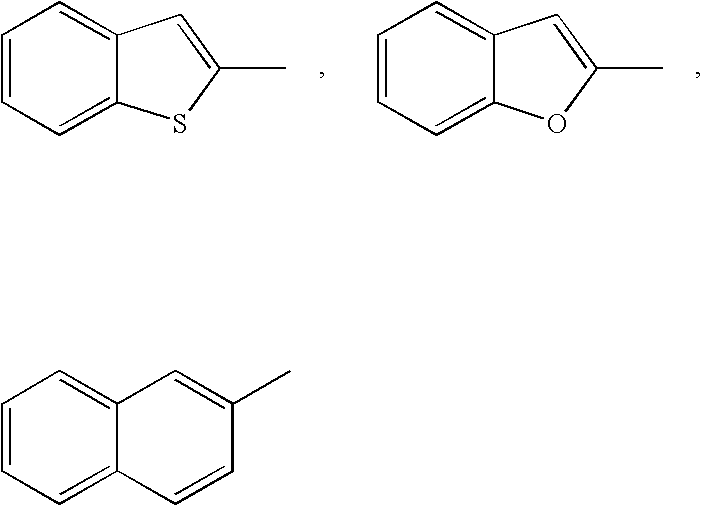

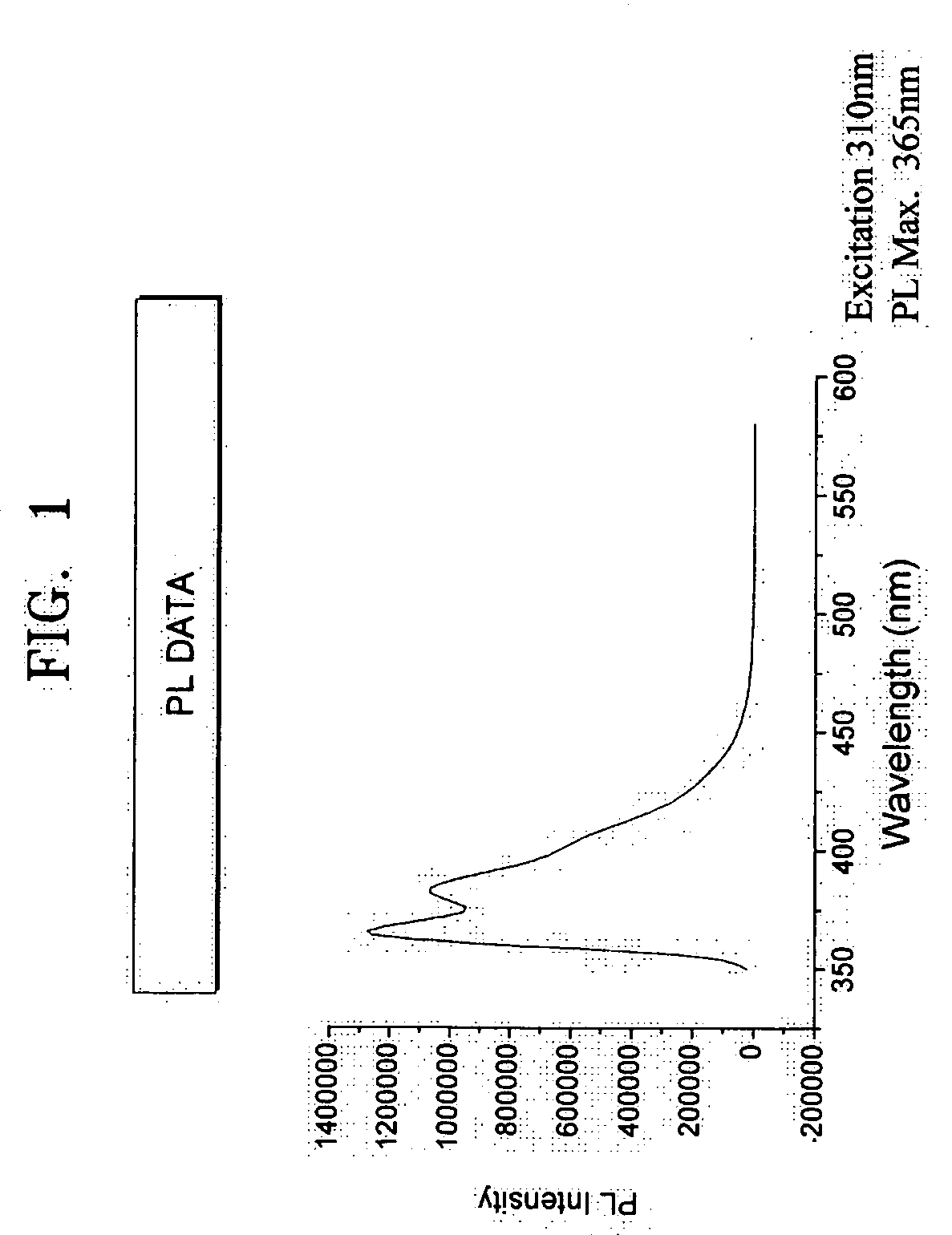

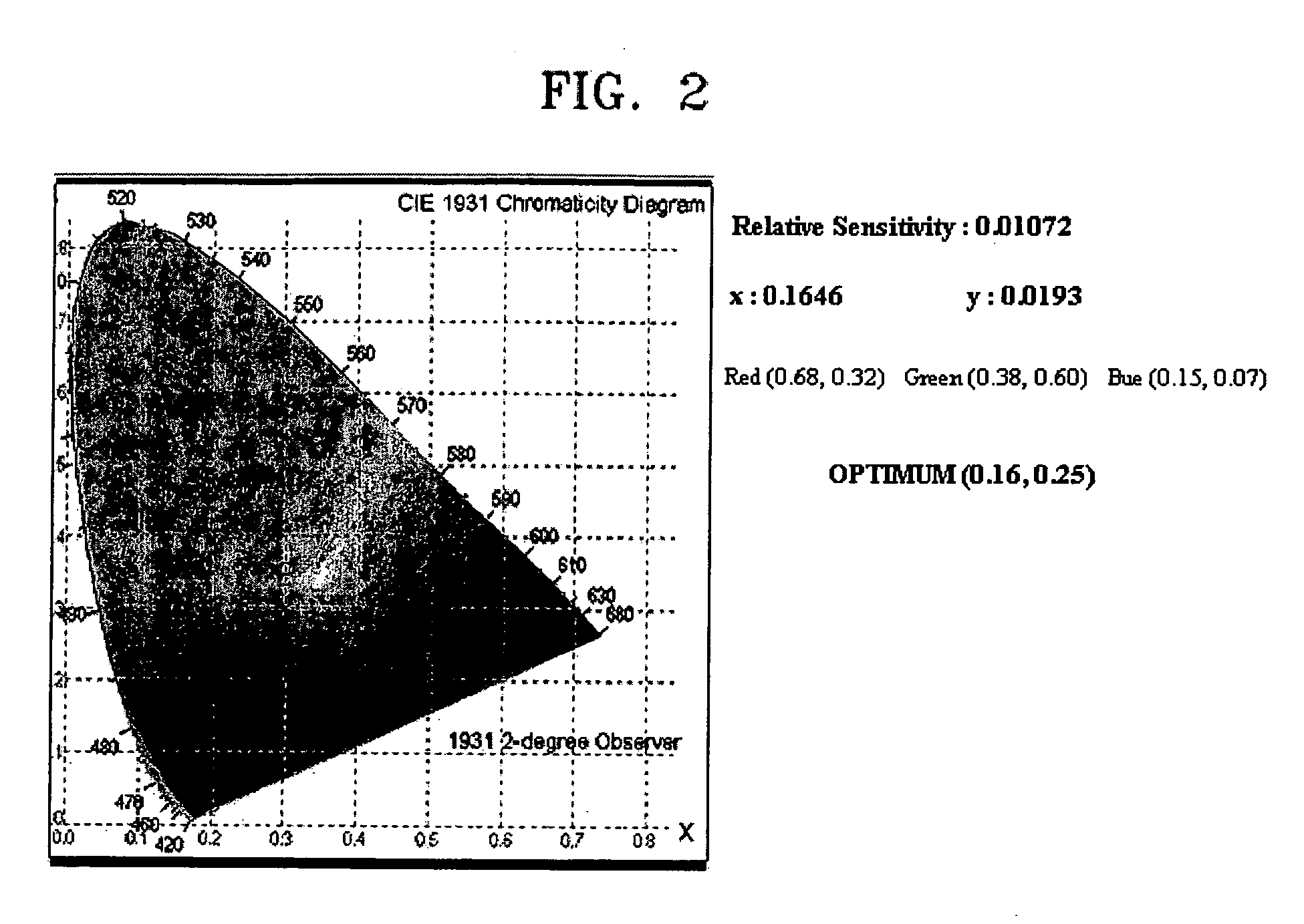

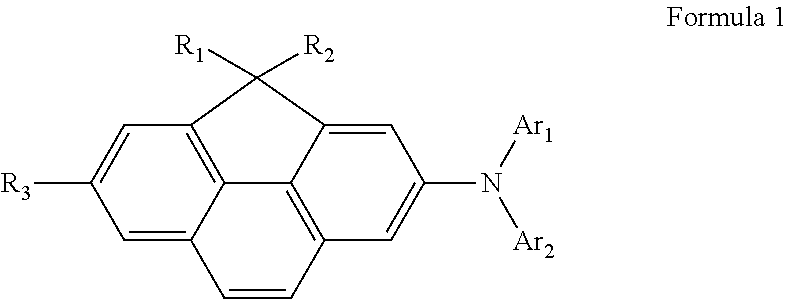

Cyclopentaphenanthrene-based compound and organoelectroluminescent device employing the same

ActiveUS20050106418A1Improve efficiencyHigh purityOrganic chemistryDischarge tube luminescnet screensSolubilityOrganic layer

The present invention is related to a cyclopentaphenanthrene-based compound and an organic electroluminescence device using the same. In particular, the cyclopentaphenanthrene-based compound offers several advantages, including easy processibility, high solubility, superior color purity, color stability and thermal stability. Moreover, the cyclopentaphenanthrene-based compound may be used not only as a material for forming an organic layer of an organic electroluminescence device, particularly, a light-emitting layer, but also as a material of an organic pigment or nonlinear optical substance.

Owner:SAMSUNG DISPLAY CO LTD

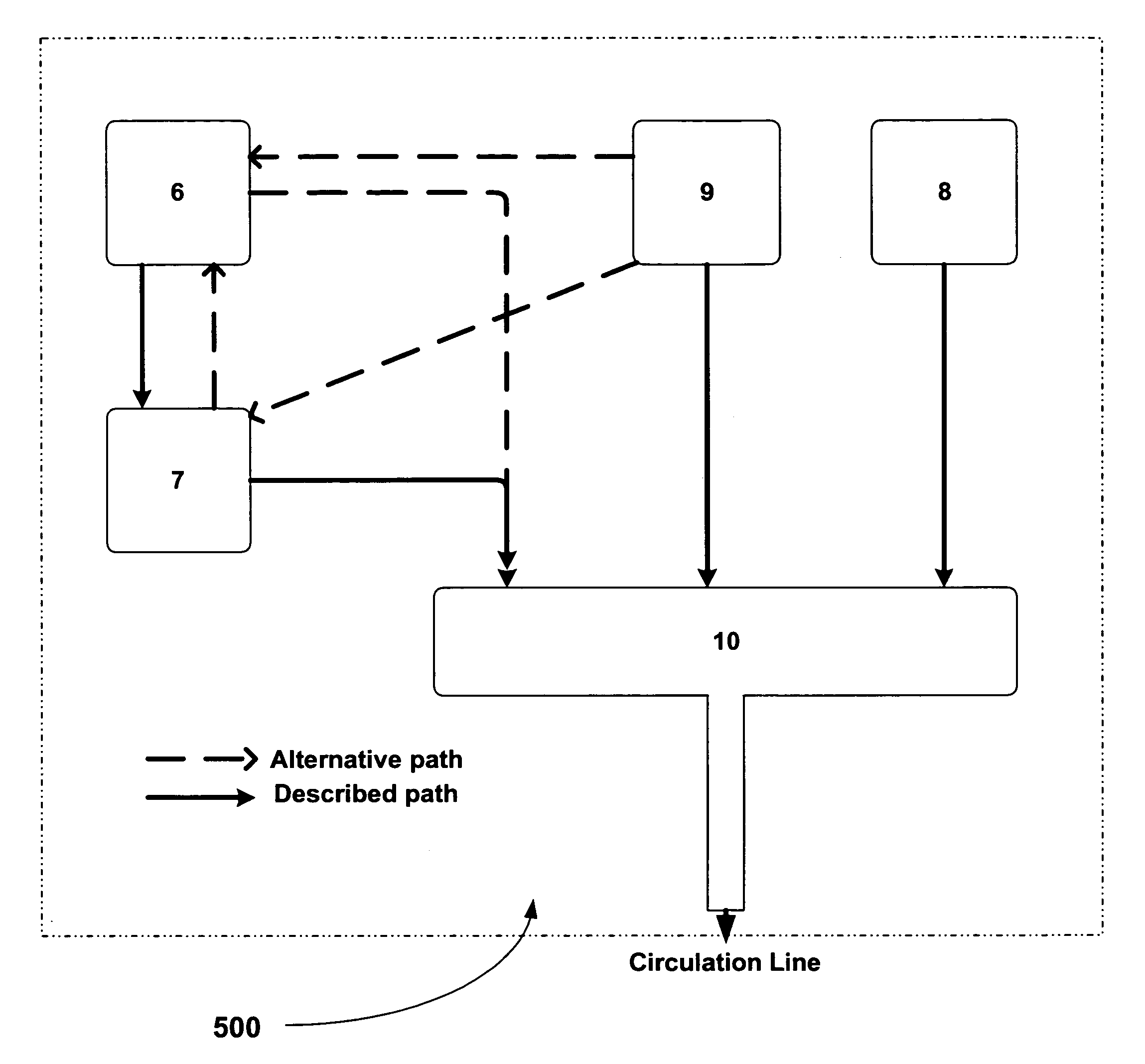

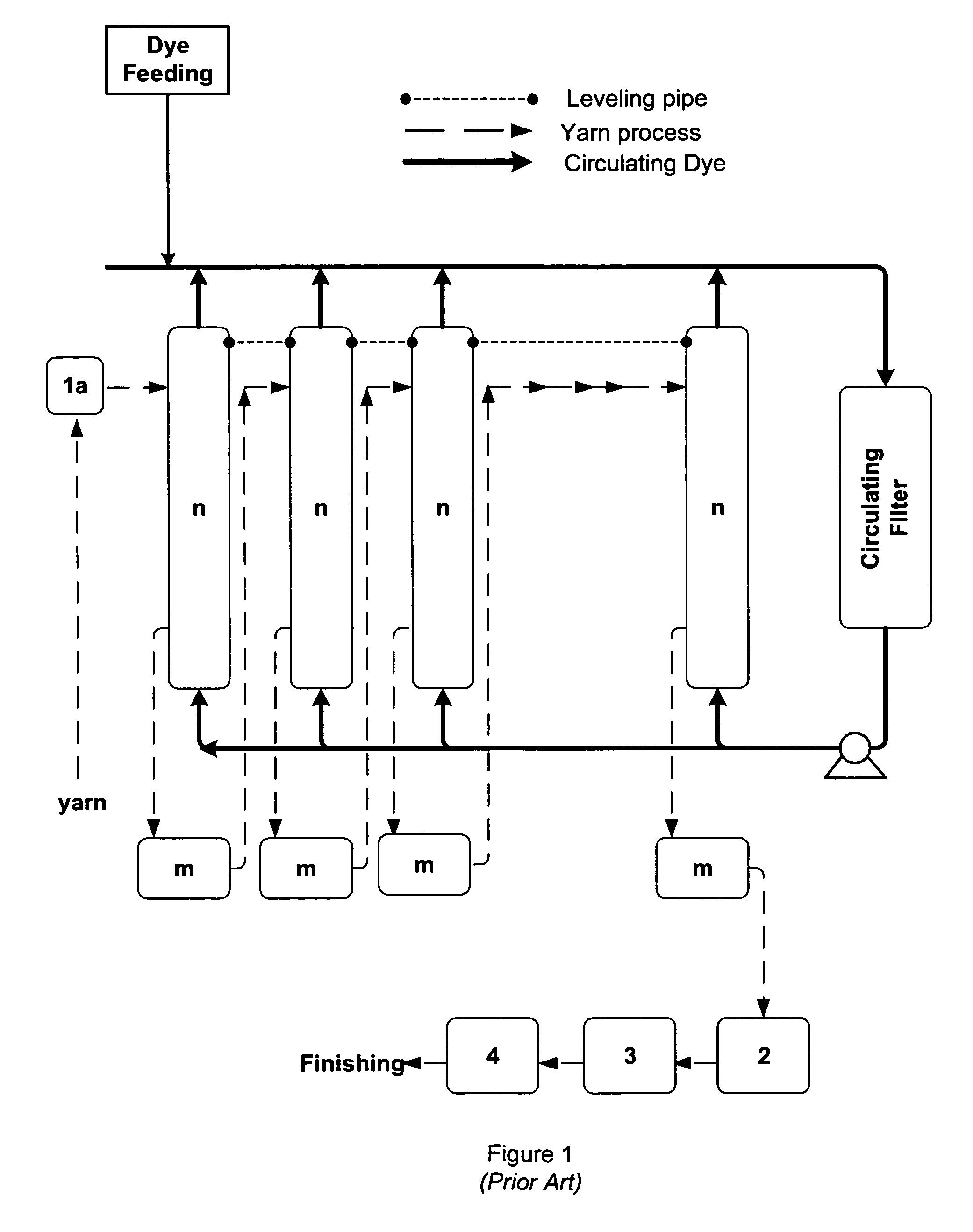

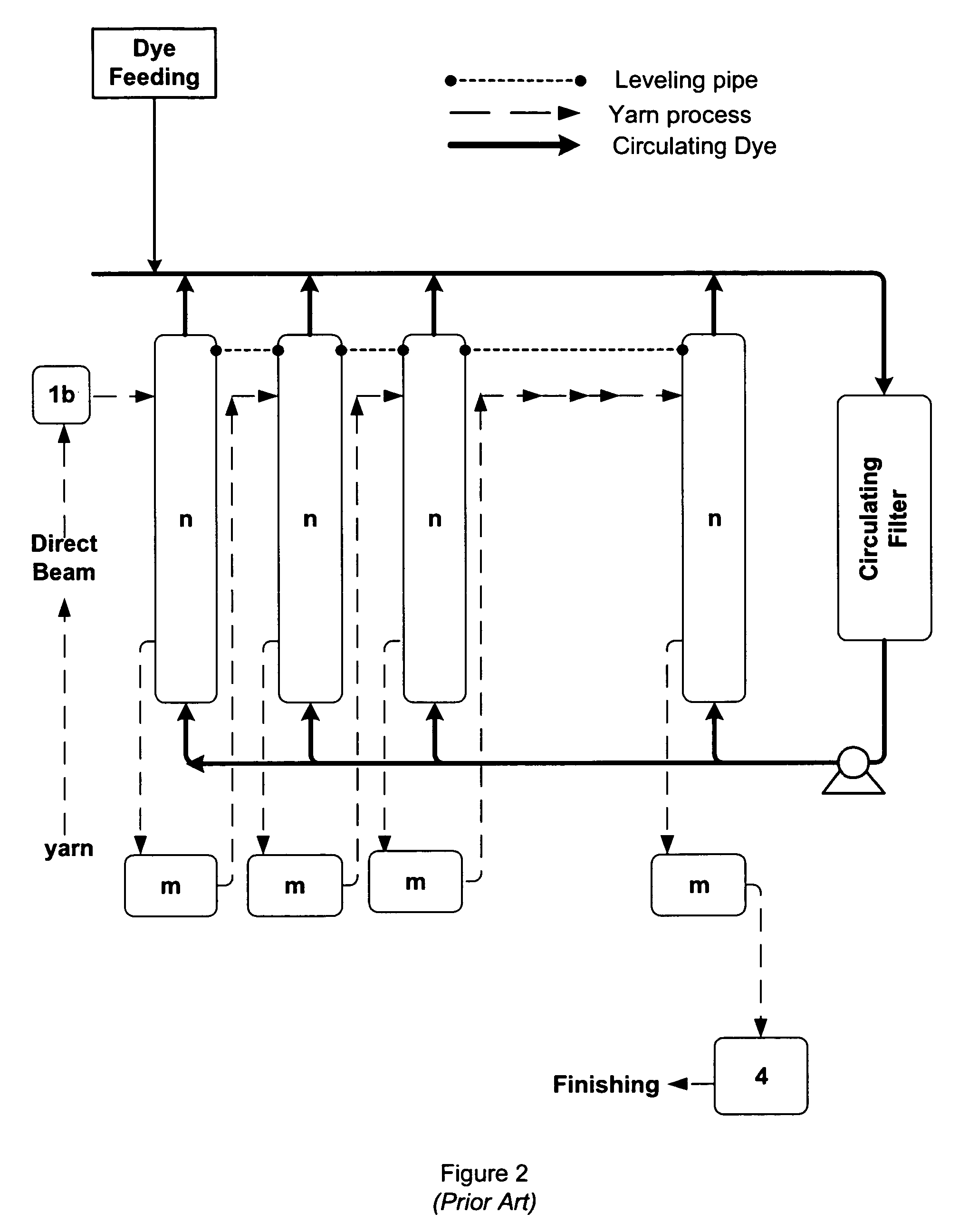

Process for introducing vat dyes and chemicals into textiles

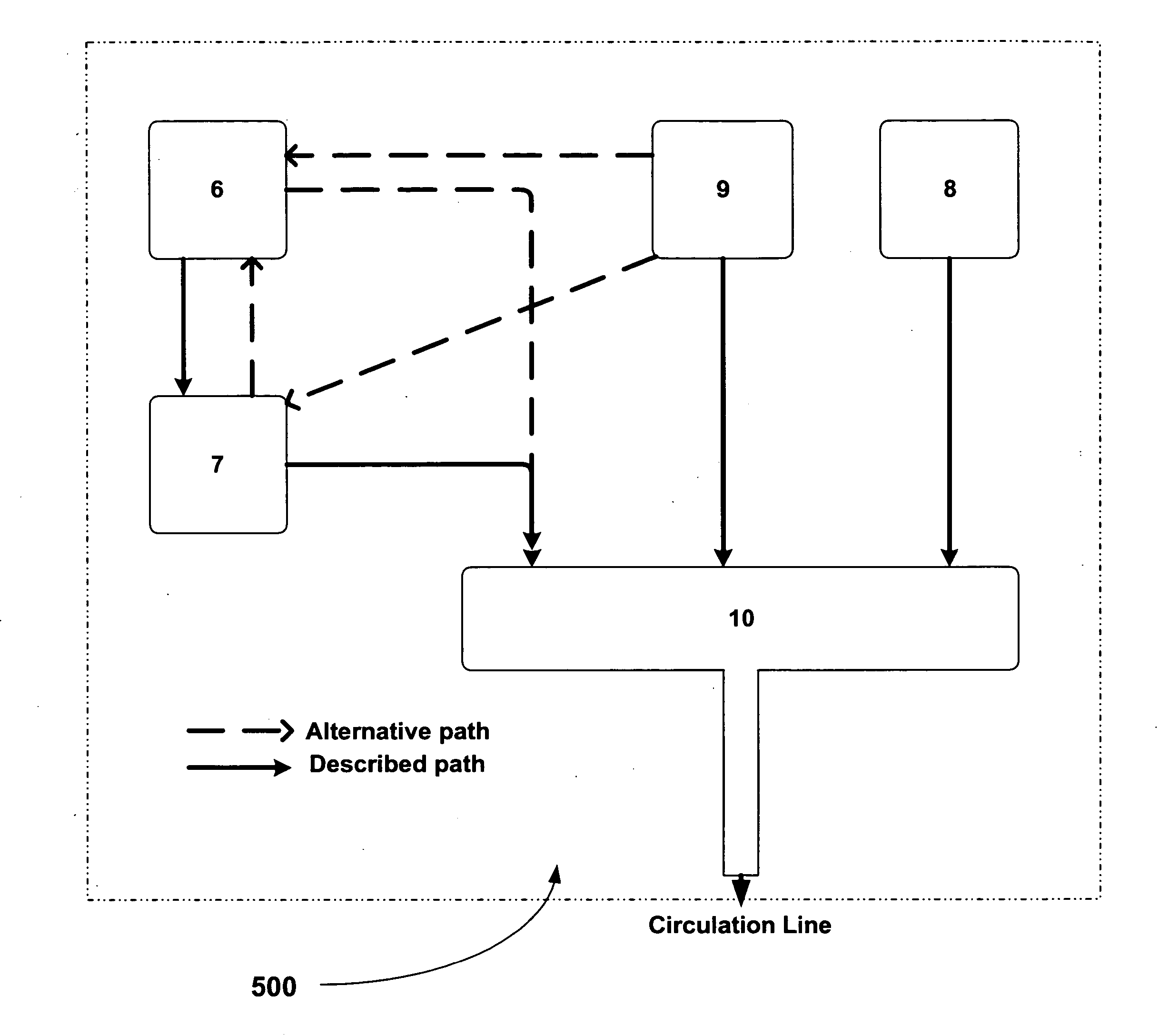

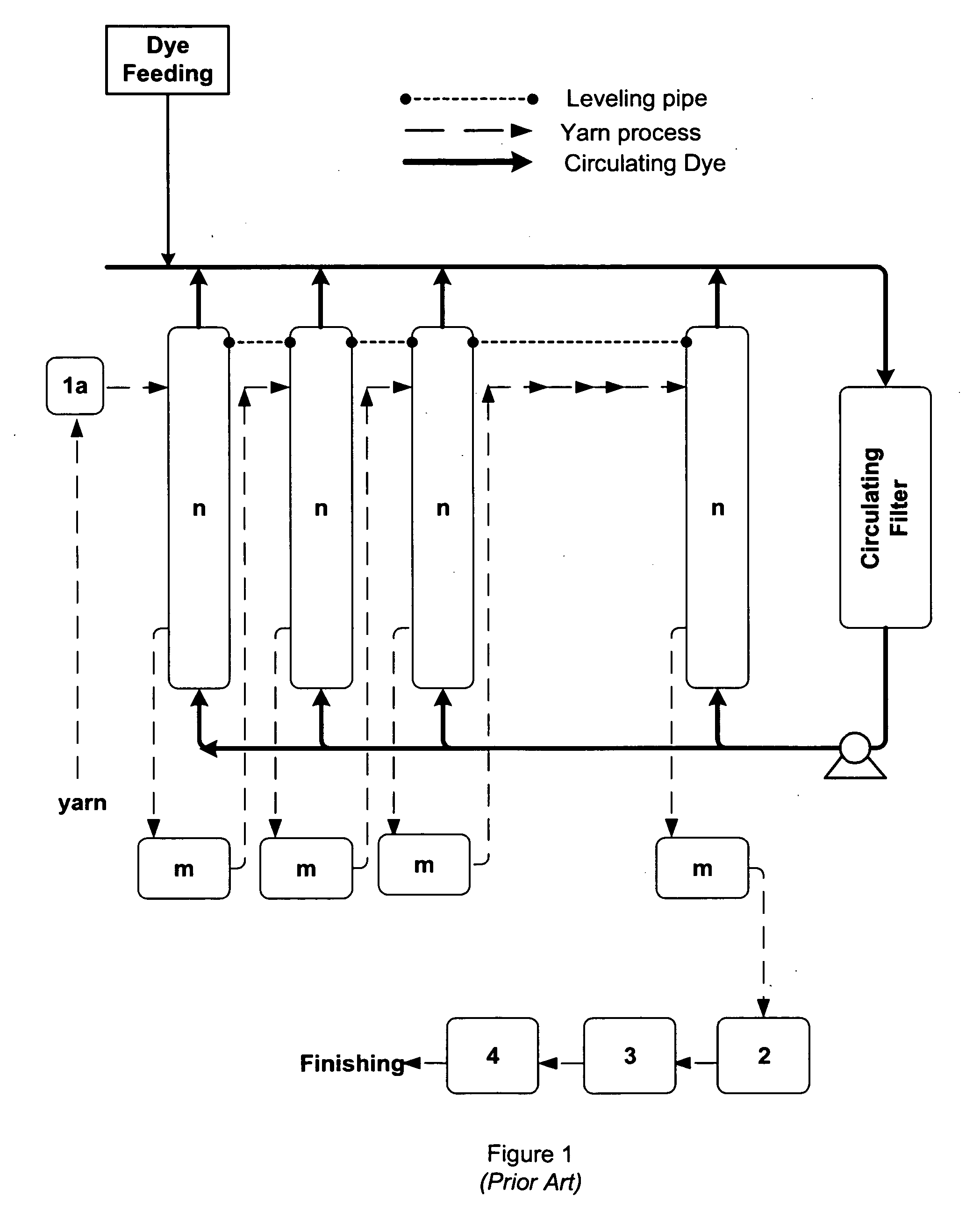

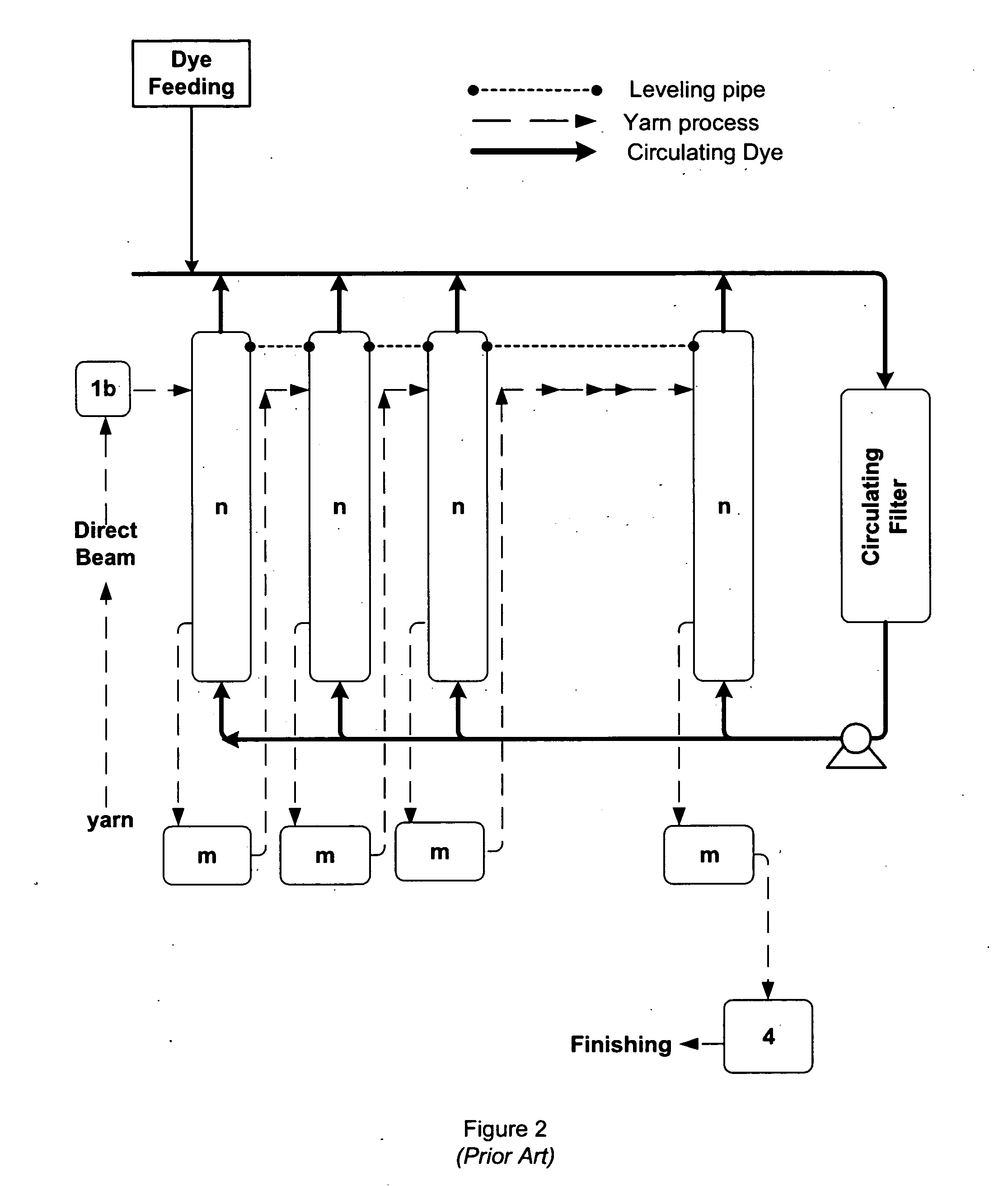

ActiveUS20070033748A1Efficient reductionDye is reduced efficientlyTextile treatment machine partsDyeing processYarnVat dye

A process for using reduced vat dyes in a continuous dyeing process for production of dyed yarns and fabrics of different colors. In the process, dye composition is introduced to a treatment unit for reduction to desired dye composition. The dye concentration in the treatment unit is lower than feeding dye concentration so that dye precipitation does not occur, but significantly higher than the circulating dye concentration so that the dye is reduced efficiently. Although the preferred location for the treatment unit is before the circulation line, it may be at any location before the dip-dye tank.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

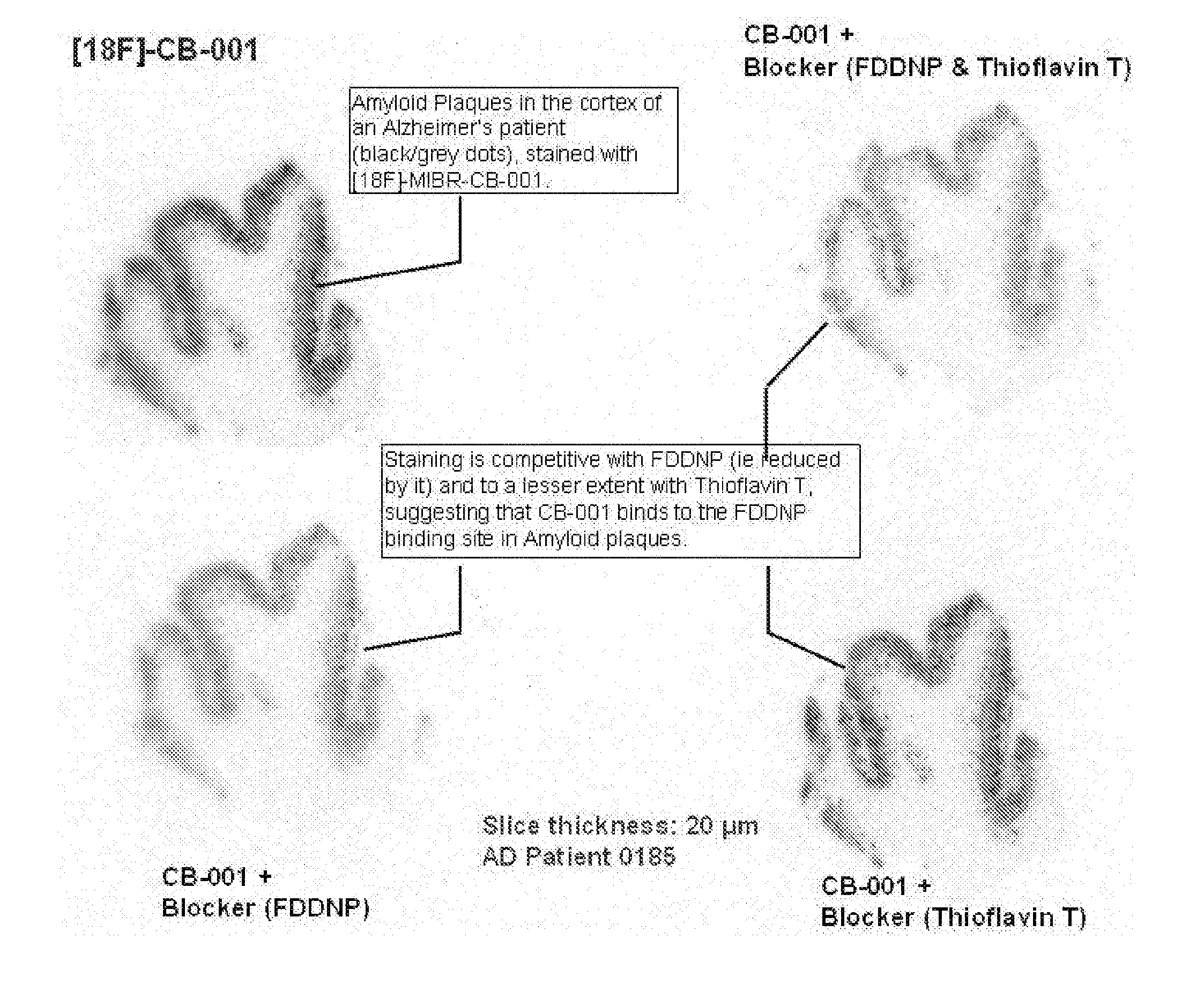

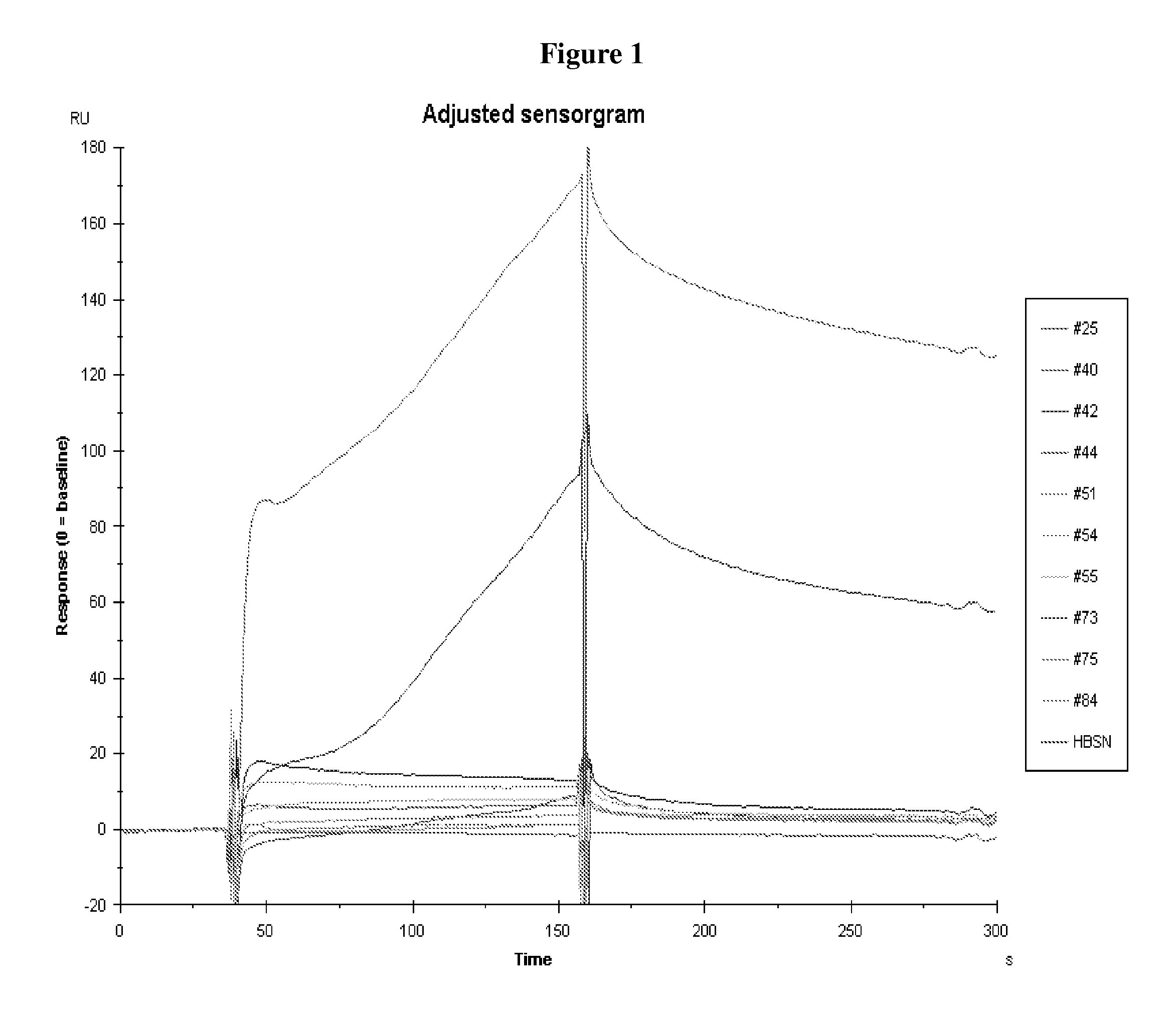

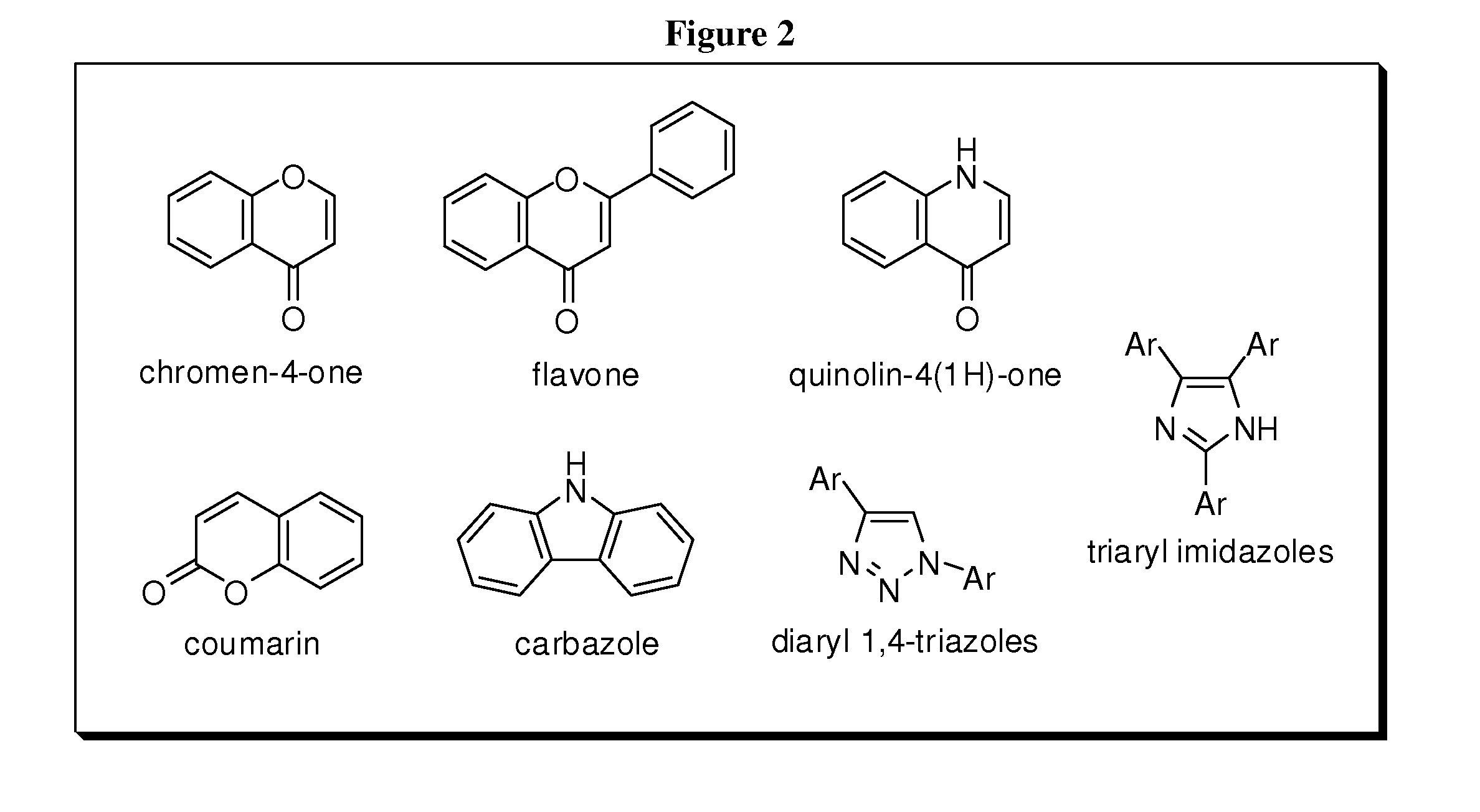

Novel Imaging Agents for Detecting Neurological Dysfunction

InactiveUS20110046378A1Isotope introduction to heterocyclic compoundsNervous disorderImaging agentTriazole derivatives

Disclosed here in are compounds and methods of diagnosing Alzheimer's Disease or a predisposition thereto in a mammal, the method comprising administering to the mammal a diagnostically effective amount of a radiolabeled compound, wherein the compound is selected from the group consisting of radiolabeled flavones, coumarins, carbazoles, quinolinones, chromenones, imidazoles and triazoles derivatives, allowing the compound to distribute into the brain tissue, and imaging the brain tissue, wherein an increase in binding of the compound to the brain tissue compared to a normal control level of binding indicates that the mammal is suffering from or is at risk of developing Alzheimer's Disease

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Fluorogenic ph sensitive dyes and their method of use

A new class of pH sensitive fluorescent dyes and assays relating thereto are described. The dyes and assays are particularly suited for biological applications including phagocytosis and monitoring intracellular processes. The pH sensitive fluorescent dyes of the present invention include compounds of Formula I:wherein the variables are described throughout the application.

Owner:LIFE TECH CORP

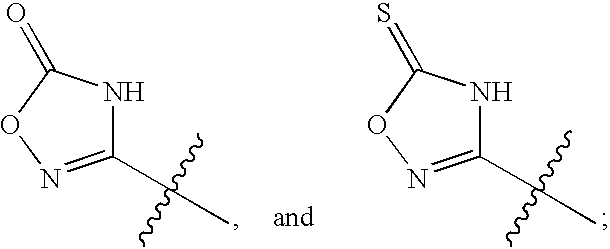

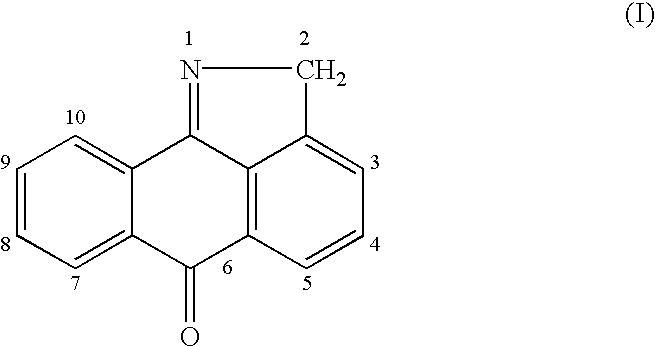

Isothiazoloanthrones, isoxazoloanthrones, isoindolanthrones and derivatives thereof as JNK inhibitors and compositions and methods related thereto

Isothiazoloanthrones, isooxazoloanthrones, isoindolanthrones, and derivatives thereof having the general formula: and pharmaceutically acceptable salts thereof, wherein R0 is -CH2-, -SO-, -O-, -SO2-, or -S-; compositions comprising the isothiazoloanthrones, isooxazoloanthrones, isoindolanthrones, and derivatives thereof; and methods for treating or preventing a disorder alleviated by inhibiting Jun N-terminal kinase (JNK) by administering the isothiazoloanthrones, isooxazoloanthrones, isoindolanthrones, and derivatives thereof are described herein.

Owner:SIGNAL PHARMA LLC

Carbazole derivative and semiconductor nanocrystal

InactiveUS20130026426A1Increased durabilityImprove emission efficiencySilicon organic compoundsMaterial nanotechnologyArylCarboxyl radical

A carbazole derivative represented by the following General Formula (1) where at least one aromatic ring has one to three substituents each represented by the following General Formula (2):in General Formula (1), Ar1 and Ar2 each independently represent a substituted or unsubstituted aryl group which may form a ring with a benzene ring, a substituted or unsubstituted heterocyclic group, a substituted or unsubstituted arylsilyl group, or a hydrogen atom, and Ar3 represents a substituted or unsubstituted aryl group,—X—Y—Z (2)in General Formula (2), X represents a methylene group, a carbonyloxy group, an oxycarbonyl group, a carbonyl group, an oxygen atom or a sulfur atom, Y represents a substituted or unsubstituted alkylene group, and Z represents a carboxyl group, a hydroxyl group or a thiol group.

Owner:RICOH KK

Recovery, balance adjustment and comprehensive utilization technology for mixing alkali in indigo blue production

ActiveCN102924956AGood profitLess investmentCarbonate preparationIndigoid dyesResource savingPotassium hydroxide

A purpose of the invention is to achieve sodium reduction, potassium retention, and no use or less use of potassium hydroxide based on recovery utilization of mixing alkali and potassium-sodium balance adjustment in an indigo blue production process. According to the present invention, waste alkali residue, washing alkali water and surplus sodium hydroxide in oxidation alkali in the existing production are utilized, bicarbonate or carbon dioxide, and a plurality of ways are applied and introduced to the concentrate, and difference between dissolubility of sodium carbonate and potassium carbonate and a common ion effect are delicately utilized to generate sodium carbonate precipitate and separate, such that removal of surplus sodium hydroxide in the liquid alkali is achieved without introduction of new impurities, the sodium carbonate product is co-produced, about 0.5 ton of the potassium hydroxide is saved and about 1 ton of the sodium carbonate is by-produced when per ton of the indigo blue product is produced, and a new process route with characteristics of alkali resource comprehensive utilization and delicate potassium and sodium balance is developed. With the present invention, characteristics of low investment, resource saving, cleaning, environmental protection, economy, novelty, strong practicality and wide generalization application value are provided, significant theory and application values are provided for the circular economy and sustainable development strategy, ??and wide social benefits, economic benefits and ecological benefits are provided.

Owner:JIANGSU TAIFENG CHEM +1

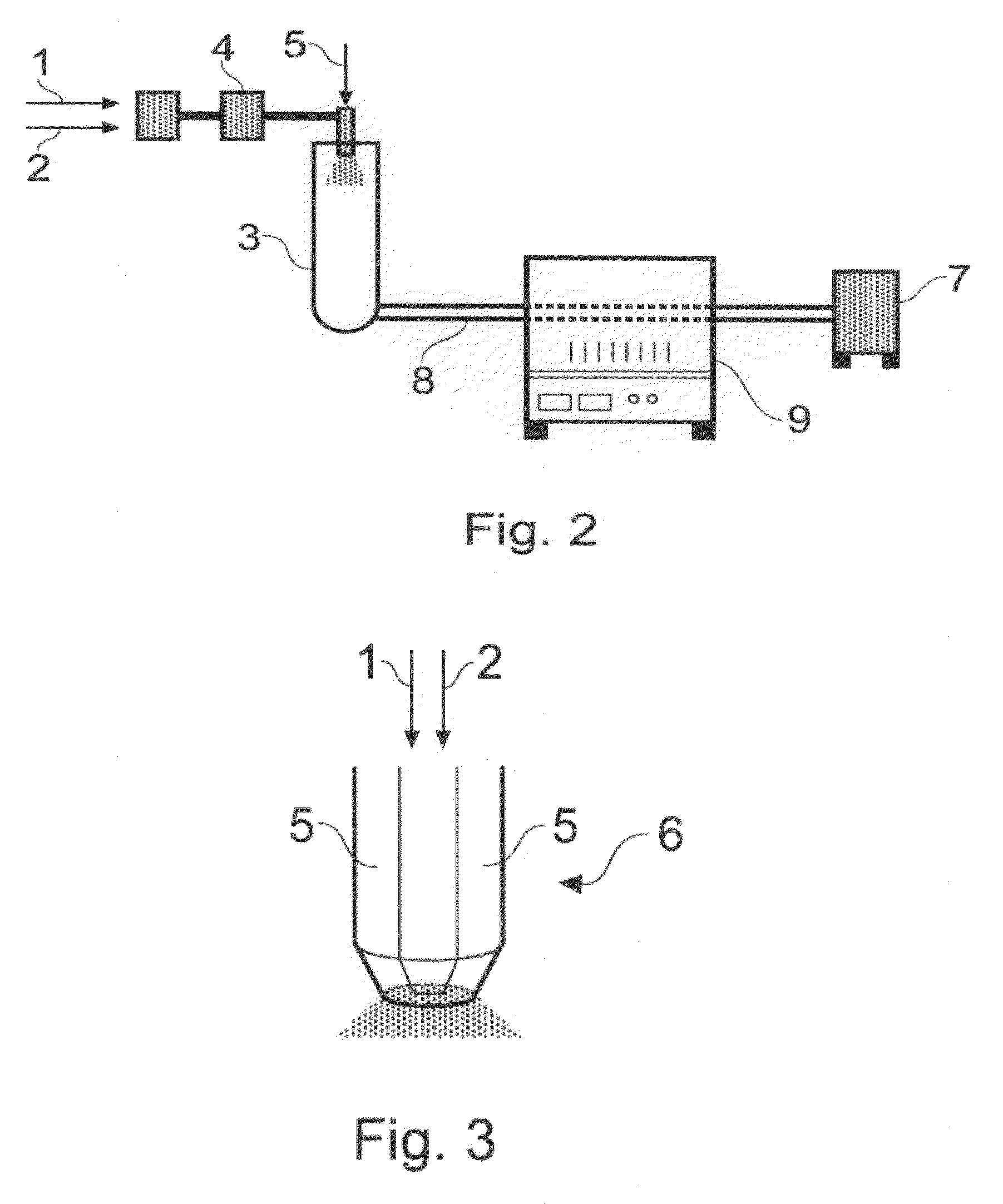

Spray-drying process for the manufacture of dye-loaded particlesä

According to a first aspect of the invention, a process is provided for the preparation of amorphous particles comprising a homogeneous distribution of one or more dyes encapsulated by an amorphous, siliceous encapsulating agent, the process comprising:(a) providing a precursor of the encapsulating agent in liquid form;(b) providing the one or more dyes in liquid form;(c) mixing the liquid forms;(d) aerosolizing the mixture to form droplets comprising the one or more dyes and encapsulating agent; and(e) heating the droplets to form the particles comprising the one or more dyes encapsulated by the siliceous encapsulating agent;wherein at least one of the liquid forms provided is aqueous and the or each aqueous liquid form is acidic.According to a second aspect of the invention, encapsulated dyes made by the process of the first aspect of the invention are provided.

Owner:NOXELL CORP

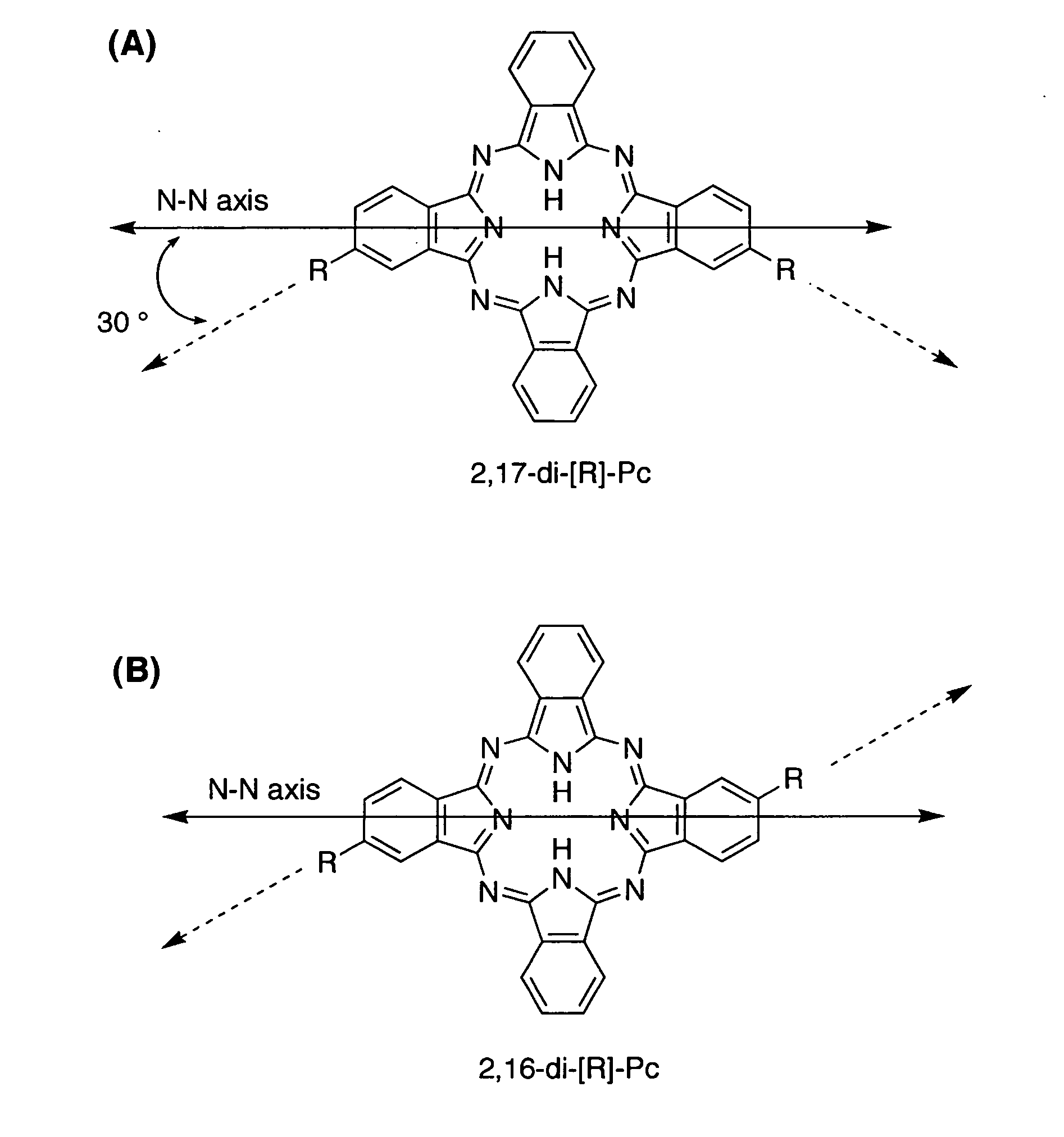

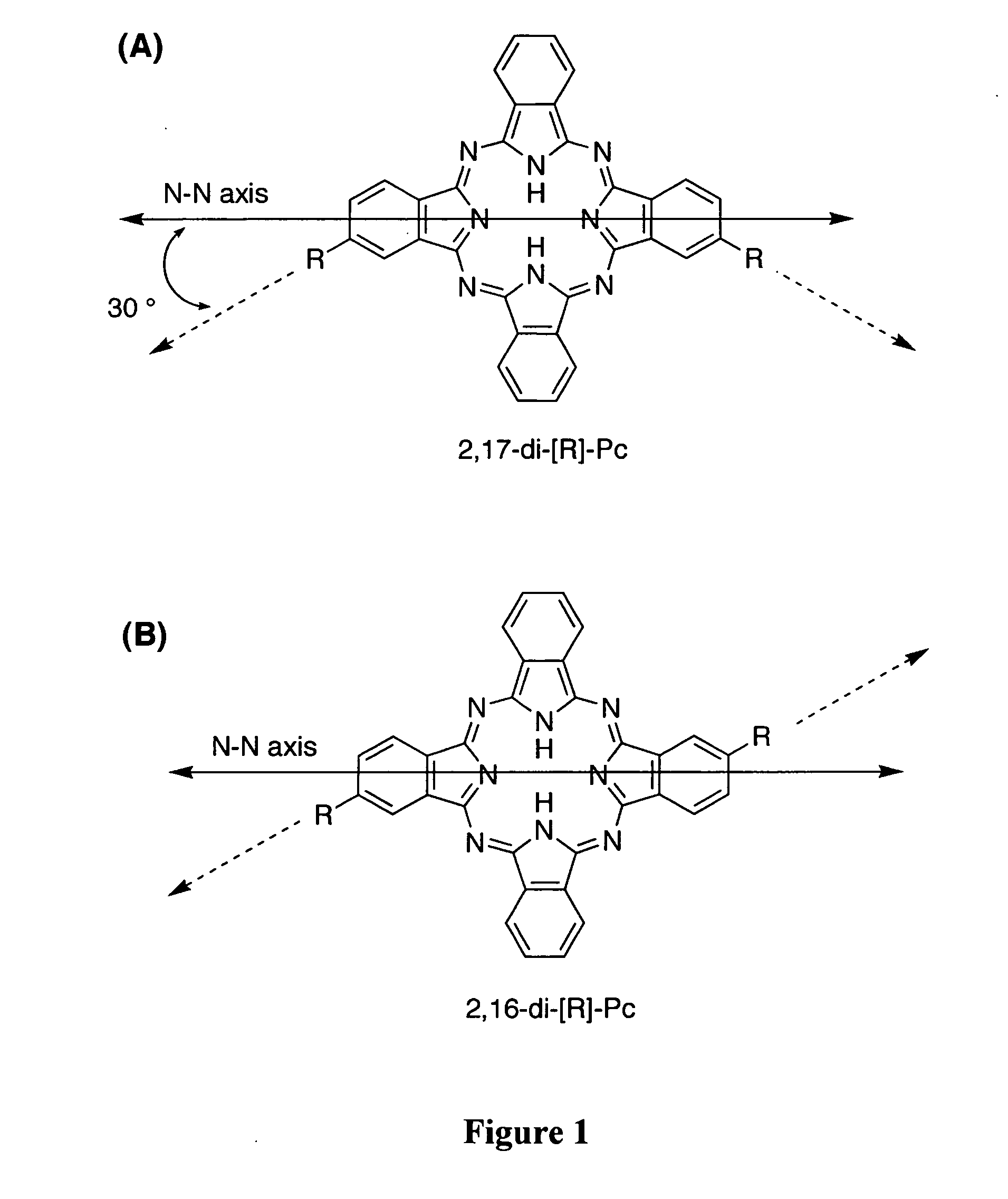

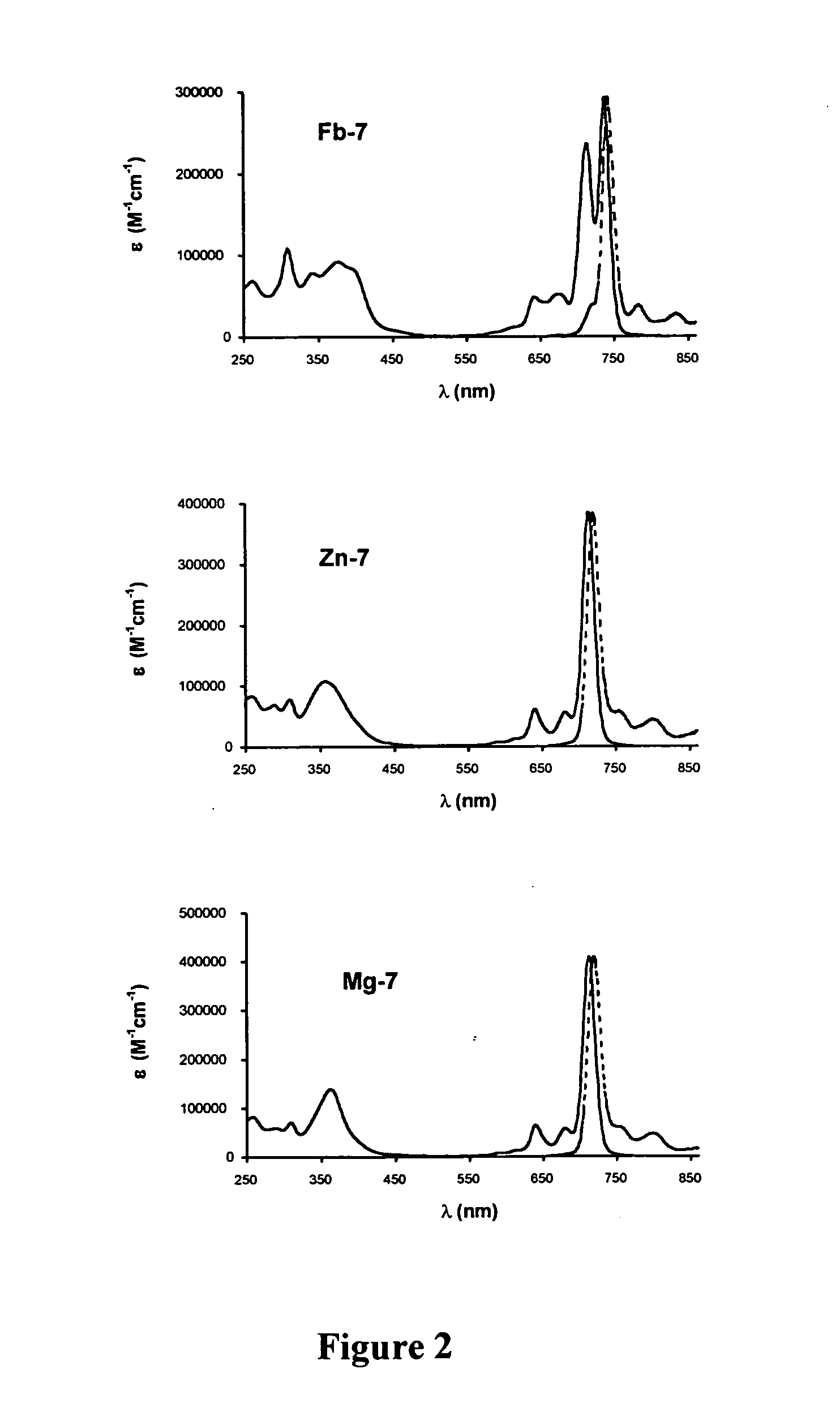

Substituted benzazoloporphyrazines for polymerization and surface attachment and articles formed therefrom

The present invention provides an article of manufacture formed from a substrate and a benzazoloporphyrazine bound to the substrate. The article may take a variety of different forms and may be for example an electrochromic display, a molecular capacitor, a battery, a solar cell, or a molecular memory device. Methods of making such articles, along with compounds, methods and intermediates useful for making such benzazoloporphyrazines, are also described.

Owner:NORTH CAROLINA STATE UNIV

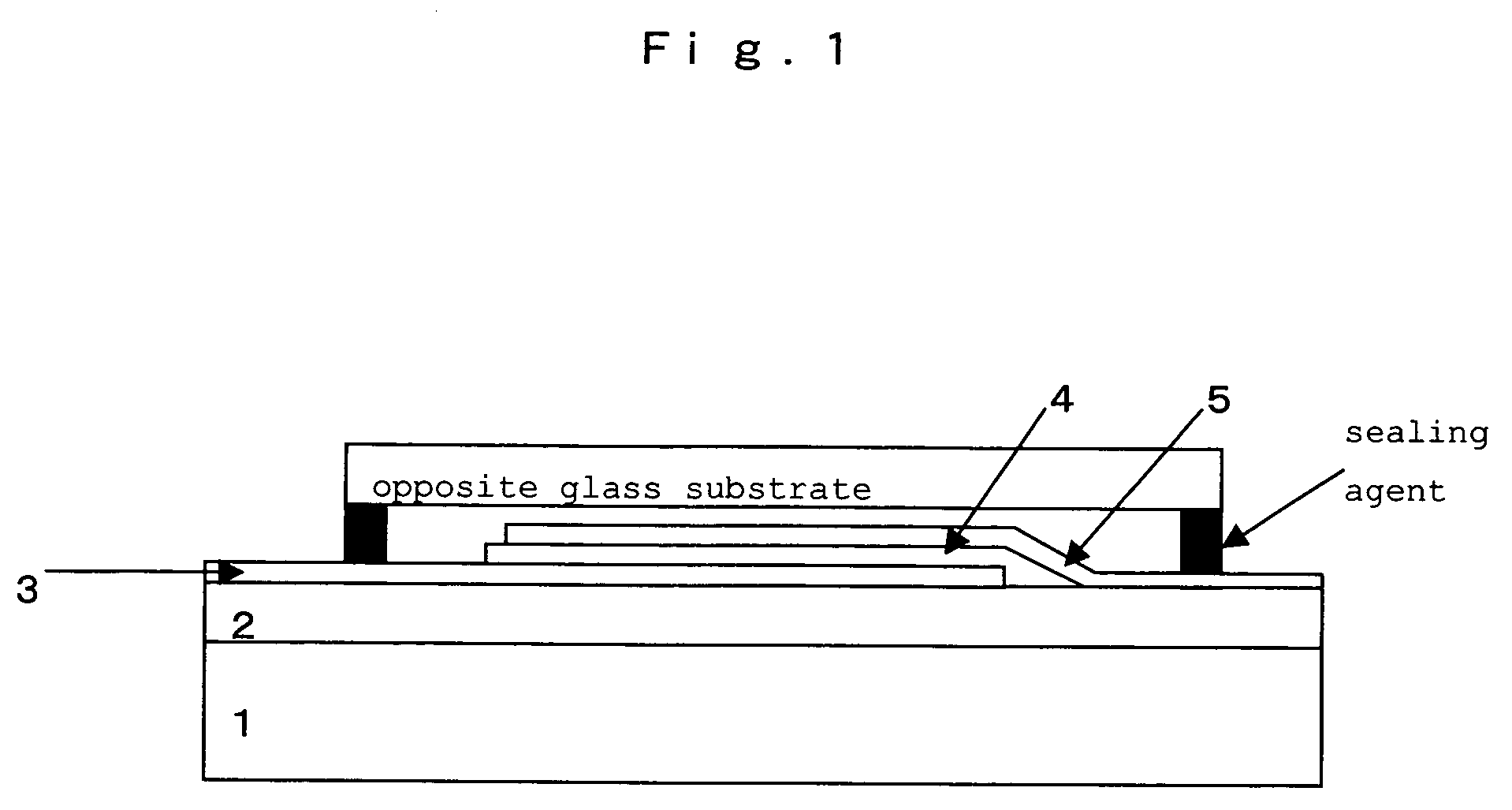

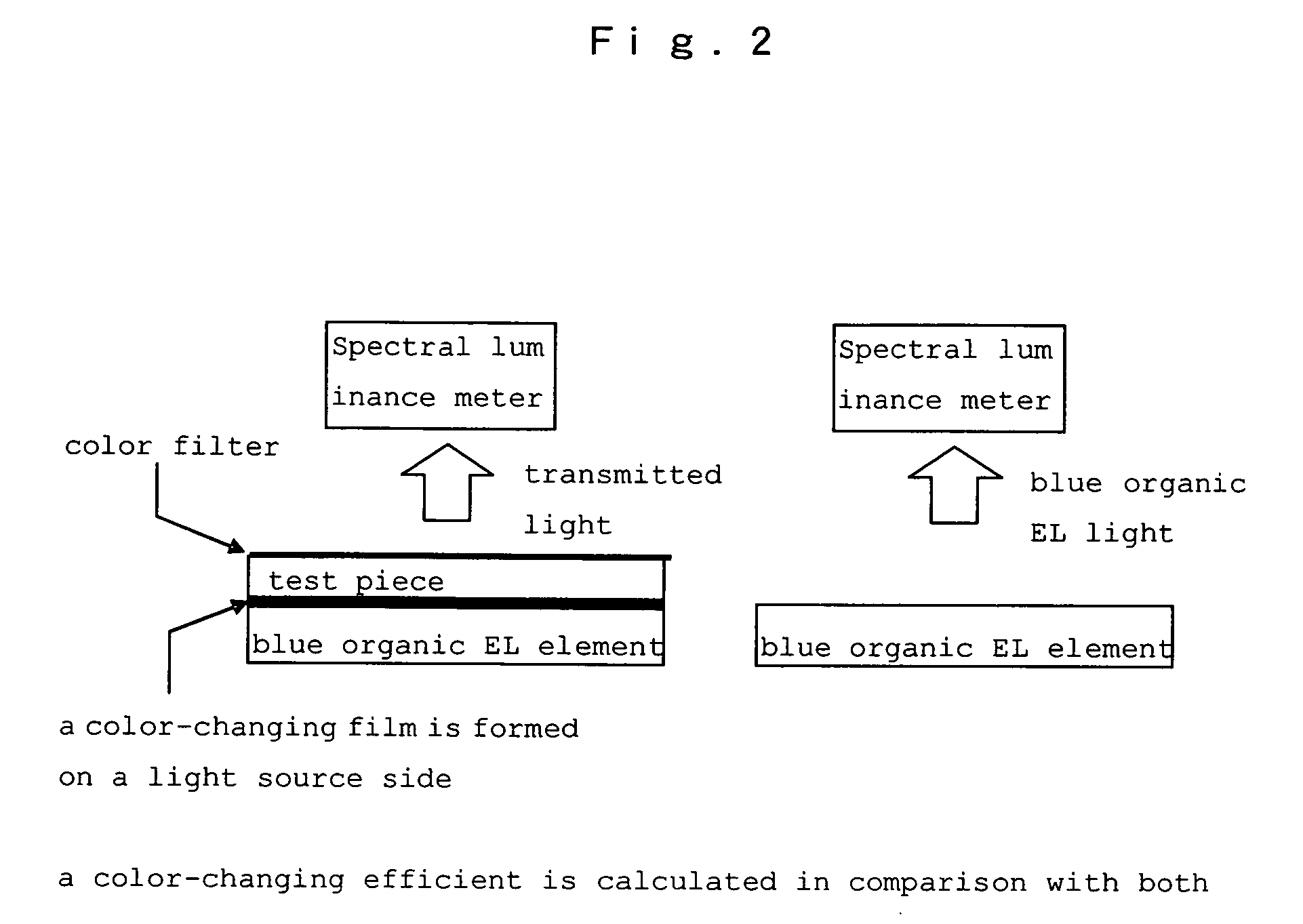

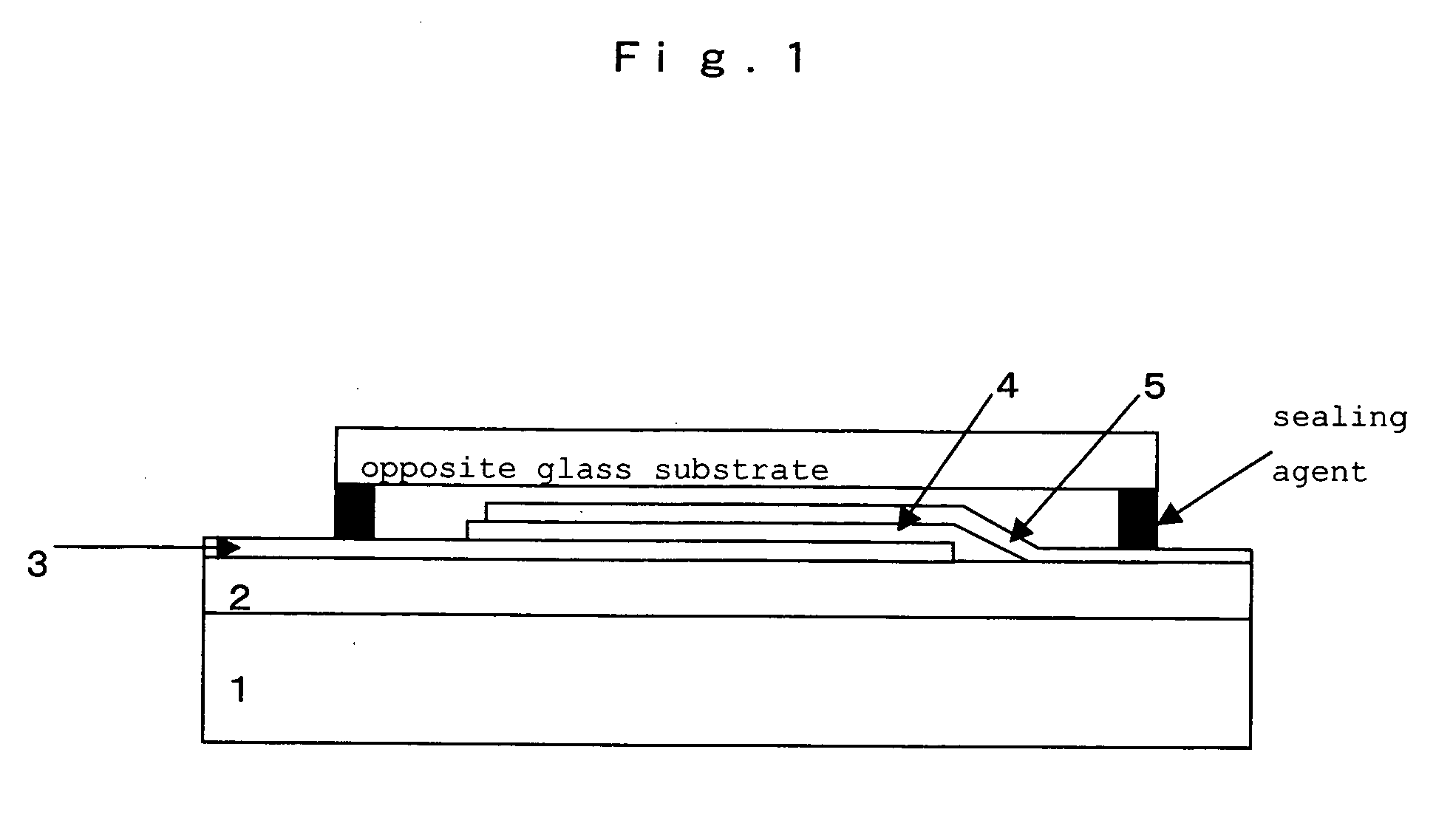

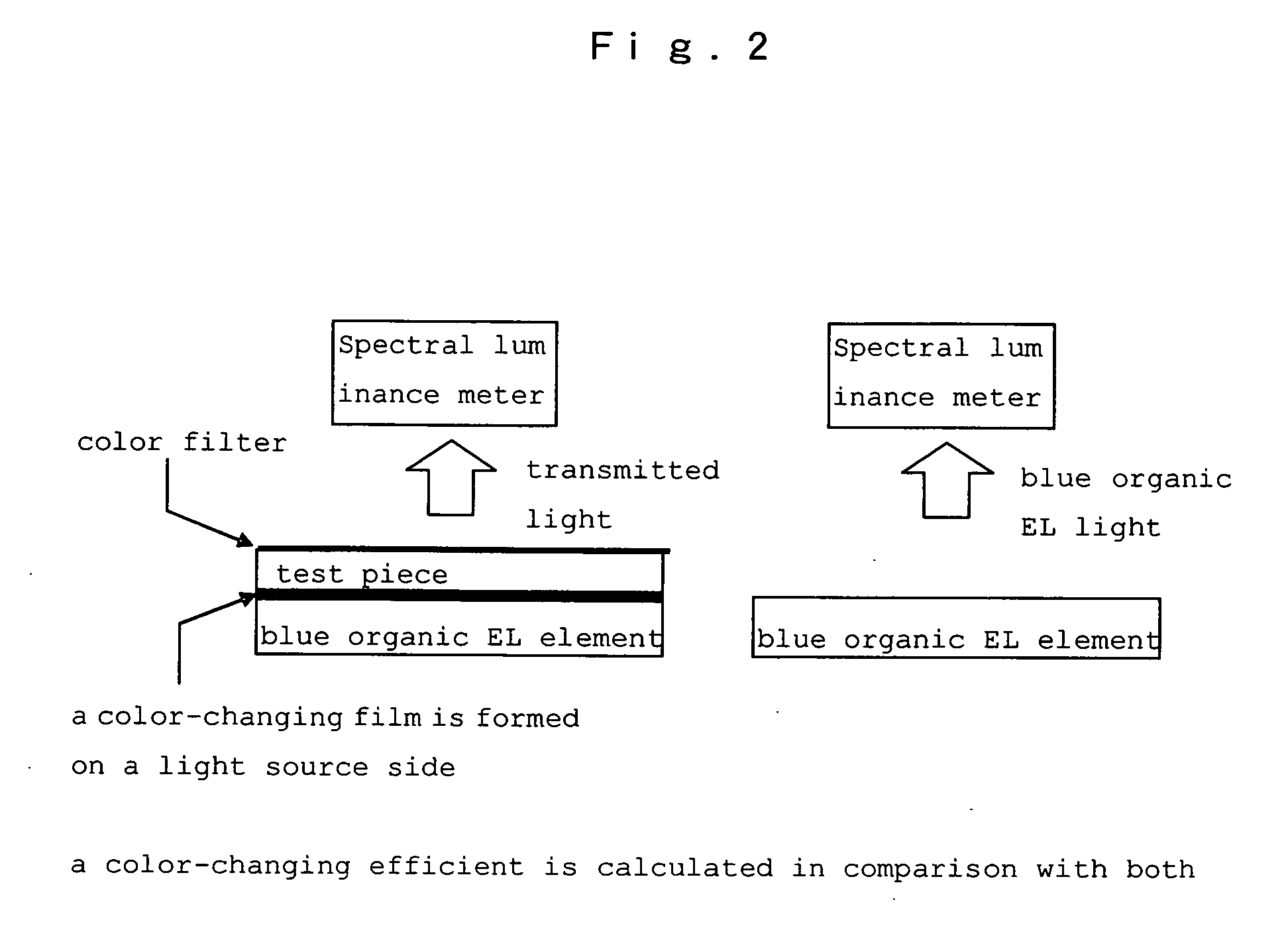

Hetero-polycyclic compounds, and coloring matters, pigments, dyes, color-changing material compositions, and color-changing films, made by using the compounds

Owner:IDEMITSU KOSAN CO LTD +1

Hetero-polycyclic compounds, and coloring matters, pigments, dyes, color-changing material compositions, and color-changing films, made by using the compounds

Owner:IDEMITSU KOSAN CO LTD +1

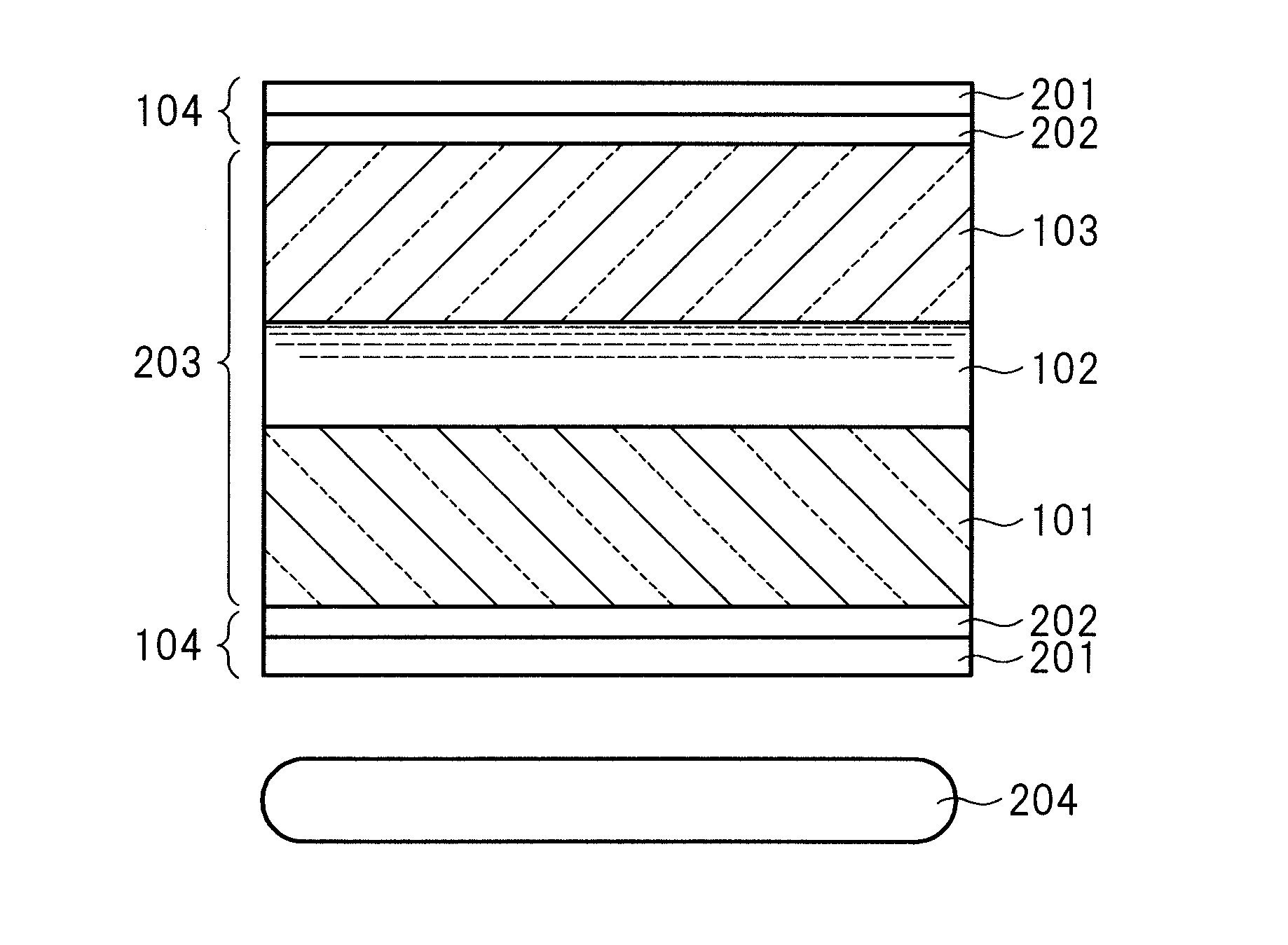

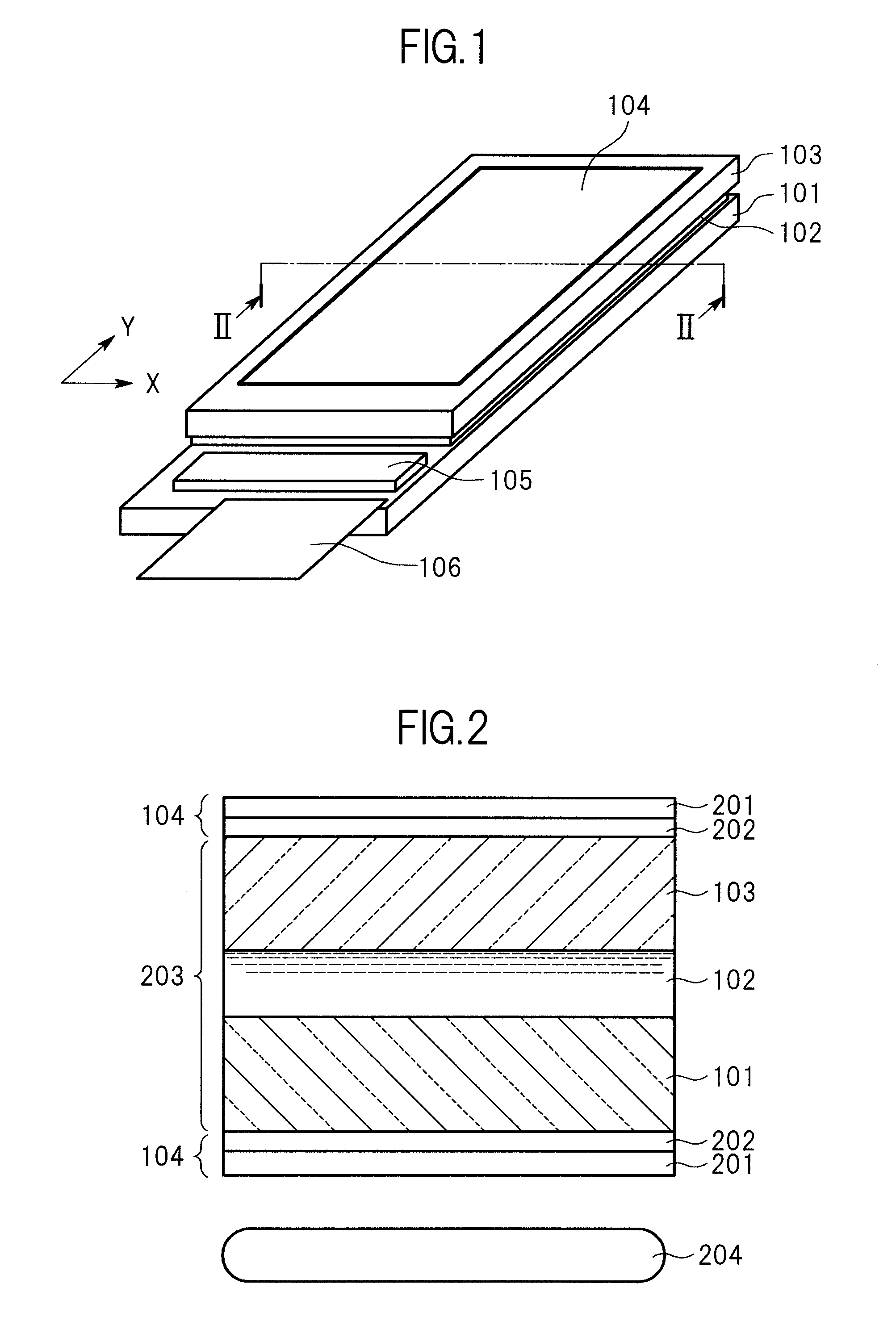

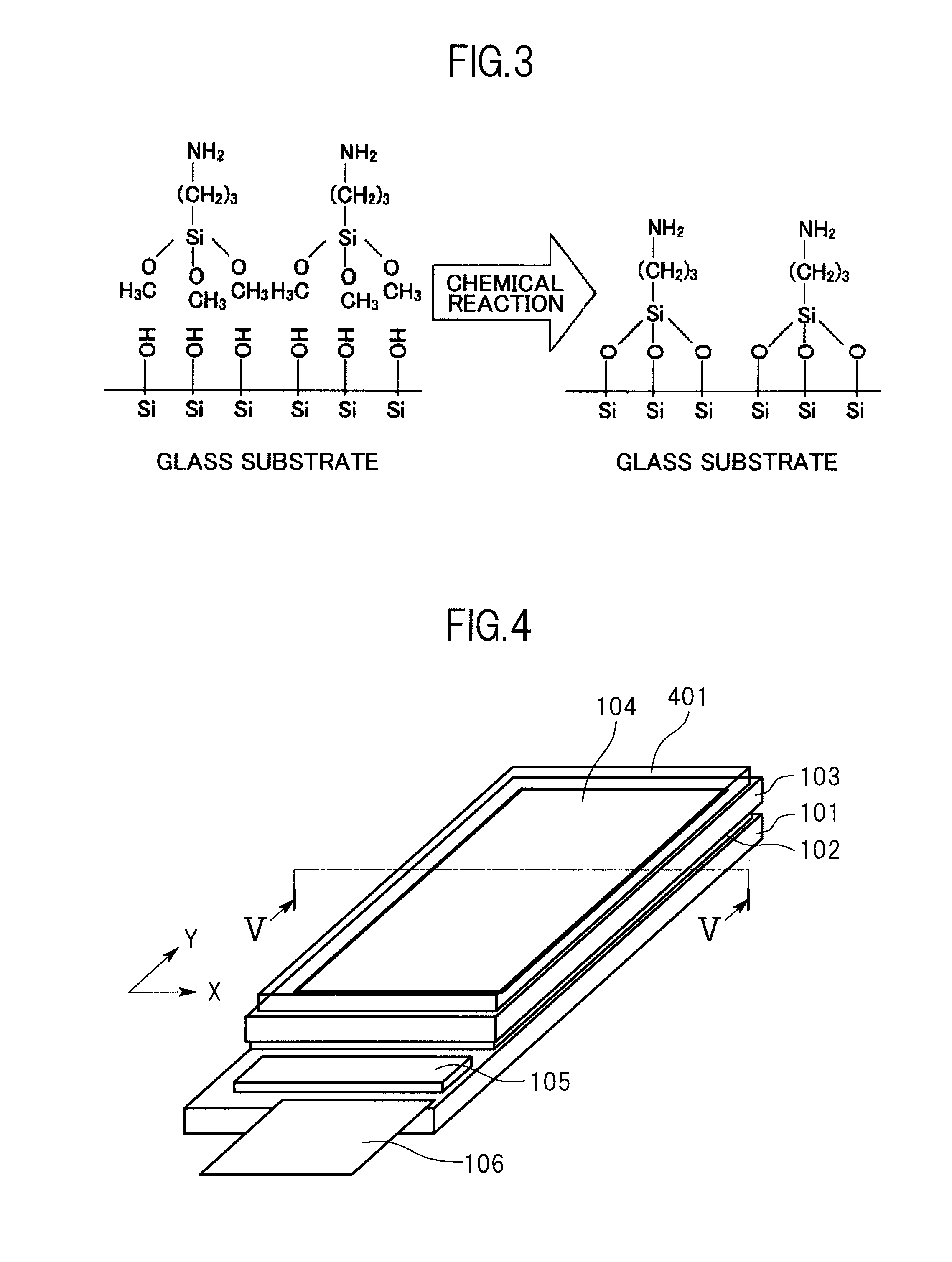

Liquid crystal display device

InactiveUS20110007243A1Established reliabilityIncrease molecular alignmentLiquid crystal compositionsSemiconductor/solid-state device manufacturingLiquid-crystal displayElectrical and Electronics engineering

Provided is a liquid crystal display device including a liquid crystal panel including: a first substrate on which a plurality of drain lines and a plurality of gate lines are formed, the plurality of gate lines crossing the plurality of drain lines; a second substrate which is arranged opposite to the first substrate via a liquid crystal; and an optical anisotropic film formed on a side of one of the first substrate and the second substrate, the side not being in contact with the liquid crystal; in which a region surrounded by the plurality of drain lines and the plurality of gate lines serves as a pixel region, in which the optical anisotropic film is formed of molecules which chemically bond to one of the first substrate and the second substrate in an aligned state.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Process for introducing vat dyes and chemicals into textiles

ActiveUS8523957B2Dye is reduced efficientlyTextile treatment machine partsDyeing processYarnPhotochemistry

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Compound for organic light-emitting diode and organic light-emitting diode including the same

ActiveUS20130270524A1Improve luminous performanceHigh glass transition temperatureOrganic chemistry methodsElectroluminescent light sourcesLight-emitting diodeOLED

Owner:SAMSUNG DISPLAY CO LTD

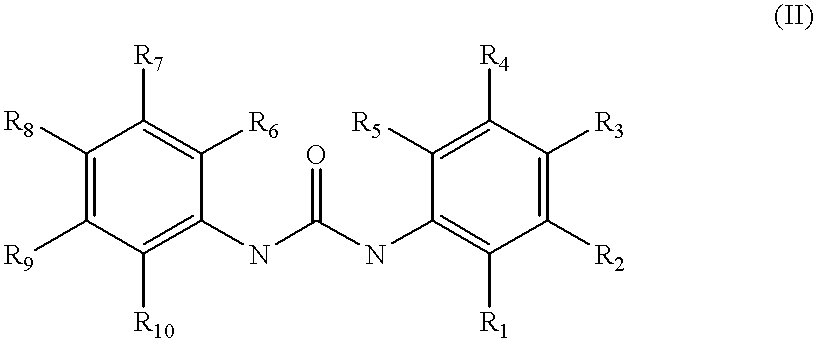

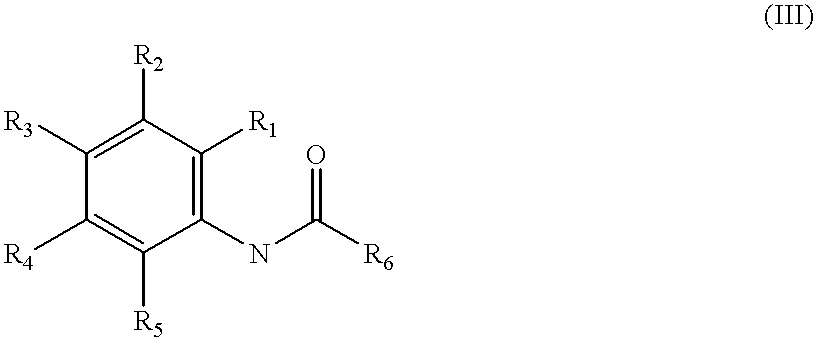

Inhibitors of multidrug transporters

The present invention relates generally to the fields of bacteriology and mycology. More particularly, the present invention provides novel inhibitors of multidrug transport proteins that may be used in combination with existing antibacterial agent and / or antifungal agents to increase the toxic effects of the antimicrobial agents. More specifically the present invention provides methods and compositions for enhancing the antibacterial action of fluoroquinolones by administering fluoroquinolones in combination with an inhibitor of multidrug transporters and of enhancing the antifungal action of azole antifungal agents by administering an azole antifungal agent in combination with an inhibitor of multidrug transporters. Compositions comprising indole, urea, quinoline or aromatic amide based inhibitors also are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com