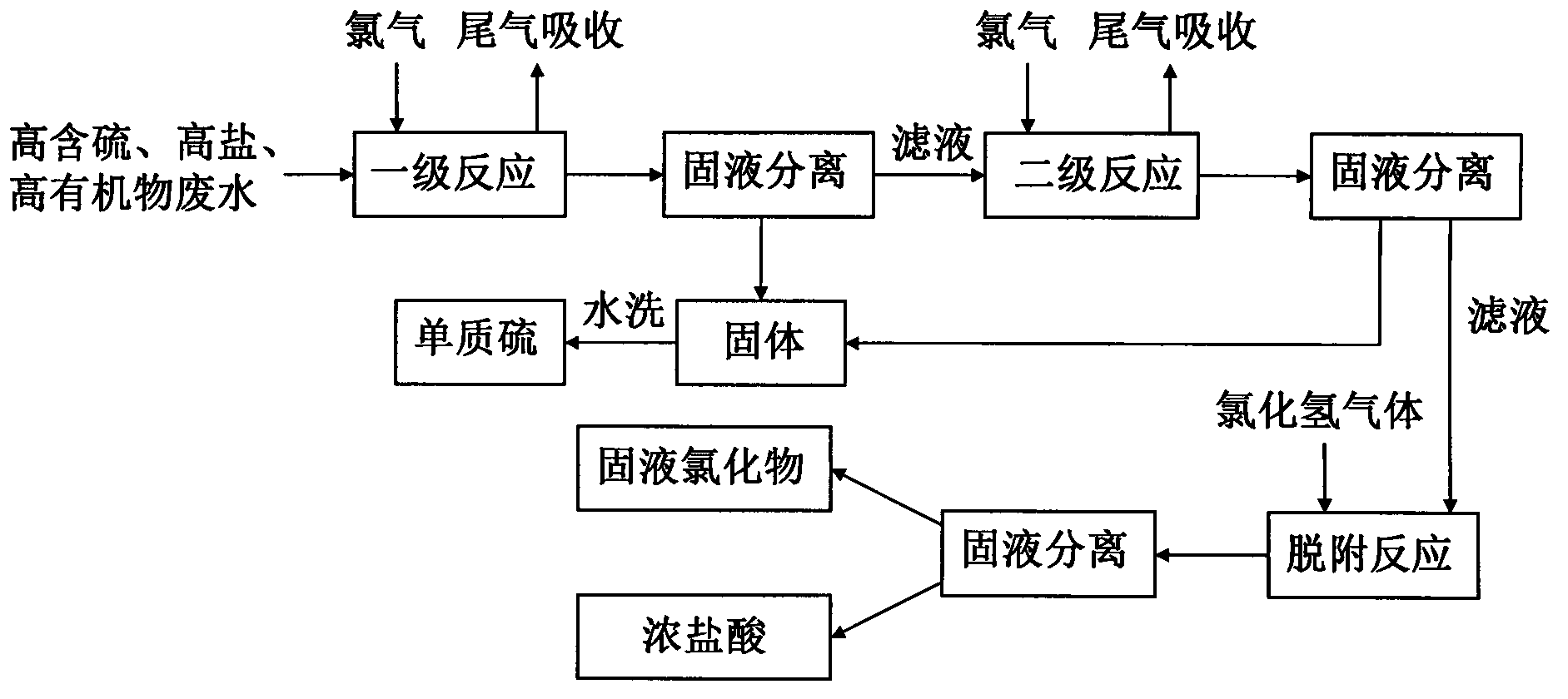

Method for treating high-sulfide high-salinity high-COD (Chemical Oxygen Demand) waste water

A treatment method, sulfide technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of environmental pollution, complicated operation, low efficiency, etc., and achieve saving of operating costs and The effects of energy consumption, high processing efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The production wastewater of a pesticide factory has a COD content of 10000mg / L, a sulfide content of 1000mg / L, and a salt content of 12000mg / L. Take 10L of waste water for treatment, and pass chlorine gas into the first-stage closed reactor at a speed of 1.5m / s for 0.177m 3 , using a temperature control device to maintain the temperature of the wastewater at 20°C. Under the same conditions, feed chlorine gas 0.032m into the secondary closed reactor 3 , obtained sulfur 9g after washing and separating with water. The rest of the waste water is injected with HCl gas for 2.24m at a speed of 0.5m / s at 10°C 3 , after filtration and separation, 119g of sodium chloride and 9.8kg of 11mol / L hydrochloric acid were obtained, realizing zero discharge of waste water.

Embodiment 2

[0018] The wastewater produced by a leather factory has a COD content of 5000mg / L, a sulfide content of 500mg / L, and a salt content of 15000mg / L. Take 10L of waste water for treatment, and pass chlorine gas into the first-stage closed reactor at a speed of 1.0m / s for 0.085m 3 , using a temperature control device to maintain the temperature of the wastewater at 15°C. Under the same conditions, feed chlorine gas 0.017m into the secondary closed reactor 3 , after separation and washing with water, 4.6 g of sulfur was obtained. The rest of the waste water is injected with HCl gas for 2.68m at a speed of 0.3m / s at 8°C 3 , after filtration and separation, 148g of sodium chloride and 9.75kg of 12mol / L hydrochloric acid were obtained, realizing zero discharge of waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com